Trestle Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442946 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Trestle Market Size

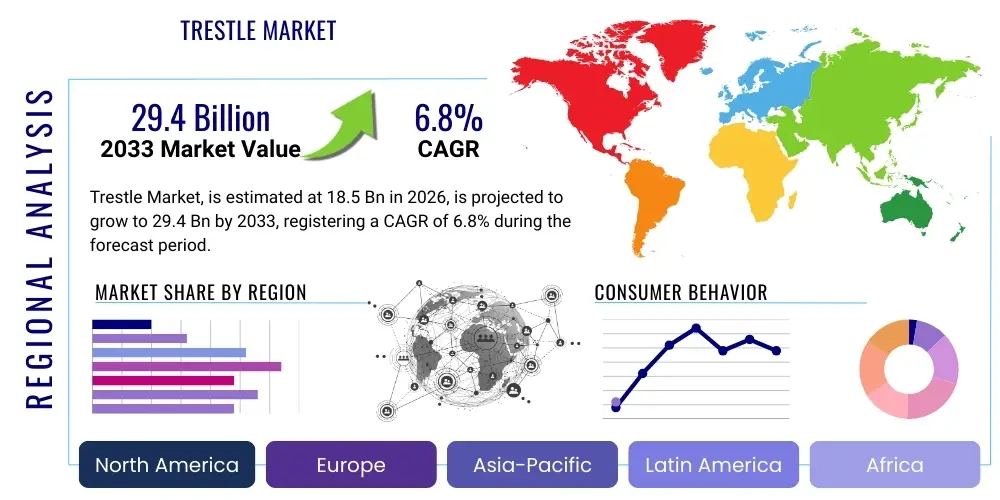

The Trestle Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $18.5 Billion in 2026 and is projected to reach $29.4 Billion by the end of the forecast period in 2033.

Trestle Market introduction

The Trestle Market encompasses the production, distribution, and utilization of structural support frames, widely known as trestles, used across diverse sectors including construction, infrastructure development, industrial maintenance, and furniture manufacturing. Trestles, characterized by their robust support structure—often triangular or A-shaped—provide stability for elevated surfaces, temporary platforms, bridges, and heavy machinery setups. The core product range includes high-load-bearing steel trestles for civil engineering projects, adjustable aluminum trestles for scaffolding and renovation, specialized wooden trestles for traditional crafts and light-duty applications, and engineered plastic or composite trestles for corrosive environments or specific furniture designs. Demand is fundamentally linked to global capital expenditures in infrastructure and the cyclical nature of the residential and commercial construction sectors.

Major applications of trestles span from providing temporary support during the construction of viaducts and bridges—where their load-bearing capacity and modularity are indispensable—to serving as stable bases for heavy-duty workbenches in industrial workshops. In the rapidly evolving office furniture sector, aesthetically designed trestle legs are popular for minimalist and flexible desking solutions, reflecting trends towards open-plan and adaptable workspaces. The primary benefit derived from the adoption of high-quality trestles is enhanced operational safety due to superior stability, coupled with efficiency gains achieved through quick assembly and disassembly, reducing downtime on project sites. Furthermore, modern trestles often feature adjustable height mechanisms, significantly improving ergonomic conditions for end-users across various applications.

Key factors driving the expansion of the Trestle Market include intensive global infrastructure spending, particularly in emerging economies focused on developing extensive rail and road networks. The rising adoption of modular construction techniques, which require precise and reusable temporary support systems, further accelerates market growth. Additionally, stringent safety regulations governing elevated work platforms compel contractors to utilize certified, high-standard trestle systems, boosting the segment for steel and aluminum products. Technological advancements in material science, such as the introduction of lightweight and high-strength alloys and composite materials, are broadening the application scope and improving the longevity and portability of trestle systems, appealing to a wider range of end-users.

Trestle Market Executive Summary

The Trestle Market is currently experiencing robust growth, primarily driven by substantial rebound in global construction activity and accelerated government investment in infrastructure renewal programs, particularly across Asia Pacific and specific regions of North America and Europe. Business trends indicate a noticeable shift toward sustainable and modular trestle designs, with manufacturers focusing on recyclable materials like aluminum and engineered wood, addressing increasing regulatory pressures and corporate sustainability mandates. The integration of advanced manufacturing techniques, such as automated welding and precision CNC fabrication, is improving product quality and reducing lead times, offering a competitive edge to larger market players who can leverage economies of scale in high-volume production.

Regionally, the Asia Pacific (APAC) stands out as the dominant growth engine, fueled by rapid urbanization and massive national infrastructure projects in countries like China, India, and Southeast Asian nations, where the demand for construction-grade scaffolding and bridging supports is paramount. North America and Europe, while mature markets, demonstrate strong demand for specialized, high-specification trestles, driven by strict occupational safety standards and a continuous trend toward renovation and commercial facility upgrades rather than entirely new builds. Latin America and the Middle East & Africa (MEA) are emerging as significant markets, characterized by large-scale energy projects and rapidly developing urban centers, although market stability can be influenced by fluctuations in commodity prices and political stability.

Segment trends reveal that the Material segment sees steel maintaining its dominance due to superior load-bearing capacity, while the Aluminum segment is growing rapidly, favored for its light weight, corrosion resistance, and ease of deployment in smaller and mid-sized construction projects. The Application segment highlights the robust growth of the Infrastructure segment (bridges, tunnels, rail), surpassing traditional residential construction usage. Furthermore, the specialized Industrial Maintenance segment is expanding due to the need for safe, temporary access supports during plant shutdowns and upgrades. The Furniture/Office trestle segment is driven by aesthetic preference and the demand for flexible, customizable workspace solutions, increasingly incorporating embedded features such as cable management systems.

AI Impact Analysis on Trestle Market

Common user questions regarding AI’s influence on the Trestle Market frequently revolve around optimizing complex supply chains for raw materials (steel, wood), predicting maintenance schedules for leased structural trestle assets, and automating the design verification process for custom-engineered supports. Users are keen to understand how AI can improve manufacturing efficiency, specifically asking if AI-driven robotic welding or material sorting systems can reduce production costs and defects. Furthermore, there is significant inquiry into how machine learning models can be utilized for real-time stress analysis and performance monitoring of large-scale trestle systems used in critical infrastructure, addressing concerns about safety and longevity under variable load conditions. These discussions synthesize into an expectation that AI will primarily enhance operational intelligence, ensure regulatory compliance through predictive modeling, and enable highly efficient modular design for specialized construction projects.

- Enhanced Supply Chain Predictability: AI algorithms forecast demand volatility for raw materials (e.g., steel, aluminum) and optimize inventory levels, minimizing price risk exposure for manufacturers.

- Automated Structural Design: Generative AI assists engineers in rapidly iterating optimized trestle geometries for specific load requirements, potentially reducing material usage while maintaining or increasing structural integrity.

- Predictive Maintenance for Rental Fleets: Machine learning models analyze usage data, environmental factors, and inspection reports to predict component failure in heavy-duty rental trestles, ensuring timely refurbishment and maximizing asset utilization.

- Quality Control and Defect Reduction: AI-powered vision systems monitor manufacturing lines, identifying welding imperfections or material flaws in real-time, thereby increasing the overall reliability and safety of the final product.

- Optimized Logistics and Deployment: AI routes and scheduling software improve the delivery and setup processes for large construction sites, calculating optimal loading configurations and minimizing transportation costs.

DRO & Impact Forces Of Trestle Market

The Trestle Market dynamics are shaped by a complex interplay of growth accelerators and constraining factors, balanced by emerging possibilities that fundamentally influence strategic positioning. The primary drivers are the worldwide investment push in infrastructure, especially in developing economies addressing significant deficits in transportation and energy facilities, and the rapid pace of global urbanization which necessitates high-density commercial and residential construction. Restraints largely center on the intense volatility of raw material prices, particularly steel and aluminum, which directly impact manufacturing margins and product pricing. Furthermore, the market faces constraints from increasingly stringent international and local occupational safety regulations that require specialized certification and often increase complexity in design and testing, demanding higher capital expenditure from producers. The opportunities lie primarily in the modular construction movement, which favors standardized, reusable support systems, and the application of advanced materials like carbon fiber composites to achieve superior strength-to-weight ratios.

The impact forces driving market evolution are strong and multifaceted. Economically, the rebound in construction permits post-pandemic coupled with government stimulus packages focused on public works provides a substantial market uplift. Technologically, the adoption of digital tools such as Building Information Modeling (BIM) mandates detailed specifications for temporary support structures, boosting demand for digitally integrated trestle components and smart monitoring systems. Socio-demographically, the persistent need for safer working environments worldwide compels a continuous upgrade cycle away from older, uncertified equipment toward modern, robust trestle solutions. Environmentally, the push for sustainable construction practices is increasing the market share for trestles made from recycled or rapidly renewable resources, influencing procurement decisions among major contractors.

The combination of these forces suggests a market trajectory favoring innovation, quality, and regulatory compliance. Companies able to integrate smart technologies, offer durable and reusable systems, and navigate the volatile raw material landscape through strategic sourcing or substitution will secure market leadership. The shift toward higher-value, specialized trestles for unique applications, such as heavy lifting operations or cleanroom environments, provides significant margin expansion opportunities, moving beyond the commoditized low-end segments that remain sensitive to price competition and raw material costs. Effective management of these DRO factors is essential for sustained growth in this foundational construction and industrial supply sector.

Segmentation Analysis

The Trestle Market is segmented primarily across four critical axes: Material Type, Application, End-User, and Load-Bearing Capacity, reflecting the diverse requirements of end-users ranging from small-scale DIY enthusiasts to major infrastructure developers. Understanding these segmentation nuances is key to strategic positioning, as material choice dictates durability and cost, while application defines necessary specifications like adjustability and portability. The segmentation reveals a bifurcation between the high-volume, cost-sensitive generic trestle market (often steel and wood) and the high-value, specification-driven engineered trestle market (aluminum and composites) tailored for specific industrial or infrastructural uses. The rapid growth of modular construction continues to blur the lines between temporary and permanent support structures, increasing the demand for highly durable, reusable systems that fit standardized dimensions.

- Material Type:

- Steel Trestles

- Aluminum Trestles

- Wooden Trestles

- Composite/Fiberglass Trestles

- Application:

- Construction (Scaffolding Support, Formwork)

- Infrastructure (Bridge/Viaduct Maintenance, Temporary Shoring)

- Industrial (Heavy Equipment Support, Maintenance Access)

- Office & Furniture (Desking Systems, Workstations)

- Residential & DIY

- End-User:

- Contractors & Construction Companies

- Rental Equipment Providers

- Infrastructure Developers

- Manufacturing Facilities

- Furniture OEMs

- Load-Bearing Capacity:

- Light-Duty (Up to 500 kg)

- Medium-Duty (500 kg to 2000 kg)

- Heavy-Duty (Above 2000 kg)

Value Chain Analysis For Trestle Market

The value chain for the Trestle Market begins with upstream activities focused on sourcing and processing essential raw materials, primarily steel billets, aluminum extrusions, and various grades of lumber or engineered wood. This stage is highly susceptible to global commodity price fluctuations, necessitating robust supply chain management and strategic hedging by major manufacturers. Key upstream suppliers include global steel mills, aluminum smelters, and large timber companies. Midstream, the value chain involves the core manufacturing process: cutting, shaping, welding, powder coating, and assembly of the trestle components. Advanced manufacturers utilize highly automated fabrication lines to ensure precision, structural integrity, and adherence to strict safety certifications (e.g., OSHA, EN standards). Quality assurance and testing are critical midstream functions, adding significant value and distinguishing premium products from lower-cost alternatives.

Downstream activities center around the distribution channels and direct engagement with end-users. Trestles are distributed through a complex network comprising large construction equipment rental companies, specialized industrial distributors, hardware wholesalers, and direct sales channels targeting major infrastructure projects or large furniture OEMs. The rental market plays a pivotal role, particularly for heavy-duty steel trestles used in multi-year projects, offering capital expenditure savings to contractors. Direct channels are often preferred for highly customized or specialized trestle systems where technical consultation, specific installation training, and after-sales support are required, such as in specialized bridge shoring or industrial plant maintenance. Conversely, light-duty and furniture trestles are widely sold through indirect channels like e-commerce platforms and big-box retailers, emphasizing accessibility and competitive pricing.

Effective value capture within the Trestle Market requires manufacturers to optimize the flow between fabrication and distribution. Direct channels provide better control over pricing and customer relationships, enabling higher margins on customized, heavy-duty products. Indirect distribution channels, particularly through established rental fleets, offer superior market penetration and volume stability, especially for standardized products. Strategic management of logistics, including minimizing bulk shipping costs for large, heavy steel units, is paramount to maintaining profitability. Furthermore, integrating digital tools for tracking rental assets and managing product lifecycles enhances the value proposition for large-scale rental providers, solidifying their position as critical downstream partners in the market ecosystem.

Trestle Market Potential Customers

The Trestle Market serves a broad spectrum of end-users whose needs range significantly based on load requirements, frequency of use, and regulatory environment. The largest segment of potential customers includes Civil Engineering and Construction firms that require robust, high-capacity trestles for supporting heavy concrete forms, temporary bridging, or shoring during excavation and structural modification. These users prioritize load certification, ease of adjustment, and durability under harsh site conditions. Infrastructure Developers, specifically those engaged in building or repairing highways, railways, and utilities, represent high-value clientele demanding specialized, often custom-engineered trestle solutions capable of handling extreme loads and large spans. Their purchasing decisions are heavily influenced by project specifications and adherence to rigorous government standards and timelines.

Another significant customer segment is Equipment Rental Companies. These firms purchase trestles in bulk to maintain extensive fleets, which are subsequently leased to smaller contractors, industrial clients, and DIY users. Rental companies demand high durability, modularity for easy transport and storage, and products with low maintenance requirements to maximize return on assets (ROA). Furthermore, Industrial Maintenance and Manufacturing facilities are crucial buyers, requiring medium to heavy-duty trestles for supporting machinery, creating temporary access platforms during maintenance shutdowns (turnarounds), or providing stable bases for fabrication work. These environments often necessitate specialized materials, such as fiberglass or composite trestles, due to requirements for non-conductivity or chemical resistance.

Finally, the consumer-facing segment includes Office Furniture Manufacturers (OEMs) and Residential End-Users. Furniture OEMs utilize aesthetic, usually lighter-duty aluminum or wooden trestles as components for modern desks and tables, valuing design, finish, and integration capabilities (e.g., cable management). Residential and DIY customers purchase light-duty trestles from retail channels for home renovation projects, prioritizing portability, affordability, and basic functionality. Targeting each of these distinct buyer groups requires tailored product specifications, pricing strategies, and distribution channels, reflecting the multifaceted nature of the Trestle Market demand.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $18.5 Billion |

| Market Forecast in 2033 | $29.4 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Layher, Waco Kwikform, Safway Group, HAKI, PERI GmbH, RMD Kwikform, BrandSafway, ULMA Construction, Altrad Group, Doka GmbH, Metaltech-Omega, Adjustable Trestles Co., Spanlift, WernerCo., Gorilla Ladders, Zhejiang Zhongjian Steel, Guangxi Futeng Engineering, KLT Group, Strongwell Corporation, Trestle Desk Co. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Trestle Market Key Technology Landscape

The technological landscape of the Trestle Market is increasingly characterized by advancements in material engineering and sophisticated manufacturing processes designed to enhance product performance, portability, and safety compliance. Modern fabrication techniques heavily rely on robotic welding and Computer Numerical Control (CNC) machining to achieve extremely tight tolerances, critical for ensuring the structural integrity of complex, high-load-bearing assemblies, especially those used in shoring and bridge construction. Furthermore, the development of high-strength, low-alloy (HSLA) steels and specialized aluminum alloys allows manufacturers to reduce the overall weight of heavy-duty trestles without compromising required load capacity, addressing the persistent logistical challenge of transporting and manually assembling bulky equipment on-site. This technological pivot focuses on optimizing the strength-to-weight ratio to improve efficiency and reduce worker fatigue, thereby enhancing overall operational safety.

A significant trend involves the integration of digital technology, pushing the market towards "smart trestles." This includes the incorporation of sensor technology and IoT devices, particularly in large-scale infrastructure projects, to monitor real-time load distribution, vibration, and structural deflection. This data is critical for predictive maintenance and ensuring compliance throughout the project lifecycle. Digital twins, which are virtual replicas of the physical trestle setup, are also being utilized to model various stress scenarios before deployment, allowing engineers to refine shoring plans and minimize risks. These digital tools not only improve safety but also create opportunities for rental companies to offer value-added monitoring services, transitioning from simple hardware suppliers to comprehensive project support partners.

Material innovation extends to the growing use of composite materials, such as pultruded fiberglass or advanced carbon fiber reinforced polymers (CFRPs), especially in applications where corrosion resistance, electrical non-conductivity, or exceptional longevity is required, such as in chemical processing plants or near saltwater infrastructure. While composites currently represent a smaller, high-cost segment, their adoption is accelerating due to their superior performance profile in niche markets. Finally, additive manufacturing (3D printing) is beginning to impact the market by enabling rapid prototyping of complex connectors and custom joint components, allowing for faster development cycles and highly tailored solutions for unique architectural or engineering challenges that standard modular systems cannot easily accommodate, thus driving specialization within the supply chain.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing regional market, primarily driven by massive government investments in infrastructure, encompassing high-speed rail, metro networks, and extensive urban development projects, particularly in China, India, and Southeast Asia. The region benefits from a large, competitive manufacturing base, though quality control and safety standards enforcement vary widely, leading to a strong dual market for low-cost, high-volume products and specialized, high-standard European imports for critical projects.

- North America: The North American market is characterized by high safety standards (OSHA compliance) and a strong emphasis on aluminum and specialized steel trestles for commercial construction, renovation, and industrial maintenance. Growth is sustained by the revitalization of existing infrastructure and large commercial investments, with a high proportion of market activity channelled through sophisticated rental equipment providers who demand robust, highly certified, and reusable systems.

- Europe: Europe is a mature market defined by strict regulatory environments and a strong preference for durable, sustainable, and innovative systems. Key drivers include rigorous construction safety mandates and a focus on circular economy principles, boosting demand for aluminum and advanced, recyclable materials. Germany, the UK, and France are hubs for high-quality scaffolding and shoring system manufacturers, often setting the global benchmark for design and safety.

- Latin America (LATAM): This region exhibits moderate growth, tied closely to commodity extraction projects and varying levels of public infrastructure spending. The market is characterized by sensitivity to economic volatility and relies heavily on imported or locally produced low-cost steel trestles. Brazil and Mexico are key markets, showing increasing demand for modern, safer systems as international contractors enter the market.

- Middle East and Africa (MEA): Growth in the MEA is highly concentrated in the GCC states (Saudi Arabia, UAE) due to mega-projects in construction, tourism, and energy infrastructure. These projects demand specialized, heavy-duty shoring and access solutions, often procured directly from international European and North American suppliers. The African segment remains nascent, with growth tied to urbanization and resource development projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Trestle Market.- Layher

- Waco Kwikform

- Safway Group

- HAKI

- PERI GmbH

- RMD Kwikform

- BrandSafway

- ULMA Construction

- Altrad Group

- Doka GmbH

- Metaltech-Omega

- Adjustable Trestles Co.

- Spanlift

- WernerCo.

- Gorilla Ladders

- Zhejiang Zhongjian Steel

- Guangxi Futeng Engineering

- KLT Group

- Strongwell Corporation

- Trestle Desk Co.

Frequently Asked Questions

Analyze common user questions about the Trestle market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary material driving the Trestle Market?

Steel remains the foundational material, especially in heavy-duty construction and infrastructure applications, due to its high load-bearing capacity and cost-effectiveness. However, aluminum is the fastest-growing segment due to its lightweight properties, portability, and excellent resistance to corrosion.

How do safety regulations affect the Trestle Market?

Stringent global safety regulations, such as OSHA and EN standards, significantly impact the market by necessitating certified, high-quality, and robust trestle systems. This drives contractors away from uncertified, cheaper options toward premium, compliant products, increasing demand for structural testing and specialized training services.

Which application segment holds the largest market share?

The Construction and Infrastructure segment collectively holds the largest market share, driven by global urbanization and government spending on transportation, energy, and commercial building projects, requiring extensive temporary shoring and access support solutions.

What role does the rental market play in trestle distribution?

The equipment rental market is crucial, particularly for heavy-duty and specialized trestles. Rental companies provide contractors with flexible, cost-effective access to certified equipment without significant capital investment, maximizing asset utilization and minimizing maintenance burdens for end-users.

What emerging technology is reshaping trestle design?

Advanced materials, specifically high-strength aluminum alloys and structural composites, are reshaping design by enabling lighter, stronger, and more corrosion-resistant products. Additionally, IoT sensors for real-time load monitoring are transforming high-risk infrastructure applications, enhancing overall safety and predictive maintenance capabilities.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager