Tension Clutch Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442507 | Date : Feb, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Tension Clutch Market Size

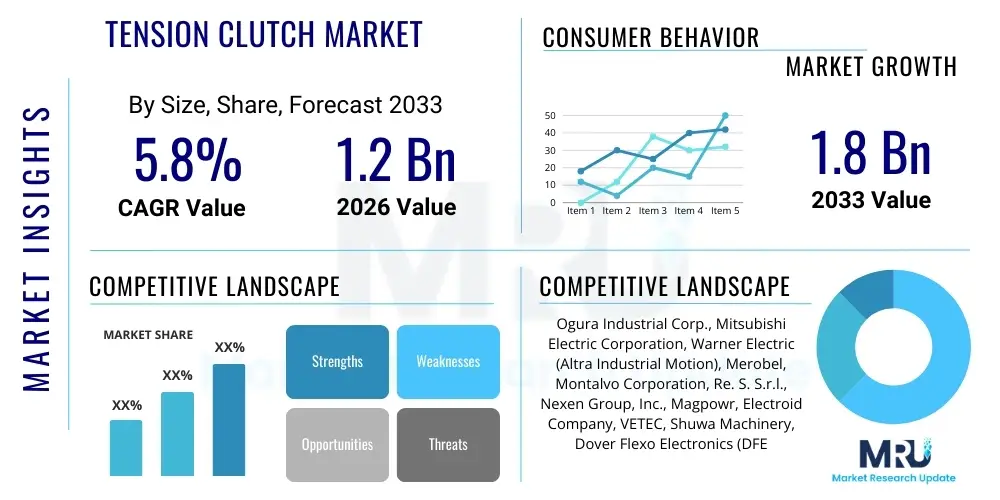

The Tension Clutch Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 1.8 Billion by the end of the forecast period in 2033.

Tension Clutch Market introduction

Tension clutches are critical components engineered to maintain precise and consistent tension on continuous material webs, such as film, paper, foil, or wire, during various industrial processing stages, including winding, unwinding, and intermediate roller operations. These devices function by applying a controlled braking torque or driving torque to the material roll, ensuring that the web maintains optimal tension levels necessary for quality production, minimizing material breakage, wrinkling, or stretching. The basic mechanism often involves magnetic particles, pneumatic pressure, or mechanical friction systems that are highly responsive to changes in speed and diameter, providing crucial stability in high-speed converting and processing environments.

The primary applications for tension clutches span across high-throughput industries like printing and packaging, where consistent registration and material handling are paramount; the textile industry, particularly in fabric finishing and continuous dyeing lines; and the burgeoning sector of battery and electronic component manufacturing, where handling delicate films and foils requires micron-level precision. The operational integrity of these machines is directly tied to the performance of the tension control system. Key benefits of utilizing high-precision tension clutches include significant reduction in material waste, enhanced production efficiency, improved product quality uniformity, and the ability to run complex materials at faster speeds. These benefits solidify the clutch's role as a non-negotiable component in modern automated manufacturing.

The market driving factors are intrinsically linked to the global acceleration of industrial automation and the expanding demand for high-quality packaged goods. As manufacturers adopt Industry 4.0 principles, the need for components capable of integrating seamlessly into closed-loop control systems—providing real-time feedback and requiring minimal human intervention—propels the demand for advanced tension clutch technologies. Furthermore, the growth of flexible packaging and disposable consumer goods, often utilizing multi-layer substrates, necessitates sophisticated tension control solutions to handle the variability and fragility of these materials during high-speed converting operations.

Tension Clutch Market Executive Summary

The Tension Clutch Market is currently experiencing robust growth, primarily fueled by significant business trends such as the pervasive adoption of automated machinery and the critical necessity for waste reduction across process industries. The shift towards lighter, more complex packaging materials, particularly in the e-commerce sector, demands tension control systems with greater sensitivity and dynamic response capabilities, pushing manufacturers toward advanced magnetic particle and pneumatic clutch technologies over traditional mechanical systems. Key business stakeholders are focusing heavily on developing smart clutches embedded with IoT sensors, enabling predictive maintenance capabilities and real-time operational optimization, which is enhancing machine uptime and overall manufacturing efficiency, representing a pivotal technological trend.

Geographically, the Asia Pacific (APAC) region continues its dominance and is poised for the fastest expansion, driven by massive investments in manufacturing infrastructure, particularly in countries like China, India, and Southeast Asian nations that are establishing themselves as global hubs for textile, printing, and packaging production. North America and Europe, while mature, exhibit high demand for premium, high-accuracy tension clutch systems that comply with stringent quality and safety standards, favoring highly integrated, digitally controllable solutions. Regional trends emphasize sustainable manufacturing practices, leading to demand for energy-efficient clutch designs that minimize power consumption while maintaining superior performance, aligning with broader environmental regulatory pressures and corporate sustainability goals.

Segment trends reveal that the magnetic particle tension clutch segment is capturing substantial market share due to its inherent advantages in precise torque control and smooth operation across a wide range of speeds, making it ideal for sensitive applications like film converting and specialized printing. Concurrently, the application segment is heavily weighted towards the packaging and printing industries, reflecting the enduring consumer demand for packaged goods and the rapid turnover of promotional materials. However, the wire and cable manufacturing sector is emerging as a significant high-growth segment, driven by global infrastructure development and the widespread rollout of 5G networks, which require sophisticated tensioning equipment for fiber optic cable production and high-tolerance wire drawing processes.

AI Impact Analysis on Tension Clutch Market

User inquiries regarding the integration of Artificial Intelligence (AI) into tension control systems primarily revolve around expectations for autonomous process optimization, predictive failure identification, and the feasibility of achieving 'zero-defect' web handling. Users frequently question how AI algorithms can move beyond simple PID (Proportional-Integral-Derivative) control loops to anticipate material behavior, compensate for environmental variables like temperature and humidity, and dynamically adjust clutch torque in real-time based on upstream and downstream process variations. There is a strong interest in understanding the ROI derived from implementing AI-driven tension monitoring, specifically concerning reductions in downtime, minimizing scrap material, and extending the lifespan of critical mechanical components like the clutch itself, signaling a focus on operational efficiency and cost savings.

The core expectation from end-users is that AI integration will transform tension clutches from mere torque application devices into intelligent nodes within the overall manufacturing ecosystem. This shift entails using machine learning models trained on historical performance data—including material elasticity, roll diameter decay curves, and environmental sensor readings—to predict anomalies before they manifest as costly production interruptions. For instance, AI can analyze subtle fluctuations in required torque that traditional controls might ignore, flagging potential issues such as uneven web material density or impending bearing failure within the clutch mechanism, thereby enabling truly proactive maintenance scheduling rather than reactive intervention, optimizing throughput.

Furthermore, AI-powered systems are expected to democratize high-precision manufacturing by simplifying the setup and calibration process for operators. Currently, tension control often requires highly skilled technicians to manually tune complex parameters for different material recipes. AI systems can utilize pattern recognition to automatically identify the material being processed and select the optimal control profile, drastically reducing setup time and minimizing operator error, thus improving consistency across shifts and machine lines. This technological advancement not only drives productivity gains but also addresses the prevailing industrial challenge of skilled labor shortages, offering an automated solution for achieving peak operational performance in high-speed converting machinery.

- Implementation of predictive maintenance algorithms to forecast clutch wear and component failure, minimizing unplanned downtime.

- Real-time, dynamic tension optimization based on material characteristics (e.g., thickness, friction coefficient) learned through machine learning models.

- Autonomous fault detection and isolation, instantly identifying irregularities in web tension indicative of upstream or downstream equipment malfunctions.

- Enhanced energy efficiency through AI-optimized torque application, ensuring minimum required power is used for stability.

- Automated calibration and recipe management for rapid changeovers between different material types and job specifications.

DRO & Impact Forces Of Tension Clutch Market

The dynamics of the Tension Clutch Market are largely shaped by a powerful confluence of drivers related to industrial modernization and consumer trends, tempered by significant operational restraints and punctuated by substantial technological opportunities. A primary driver is the accelerating pace of factory automation globally, particularly in emerging economies, where the upgrade cycle involves replacing older mechanical controls with sophisticated closed-loop pneumatic and magnetic systems to meet stringent quality requirements. The rapid expansion of the e-commerce sector and the resulting boom in flexible packaging, requiring extremely high throughput and precision in handling delicate films, further mandates the adoption of advanced tension clutches. Coupled with this is the continuous pressure on manufacturing firms to minimize waste and maximize material yield, making precise tension control an economic necessity, directly impacting profit margins and sustainability targets across various industries.

However, the market faces several significant restraints that impede growth, particularly the high initial capital investment required for installing advanced digital tension control systems, including the high-precision clutches, load cells, and associated electronic controllers. This cost barrier can deter smaller and medium-sized enterprises (SMEs) from upgrading their legacy equipment. Furthermore, the technical complexity associated with the calibration, integration, and maintenance of high-end magnetic particle and pneumatic clutches necessitates specialized technical expertise. The scarcity of personnel trained in sophisticated industrial automation and closed-loop tension control systems poses an operational challenge, limiting the rapid deployment and optimal utilization of these advanced components in certain geographical markets.

Opportunities for market expansion are centered on the development and commercialization of "smart" or "IoT-enabled" tension clutches, which offer wireless communication, remote diagnostics, and seamless integration into overarching Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) platforms. The growing demand for specialized, high-precision clutches in niche applications, such as the production of lithium-ion battery electrodes and high-end photographic films, presents lucrative avenues for manufacturers specializing in ultra-low torque and high-sensitivity products. Furthermore, strategic opportunities lie in expanding services related to retrofitting and upgrading existing machinery with modern tension control systems, particularly in developed regions where capital expenditure on entirely new production lines is often constrained, favoring modular upgrades.

Segmentation Analysis

The Tension Clutch Market is comprehensively segmented based on the mechanism employed (Type), the specific industry where the device is used (Application), and the geographic location of demand. Understanding these segments is crucial for market participants to tailor product offerings and sales strategies, as performance requirements vary dramatically across different operational contexts. The Type segmentation highlights the fundamental technological differences, differentiating between systems that use electromagnetic principles, compressed air, or pure mechanical friction to modulate torque. Magnetic particle clutches are valued for their unparalleled smoothness and fine torque adjustment, while pneumatic clutches offer high torque capacity and quick response times, suitable for heavy-duty applications, creating distinct competitive landscapes within the broader market structure.

The Application segmentation underscores the diverse industrial environments utilizing tension control, with the Printing and Packaging sector remaining the largest consumer, given the critical need for color registration and web integrity in flexible packaging films, labels, and offset printing. However, the rapid expansion of the Wire and Cable Manufacturing sector, driven by global electrification projects and the demand for high-performance communication cables, is exhibiting the highest growth trajectory, demanding robust, high-durability clutches. Analyzing these application segments allows manufacturers to focus R&D efforts on durability standards and contamination resistance specific to each industrial environment, such as resistance to airborne particulates in textile mills or high heat resistance in metal processing operations.

Moreover, the segmentation based on geography reflects the uneven distribution of heavy manufacturing capacity and the varying technological adoption rates worldwide. Asia Pacific’s dominance is driven by sheer volume of manufacturing output, whereas North America and Europe lead in the adoption of premium, fully integrated digital systems, emphasizing quality over volume. This granular segmentation provides a framework for evaluating market maturity, competitive intensity, and potential entry points for new products, guiding strategic investment decisions regarding regional manufacturing and distribution networks essential for maximizing market penetration and responsiveness to local demand variations.

- By Type:

- Pneumatic Tension Clutch

- Magnetic Particle Tension Clutch

- Mechanical Tension Clutch (Friction Plate, Hysteresis)

- Electromagnetic Tension Clutch

- By Application:

- Printing and Packaging Industry

- Textile Industry

- Wire and Cable Manufacturing

- Metal Processing (Slitting, Shearing)

- Converting Machinery (Paper, Film, Foil)

- Food and Beverage Processing

- By Torque Range:

- Low Torque (Below 50 Nm)

- Medium Torque (50 Nm to 500 Nm)

- High Torque (Above 500 Nm)

Value Chain Analysis For Tension Clutch Market

The value chain for the Tension Clutch Market begins with the upstream sourcing of specialized raw materials and intricate components, critical to the performance and longevity of the final product. This stage involves acquiring high-grade metals for casings and shafts, specialized magnetic powders (for magnetic clutches), high-durability friction linings (for mechanical clutches), and sensitive electronic components such as load cells and sensors crucial for feedback control loops. Key upstream suppliers include specialized material science companies and precision bearing manufacturers. Quality control at this stage is paramount, as the consistency of components like magnetic particles directly dictates the clutch’s torque precision and responsiveness, making supply chain robustness a competitive differentiator for clutch manufacturers.

Moving downstream, the value chain encompasses the sophisticated processes of assembly, integration, and final distribution to end-users. Tension clutch manufacturers often integrate their products into larger, complete web tension control systems, including controllers, amplifiers, and feedback sensors. Distribution channels are typically specialized, involving direct sales teams for large OEMs (Original Equipment Manufacturers) who purchase clutches in bulk for new machinery lines, and a robust network of industrial distributors and system integrators for the aftermarket and retrofitting business. Direct channels facilitate deep technical support and customization for OEMs, while indirect channels leverage geographical reach and provide immediate replacement parts and localized maintenance services to a dispersed base of end-user facilities, ensuring wider market penetration.

The crucial role of system integrators in the midstream market cannot be overstated; these entities specialize in combining various industrial components—including the clutch, motor, control panel, and proprietary software—into a functional, optimized production line specific to the customer’s needs (e.g., a high-speed printing press or a specialized film laminator). This integration service ensures that the tension clutch operates optimally within the context of the entire machine, accounting for variables like inertia and friction. Ultimately, the downstream segment is characterized by service and maintenance, where the long-term profitability of the installed base relies heavily on the provision of timely spare parts, repair services, and technical training, driving customer loyalty and supporting the longevity of high-investment production equipment.

Tension Clutch Market Potential Customers

The primary cohort of potential customers for the Tension Clutch Market consists of large-scale industrial processors and machinery builders who operate continuous web handling systems requiring precise torque control for material transport. This includes two major segments: Original Equipment Manufacturers (OEMs) who design and build complex machinery such as printing presses (flexographic, gravure), slitting and rewinding machines, laminators, and coating lines, and End-User Factories (EUFs) operating in the packaging, textile, and metal industries. OEMs represent a highly consolidated customer base, purchasing clutches in large quantities, often demanding customized solutions and strong technical partnership to meet the specific performance characteristics of their proprietary machinery designs, valuing integration ease and reliability above all else.

The second, and perhaps larger, customer base comprises End-User Factories, specifically those managing high-volume production where material waste is a significant cost factor. These buyers are typically procurement managers or plant engineers in flexible packaging converters, major textile mills, wire and cable producers, and specialized composite material manufacturers. Their purchasing decisions are heavily influenced by the clutch's reliability, ease of maintenance, mean time between failures (MTBF), and its capability to integrate into existing control infrastructure for retrofitting projects. These EUFs are continually seeking solutions that reduce operational expenses, improve material yield, and ensure consistent product quality, prioritizing durability and the availability of local technical support and replacement parts.

Emerging potential customers include manufacturers in new high-tech sectors, such as those involved in the production of lithium-ion batteries and advanced electronic displays. These specialized fields require tension clutches capable of handling extremely thin, fragile, and valuable materials (like battery separator films or optical films) with ultra-low torque and exceptional precision, often operating within cleanroom environments. This segment demands cutting-edge technology, including hysteresis clutches and high-sensitivity magnetic systems, representing a growing niche that prioritizes technological superiority and micro-level control, driving innovation towards smaller, cleaner, and more highly digitized tension control solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 1.8 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ogura Industrial Corp., Mitsubishi Electric Corporation, Warner Electric (Altra Industrial Motion), Merobel, Montalvo Corporation, Re. S. S.r.l., Nexen Group, Inc., Magpowr, Electroid Company, VETEC, Shuwa Machinery, Dover Flexo Electronics (DFE), Maxcess International, Tsubaki Nakashima Co., Ltd., Matrix International, Lenze SE, Siemens AG, Rexnord Corporation, Wichita Clutch, Horton, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Tension Clutch Market Key Technology Landscape

The contemporary Tension Clutch Market is defined by a technological shift towards high-precision, closed-loop control systems, driven by the necessity for flawless web handling at escalating production speeds. Central to this landscape is the ubiquitous integration of highly sensitive load cells and advanced displacement sensors, which provide the crucial real-time feedback loop necessary for the control system. Load cells measure the actual tension force exerted on the web material, allowing the controller to compare this reading with the setpoint and instantaneously adjust the power supplied to the clutch. This closed-loop mechanism drastically minimizes tension variation, which is critical for complex processes like multi-color printing registration and precise winding operations where even slight fluctuations can lead to scrap material and quality defects, thus representing a significant technological step up from older open-loop torque estimation methods.

Further innovation is concentrated in the control system architecture, with a strong move towards digital control interfaces and fieldbus communication protocols such as EtherNet/IP, PROFINET, and EtherCAT. This digitalization allows the tension clutch system to be managed centrally by a plant’s Programmable Logic Controller (PLC) or Distributed Control System (DCS), enabling remote diagnostics, centralized data logging, and synchronization with other machine axes (e.g., motor speed control). The ability to communicate seamlessly and rapidly across the production network is essential for high-speed synchronization, where latency in torque adjustment can severely compromise output quality, thereby enhancing overall machine performance and facilitating integration into smart factory (Industry 4.0) frameworks which rely heavily on interconnected devices for optimal workflow.

Material science and mechanical design also remain pivotal technological areas, particularly in developing clutches with improved heat dissipation capabilities and longer service life. For high-torque pneumatic and magnetic clutches, operational heat generation is a major constraint that affects performance stability and longevity. Manufacturers are employing advanced cooling mechanisms, often liquid-cooled or forced-air systems, and utilizing specialized materials that maintain consistent friction coefficients across extreme temperature ranges, minimizing torque fade. Furthermore, the push for energy efficiency is driving the development of highly responsive and low-inertia clutch designs that minimize the power required for actuation and reduce the energy consumption associated with braking or driving large rolls of material, aligning with global trends toward sustainable industrial operation.

Regional Highlights

- Asia Pacific (APAC): APAC is the largest and fastest-growing regional market, primarily due to its status as the world’s manufacturing powerhouse for textiles, consumer electronics, and packaging. Rapid industrialization, substantial government investments in infrastructure, and the continuous establishment of new production facilities across China, India, and Southeast Asia drive high volume demand for tension clutches. While cost remains a factor, the increasing adoption of automated, high-speed converting machinery for export markets is driving demand for advanced magnetic and pneumatic clutch systems to ensure compliance with international quality standards.

- North America: This region is characterized by high adoption rates of premium, fully integrated digital tension control systems. The focus here is less on sheer volume and more on precision, reliability, and maximizing machine uptime. Driven by stringent quality requirements in food and beverage packaging, specialized medical films, and aerospace materials, North American customers invest heavily in IoT-enabled clutches offering predictive maintenance and seamless integration with existing high-level factory management software.

- Europe: Europe maintains a mature market driven by rigorous environmental regulations and a strong emphasis on operational efficiency and sustainable manufacturing. Demand is high for energy-efficient clutches, often incorporating sophisticated thermal management and closed-loop technologies to reduce energy consumption and material waste. Germany, Italy, and Switzerland, being leaders in specialized machinery manufacturing, serve as key hubs for both innovation and consumption, favoring pneumatic and high-performance mechanical systems optimized for continuous, demanding industrial operations.

- Latin America (LATAM) and Middle East & Africa (MEA): These regions represent emerging markets exhibiting moderate growth, largely supported by expanding local packaging and printing industries fueled by rising domestic consumer consumption. Market activity in these areas focuses on reliable, mid-range technology solutions and robust clutches that can handle varying environmental conditions, often sourced via system integrators undertaking modernization projects in countries like Brazil, Mexico, and Saudi Arabia.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Tension Clutch Market.- Ogura Industrial Corp.

- Mitsubishi Electric Corporation

- Warner Electric (Altra Industrial Motion)

- Merobel

- Montalvo Corporation

- Re. S. S.r.l.

- Nexen Group, Inc.

- Magpowr

- Electroid Company

- VETEC

- Shuwa Machinery

- Dover Flexo Electronics (DFE)

- Maxcess International

- Tsubaki Nakashima Co., Ltd.

- Matrix International

- Lenze SE

- Siemens AG

- Rexnord Corporation

- Wichita Clutch

- Horton, Inc.

Frequently Asked Questions

Analyze common user questions about the Tension Clutch market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a tension clutch in industrial machinery?

A tension clutch is a crucial component used to maintain precise, consistent tension on continuous web materials (like paper, film, or foil) during winding, unwinding, or converting processes. It applies controlled torque to prevent material damage such as stretching, wrinkling, or breaking, ensuring high product quality and process stability.

Which type of tension clutch is best suited for high-precision, low-torque applications?

Magnetic particle clutches are typically preferred for high-precision, low-torque applications, such as handling delicate films and foils in battery or electronics manufacturing. They offer extremely smooth, linear torque control that responds rapidly to subtle changes in speed or material diameter, minimizing process variation.

How is the growth of the E-commerce sector impacting the demand for tension clutches?

The E-commerce boom drives increased demand for flexible packaging and specialized labeling, requiring high-speed converting machinery. This necessitates advanced, high-accuracy tension clutches to handle thinner, multi-layer films reliably and quickly, directly boosting market growth in the printing and packaging application segment.

What role does closed-loop control play in modern tension clutch systems?

Closed-loop control is essential for modern systems, utilizing load cells to measure actual web tension in real-time. The system compares this reading to the required setpoint and automatically adjusts the clutch torque, ensuring superior precision, immediate response to disturbances, and significantly improved consistency compared to older open-loop methods.

Which geographic region currently dominates the Tension Clutch Market?

The Asia Pacific (APAC) region currently dominates the Tension Clutch Market in terms of volume and is projected to exhibit the fastest growth. This dominance is attributed to massive industrial infrastructure investment, high rates of manufacturing output, and expansion across the textile, printing, and cable manufacturing sectors in countries like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager