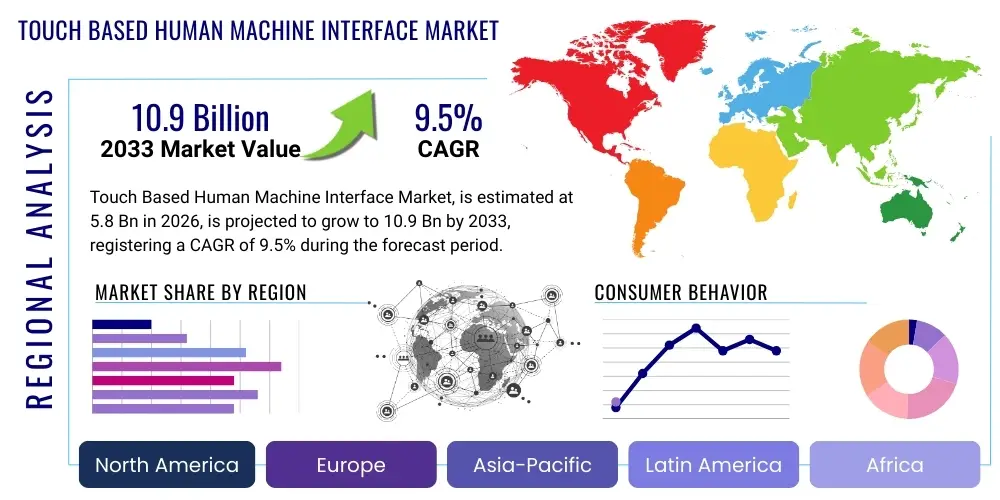

Touch Based Human Machine Interface Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441421 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Touch Based Human Machine Interface Market Size

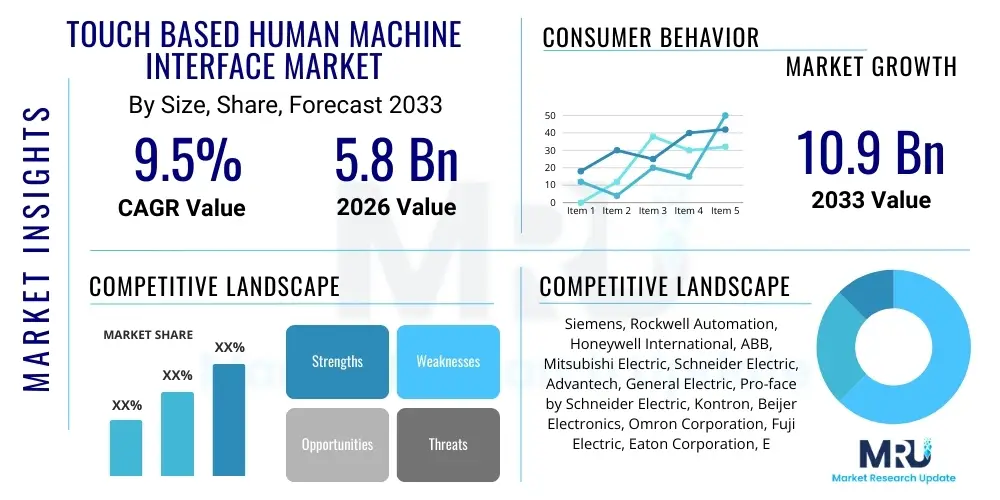

The Touch Based Human Machine Interface Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2026 and 2033. The market is estimated at USD 5.8 Billion in 2026 and is projected to reach USD 10.9 Billion by the end of the forecast period in 2033.

Touch Based Human Machine Interface Market introduction

The Touch Based Human Machine Interface (HMI) Market encompasses hardware and software solutions that facilitate seamless interaction between human operators and machinery or industrial systems through tactile input. These interfaces, ranging from industrial panel PCs and specialized operator terminals to integrated mobile devices, utilize technologies such as capacitive and resistive touchscreens to provide real-time control, monitoring, and data visualization. The core product description involves ruggedized displays designed for harsh operational environments, equipped with powerful processing capabilities and standardized communication protocols (e.g., EtherNet/IP, Profibus) necessary for integration into complex automation architectures. The evolution of HMIs is shifting towards advanced graphical interfaces, multi-touch capabilities, and enhanced cyber-security features, crucial for modern manufacturing and infrastructure management.

Major applications of touch-based HMI technology span critical sectors including industrial automation, automotive manufacturing, healthcare systems (medical devices), and public infrastructure (kiosks, transportation). In industrial settings, HMIs are indispensable for controlling Programmable Logic Controllers (PLCs), monitoring production efficiency, and executing supervisory control and data acquisition (SCADA) functions. The primary benefits derived from adopting these systems include significant improvements in operational efficiency, reduction in human error through intuitive control layouts, and accelerated diagnostic times. Furthermore, touch-based HMIs enhance worker safety by providing immediate access to critical system information and alarms, supporting predictive maintenance strategies.

The market growth is primarily driven by the pervasive adoption of Industry 4.0 standards, which necessitate robust, data-driven interfaces for smart factory operations. Increased investment in automated production lines, particularly across high-growth regions like Asia Pacific, further fuels demand. The shift from traditional button-and-switch interfaces to highly intuitive, graphical touch interfaces is a fundamental driver, improving user experience and minimizing training requirements. Additionally, the miniaturization and increased ruggedization of touch technology allow deployment in challenging environments, expanding the application base across energy, oil and gas, and pharmaceutical manufacturing.

Touch Based Human Machine Interface Market Executive Summary

The Touch Based Human Machine Interface (HMI) market is experiencing robust growth driven by accelerating industrial digitalization and the necessity for intuitive operational control within complex systems. Business trends indicate a strong movement toward incorporating IIoT (Industrial Internet of Things) connectivity, enabling HMIs to function as centralized data hubs that integrate production data with enterprise-level systems (MES/ERP). Key players are focusing on developing scalable, modular HMI platforms that support remote accessibility and cloud integration, transforming the HMI from a mere control panel into a critical component of the digital thread. Furthermore, there is a distinct competitive trend favoring solutions that offer high-resolution displays, multi-touch gesture support, and advanced software features such as integrated historizing and advanced alarming management, prioritizing user-centric design principles to reduce operator cognitive load.

Regionally, the market is spearheaded by Asia Pacific, attributed to rapid industrial expansion, massive foreign direct investment in setting up smart manufacturing facilities (especially in China, Japan, and South Korea), and government initiatives promoting factory automation. North America and Europe maintain significant market shares, characterized by early adoption of sophisticated automation technologies, high penetration of smart grid infrastructure, and stringent regulatory requirements that mandate high levels of monitoring and control, particularly in regulated industries like pharmaceuticals and aerospace. European manufacturers are strong innovators in ergonomic design and functional safety standards for HMIs, influencing global product specifications.

Segmentation trends highlight the dominance of the capacitive technology segment, favored for its superior clarity, durability, and responsiveness, particularly in consumer electronics and increasingly in automotive and high-end industrial applications. The hardware segment, including specialized industrial monitors and panel PCs, remains the largest revenue generator due to the fundamental requirement for rugged physical displays in manufacturing environments. However, the software segment, driven by the need for advanced visualization tools, remote monitoring capabilities, and SCADA integration software, is projected to register the highest growth rate. Application-wise, the automotive and heavy machinery sectors represent the most significant opportunity due to ongoing automation efforts and the need for sophisticated cockpit and operator control systems.

AI Impact Analysis on Touch Based Human Machine Interface Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Touch Based Human Machine Interface (HMI) market center primarily on three areas: how AI will enhance predictive diagnostics and decision support, the feasibility of incorporating natural language processing (NLP) and voice commands alongside touch interfaces, and the role of AI in personalizing the operator experience and optimizing workflow efficiency. Users are concerned about whether AI will replace traditional HMI functions or simply augment them, demanding clear analysis on how machine learning algorithms can analyze vast amounts of operational data collected via the HMI to provide actionable insights far beyond conventional alarming systems. The key expectation is that AI integration will shift the HMI paradigm from reactive control to proactive, intelligent supervision, reducing unexpected downtime and improving overall equipment effectiveness (OEE).

AI is transforming HMIs into intelligent interaction points capable of complex data interpretation and autonomous recommendation generation. By deploying embedded AI models at the edge or leveraging cloud-based machine learning services, HMIs can now predict equipment failures before they occur, optimize process parameters in real-time, and provide operators with prescriptive guidance rather than raw data feeds. This shift enhances the cognitive load capacity of the human operator, allowing them to focus on high-level strategic oversight rather than routine monitoring. For example, AI algorithms can analyze historical touch patterns and operational data to automatically suggest optimal control sequences or adjust display layouts based on the current machine state or operator preference, drastically improving efficiency and reducing error rates.

Furthermore, AI facilitates the creation of truly adaptive and multi-modal HMIs. While touch remains essential for precise control inputs, AI enables seamless integration of voice activation, gesture recognition, and even eye-tracking capabilities, offering flexible interaction methods particularly useful in sterile environments or when operators are wearing heavy protective gear. AI-powered diagnostic assistants, accessible directly through the HMI screen, can interpret complex system faults and display tailored, step-by-step troubleshooting instructions, democratizing expertise across the workforce. This intelligent augmentation ensures that the human operator retains ultimate authority while leveraging AI for enhanced situational awareness and advanced operational support.

- AI enables predictive maintenance insights displayed directly on the HMI interface.

- Machine learning algorithms personalize HMI layouts based on operator behavior and operational context.

- AI facilitates multi-modal interaction (voice, gesture) augmenting traditional touch controls.

- Real-time anomaly detection driven by AI minimizes latency in critical operational responses.

- Embedded AI enhances cyber resilience by continuously monitoring and flagging unusual access patterns via the interface.

DRO & Impact Forces Of Touch Based Human Machine Interface Market

The Touch Based Human Machine Interface (HMI) market is significantly influenced by a dynamic combination of drivers, restraints, and opportunities that collectively determine its trajectory and impact forces. A primary driver is the global acceleration of industrial automation across sectors, particularly the widespread deployment of the Industrial Internet of Things (IIoT) and smart factory initiatives. These trends mandate intuitive, centralized, and data-rich interfaces for effective supervision and control of complex, interconnected machinery. The increasing need for sophisticated data visualization and remote asset management capabilities further pushes manufacturers to adopt advanced touch technologies offering higher resolution, greater responsiveness, and enhanced integration features. Simultaneously, regulatory pressures in industries like pharmaceuticals and food and beverage, requiring detailed data logging and audit trails, solidify the HMI’s role as the primary point of data entry and monitoring.

However, the market faces notable restraints. The high initial cost associated with implementing advanced industrial touch panel PCs and integrating them into legacy systems presents a significant barrier, especially for small and medium-sized enterprises (SMEs) with limited capital expenditure budgets. Furthermore, the perennial challenge of cybersecurity risks associated with networked HMI systems is a major concern. As HMIs transition from isolated systems to networked endpoints connected to the internet or cloud services, they become potential entry points for malicious actors, necessitating continuous investment in robust security protocols and software updates, which can be costly and operationally disruptive. Operator resistance to change, particularly in established manufacturing environments where older, familiar control systems are entrenched, also slows down the adoption of new, complex touch technologies.

Opportunities for market expansion are centered around the development of specialized and highly ruggedized HMIs for extreme environments (e.g., oil rigs, heavy outdoor machinery, mining operations), where durable and reliable interfaces are critical. The proliferation of mobile HMI applications, leveraging tablets and smartphones for operational flexibility and remote diagnostics, represents a high-growth avenue. Impact forces driving the market include technological substitution, where traditional control panels are rapidly being replaced by multi-functional touch interfaces, and the intensifying competitive landscape forcing innovation in user interface (UI) and user experience (UX) design. Overall, while cost and security pose resistance, the unstoppable force of digitalization and the tangible benefits in efficiency and error reduction ensure a strong, sustained positive market impact.

Segmentation Analysis

The Touch Based Human Machine Interface market is intricately segmented based on technology, component, application, and end-user industry, providing a granular view of market dynamics and opportunity mapping. Understanding these segments is crucial for strategic planning, as different sectors exhibit varying demands for interface complexity, ruggedness, and connectivity standards. The core differentiation lies between the foundational technologies, such as capacitive and resistive, which dictate the operating environment suitability and overall responsiveness of the interface. Component segmentation separates the revenue streams generated by the physical hardware (panel PCs, displays) versus the specialized software (SCADA visualization, configuration tools) required for functionality.

Component analysis shows that while the hardware segment currently accounts for the largest share of market revenue due to the inherent necessity of physical displays and processors, the software segment is poised for the fastest growth. This acceleration is driven by the increasing complexity of modern industrial processes, requiring sophisticated visualization, advanced alarming, and greater integration with IIoT platforms and cloud services. The migration towards browser-based HMI solutions also contributes significantly to software market expansion, offering flexible deployment options and reduced dependence on proprietary hardware.

Application segmentation reveals the crucial role HMIs play across discrete and process industries. Industrial automation remains the largest application area, encompassing factory machinery control and process monitoring. The automotive sector, encompassing both in-vehicle infotainment systems and sophisticated manufacturing control panels, is a critical growth area, demanding high-durability and high-performance solutions. The end-user analysis confirms that discrete manufacturing, particularly electronics and automotive, drives the largest volume demand, while the healthcare sector exhibits strong demand for high-reliability, sterile-grade interfaces for medical equipment.

- By Technology: Capacitive, Resistive, Surface Acoustic Wave (SAW), Infrared

- By Component: Hardware (Industrial Panel PC, Operator Interface Terminals, Industrial Monitors, Others), Software (SCADA Software, Visualization Software, HMI Development Tools)

- By Application: Industrial Automation (Factory Automation, Process Control), Automotive (Vehicle Control Systems, Manufacturing), Healthcare (Medical Equipment, Diagnostics), Consumer Electronics, Public Infrastructure (Kiosks, ATMs)

- By End-User Industry: Discrete Manufacturing (Automotive, Electronics), Process Manufacturing (Oil & Gas, Chemicals, Food & Beverage), Infrastructure (Utilities, Transportation), Energy & Power

Value Chain Analysis For Touch Based Human Machine Interface Market

The value chain for the Touch Based HMI market starts with upstream activities involving core component manufacturing and technology development. This stage includes sourcing high-quality semiconductor chips, specialized display panels (LCD/OLED), sensors (for touch recognition), and robust enclosures suitable for industrial environments. Key suppliers in this phase are technology giants specializing in display manufacturing and microprocessors. Efficient sourcing and integration of these proprietary and complex components are vital for maintaining cost competitiveness and product quality. Upstream players invest heavily in R&D to enhance display ruggedness, improve touch sensitivity, and ensure compliance with electromagnetic compatibility (EMC) standards required for industrial deployment.

The midstream phase focuses on the design, assembly, and software integration of the HMI unit. Major HMI manufacturers undertake the development of proprietary operating systems, configuration software, and human-centric graphical user interfaces (GUI). This phase adds significant value through industrial design, ensuring the product meets specific functional safety standards (e.g., IEC 61508) and ergonomic requirements. Downstream activities involve distribution, installation, system integration, and post-sale services. Distribution channels are predominantly indirect, relying on a robust network of authorized distributors, system integrators (SIs), and value-added resellers (VARs) who customize the HMI solutions to fit specific plant floor architectures and customer requirements. Direct sales channels are typically reserved for large-scale contracts with major multinational corporations.

The distribution network is bifurcated into direct and indirect channels. Direct channels offer manufacturers maximum control over pricing and customer relationship management, primarily serving high-volume or highly technical projects. However, the majority of the market utilizes indirect channels, where SIs play a critical role. System integrators are the crucial link, providing the necessary expertise to connect the HMI hardware and software seamlessly with the client's existing PLCs, SCADA systems, and enterprise resource planning (ERP) platforms. Their ability to provide localized support, training, and customized application development determines the success of HMI deployment, making post-sales support and ongoing software updates a critical value-added element in the downstream segment.

Touch Based Human Machine Interface Market Potential Customers

The primary consumers and end-users of Touch Based HMI solutions are organizations engaged in operational technology (OT) across various critical infrastructure and manufacturing sectors. The largest segment of potential customers resides within the discrete manufacturing industry, particularly automotive OEMs, aerospace component manufacturers, and electronics assembly plants. These entities require high-speed, reliable interfaces to manage complex production lines, robotics, and quality control systems. Their purchasing decisions are driven by the need for integration capability, modularity, and the ability to withstand harsh environments characterized by vibrations, temperature fluctuations, and exposure to cleaning agents.

The process manufacturing sector, encompassing chemicals, oil and gas, pharmaceuticals, and food and beverage, represents another significant customer base. In these industries, HMIs are essential for monitoring continuous processes, managing recipes, ensuring adherence to strict safety and regulatory protocols, and providing detailed historical data logs. Customers in this segment prioritize intrinsic safety ratings (e.g., ATEX or IECEx certifications) and seamless integration with distributed control systems (DCS). The healthcare sector, including hospitals and medical device manufacturers, also forms a substantial customer segment, demanding highly sanitary, easy-to-clean interfaces for operating patient monitoring systems, diagnostic equipment, and surgical robots.

Beyond traditional manufacturing, potential customers include infrastructure and utility providers (power generation, water treatment plants, transportation networks). These users rely on HMIs for supervisory control of critical grid infrastructure, traffic management systems, and building automation. The procurement decision for these groups is heavily influenced by long product lifecycle support, high reliability (24/7 operation capability), and advanced connectivity features that allow for remote diagnostics and centralized fleet management. Ultimately, any enterprise seeking to optimize operational efficiency, enhance worker safety, and digitalize their control interface is a potential customer for Touch Based HMI technology.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 5.8 Billion |

| Market Forecast in 2033 | USD 10.9 Billion |

| Growth Rate | CAGR 9.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces | >|

| Segments Covered | >|

| Key Companies Covered | Siemens, Rockwell Automation, Honeywell International, ABB, Mitsubishi Electric, Schneider Electric, Advantech, General Electric, Pro-face by Schneider Electric, Kontron, Beijer Electronics, Omron Corporation, Fuji Electric, Eaton Corporation, Emerson Electric, Bosch Rexroth, Red Lion Controls, AAEON Technology, Parker Hannifin, Phoenix Contact |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Touch Based Human Machine Interface Market Key Technology Landscape

The technological landscape of the Touch Based Human Machine Interface market is defined by the evolution of display and sensor technologies coupled with advancements in computational power and connectivity protocols necessary for Industry 4.0 environments. The fundamental technologies are resistive, capacitive, and more niche solutions like Surface Acoustic Wave (SAW) and infrared. Capacitive touch technology, particularly projective capacitive (PCAP), dominates the industrial and high-end consumer sectors due to its superior multi-touch capability, optical clarity, durability, and resistance to scratches, making it ideal for graphical, intuitive interfaces that mimic modern smartphone functionality. Resistive technology, while older, remains relevant in environments requiring operation while wearing gloves or where resistance to water and dust ingress is paramount, offering a cost-effective, rugged solution for basic control panels.

Beyond the touch input method, the key technological development revolves around the integration of advanced computing platforms (e.g., high-performance CPUs and specialized GPUs) within the HMI unit to facilitate edge computing and complex graphical rendering. Modern HMIs are increasingly becoming full-fledged industrial panel PCs capable of running analytics, virtualization software, and security applications directly on the plant floor, minimizing latency and reducing reliance on centralized servers. Furthermore, the adoption of web-based visualization standards (like HTML5) allows for platform-independent HMI deployment and easier remote access via standard web browsers, drastically simplifying system maintenance and updates across diverse enterprise architectures.

Connectivity is another defining factor, with a strong push towards incorporating robust wireless communication capabilities (Wi-Fi, 5G) and standardized industrial Ethernet protocols (e.g., Profinet, EtherCAT). This enables seamless integration of HMIs within IIoT ecosystems, facilitating real-time data exchange with sensors, actuators, and cloud platforms for big data analysis. Furthermore, enhancements in display technology, such as the use of optically bonded displays to improve readability in direct sunlight and the development of specialized coatings for antimicrobial resistance in healthcare settings, underscore the market’s responsiveness to application-specific environmental challenges, reinforcing the trend toward highly customized, technologically sophisticated HMI solutions.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to be the fastest-growing and largest market due to aggressive government initiatives promoting manufacturing automation (e.g., "Made in China 2025," "Make in India") and the region's concentration of electronics, automotive, and heavy machinery production. Countries like China, South Korea, and Japan are massive consumers of high-end HMIs necessary for advanced smart factories. The rapid modernization of infrastructure and power utilities further contributes to high demand for rugged, networked interfaces.

- North America: This region holds a substantial market share characterized by the early adoption of advanced industrial technologies, strong presence of key HMI manufacturers, and significant investment in aerospace, defense, and oil & gas sectors. The market here is driven by the demand for highly secure, high-performance solutions capable of complex data processing and full compliance with strict cybersecurity and regulatory standards. The push towards predictive maintenance and remote monitoring heavily utilizes mobile HMI applications.

- Europe: Europe is a mature market known for prioritizing functional safety, high-quality engineering, and ergonomic design in HMI development. Germany, as a manufacturing powerhouse, leads in adopting Industry 4.0 standards, demanding highly integrated HMI solutions compatible with complex fieldbus systems. The region’s focus on energy efficiency and sustainable manufacturing also drives the use of HMIs for detailed resource monitoring and optimization in utilities and process industries.

- Latin America (LATAM): The LATAM market is developing, with growth concentrated primarily in countries like Brazil and Mexico, fueled by foreign investment in manufacturing and the expansion of the mining and agriculture sectors. Adoption is often linked to the modernization of legacy infrastructure, creating demand for cost-effective, scalable HMI solutions that offer enhanced connectivity and data visualization capabilities to improve operational oversight in remote locations.

- Middle East and Africa (MEA): Growth in MEA is primarily propelled by extensive investments in the oil and gas sector, alongside ambitious infrastructure and diversification projects (e.g., NEOM in Saudi Arabia). HMIs are crucial for managing complex, remote pipelines, processing facilities, and power generation units, necessitating extremely rugged, explosion-proof (Ex-rated) interfaces compliant with stringent safety regulations under harsh desert climates.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Touch Based Human Machine Interface Market.- Siemens AG

- Rockwell Automation, Inc.

- Honeywell International Inc.

- ABB Ltd.

- Mitsubishi Electric Corporation

- Schneider Electric SE

- Advantech Co., Ltd.

- General Electric Co. (GE)

- Pro-face by Schneider Electric

- Kontron S&T AG

- Beijer Electronics Group AB

- Omron Corporation

- Fuji Electric Co., Ltd.

- Eaton Corporation plc

- Emerson Electric Co.

- Bosch Rexroth AG

- Red Lion Controls, Inc.

- AAEON Technology Inc.

- Parker Hannifin Corporation

- Phoenix Contact GmbH & Co. KG

Frequently Asked Questions

Analyze common user questions about the Touch Based Human Machine Interface market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technology driving growth in the Touch Based HMI Market?

The primary growth driver is Projective Capacitive (PCAP) touch technology. PCAP offers superior multi-touch support, high durability, excellent optical clarity, and sensitivity, making it the preferred standard for modern industrial panel PCs and complex graphical interfaces that are essential for Industry 4.0 integration.

How does IIoT influence the function of modern Touch Based HMIs?

The Industrial Internet of Things (IIoT) transforms HMIs into secure, intelligent edge devices. They now serve as gateways that collect operational data, execute local processing, and communicate seamlessly with cloud analytics platforms and other networked devices, enabling advanced remote diagnostics and system optimization.

Which end-user industry accounts for the largest demand for Touch Based HMI solutions?

The Discrete Manufacturing industry, encompassing automotive production, electronics assembly, and machine building, accounts for the largest volume demand. This sector requires HMIs for high-precision control, robotic management, and detailed quality oversight on rapidly changing production lines.

What are the key differences between industrial panel PCs and traditional operator terminals?

Industrial Panel PCs (PPCs) offer superior processing power, allowing them to run full operating systems (like Windows or Linux), host complex software (SCADA, MES), and perform edge computing. Traditional operator terminals typically run proprietary, purpose-built firmware for basic control functions and have limited integration capabilities beyond standard PLC communication.

What role does AI play in enhancing HMI security and efficiency?

AI significantly enhances HMI efficiency by providing predictive failure alerts and context-aware operational guidance, minimizing human intervention for non-critical tasks. In security, AI monitors access patterns and network traffic via the HMI interface, detecting anomalies and potential cyber threats in real-time, bolstering overall system resilience.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager