Textile Dyeing Equipment Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441801 | Date : Feb, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Textile Dyeing Equipment Market Size

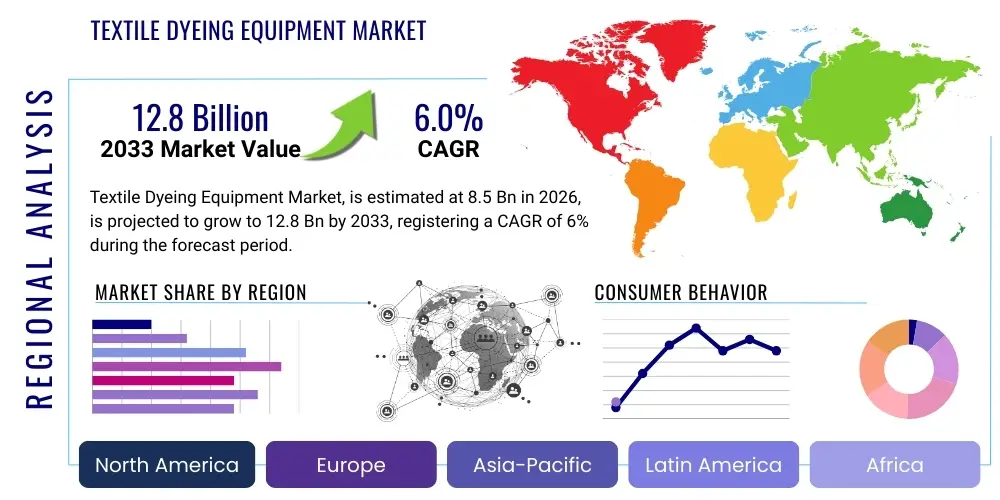

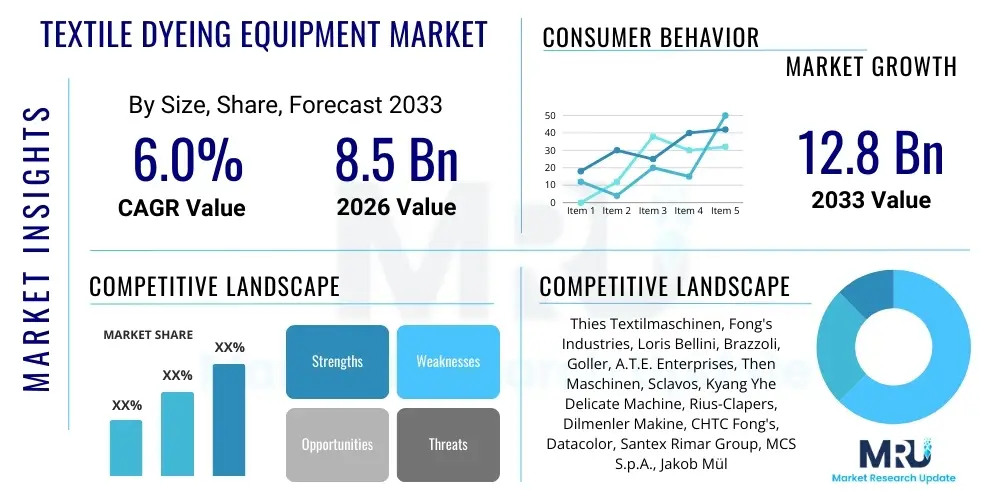

The Textile Dyeing Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.0% between 2026 and 2033. The market is estimated at USD 8.5 Billion in 2026 and is projected to reach USD 12.8 Billion by the end of the forecast period in 2033.

Textile Dyeing Equipment Market introduction

The Textile Dyeing Equipment Market encompasses machinery and systems used for imparting color to textile substrates, including fibers, yarns, fabrics, and garments. These specialized machines are critical for the global textile manufacturing industry, ensuring color fastness, quality, and uniformity across various material types. Products range from high-pressure jet dyeing machines suitable for delicate synthetic fabrics to continuous dyeing ranges utilized for high-volume production of woven and knitted goods. The evolution of this market is intrinsically linked to advancements in material science, demanding equipment that can handle complex new fibers and sustainable dyeing processes while minimizing water and energy consumption.

The primary applications of textile dyeing equipment span across the apparel industry, which demands flexible and precise coloring solutions; the home textiles sector, focusing on large-scale batch processing for bedding and upholstery; and the burgeoning technical textiles segment, requiring specialized machinery for high-performance materials used in automotive, medical, and protective wear. Benefits derived from modern dyeing equipment include significant operational efficiencies, reduced waste, improved reproducibility of color shades (right-first-time dyeing), and compliance with increasingly stringent environmental regulations regarding effluent discharge and chemical usage. Precision dosing and automated control systems are now standard features, enhancing both quality and speed.

Key driving factors propelling market growth include the robust demand for textiles globally, particularly from emerging economies in Asia Pacific where manufacturing capabilities are expanding rapidly. Furthermore, the imperative for sustainable manufacturing practices, driven by consumer awareness and regulatory pressure, fuels the demand for innovative, eco-friendly dyeing technologies such as supercritical CO2 dyeing and optimized waterless systems. Technological migration towards automation and digitalization also plays a significant role, as manufacturers seek to integrate dyeing processes within Industry 4.0 frameworks to improve competitiveness and flexibility in handling diverse order sizes.

Textile Dyeing Equipment Market Executive Summary

The Textile Dyeing Equipment Market is experiencing a substantial shift toward automation, sustainability, and process optimization, driven primarily by cost pressures and environmental mandates. Business trends indicate a strong move away from traditional, high water-consuming batch processes toward continuous and innovative low-liquor ratio dyeing machines. Manufacturers are investing heavily in integrated control systems, utilizing sensors and software for real-time monitoring of temperature, pH, and dye concentration, thus ensuring minimal resource wastage and high color accuracy. Strategic collaborations between machinery producers and chemical suppliers are also becoming common to develop integrated solutions that enhance dye exhaustion and fixation rates.

Regionally, the Asia Pacific (APAC) continues to dominate the market, anchored by colossal textile production hubs in China, India, and Vietnam. However, investment patterns are diversifying; while APAC focuses on capacity expansion and efficiency upgrades, Europe and North America prioritize niche high-value technical textile applications and retrofitting existing plants with advanced sustainable technologies to meet strict local regulations. Latin America and the Middle East & Africa (MEA) represent emerging growth zones, primarily driven by domestic apparel demand and the establishment of local textile value chains aimed at reducing reliance on imports, spurring initial investments in semi-automatic and mid-range continuous dyeing equipment.

Segment trends reveal that the Jet Dyeing Machines segment, particularly those offering ultra-low liquor ratios, maintains high adoption rates due to versatility and efficiency, especially for synthetic and blended fabrics. In terms of automation, the Fully Automatic segment is projected to exhibit the highest CAGR, reflecting the global trend toward minimizing human error, enhancing reproducibility, and facilitating seamless integration into smart factory operations. Application-wise, the technical textiles segment is exhibiting robust growth, necessitating specialized dyeing solutions that can withstand harsh chemical environments and maintain the integrity of complex material structures, pushing innovation in beam and package dyeing technologies.

AI Impact Analysis on Textile Dyeing Equipment Market

Common user questions regarding AI's impact on the Textile Dyeing Equipment Market revolve around three core themes: predictive maintenance, optimization of color matching and recipe formulation, and autonomous process control. Users frequently inquire about how AI can reduce the common industry problem of "right-first-time" failures, minimize energy and water consumption through real-time adjustments, and forecast equipment breakdowns to avoid costly downtime. There is also significant interest in leveraging machine learning models to analyze vast datasets of dye formulations, material properties, and environmental conditions (such as water quality) to instantly generate optimal dyeing recipes, thereby enhancing production speed and color consistency across batches and machines, leading to unprecedented levels of operational efficiency and quality control.

- AI-driven Predictive Maintenance: Analyzing machine sensor data (vibration, temperature, pressure) to forecast component failure, minimizing unplanned downtime and optimizing maintenance schedules.

- Automated Color Recipe Generation: Utilizing machine learning algorithms to instantly calculate precise dye, chemical, and auxiliary requirements based on target shade and substrate type, significantly reducing color correction cycles.

- Real-time Process Optimization: Adjusting liquor ratios, flow rates, and heating curves dynamically during the dyeing cycle based on immediate chemical absorption data, leading to maximum dye exhaustion and resource efficiency.

- Quality Control and Defect Detection: Employing computer vision and AI to automatically scan fabrics post-dyeing for minute shade variations, patches, or unevenness, ensuring 100% quality inspection.

- Supply Chain Resilience: Using AI models to predict raw material (dyes and chemicals) price fluctuations and availability, optimizing inventory management for dyeing operations.

DRO & Impact Forces Of Textile Dyeing Equipment Market

The dynamics of the Textile Dyeing Equipment Market are fundamentally shaped by the confluence of sustainability drivers, stringent regulatory frameworks, and the continuous need for manufacturing efficiency improvements. The major drivers include global environmental concerns that necessitate reduced water and energy footprint in textile processing, pushing manufacturers towards advanced low-liquor ratio and waterless dyeing technologies. Conversely, the high initial capital investment required for installing advanced, automated dyeing ranges, coupled with fluctuating raw material costs (dyes and auxiliaries), acts as a significant restraint, particularly for Small and Medium-sized Enterprises (SMEs). This financial hurdle often slows down the adoption of state-of-the-art machinery in developing economies.

Opportunities for growth are predominantly centered around the rising prominence of technical textiles—materials used in non-traditional applications like aerospace, agriculture, and healthcare—which require specialized, high-precision dyeing processes. Furthermore, the expansion of circular economy models presents an opportunity for equipment manufacturers to develop solutions specifically tailored for dyeing recycled fibers and complex blends, which currently pose technical challenges for standard equipment. Impact forces, such as the increasing stringency of global chemical regulations (e.g., REACH in Europe), compel equipment producers to innovate continuously, embedding features that guarantee safe handling and minimal discharge of hazardous substances, effectively making compliance a non-negotiable factor influencing procurement decisions.

The intensity of competitive rivalry is high, driven by technological differentiation and the need for localized service support in key manufacturing regions. Suppliers compete not only on the price and efficiency of the machines but also on the integration capabilities, software intelligence (Industry 4.0 readiness), and the long-term cost of ownership (maintenance and spare parts availability). The bargaining power of buyers, especially large textile conglomerates, remains moderate to high, as they often demand customized, integrated solutions and significant energy guarantees before making large-scale investments. These forces collectively steer the market toward consolidated, technologically advanced, and environmentally responsible equipment solutions.

Segmentation Analysis

The Textile Dyeing Equipment Market is comprehensively segmented based on the type of machinery, the level of automation utilized, and the final application of the dyed textiles. This segmentation helps manufacturers tailor their offerings to specific industry needs, whether they involve high-volume continuous processes for standard materials or flexible, batch processes for specialized, sensitive fabrics. Analysis across these segments reveals clear trends in technological preferences, investment patterns, and regional specialization, providing a detailed view of current market dynamics and future growth vectors. The Type segmentation (Jet, Jigger, Pad, etc.) dictates the material handled and the operational scale, while the Automation segmentation (Semi vs. Fully Automatic) reflects investment capacity and the drive toward smart manufacturing.

- By Type:

- Jet Dyeing Machines

- Jigger Dyeing Machines

- Pad Dyeing Machines (Cold Pad Batch, Hot Pad Steam)

- Continuous Dyeing Ranges

- Beam Dyeing Machines

- Package Dyeing Machines

- Garment Dyeing Machines

- By Automation:

- Semi-Automatic

- Fully Automatic

- By Application:

- Apparel Textiles

- Home Textiles (e.g., Upholstery, Towels, Bedding)

- Technical Textiles (e.g., Medical, Automotive, Protective Wear)

- Carpets and Rugs

Value Chain Analysis For Textile Dyeing Equipment Market

The value chain for textile dyeing equipment begins with upstream activities involving the sourcing and processing of core raw materials such as specialized high-grade metals (stainless steel, corrosion-resistant alloys), complex electronic components (sensors, PLCs, motor drives), and high-precision fluid dynamics components (pumps, valves). Equipment manufacturers then engage in sophisticated R&D, design, and manufacturing, focusing on integrating advanced software for automation and resource management. The efficiency of the upstream supply chain in providing reliable, durable components directly impacts the final equipment's performance and longevity, requiring strong relationships with specialized industrial component suppliers.

The distribution channel plays a critical intermediate role, facilitating the movement of complex machinery from the producer to the end-user. Distribution involves both direct sales channels, typically utilized for large, highly customized continuous dyeing ranges sold directly to major textile conglomerates, and indirect channels, relying on regional distributors, agents, and local service providers. These indirect partners often provide essential services like installation, local training, and ongoing maintenance support, which are crucial given the highly technical nature of the equipment and the global spread of textile production centers.

Downstream activities center on the end-users—the textile mills, processing houses, and garment manufacturers—who use the equipment to dye fabrics, yarns, and garments. This stage is heavily influenced by aftermarket services, including spare parts supply, software upgrades, and preventative maintenance contracts, which constitute a significant revenue stream for equipment providers. The proximity and responsiveness of service centers are critical factors in the purchasing decision, as downtime in high-volume dyeing operations can lead to substantial financial losses. Potential customers are heavily focused on Return on Investment (ROI), measured by efficiency gains, energy savings, and consistency of output quality.

Textile Dyeing Equipment Market Potential Customers

Potential customers for the Textile Dyeing Equipment Market are predominantly large-scale textile processing units, integrated textile mills, independent dyeing and finishing houses, and specialized producers of technical textiles globally. These buyers seek machinery that offers optimal efficiency, reduced environmental footprint, and high color accuracy across diverse fabric types. The procurement decisions are typically made by senior management and technical directors, heavily relying on criteria such as liquor ratio performance, automation capabilities, compliance with international standards (e.g., ZDHC), and the proven reliability of the equipment under continuous operational stress. Investment often aligns with global trends like fast fashion (requiring quick turnaround batch machines) or sustainability mandates (demanding low water/energy consumption systems).

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 8.5 Billion |

| Market Forecast in 2033 | USD 12.8 Billion |

| Growth Rate | 6.0% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Thies Textilmaschinen, Fong's Industries, Loris Bellini, Brazzoli, Goller, A.T.E. Enterprises, Then Maschinen, Sclavos, Kyang Yhe Delicate Machine, Rius-Clapers, Dilmenler Makine, CHTC Fong's, Datacolor, Santex Rimar Group, MCS S.p.A., Jakob Müller AG, Setex Schermuly, CIBITEX, Benninger AG, Menzel Maschinenbau. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Textile Dyeing Equipment Market Key Technology Landscape

The modern Textile Dyeing Equipment landscape is characterized by a strong push towards technologies that minimize resource usage while maximizing color reproducibility. A central technology is the development of Ultra-Low Liquor Ratio (ULLR) dyeing machines, particularly in the jet and air-flow segments. These systems drastically reduce water and energy consumption by operating with minimal liquid relative to the fabric weight, making them essential for sustainable textile production. Further sophistication is achieved through advanced process control systems (PCS), which utilize PLC controllers, embedded sensors, and proprietary software algorithms to manage every variable—from pH and temperature to precise chemical dosing—in real-time, significantly improving "right-first-time" rates.

Another transformative technology is Supercritical Carbon Dioxide (SC-CO2) Dyeing, often referred to as waterless dyeing. This innovative process uses CO2 in its supercritical state as the solvent to transport disperse dyes into polyester fibers. While still a niche segment due to the high initial investment required for the pressure vessels, SC-CO2 dyeing eliminates the need for water entirely and subsequently avoids effluent generation, positioning it as the ultimate sustainable dyeing solution for specific synthetic materials. The maturation and cost reduction of this technology will significantly disrupt traditional water-based dyeing methods in the long term, attracting substantial R&D focus from major players.

Furthermore, Industry 4.0 integration is redefining the operational model of dyeing plants. This involves incorporating advanced sensor technology, big data analytics, and cloud connectivity into dyeing equipment. These smart machines can communicate their operational status, material usage, and performance metrics to a centralized Manufacturing Execution System (MES). This integration facilitates predictive maintenance, optimizes energy scheduling across the factory floor, and allows for remote diagnostics and software updates, ensuring that modern dyeing equipment operates as part of an intelligent, interconnected manufacturing ecosystem, moving the industry toward truly autonomous and highly efficient production cycles.

Regional Highlights

- Asia Pacific (APAC): APAC is the dominant market shareholder due to its immense textile manufacturing base, particularly in China, India, and Southeast Asian nations like Vietnam and Bangladesh. The region is characterized by high volume production, leading to strong demand for continuous dyeing ranges and high-capacity jet dyeing machines. While cost-effectiveness remains a primary driver, increasing environmental regulations in countries like China are spurring substantial investments in advanced, resource-efficient equipment, shifting the focus from capacity alone to capacity coupled with sustainability compliance.

- Europe: Europe represents a mature market focused on innovation, technical textiles, and high-value fashion products. The demand here is driven primarily by stringent environmental mandates (e.g., EU Green Deal) and the need for highly flexible, small-batch dyeing equipment that supports rapid changes in fashion trends. European manufacturers prioritize automation, digital integration (Industry 4.0), and the adoption of cutting-edge sustainable technologies, including CO2 dyeing and sophisticated exhaust air purification systems. Germany and Italy remain crucial centers for advanced machinery manufacturing and consumption.

- North America: The North American market emphasizes technical textiles, specialized functional fabrics (e.g., military, medical, industrial), and quick domestic turnaround capabilities. Investments are concentrated on replacing aging infrastructure with modern, fully automated systems that guarantee high quality and labor efficiency. Sustainability is a key procurement factor, encouraging the adoption of equipment with the lowest possible environmental impact to meet corporate social responsibility goals and high domestic environmental standards.

- Latin America (LATAM): LATAM is an emerging market characterized by localized textile production growth, particularly in Brazil and Mexico. The market shows a mixed adoption pattern, with investments in both affordable semi-automatic machines for local markets and highly efficient, modern equipment to serve export-oriented industries. Market growth is moderately paced, dependent on regional economic stability and government support for local textile revitalization initiatives.

- Middle East and Africa (MEA): The MEA region, particularly Turkey and Egypt, is expanding its textile manufacturing base, driven by strategic governmental efforts to diversify economies and establish regional textile hubs. Turkey serves as a key gateway to European markets, driving demand for compliant, modern, and efficient dyeing equipment. Investment in the broader African continent is accelerating, focusing on establishing necessary infrastructure and importing reliable, versatile machinery to build sustainable local textile value chains.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Textile Dyeing Equipment Market.- Thies Textilmaschinen GmbH

- Fong's Industries Co., Ltd. (CHTC Fong's Group)

- Loris Bellini S.p.A.

- Brazzoli S.r.l.

- Goller Textilmaschinen GmbH

- A.T.E. Enterprises Private Limited

- Then Maschinen GmbH

- Sclavos S.A.

- Kyang Yhe Delicate Machine Co., Ltd.

- Rius-Clapers S.A.

- Dilmenler Makine Tekstil Sanayi Ve Ticaret A.S.

- Datacolor

- Santex Rimar Group

- MCS S.p.A.

- Jakob Müller AG

- Setex Schermuly textile computer GmbH

- CIBITEX S.R.L.

- Benninger AG

- Menzel Maschinenbau GmbH

- Gaston Systems, Inc.

Frequently Asked Questions

Analyze common user questions about the Textile Dyeing Equipment market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for new textile dyeing equipment?

The primary driver is the global regulatory and consumer pressure for sustainability, compelling manufacturers to invest in resource-efficient machinery, specifically ultra-low liquor ratio (ULLR) and waterless dyeing systems, to meet environmental compliance and reduce operational costs associated with water and energy consumption.

How is Industry 4.0 impacting the design and operation of dyeing machinery?

Industry 4.0 facilitates the integration of advanced sensors, AI-driven control systems, and centralized software platforms (MES). This enables real-time monitoring, predictive maintenance, automated recipe adjustment, and improved color reproducibility ("right-first-time"), maximizing efficiency and minimizing human error in the dyeing process.

Which type of dyeing equipment is most suitable for synthetic fabrics and blends?

Jet dyeing machines, particularly those designed for high-pressure and high-temperature operation with ultra-low liquor ratios, are generally the most suitable equipment for efficiently and gently processing sensitive synthetic fabrics and their blends while achieving excellent color penetration and uniformity.

Which geographical region represents the largest market for textile dyeing equipment?

Asia Pacific (APAC) currently holds the largest market share, driven by its expansive manufacturing capacity in key countries such as China, India, and Vietnam. This dominance is supported by ongoing investments in both scaling production and upgrading equipment to meet modern efficiency standards.

What is the main challenge restraining the widespread adoption of advanced dyeing technology?

The most significant restraint is the high initial capital expenditure (CapEx) required for sophisticated, fully automated, and sustainable dyeing systems, which presents a financial barrier, especially for small and medium-sized textile enterprises operating in cost-sensitive environments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager