Surgical Gowns and Helmets Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442843 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Surgical Gowns and Helmets Market Size

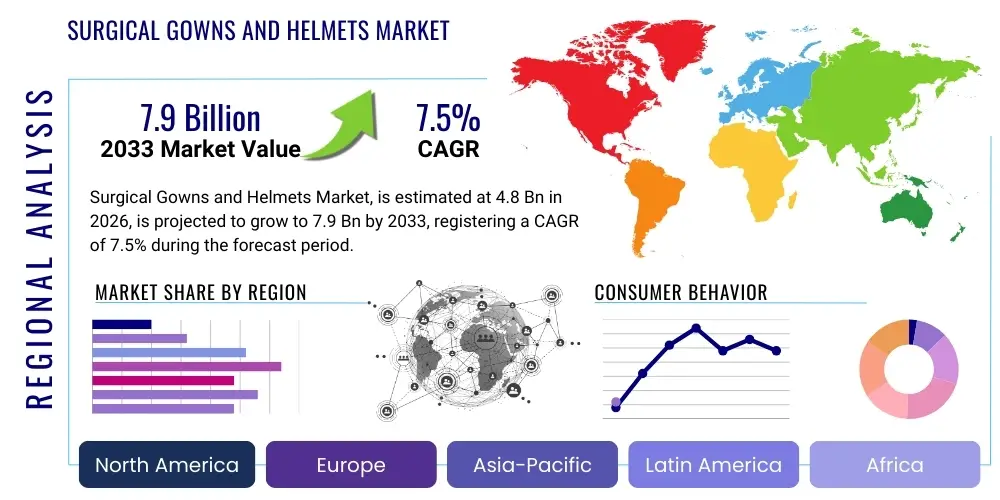

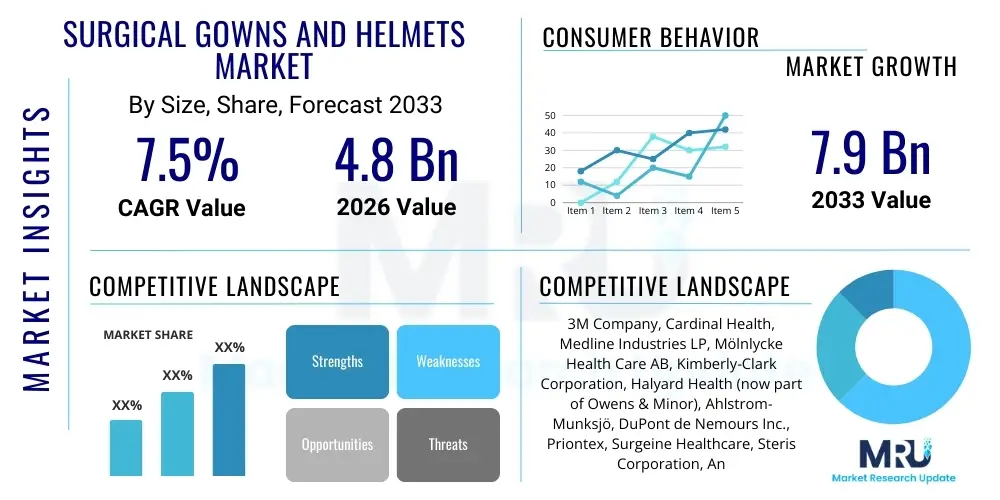

The Surgical Gowns and Helmets Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 4.8 Billion in 2026 and is projected to reach USD 7.9 Billion by the end of the forecast period in 2033.

Surgical Gowns and Helmets Market introduction

The Surgical Gowns and Helmets Market encompasses essential personal protective equipment (PPE) designed to maintain sterility and prevent the transfer of infectious agents between surgical teams and patients during invasive procedures. Surgical gowns function as a critical barrier, manufactured predominantly from non-woven materials such as SMS (Spunbond-Meltblown-Spunbond) fabric, offering varying levels of fluid resistance defined by international standards (e.g., ANSI/AAMI PB70). These products are indispensable in operating rooms, ambulatory surgical centers, and emergency settings, ensuring compliance with rigorous infection control protocols globally. The design evolution focuses heavily on wearer comfort, breathability, and reliable barrier performance against blood-borne pathogens and other contaminants, crucial for maintaining patient safety and reducing healthcare-associated infections (HAIs).

Surgical helmets, often used in conjunction with specialized orthopedic or neurosurgical procedures, provide comprehensive head and facial protection, featuring clear visors and integrated ventilation systems. These systems are pivotal in procedures involving high fluid splash potential or airborne particulate generation, offering enhanced safety for the surgical staff. Major applications for both gowns and helmets span across general surgery, orthopedic surgery, cardiovascular surgery, and obstetrics/gynecology. The ongoing global emphasis on hygiene standards, coupled with an increasing volume of surgical procedures driven by an aging population and rising prevalence of chronic diseases, serves as a primary driver for sustained market expansion.

The core benefits of these products lie in their ability to establish an impermeable barrier, minimizing microbial migration and mitigating risks associated with cross-contamination. Driving factors include stringent regulatory mandates concerning healthcare safety, technological advancements leading to superior barrier materials, and the persistent threat of emerging infectious diseases, which necessitates continuous stocking and utilization of high-quality disposable PPE in all healthcare settings. Moreover, the shift toward single-use, disposable items is accelerating due to the logistical challenges and sterilization risks associated with reusable alternatives, cementing the market trajectory.

Surgical Gowns and Helmets Market Executive Summary

The Surgical Gowns and Helmets Market is poised for significant growth, primarily fueled by the persistent focus on preventing Healthcare-Associated Infections (HAIs) and the global expansion of surgical infrastructure, particularly in emerging economies. Key business trends include the consolidation among major manufacturers aiming to achieve economies of scale and the heavy investment in automated production processes to meet fluctuating global demand. Furthermore, manufacturers are increasingly innovating with eco-friendly and sustainable material options, such as bio-based polymers, in response to growing environmental consciousness among healthcare providers and regulatory bodies. The supply chain stability and resilience, severely tested during recent global health crises, remain a critical area of focus for market participants.

Regionally, North America and Europe maintain dominance owing to well-established healthcare systems, stringent regulatory frameworks mandating high-level PPE usage, and high per capita healthcare spending. However, the Asia Pacific (APAC) region is projected to exhibit the fastest growth, propelled by the rapid construction of new hospitals, rising medical tourism, and improving access to quality healthcare in populous nations like China and India. Government initiatives focused on public health preparedness and the localized manufacturing scaling in APAC are contributing substantially to this accelerated regional expansion, creating lucrative opportunities for both domestic and international market players.

Segment trends indicate a strong preference for disposable surgical gowns due to their convenience and guaranteed sterility profile, overshadowing the reusable segment. Within product type, specialized high-performance gowns (Level 3 and Level 4) are experiencing rapid adoption, especially in high-risk surgical environments involving large volumes of blood or fluid. Segmentation based on material shows non-woven materials, particularly SMS composites, dominating the landscape due to their optimal balance of barrier efficacy, breathability, and cost-effectiveness. The increasing complexity of surgical procedures is also bolstering the demand for integrated helmet systems that provide filtered air and superior visibility, enhancing the safety profile for long operations.

AI Impact Analysis on Surgical Gowns and Helmets Market

Common user questions regarding AI's impact on the Surgical Gowns and Helmets Market often center on how automation affects manufacturing efficiency, the role of AI in supply chain optimization, and whether AI can influence material selection or barrier efficacy testing. Users are keen to understand if AI-driven diagnostics will reduce the necessity of certain surgical procedures, potentially impacting overall volume, or if predictive analytics can stabilize the traditionally volatile demand cycles for PPE. The overarching theme is the expectation that AI and Machine Learning (ML) will primarily optimize the operational efficiency and quality control aspects of PPE production, rather than directly changing the core product utility. Concerns also exist about the initial investment required for integrating sophisticated AI systems into existing manufacturing facilities.

The application of Artificial Intelligence is revolutionizing the manufacturing processes of surgical PPE, primarily through enhanced quality control and defect detection. High-speed camera systems coupled with machine vision algorithms are being deployed on production lines to inspect every gown and helmet for micro-tears, inconsistent seams, or material flaws that are often missed by human inspectors. This drastic improvement in quality assurance minimizes product recall risks and ensures that every piece of PPE meets stringent regulatory standards before reaching the operating room. Furthermore, AI-driven predictive maintenance schedules for manufacturing machinery prevent unexpected downtime, significantly boosting overall equipment effectiveness (OEE) and maintaining steady supply volumes, critical for healthcare logistics.

In the supply chain domain, AI algorithms are instrumental in forecasting demand volatility, a critical factor for disposable medical supplies. By analyzing historical consumption data, seasonal trends, surgical procedure schedules, and even real-time public health data (such as localized infection spikes), AI models provide highly accurate predictions. This allows manufacturers and distributors to optimize inventory levels, reduce wastage due to overstocking, and prevent critical shortages during unforeseen healthcare crises. Though AI does not directly alter the barrier properties of the non-woven fabrics themselves, it indirectly influences material science by rapidly analyzing performance data from various composite structures, accelerating the R&D cycle for next-generation breathable and impermeable materials.

- AI-powered defect detection ensures zero-tolerance quality control in manufacturing.

- Predictive analytics optimizes inventory levels and stabilizes volatile supply chains for disposables.

- Machine learning enhances operational efficiency through predictive maintenance of production machinery.

- AI models accelerate material R&D by analyzing complex barrier performance datasets.

- Robotics integrated with AI facilitates highly automated, contamination-free gown and helmet assembly.

DRO & Impact Forces Of Surgical Gowns and Helmets Market

The Surgical Gowns and Helmets Market is primarily driven by rigorous regulatory mandates concerning infection control and the continuous increase in surgical procedure volumes globally. Restraints largely center on environmental concerns associated with single-use plastics and the significant fluctuations in raw material costs, particularly petrochemical derivatives used in non-woven fabrics. Opportunities are abundant in the development of sustainable, biodegradable PPE alternatives and the expansion into rapidly developing healthcare markets in APAC and Latin America. These factors collectively exert a substantial impact force on market dynamics, compelling manufacturers to balance high-quality barrier protection with cost efficiency and environmental stewardship.

Drivers: The dominant driver remains the imperative need to curb Healthcare-Associated Infections (HAIs), which imposes immense economic and public health burdens. Global organizations, including the WHO and CDC, consistently issue guidelines emphasizing the use of high-grade surgical PPE, directly boosting demand. Furthermore, the rising adoption of specialized surgical techniques, such as minimally invasive and robotic surgeries, still requires comprehensive sterile barriers. The increasing awareness and education among healthcare workers regarding proper PPE usage also contribute positively to consistent market demand. The necessity for reliable, sterile barriers during high-stakes procedures ensures sustained investment in premium-grade products.

Restraints: Significant restraints include the volatility of raw material prices, particularly polypropylene and polyethylene, which form the core structure of non-woven PPE. This volatility makes long-term pricing contracts challenging. Another major impedance is the environmental impact of massive waste generation from disposable PPE; hospitals worldwide are facing pressure to reduce plastic waste, leading to calls for increased adoption of reusable or sustainable options, which could slow the growth of the dominant disposable segment. Additionally, the risk of counterfeiting and the proliferation of low-quality, non-certified products in unregulated markets pose a threat to brand integrity and patient safety.

Opportunities: The primary opportunity lies in material innovation, specifically the creation and mass production of highly protective, biodegradable, or compostable surgical gowns and helmet components. There is immense potential in integrating smart technology, such as sensors that monitor the integrity of the barrier or wearer vital signs, into surgical helmets. Geographic expansion into underserved and developing healthcare markets presents high growth potential, capitalizing on improving healthcare infrastructure. Developing standardized, globally compliant products that simplify procurement processes for international healthcare systems also represents a crucial market opening.

- Drivers: Stringent infection control regulations; rising surgical procedure volume; increased prevalence of chronic diseases; high demand for disposable products.

- Restraints: Volatile raw material costs; environmental concerns related to plastic waste; supply chain vulnerabilities; challenges in maintaining ergonomic comfort in high-barrier materials.

- Opportunities: Development of sustainable and biodegradable materials; market penetration in emerging economies; integration of smart technologies (e.g., ventilation sensors); standardization of regulatory approvals across regions.

- Impact Forces: High regulatory pressure mandates quality; public health emergencies create unpredictable demand spikes; material science advancements redefine barrier efficacy and sustainability.

Segmentation Analysis

The Surgical Gowns and Helmets Market is comprehensively segmented based on product type, usability, material composition, level of protection, and end-user application, providing granular insights into specific market dynamics. Analyzing these segments helps stakeholders understand consumer preferences, identify areas for product differentiation, and target investment strategies effectively. The dominant trend across most segments is the push towards single-use disposables, driven by enhanced safety protocols and the logistical complexity associated with sterilizing reusable items.

The primary segmentation divides the market into Gowns and Helmets, with Gowns holding the largest revenue share due to their ubiquitous necessity in almost every surgical procedure. Further segmentation by protection level (AAMI Levels 1 through 4) is critical, as it dictates the suitability of the product for different surgical environments, ranging from minimal fluid contact to high-risk orthopedic surgeries involving substantial fluid exposure. Understanding the interplay between material science (SMS, spunlace, polyethylene) and regulatory classification is essential for market positioning, particularly as global standards evolve.

End-user segmentation highlights the dominance of hospitals and surgical centers, which are the primary procurement entities. However, the rapidly growing number of Ambulatory Surgical Centers (ASCs) and specialty clinics represents a high-growth pocket, particularly for mid-to-high barrier protection gowns used in shorter, less invasive procedures. Strategic focus on customization for specific surgical disciplines, such as specialized gowns for cardiac surgery or robust systems for orthopedic procedures, is key to capturing niche market value.

- Product Type: Surgical Gowns, Surgical Helmets/Hoods, Accessory Components (e.g., ventilation systems, face shields).

- Usability: Disposable, Reusable.

- Material Type: Non-woven (SMS, Spunbond, Meltblown), Woven (Cotton/Polyester Blends), Films/Laminates (Polyethylene, Polypropylene).

- Risk Level (AAMI Standard): Level 1 (Minimal Risk), Level 2 (Low Risk), Level 3 (Moderate Risk), Level 4 (High Risk).

- End-User: Hospitals (Public and Private), Ambulatory Surgical Centers (ASCs), Specialty Clinics, Diagnostic Laboratories.

Value Chain Analysis For Surgical Gowns and Helmets Market

The value chain for the Surgical Gowns and Helmets Market begins with upstream analysis, focusing on the sourcing and processing of raw materials, primarily petrochemical-based polymers (polypropylene pellets) for non-woven fabric production. Key activities at this stage include polymerization, extrusion, and the complex process of turning raw materials into usable non-woven textiles (such as SMS laminates) that provide the necessary barrier properties. The efficiency and cost-effectiveness of this upstream stage are heavily dependent on global oil and gas prices and the technological capabilities of textile manufacturers to create high-performance, cost-optimized materials.

The midstream segment involves manufacturing, where specialized machinery is utilized for cutting, thermal sealing, and stitching the materials into the final gown and helmet configurations. Automation is increasingly critical here to minimize contamination risk and ensure product consistency. Quality control, packaging, sterilization (often using ethylene oxide or gamma irradiation), and regulatory compliance documentation form the bridge to the downstream activities. Manufacturers must strategically locate their production facilities near raw material sources or key consumption hubs to mitigate logistical costs and enhance responsiveness to regional demand surges.

Downstream analysis focuses on distribution channels, which are typically multilayered. Direct distribution often occurs for large hospital systems or government public health agencies that purchase in bulk. Indirect distribution relies heavily on medical device distributors and wholesalers who manage regional inventories and logistical networks to reach smaller clinics and ASCs. The integrity of this distribution channel is paramount, as maintaining the sterility of the packaged product until the point of use is non-negotiable. Effective inventory management systems and robust warehousing capabilities are vital for market success.

Surgical Gowns and Helmets Market Potential Customers

The primary potential customers and end-users of surgical gowns and helmets are large institutional healthcare providers that operate complex surgical environments where sterility is paramount. Hospitals, both public and private, represent the largest customer base due to the high volume and complexity of procedures performed daily, ranging from emergency trauma surgery to elective operations. Procurement decisions within these organizations are typically centralized, highly regulated, and focused on securing long-term contracts that guarantee consistent supply of AAMI Level 3 and 4 protection products.

Ambulatory Surgical Centers (ASCs) constitute a rapidly expanding customer segment. As healthcare shifts towards outpatient settings for cost efficiency, ASCs are increasing their demand for medium-to-high risk PPE, particularly tailored for orthopedic, ophthalmic, and gastrointestinal procedures. These customers prioritize ease of use, swift procurement, and cost-effective bundling of disposable products. The third key customer group includes specialty clinics (e.g., dental or cosmetic surgery) and diagnostic laboratories that utilize lower-risk (Level 1 and 2) gowns and headwear for routine procedures and cleanroom maintenance, indicating a diverse range of procurement needs based on exposure risk.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.8 Billion |

| Market Forecast in 2033 | USD 7.9 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, Cardinal Health, Medline Industries LP, Mölnlycke Health Care AB, Kimberly-Clark Corporation, Halyard Health (now part of Owens & Minor), Ahlstrom-Munksjö, DuPont de Nemours Inc., Priontex, Surgeine Healthcare, Steris Corporation, Anhui Kangning Industrial, Lohmann & Rauscher, Standard Textile, Lyssé Medical, Dynarex Corporation, Medicom, Integra Lifesciences, Paul Hartmann AG, K-MAC Medical |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Surgical Gowns and Helmets Market Key Technology Landscape

The technology landscape for surgical gowns and helmets is defined by advancements in textile engineering and manufacturing processes aimed at achieving superior barrier performance without compromising comfort or breathability. A core technology involves the proprietary methods used to produce multi-layer non-woven fabrics, particularly SMS technology, which utilizes layers of spunbond for strength and meltblown fibers for filtration efficiency. Recent innovations focus on incorporating microfilament technologies and chemical treatments that enhance fluid repellency and viral penetration resistance while ensuring the material remains lightweight and comfortable for prolonged surgical use. Sterilization technology, mainly Ethylene Oxide (EtO) and gamma irradiation, also remains a critical component, ensuring the required Sterility Assurance Level (SAL) for disposable products.

In the segment of surgical helmets, technological progress centers on optimizing ventilation systems to manage heat and humidity buildup, thereby maintaining the wearer’s focus and mitigating visor fogging. Battery-powered, integrated air filtration systems (often P3-rated) are becoming standard, offering superior protection against aerosolized contaminants and bone fragments generated during procedures like orthopedic cutting. Materials technology in visors is moving towards anti-scratch and anti-fog coatings to ensure consistent visual acuity. Furthermore, ergonomic design innovations, utilizing advanced CAD and human factors engineering, are improving the fit and balance of helmet systems, crucial for reducing fatigue in long surgeries.

The manufacturing process itself leverages advanced automation technologies. Ultrasonic welding and thermal bonding are rapidly replacing traditional stitching methods for assembling gowns, as they eliminate needle holes, which can be potential breach points for fluids, thereby enhancing the overall barrier integrity. The integration of advanced testing equipment, such as hydrostatic pressure testers and Synthetic Blood Penetration Testers, ensures that every batch of manufactured PPE complies with rigorous international standards (e.g., ISO 16604 and AAMI PB70). Traceability technology, including RFID tagging, is also gaining traction, enabling rapid tracking of individual gown and helmet units through the supply chain for enhanced inventory management and recall readiness.

Regional Highlights

North America holds the dominant position in the Surgical Gowns and Helmets Market, primarily driven by the presence of a highly developed healthcare infrastructure, substantial healthcare expenditure, and the early adoption of advanced, high-barrier protection standards (AAMI Level 3 and 4). The United States, in particular, has stringent regulatory enforcement by bodies like the FDA and CDC regarding infection control protocols, ensuring consistently high demand for certified disposable PPE. The region also benefits from a high concentration of key market players and a robust technological environment that drives innovation in material science and ergonomic design. The high volume of complex surgical procedures, especially in orthopedics and cardiovascular disciplines, necessitates continuous procurement of premium surgical barrier systems.

Europe represents another mature market, characterized by standardized procurement processes and significant focus on sustainability alongside protection efficacy. Countries like Germany, France, and the UK demonstrate steady demand, supported by well-funded public and private hospital networks. Recent shifts in the European market involve a dual focus: maintaining adherence to the high standards set by the European Union’s medical device regulations (MDR) while simultaneously exploring and implementing solutions for environmentally sustainable PPE waste management. The region shows increasing interest in certified reusable surgical textiles, although disposables maintain market share due to ease of use and reduced cross-contamination risk.

Asia Pacific (APAC) is projected to be the fastest-growing region during the forecast period. This accelerated expansion is attributed to several macroeconomic and healthcare-specific factors, including rapid urbanization, increasing governmental investment in public health infrastructure, and the expansion of private hospital chains in populous nations like China, India, and Southeast Asia. The rising prevalence of chronic diseases requiring surgical intervention and the increasing awareness of infection control standards among healthcare professionals are major catalysts. While cost sensitivity remains a factor, the shift toward international-grade PPE, often driven by international collaborations and medical tourism, is rapidly boosting the demand for high-quality surgical gowns and integrated helmet systems.

Latin America (LATAM) and the Middle East and Africa (MEA) regions are also witnessing gradual yet steady growth. LATAM growth is influenced by improving economic conditions and investments in modernizing hospital facilities across Brazil and Mexico. The MEA region, particularly the Gulf Cooperation Council (GCC) countries, exhibits strong demand for premium healthcare products, largely imported, supported by high per capita incomes and a focus on attracting international medical expertise. Challenges in these regions include fragmented distribution networks and varying regulatory standards, though harmonization efforts are underway, creating mid-to-long-term market opportunities for established global manufacturers.

- North America: Market leader; driven by strict regulatory standards (FDA/CDC) and high surgical volumes; focus on advanced AAMI Level 4 protection.

- Europe: Mature market prioritizing high-quality, regulated products; increasing governmental push toward sustainable and waste-reducing PPE solutions.

- Asia Pacific (APAC): Highest growth rate; propelled by infrastructure expansion, rising health awareness, and increasing surgical procedure volumes in China and India.

- Latin America (LATAM): Moderate growth tied to healthcare modernization and economic stability, particularly in Brazil and Mexico.

- Middle East & Africa (MEA): Growth centered in GCC nations due to high investment in specialized medical centers and reliance on high-quality imported products.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Surgical Gowns and Helmets Market.- 3M Company

- Cardinal Health

- Medline Industries LP

- Mölnlycke Health Care AB

- Kimberly-Clark Corporation

- Halyard Health (now part of Owens & Minor)

- Ahlstrom-Munksjö

- DuPont de Nemours Inc.

- Priontex

- Surgeine Healthcare

- Steris Corporation

- Anhui Kangning Industrial

- Lohmann & Rauscher

- Standard Textile

- Lyssé Medical

- Dynarex Corporation

- Medicom

- Integra Lifesciences

- Paul Hartmann AG

- K-MAC Medical

Frequently Asked Questions

Analyze common user questions about the Surgical Gowns and Helmets market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary standards used to classify surgical gown protection levels?

The widely accepted benchmark for classifying surgical gown protection levels is the ANSI/AAMI PB70 standard, which defines four levels (Level 1 to Level 4) based on barrier performance against liquid penetration and microbial transmission. Level 1 indicates minimal risk protection, suitable for basic patient care. Level 4 denotes the highest protection level, required for long, fluid-intensive surgeries where the risk of pathogen transfer is significant, necessitating complete fluid resistance across critical zones. Understanding these classifications is crucial for healthcare facility procurement to ensure regulatory compliance and optimal patient safety during varying procedural risks.

What is driving the market shift towards disposable surgical gowns over reusable options?

The major driver behind the preference for disposable surgical gowns is the guaranteed sterility and consistent barrier integrity offered by single-use products, which minimizes the risk of cross-contamination inherent in laundering and re-sterilizing reusable textiles. While reusable gowns are environmentally preferred, their barrier performance degrades over multiple wash cycles, and the complex logistics of tracking, cleaning, and validating sterilization often increase operational costs and regulatory burden for healthcare facilities. Disposable gowns, typically made of non-woven synthetics like SMS, provide a reliable, cost-predictable solution that consistently meets stringent infection control guidelines, particularly for high-risk surgical environments.

How do advancements in material science enhance the performance of surgical helmets?

Advancements in material science significantly boost surgical helmet performance by improving filtration efficacy, ergonomic comfort, and anti-fog/anti-scratch visibility. Modern helmet systems utilize highly efficient P3-rated particulate filters integrated with lightweight, powerful battery packs to provide filtered, cooled air, crucial for long orthopedic or trauma surgeries. The helmet shells themselves incorporate advanced polymers engineered for impact resistance while maintaining a light structure. Visor technologies now feature specialized molecular coatings that actively resist temperature condensation and abrasion, ensuring clear vision for the surgical team throughout the procedure and enhancing overall occupational safety.

What impact does sustainability and environmental pressure have on the Surgical Gowns market?

Sustainability and environmental pressure pose a complex challenge to the predominantly disposable surgical gowns market, which generates massive volumes of non-biodegradable plastic waste. This pressure compels manufacturers to invest heavily in Green R&D, focusing on developing bio-based, compostable polymers derived from renewable resources that retain the critical AAMI Level 3/4 barrier protection properties. Hospitals are exploring advanced waste management solutions, such as non-incineration technologies, and are cautiously re-evaluating hybrid models that incorporate certified reusable systems for lower-risk areas. Market success increasingly relies on balancing high safety standards with credible, verified environmental responsibility to meet institutional purchasing mandates.

Which geographical region is anticipated to demonstrate the fastest growth rate and why?

The Asia Pacific (APAC) region is forecasted to achieve the highest Compound Annual Growth Rate (CAGR) due to several converging factors: expansive healthcare infrastructure development driven by massive governmental investment in countries like China and India; burgeoning medical tourism, which demands international standards of care including premium PPE; and a growing middle class with enhanced access to surgical healthcare services. Furthermore, increased regulatory awareness and the standardization of surgical protocols across APAC nations are rapidly replacing locally manufactured, low-grade products with globally compliant surgical gowns and integrated helmet systems, unlocking significant new market opportunities.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager