Tower Filter Presses Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442881 | Date : Feb, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Tower Filter Presses Market Size

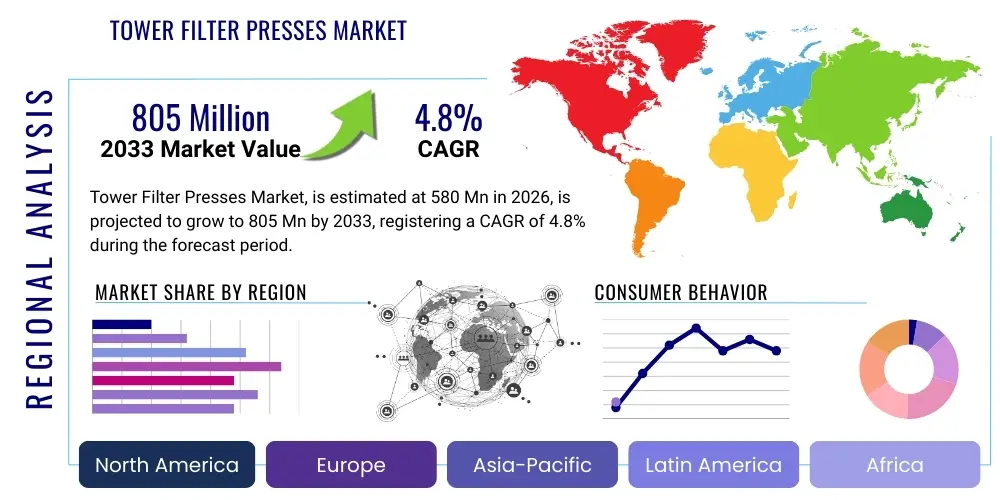

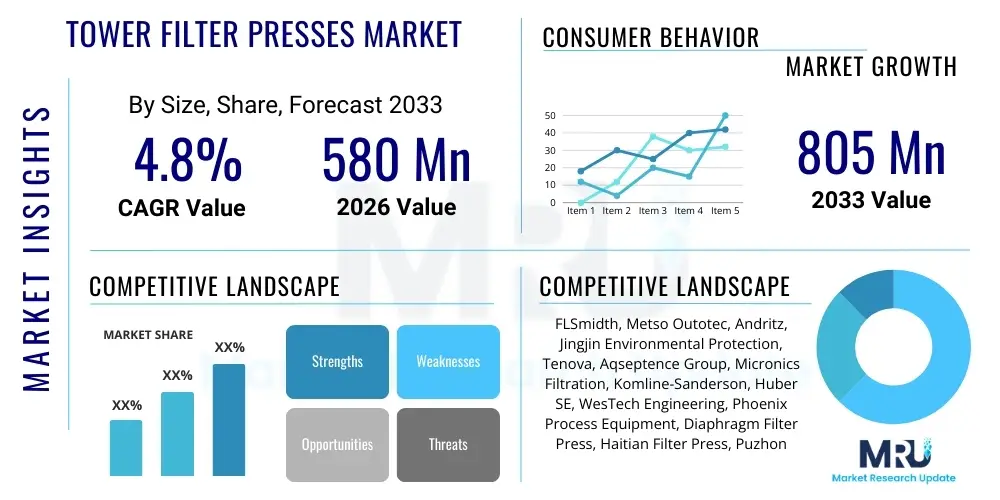

The Tower Filter Presses Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at $580 Million in 2026 and is projected to reach $805 Million by the end of the forecast period in 2033.

Tower Filter Presses Market introduction

The Tower Filter Press market encompasses specialized industrial equipment designed for high-efficiency solid-liquid separation, primarily utilized in large-scale dewatering applications across heavy industries. These presses operate based on pressure filtration principles, employing vertically stacked filter plates and mechanisms to achieve exceptionally low moisture content in the filter cake, which is critical for reducing disposal costs and maximizing resource recovery. Distinct from traditional chamber or plate-and-frame presses, the tower configuration allows for continuous or highly automated batch processing, offering significant advantages in throughput and operational reliability, especially in environments demanding stringent environmental compliance and operational efficiency. The robust design and advanced automation features position the tower filter press as a premium solution for complex slurry dewatering tasks, impacting sectors ranging from mining to environmental management.

Product descriptions of modern tower filter presses emphasize automation, large capacity, and high filtration pressure capabilities, often exceeding 15 bar, enabling superior filtration rates and dryness levels. The core technology involves automated cloth washing, mechanical or hydraulic plate shifting, and advanced control systems that monitor and adjust filtration cycles in real-time. Major applications predominantly include the dewatering of mineral concentrates (such as iron ore, copper, and bauxite tailings), municipal and industrial wastewater sludge, and certain chemical processing intermediates. The ability to handle high volumes of fine particles and corrosive slurries makes them indispensable in environments where operational continuity and cake quality are paramount, driving their adoption over conventional filtration technologies.

Key benefits driving market adoption include enhanced dewatering efficiency, leading to significant reduction in residual moisture content (often below 15%), which lowers transportation and disposal costs for waste materials. Furthermore, the high degree of automation minimizes manual intervention, improves safety, and ensures process repeatability, contributing to lower overall operational expenditure (OPEX). The increasing global focus on sustainability, stricter regulations regarding wastewater discharge, and the imperative for water recycling in industrial processes act as fundamental driving factors. The rising demand for fine mineral concentrates and the necessity to manage massive volumes of tailings efficiently further cement the tower filter press's critical role in the global industrial landscape, especially within Asia Pacific's rapidly expanding mining and infrastructure sectors.

Tower Filter Presses Market Executive Summary

The Tower Filter Presses Market is characterized by robust growth, fueled predominantly by technological advancements in automation and the stringent regulatory environment demanding superior solid-liquid separation efficiency. Business trends indicate a shift towards fully enclosed, highly automated systems that integrate digital twin technology and predictive maintenance capabilities to maximize uptime and optimize filtration cycles. Manufacturers are focusing on developing materials resistant to highly abrasive and corrosive slurries, particularly crucial for the metallurgical and chemical industries. The competitive landscape remains concentrated, dominated by key international players who leverage strong engineering expertise and extensive global service networks. Strategic collaborations and targeted acquisitions aimed at expanding regional manufacturing footprints, particularly in high-growth economies, are defining the current trajectory of market expansion.

Regionally, Asia Pacific (APAC) stands as the undisputed leader and fastest-growing segment, primarily driven by large-scale mining operations in Australia, China, and Southeast Asia, coupled with massive investments in municipal and industrial wastewater treatment infrastructure. North America and Europe, while representing mature markets, exhibit steady demand, largely centered on the replacement of aging equipment with modern, energy-efficient tower presses, and compliance with evolving environmental standards, especially concerning tailings management and Zero Liquid Discharge (ZLD) mandates. Latin America, rich in mineral resources, presents significant opportunities, albeit subject to commodity price volatility, spurring investment in robust dewatering solutions for high-grade ore processing.

Segment trends reveal a strong preference for fully automatic tower filter presses due to their superior efficiency, reduced labor costs, and consistent cake production quality, outweighing the initial capital expense. Application segmentation highlights the dominance of the Mining & Metallurgy sector, where tower presses are essential for dewatering flotation concentrates and fine tailings. However, the Municipal Sludge Dewatering segment is experiencing accelerated growth, driven by urbanization and the critical need to manage increasing volumes of sewage sludge efficiently and sustainably. Material innovation, such such as specialized polypropylene plates and advanced filter cloths tailored for specific chemical resistance, continues to shape segment dynamics, catering to niche industrial requirements demanding specialized separation parameters.

AI Impact Analysis on Tower Filter Presses Market

User inquiries concerning AI integration in tower filter presses often revolve around themes of predictive maintenance, process optimization, and operational autonomy. Key questions frequently address how AI can reduce energy consumption during filtration cycles, improve cake dryness consistency despite varying feed slurry characteristics, and enhance system reliability through early fault detection. Users are keenly interested in understanding the return on investment (ROI) associated with implementing machine learning models for control parameter adjustment and the potential for achieving truly "smart" dewatering plants. The primary expectation is that AI will transform these traditionally mechanical operations into data-driven, highly efficient processes that minimize downtime and optimize chemical dosing, thereby maximizing operational profit margins and environmental performance.

The practical application of AI in this domain centers on analyzing vast datasets collected from sensors monitoring parameters such as pressure curves, flow rates, cake thickness, and motor amperage. Machine learning algorithms process this data to create predictive models that anticipate component failure (e.g., pump wear, cloth blinding) long before it occurs, shifting maintenance strategies from reactive to predictive. Furthermore, AI systems can dynamically adjust the cycle time, squeeze pressure, and wash protocols based on real-time analysis of feed slurry characteristics (solids concentration, particle size distribution), ensuring optimal performance regardless of upstream process variability. This level of granular control is unattainable with conventional PLC-based systems, significantly boosting overall filtration plant productivity and output consistency.

Integrating Artificial Intelligence and Industrial Internet of Things (IIoT) sensors enables remote diagnostics and benchmark comparison across a fleet of presses globally. This capability is paramount for large engineering, procurement, and construction (EPC) firms and major mining operators seeking centralized operational visibility and best-practice sharing. Although the initial integration costs are substantial, the long-term benefits derived from reduced chemical consumption, optimized energy use during plate movement and pumping, and the ability to maintain higher cake solids content consistently translate into compelling economic justification, solidifying AI's role not just as an enhancement, but as a future necessity for competitive edge in high-stakes dewatering operations.

- AI-driven Predictive Maintenance: Reduces unplanned downtime by forecasting component failure, optimizing service intervals.

- Dynamic Process Optimization: Machine learning algorithms adjust filtration pressures and cycle times based on real-time slurry analysis, maximizing cake dryness.

- Energy Consumption Reduction: AI models optimize pump operation and hydraulic system usage, minimizing energy intensity per ton of solids processed.

- Autonomous Operation: Enables fully automated systems capable of self-diagnosing and correcting minor operational deviations without human intervention.

- Slurry Variability Compensation: Maintains consistent filter cake quality despite fluctuations in feed concentration and composition.

- Digital Twin Integration: Creates virtual representations for simulation and testing of new operational strategies before physical deployment.

- Enhanced Water Recovery: Optimizes filtration kinetics to maximize filtrate quality and volume for reuse in circular systems.

DRO & Impact Forces Of Tower Filter Presses Market

The dynamics of the Tower Filter Presses Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively constitute the primary impact forces. A dominant driver is the escalating global scarcity of fresh water, compelling industries, particularly mining and manufacturing, to adopt highly efficient dewatering technologies like tower presses to facilitate process water recycling and comply with strict discharge regulations. Coupled with this is the increasing need for high-grade mineral concentrates, which necessitates effective tailings management to reduce environmental footprint and improve resource utilization. Simultaneously, the market faces restraints primarily stemming from the substantial initial capital investment required for these sophisticated, high-pressure systems, often limiting adoption by smaller enterprises. Furthermore, the operational complexity and the reliance on highly skilled technical personnel for maintenance and optimization pose ongoing challenges, especially in remote operational settings.

Opportunities for market growth are vast, particularly through geographical expansion into emerging industrial hubs in Southeast Asia and Africa, where infrastructure development and resource extraction activities are accelerating. Technological advancements present a critical opportunity, specifically the integration of advanced materials science to create filter plates and cloths that extend service life in harsh chemical environments, and the implementation of advanced process controls. The global shift towards sustainable resource management provides a strong tailwind; as regulatory bodies globally enforce stricter limits on landfill use and effluent toxicity, the demand for highly compacted, dry filter cake—a specialty of tower presses—will surge. This confluence of technological push and regulatory pull creates a compelling growth trajectory for the market, focusing on long-term sustainability solutions rather than short-term cost reduction.

Impact forces are predominantly driven by macro-economic factors such as fluctuating commodity prices, which directly influence investment decisions in the mining sector, the primary end-user. Environmental policy is an irreversible positive force; stringent regulations regarding tailings dam safety (e.g., post-Brumadinho mandates) necessitate dry stacking solutions, directly favoring tower filter presses over conventional thickeners. Competition from alternative dewatering technologies, such as advanced belt presses or centrifugal separation, acts as a moderating restraint, compelling tower press manufacturers to continually innovate in terms of efficiency and automation to maintain their competitive advantage in achieving superior cake dryness. Overall, the market remains highly resilient, driven by the non-negotiable need for superior solid-liquid separation in key global industries.

Segmentation Analysis

The Tower Filter Presses Market is meticulously segmented based on type, operation mode, and end-user application to accurately reflect the varied industrial demands and technical specifications required by diverse sectors. Understanding these segments is crucial for strategic market planning and product development, as requirements for cake dryness, throughput volume, and resistance to chemical corrosion vary significantly between, for example, a high-volume iron ore dewatering facility and a smaller, specialized pharmaceutical sludge treatment plant. The segmentation highlights the predominance of fully automated, high-pressure vertical tower designs which optimize footprint efficiency and labor costs, catering to large-scale, continuous process industries where reliability and high capacity are non-negotiable operational requirements.

The segmentation by operation mode differentiates between fully automatic and semi-automatic systems. Fully automatic tower presses dominate the market share, driven by labor cost reduction and process consistency, incorporating features such as automated plate shifting, cloth washing, and cake discharge sequences controlled by sophisticated HMI interfaces. Conversely, semi-automatic presses maintain a niche presence, often suitable for smaller capacity requirements or older facilities undergoing incremental modernization. Analyzing the application segments provides deeper insights, confirming that the Mining and Metallurgy industry represents the largest segment due to the vast volumes of concentrates and tailings requiring efficient dewatering globally, followed by the growing imperative for municipal water authorities to handle sewage sludge more effectively.

Future growth analysis within segmentation points towards rapid expansion in specialized applications, particularly within the battery minerals processing sector (e.g., lithium, cobalt), where precise solid-liquid separation is critical for product purity and resource recovery. Furthermore, geographical segmentation underscores the pivotal role of APAC, fueled by heavy industrialization and resource exploration, contrasting with the demand profiles of North America and Europe, which focus more on advanced sludge stabilization and environmental remediation projects utilizing cutting-edge tower press technology tailored for complex, non-mineral slurries. Strategic product diversification across these segments, particularly in specialized corrosion-resistant models, will be key to unlocking untapped market potential.

- By Type:

- Vertical Plate Tower Filter Press

- Horizontal Plate Tower Filter Press

- Automated Membrane Tower Filter Press

- High-Pressure Tower Filter Press (15 Bar and above)

- By Operation Mode:

- Fully Automatic

- Semi-Automatic

- By Application:

- Mining & Metallurgy (Tailings, Concentrates, Dewatering)

- Chemical Processing (Pigments, Fertilizers, Specialty Chemicals)

- Municipal Sludge Dewatering and Wastewater Treatment

- Food & Beverage Industry

- Pharmaceuticals and Biotechnology

- Dredging and Infrastructure Projects

Value Chain Analysis For Tower Filter Presses Market

The value chain for the Tower Filter Presses Market begins with upstream activities involving the sourcing of high-quality raw materials, including specialized steels (for the frame and hydraulic cylinders), high-performance plastics (for filter plates, often polypropylene or PVDF), and technical textiles (filter cloths). The stability and pricing of these commodities, especially steel and engineering polymers, significantly influence the final manufacturing cost and delivery timelines. Key upstream suppliers are specialized foundries, polymer extrusion companies, and technical fabric manufacturers, who must adhere to stringent quality standards to ensure the longevity and pressure resistance of the final equipment. Manufacturing excellence, including precision machining and assembly of the massive structural components and complex hydraulic systems, forms the core of the value creation process.

Midstream activities primarily focus on Research & Development (R&D), manufacturing, and customization. R&D is crucial for developing patented features such as optimized plate design for faster cycle times, innovative cloth washing mechanisms, and integrating IIoT sensors for enhanced monitoring. The high degree of customization required—as each press is often engineered to handle specific slurry characteristics—necessitates close collaboration between the manufacturer's engineering team and the end-user. Distribution channels for tower filter presses are typically direct, given the high capital value and technical complexity of the equipment. Major manufacturers employ dedicated sales teams and technical application engineers who work directly with EPC contractors or end-user operational management throughout the procurement, installation, and commissioning phases. Indirect channels, such as authorized local distributors or system integrators, are sometimes utilized for smaller regional projects or auxiliary component sales.

Downstream activities center around installation, commissioning, maintenance, and aftermarket services, which constitute a significant portion of the total value proposition. Due to the critical nature of dewatering operations, reliable and prompt after-sales support, including the supply of spare parts (e.g., filter cloths, hydraulic seals, plates) and comprehensive maintenance contracts, is essential. This recurring revenue stream often provides stability for manufacturers. The ultimate value delivery is the efficient handling of waste or recovery of valuable product at the client site, resulting in optimized logistics (due to dry cake) and environmental compliance (due to clean filtrate). Operational feedback from downstream activities heavily informs upstream R&D, creating a continuous improvement loop focused on enhancing the press's dewatering efficiency and reducing its lifetime cost of ownership.

Tower Filter Presses Market Potential Customers

Potential customers for Tower Filter Presses are predominantly large industrial entities and public sector authorities engaged in high-volume solid-liquid separation processes where achieving minimum moisture content in the solids is a primary operational objective. The core end-users include major global mining corporations involved in ferrous and non-ferrous metal processing (iron ore, copper, gold, nickel), requiring continuous dewatering of concentrates and tailings for dry stacking. These large enterprises prioritize reliability, high throughput, and robust construction capable of 24/7 operation in abrasive environments. Their purchasing decisions are heavily influenced by the equipment's proven Mean Time Between Failure (MTBF) and overall energy efficiency, linking the purchase directly to large capital expenditure budgets for new mine development or expansion projects.

A rapidly expanding customer base is found within municipal and specialized industrial wastewater treatment plants. These buyers, often governmental bodies or large utility operators, face intense regulatory pressure to minimize sludge volume and produce stabilized cake suitable for beneficial reuse or low-cost disposal. While their throughput requirements may be lower than those of the mining sector, they demand high levels of automation, odor control features, and reliability to maintain essential public services. Furthermore, large chemical manufacturing companies processing materials such as fertilizers, pigments, or specialty chemicals require tower presses to separate final product suspensions or manage hazardous waste streams, focusing particularly on material compatibility (e.g., Hastelloy frames or specific polymer plates) to handle corrosive reagents.

Emerging potential customers include companies operating in the nascent battery minerals sector, such as lithium and cobalt processors, where precise filtration is essential for product purity, and firms involved in infrastructure and dredging projects that generate large volumes of slurry requiring rapid dewatering prior to transport or placement. These customers look for flexible, mobile, or modular tower press solutions capable of handling intermittent high-volume bursts. Ultimately, the buying decision across all segments is a complex, multi-stakeholder process involving process engineers, environmental compliance officers, and financial executives, emphasizing not just the capital cost but the total cost of ownership (TCO) and compliance assurance provided by the filtering solution.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $580 Million |

| Market Forecast in 2033 | $805 Million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | FLSmidth, Metso Outotec, Andritz, Jingjin Environmental Protection, Tenova, Aqseptence Group, Micronics Filtration, Komline-Sanderson, Huber SE, WesTech Engineering, Phoenix Process Equipment, Diaphragm Filter Press, Haitian Filter Press, Puzhong Filter Press, Evoqua Water Technologies, Diemme Filtration, Sepro Mineral Systems, McLanahan Corporation, Baker Process, BHS-Sonthofen |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Tower Filter Presses Market Key Technology Landscape

The technology landscape of the Tower Filter Presses Market is defined by continuous innovation focused on enhancing dewatering efficiency, increasing automation, and improving resistance to aggressive process environments. A primary technological focus is the evolution of the filter plates themselves, moving beyond standard plate designs to advanced membrane filter plates. These utilize compressed air or water (hydraulic squeeze) after the conventional filtration phase to physically compress the filter cake, substantially reducing residual moisture content (often by 5–10 percentage points). This membrane squeeze technology is paramount for meeting strict dry stacking mandates in mining and achieving energy savings in subsequent thermal drying processes, representing a critical competitive differentiator among leading manufacturers. Integration of high-pressure hydraulics, capable of delivering squeezing pressures exceeding 20 bar, is becoming standard in top-tier heavy-duty models.

Automation and control systems are central to the modern tower press, utilizing high-precision sensors, PLC systems, and increasingly, integrated HMI interfaces that allow for complete remote monitoring and control. Advanced process control (APC) includes sophisticated turbidity monitoring of the filtrate to detect filter cloth wear or blinding, and real-time slurry density measurements to adjust pumping speed and cycle time dynamically. The mechanical components, particularly the plate shifting mechanism and the filter cloth washing system, are engineered for robustness and speed. High-speed, simultaneous plate shifting mechanisms have significantly reduced the dead time between cycles, boosting overall throughput. Furthermore, the development of specialized filter cloths using advanced polymer fibers ensures chemical resistance and reduces cake adhesion, thereby prolonging the life of the cloth and minimizing downtime for maintenance.

The latest technological advancements are deeply rooted in IIoT and digitalization. Modern tower presses are essentially smart machines, equipped with hundreds of data points streamed to cloud platforms for real-time diagnostics and performance benchmarking against global standards. This infrastructure supports the implementation of predictive maintenance, utilizing vibration analysis and thermal monitoring of key components (like pumps and hydraulics) to forecast potential failures and schedule preemptive repairs. Material science innovation is also critical, with manufacturers investing heavily in composite materials and specialized linings for the press frame and slurry inlets to resist abrasion and chemical attack, expanding the application scope of tower presses into highly challenging industrial environments previously deemed too harsh for standard equipment. This commitment to TCO reduction through technological resilience is defining the competitive battlefield.

Regional Highlights

- Asia Pacific (APAC): Dominates the global market, accounting for the largest share driven by massive investments in infrastructure development, mineral resource extraction (iron ore, coal, copper), and rapid urbanization leading to increased municipal sludge generation. Countries like China, India, and Australia are key drivers. Demand focuses on high-capacity, high-throughput automatic presses essential for large-scale mining tailings management and meeting evolving environmental discharge limits. The region's lower manufacturing costs also contribute to its prominence as a key production hub for tower filter press components and systems.

- North America: Characterized by a mature market emphasizing modernization and environmental compliance. Growth is sustained by the replacement cycle of older equipment with advanced, automated tower presses featuring superior dewatering efficiency and reduced energy consumption. Stringent regulations on water quality and waste disposal, particularly in the US and Canada, drive demand for specialized presses capable of dewatering complex industrial and oil sands waste streams. Technological adoption, especially IIoT integration and AI-based predictive maintenance, is highest in this region, focused on maximizing operational lifespan and minimizing labor costs.

- Europe: The market is defined by strict EU environmental policies, particularly the focus on Zero Liquid Discharge (ZLD) and the circular economy. Demand is concentrated in highly specialized chemical, pharmaceutical, and water utility sectors, prioritizing presses that ensure exceptionally high-purity filtrate for reuse and minimize waste volume. Innovation focuses heavily on energy efficiency, robust corrosion protection, and compact design to fit within existing plant footprints. Germany and Nordic countries lead in the application of advanced sludge stabilization and dewatering techniques using tower press technology.

- Latin America (LATAM): Exhibits strong growth potential, primarily tied to the region's vast mining sector (Chile, Peru, Brazil, Mexico). Market fluctuations are sensitive to global commodity prices, but the necessity for modern tailings management systems, driven by increasing regulatory scrutiny following catastrophic failures, ensures steady demand for robust tower presses suitable for high-altitude, high-volume operations. Investment is focused on improving operational safety and reducing dependency on traditional tailings ponds.

- Middle East and Africa (MEA): Represents an emerging market with significant long-term potential, driven by heavy industrialization (petrochemicals, phosphates, and non-metallic mining) and large-scale municipal water scarcity challenges. Demand is currently sporadic but centered on large governmental infrastructure projects seeking reliable, drought-resistant dewatering solutions. Capital investment is often contingent upon international aid or large state-backed development funds, prioritizing durability in harsh climate conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Tower Filter Presses Market.- FLSmidth

- Metso Outotec (formerly Outotec and Metso Minerals)

- Andritz AG

- Jingjin Environmental Protection Equipment Co., Ltd.

- Tenova S.p.A.

- Aqseptence Group (via Diemme Filtration)

- Micronics Filtration Holdings, Inc.

- Komline-Sanderson Corporation

- Huber SE

- WesTech Engineering, Inc.

- Phoenix Process Equipment Co.

- Diaphragm Filter Press

- Haitian Filter Press Group Co., Ltd.

- Puzhong Filter Press

- Evoqua Water Technologies Corp.

- Sepro Mineral Systems Corp.

- McLanahan Corporation

- Baker Process

- BHS-Sonthofen GmbH

- IHI Corporation

Frequently Asked Questions

Analyze common user questions about the Tower Filter Presses market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary operational advantage of a tower filter press over traditional plate-and-frame presses?

The primary advantage lies in the high degree of automation, vertical configuration (optimizing footprint), and the application of membrane squeeze technology. This combination allows tower presses to achieve significantly higher throughput rates and produce filter cakes with lower residual moisture content (superior dryness), which is crucial for reducing disposal costs and enabling dry stacking of tailings in mining applications.

How are environmental regulations influencing the growth trajectory of the tower filter presses market?

Environmental regulations are a fundamental driver. Stricter global mandates concerning water discharge quality, minimization of waste volume, and increased requirements for safer tailings management (like dry stacking) compel industrial users to invest in highly efficient dewatering systems. Tower presses provide the necessary technology to meet these stringent regulatory thresholds, particularly regarding water reuse and minimizing landfill dependence.

Which application segment accounts for the highest demand for tower filter presses globally?

The Mining and Metallurgy segment represents the highest demand. This sector utilizes tower presses extensively for dewatering fine mineral concentrates (e.g., copper, iron ore) and massive volumes of mine tailings, where achieving high solids content is critical for efficient resource recovery and compliance with modern, non-impoundment-based waste disposal methods.

What is the role of Artificial Intelligence (AI) and IIoT in modern tower filter press operations?

AI and IIoT enable dynamic process optimization and predictive maintenance. AI algorithms analyze operational data (pressure, flow, vibration) in real-time to adjust filtration cycles for maximum cake dryness consistency and efficiency, while IIoT sensors facilitate remote diagnostics, early fault detection, and reduce unplanned downtime, significantly lowering the total cost of ownership (TCO).

What are the key technological advancements expected to shape the future of tower filter presses?

Future developments will focus on advanced material science (corrosion-resistant plates and filter cloths), increased automation through robotics for maintenance tasks, and further integration of high-pressure membrane squeeze technology to achieve ultra-low moisture content. Additionally, modular and mobile tower press designs are emerging to serve temporary or smaller-scale infrastructure and dredging projects more effectively.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager