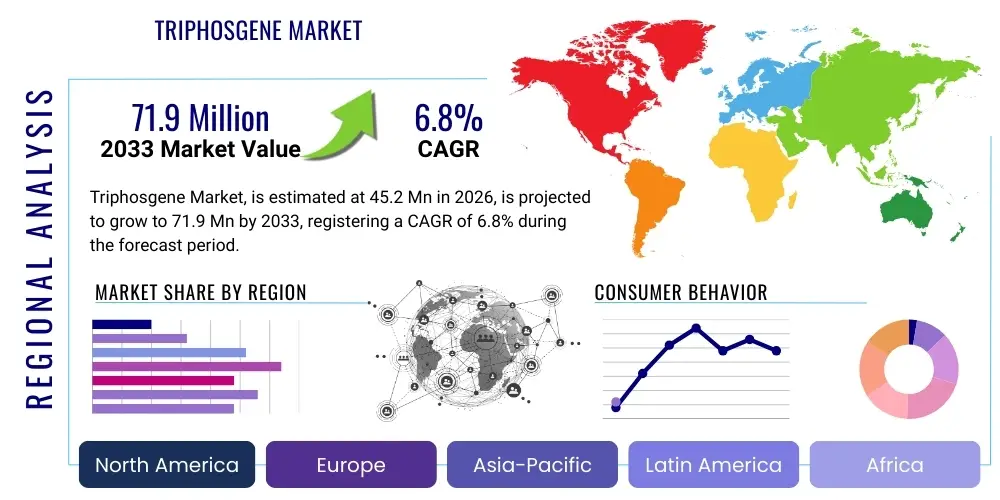

Triphosgene Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442208 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Triphosgene Market Size

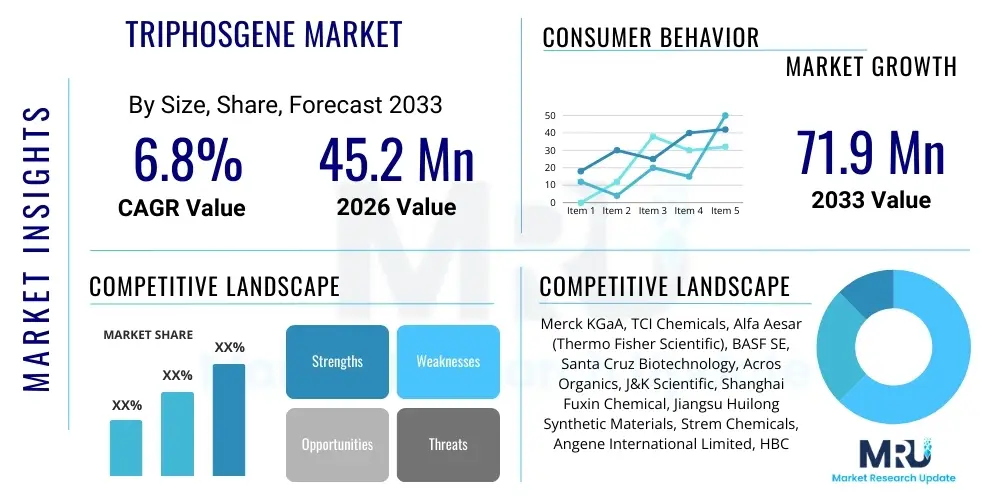

The Triphosgene Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 45.2 Million in 2026 and is projected to reach USD 71.9 Million by the end of the forecast period in 2033.

Triphosgene Market introduction

The Triphosgene market encompasses the production, distribution, and utilization of bis(trichloromethyl) carbonate (C3O3(CCl3)2), commonly known as triphosgene (TPG). Triphosgene serves as a highly effective, solid, and safer substitute for highly toxic and gaseous phosgene (COCl2). This critical reagent is primarily employed in organic synthesis for phosgenation reactions, where it acts as a mild carbonylating agent, crucial for forming chloroformates, isocyanates, and urethanes. Its solid state simplifies handling, storage, and precise metering in laboratory and industrial settings, mitigating significant safety risks associated with traditional phosgene use.

Triphosgene is highly valued across specialized chemical sectors due to its superior reactivity profile and ease of decomposition into phosgene upon heating or in the presence of certain catalysts, allowing for controlled phosgenation reactions. Major applications span the synthesis of complex pharmaceutical intermediates, the production of high-performance agrochemicals, and specialized polymer chemistry, particularly in the creation of polycarbonates and specialized resins. The inherent stability under standard conditions, coupled with the benefit of using less hazardous precursor material, drives its adoption in environments demanding stringent safety protocols and high precision.

The market growth is fundamentally driven by the escalating demand for advanced pharmaceutical molecules, particularly in developing economies, which rely heavily on efficient phosgenation steps for drug synthesis. Furthermore, the stringent global regulatory landscape concerning hazardous chemicals, such as phosgene, compels chemical manufacturers to transition towards safer, solid alternatives like triphosgene. Its key benefit lies in facilitating cleaner, more controllable, and scalable synthetic routes for complex organic compounds, solidifying its role as an indispensable reagent in modern chemical manufacturing.

Triphosgene Market Executive Summary

The Triphosgene market demonstrates robust expansion, fueled primarily by the regulatory mandates favoring safer chemical processing and the rapidly expanding pharmaceutical industry's need for high-purity intermediates. Business trends indicate a shift towards localized production in APAC to serve burgeoning manufacturing hubs, alongside significant investment in developing continuous flow chemistry processes that utilize TPG more efficiently and safely. Suppliers are focusing on enhancing product purity (High Purity Grade) to meet the exacting standards of innovator drug manufacturers.

Regionally, Asia Pacific (APAC) stands out as the fastest-growing market, propelled by the establishment of major contract manufacturing organizations (CMOs) and increasing domestic generic drug production in China and India. North America and Europe maintain leading market shares driven by advanced R&D activities, stringent safety standards, and the presence of major specialty chemical producers who rely on TPG for advanced materials synthesis. European regulations, particularly REACH directives concerning chemical handling, strongly incentivize the substitution of gaseous phosgene with solid alternatives like triphosgene.

Segment trends reveal that the Pharmaceutical Synthesis application segment retains the largest market share, given the irreplaceable role of TPG in creating critical chemical functionalities required for active pharmaceutical ingredients (APIs). Within the end-user spectrum, Pharmaceuticals & Biotechnology firms are the dominant purchasers. The market is also seeing specialized growth in the utilization of TPG for producing niche agrochemical intermediates, specifically highly complex herbicides and insecticides that require precise carbonylation.

AI Impact Analysis on Triphosgene Market

Common user inquiries regarding AI's influence on the Triphosgene market frequently center on three main areas: predictive modeling for reaction safety and optimization, enhancing supply chain transparency, and accelerating the discovery of novel synthetic pathways that might substitute or optimize TPG usage. Users are concerned about how AI can mitigate the inherent risks associated with phosgenation reactions, even when using TPG, and if machine learning can predict the optimal temperature, pressure, and catalyst conditions to maximize yield and minimize side product formation. Furthermore, there is significant interest in using AI-driven analytics to manage the complex supply logistics of controlled chemicals and predict demand fluctuations in end-user industries like pharmaceuticals.

AI's primary influence is not on the chemical production itself, but rather on the processes surrounding its use. AI-driven predictive maintenance and safety systems are being adopted by large chemical manufacturers to monitor reaction kinetics and detect anomalies in real-time, thereby improving operational safety when handling reactive intermediates derived from TPG. Furthermore, computational chemistry, powered by machine learning algorithms, is increasingly used to model complex molecular interactions involving triphosgene, drastically cutting down on the time required for route scouting in API development. This enhances efficiency and reduces the material waste associated with trial-and-error synthesis.

The integration of AI also significantly impacts quality control and regulatory compliance. Automated analytical platforms combined with deep learning models can analyze spectroscopic data (NMR, Mass Spec) instantly to ensure the high purity grade of commercial triphosgene meets pharmaceutical specifications. Moreover, in inventory management, AI algorithms forecast precise consumption rates of TPG based on downstream manufacturing schedules, minimizing stocking costs while ensuring uninterrupted supply, a critical factor for schedule-sensitive drug production.

- AI optimizes reaction parameters (temperature, solvent, concentration) in TPG-mediated synthesis, enhancing yield and purity.

- Predictive safety systems utilize machine learning to monitor real-time process data, minimizing risks associated with exothermic phosgenation reactions.

- Machine learning accelerates the discovery of greener, more efficient catalysts for TPG utilization in specialty chemical synthesis.

- AI enhances supply chain resilience by accurately forecasting demand and managing regulated chemical inventory logistics.

- Automated quality control platforms leverage computer vision and data analytics for rapid purity verification of Triphosgene batches.

DRO & Impact Forces Of Triphosgene Market

The Triphosgene market dynamics are shaped by the critical balance between mandatory safety upgrades in chemical processing (Drivers) and the high costs associated with handling regulated substances (Restraints). Opportunities emerge through innovation in green chemistry and novel applications in high-tech materials, while the regulatory strictness concerning chemical imports and exports exerts a strong, defining impact force on market accessibility and operational complexity.

Key drivers include the global push for chemical safety, where triphosgene’s solid nature makes it inherently safer than gaseous phosgene, driving its mandated adoption in many industrialized nations. The rapid growth of the global pharmaceutical industry, particularly the need for complex, chiral APIs, necessitates efficient phosgenation agents, directly boosting TPG demand. Furthermore, advancements in specialized polymer synthesis, requiring carbonylation steps for high-performance plastics, contribute substantially to market expansion.

Restraints primarily involve the regulatory burden and the high cost of production and storage. While safer than phosgene, TPG remains a highly regulated substance requiring specialized infrastructure for handling and disposal, leading to elevated operational expenditures. Additionally, the development and scaling of alternative, non-phosgenation routes in synthesis present a long-term restraint, although current alternatives often lack the efficiency or specificity of TPG-mediated reactions. Opportunities lie in expanding TPG use into emerging fields like battery electrolytes and advanced material coatings, alongside technological improvements in continuous manufacturing processes that utilize TPG more cost-effectively and safely.

The impact forces are high. Regulatory impact is severe; any changes in chemical control lists (e.g., in the US, EU, or China) directly affect TPG manufacturing and trade. Technological impact is moderate but accelerating, driven by R&D focused on maximizing TPG efficiency and minimizing byproduct formation. Economic forces, such as fluctuating raw material costs (e.g., chloroform and methanol derivatives) and global shipping costs, moderately influence the final price point of high-purity triphosgene.

Segmentation Analysis

The Triphosgene market is segmented primarily based on its purity grade, the application sector where it is utilized, and the specific end-user industry purchasing the reagent. Understanding these segments is crucial for manufacturers to tailor production capabilities and for distributors to target niche markets, particularly those requiring ultra-high purity materials for complex synthesis. The market structure reflects the varied needs of the chemical industry, ranging from bulk chemical production to small-scale, highly specialized laboratory synthesis.

Purity Grade segmentation distinguishes between Standard Grade, used primarily in bulk chemical synthesis and non-API manufacturing, and High Purity Grade, which is mandatory for pharmaceutical and biotechnology applications where impurities must be minimized to trace levels. Application segmentation is dominated by Pharmaceutical Synthesis, reflecting TPG's irreplaceable role in synthesizing key drug intermediates, but also includes significant contributions from Agrochemicals and specialized Polymer Chemistry for high-performance materials.

End-user analysis highlights the dominance of the Pharmaceuticals & Biotechnology sector, which demands premium pricing for guaranteed purity and supply chain reliability. Chemical Manufacturers, including those focused on specialty chemicals and materials science, constitute the second largest segment, utilizing TPG for a diverse range of proprietary processes. Research Institutions and Academic Laboratories, while smaller in volume, drive the demand for specific, often customized, small-batch TPG supplies for novel chemical research.

- By Grade:

- Standard Grade (98-99% Purity)

- High Purity Grade (>99.5% Purity)

- By Application:

- Pharmaceutical Synthesis (APIs and Intermediates)

- Agrochemicals (Herbicides, Insecticides)

- Polymer Chemistry (Polycarbonates, Specialty Resins)

- Specialty Chemicals and Research

- By End-User:

- Pharmaceuticals & Biotechnology Companies

- Chemical Manufacturers

- Research Institutions and Academics

Value Chain Analysis For Triphosgene Market

The Triphosgene value chain begins with the upstream procurement of raw materials, primarily chloroform (CHCl3), and subsequent chlorination processes, demanding high capital expenditure and specialized chemical engineering expertise. Upstream activities involve complex, energy-intensive manufacturing steps under controlled conditions to synthesize bis(trichloromethyl) carbonate, necessitating stringent safety and quality checks given the toxicity of immediate precursors and intermediates. Efficiency in this stage dictates the overall production cost and quality profile of the final TPG product.

Midstream activities focus on the purification, grading (especially achieving the critical high-purity levels required for pharmaceutical use), packaging, and certified storage of TPG. Due to its regulated nature, packaging requires specialized, hermetically sealed containers, often handled under inert atmospheres to maintain stability. The certification process is extensive, particularly for batches destined for regulated markets like North America and Europe, ensuring compliance with GDP (Good Distribution Practices) and relevant chemical control acts.

Downstream distribution channels are highly specialized, relying on dedicated logistics providers trained in handling regulated hazardous solids. Direct sales channels are common for large pharmaceutical and specialty chemical manufacturers, fostering close technical collaboration between producer and end-user. Indirect channels involve authorized chemical distributors who manage regional inventory, providing smaller batches to research institutions and mid-sized specialty chemical firms. The final consumption focuses heavily on batch processing in reactors, where TPG is carefully introduced for specific phosgenation, carbonylation, or chloroformate formation steps crucial for API or advanced material synthesis.

Triphosgene Market Potential Customers

The primary consumers of triphosgene are entities engaged in complex chemical synthesis requiring efficient and safe carbonylation capabilities, fundamentally comprising the global pharmaceutical and specialty chemical industries. These customers prioritize high product purity, consistent supply, and robust regulatory documentation to ensure compliance with global drug manufacturing standards (cGMP). Their purchasing decisions are heavily influenced by the supplier's capacity for certification and reliable hazardous material logistics, rather than solely price.

Within the pharmaceutical sector, potential customers include large multinational drug innovators and, crucially, contract research and manufacturing organizations (CROs/CMOs) that perform synthesis steps for innovator or generic companies. CMOs in regions like India and China represent a rapidly growing customer base due to the outsourcing trends in API production. These customers require High Purity Grade TPG for synthesizing critical intermediates used in anti-cancer drugs, antivirals, and specific cardiovascular treatments.

Beyond pharmaceuticals, specialty chemical manufacturers who produce advanced agrochemical formulations (e.g., highly selective herbicides) and specialized polymer components (e.g., certain engineering plastics or unique polyurethane precursors) are significant buyers. These end-users demand customized packaging and logistical support appropriate for bulk industrial use, often integrating TPG into proprietary, continuous flow synthesis platforms to achieve scale and efficiency in their manufacturing processes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 45.2 Million |

| Market Forecast in 2033 | USD 71.9 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Merck KGaA, TCI Chemicals, Alfa Aesar (Thermo Fisher Scientific), BASF SE, Santa Cruz Biotechnology, Acros Organics, J&K Scientific, Shanghai Fuxin Chemical, Jiangsu Huilong Synthetic Materials, Strem Chemicals, Angene International Limited, HBCChem, Inc., Meryer (Shanghai) Chemical Technology, Tokyo Chemical Industry Co., Ltd., Matrix Scientific, Chem-Impex International, BOC Sciences, Wako Pure Chemical Industries |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Triphosgene Market Key Technology Landscape

The technology landscape for the Triphosgene market centers not only on the chemical synthesis methods for TPG itself but increasingly on the methodologies employed by end-users for its safe and efficient handling in downstream processes. Traditional batch synthesis remains prevalent for TPG production, but leading manufacturers are heavily investing in continuous processing technologies to improve yield, consistency, and minimize the risk associated with handling reactive precursors. This involves highly automated, closed-loop systems that ensure precise temperature and pressure control throughout the synthesis and purification phases, essential for achieving the required high purity grades for regulated industries.

A major technological focus downstream is the integration of Triphosgene into flow chemistry setups, moving away from large batch reactors. Flow reactors allow for the quick and safe mixing of reagents and TPG under micro- or mesoscale conditions, which significantly reduces the total inventory of highly reactive intermediates at any given time, thereby enhancing safety and scalability. This shift is crucial for pharmaceutical CMOs aiming to optimize their synthetic routes for APIs, allowing for faster reaction times and easier control over exothermic phosgenation steps, which are traditionally challenging and hazardous in large vessels.

Furthermore, spectroscopic techniques, particularly high-resolution Nuclear Magnetic Resonance (NMR) and mass spectrometry coupled with advanced chromatography (HPLC), are fundamental quality control technologies. These technologies ensure that commercial triphosgene meets the stringent purity specifications, specifically verifying the absence of unreacted precursors or hazardous byproducts. The ongoing digital transformation in chemical manufacturing is also introducing advanced sensor technology and Industrial Internet of Things (IIoT) applications to monitor storage conditions and usage in real-time, providing immediate data feedback for process optimization and regulatory documentation.

Regional Highlights

The global Triphosgene market exhibits distinct regional dynamics driven by local regulatory environments, the concentration of pharmaceutical R&D, and manufacturing output.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, dominated by high volume demand from China and India. This growth is directly linked to the booming generic drug manufacturing sector and the extensive network of CMOs and CROs focused on cost-effective API production. While raw material sourcing is robust, the regulatory environment is rapidly tightening to align with Western standards, further encouraging the controlled use of safer reagents like TPG over traditional phosgene.

- North America: North America holds a significant market share, driven primarily by high-value R&D activities and the presence of major pharmaceutical innovator companies. Demand is characterized by the need for ultra-high purity grade Triphosgene for novel drug discovery and complex specialty chemical applications. Strict environmental, health, and safety (EHS) regulations in the U.S. and Canada solidify TPG's position as the preferred phosgenation agent over gaseous alternatives.

- Europe: Europe represents a mature market with high demand stemming from established specialty chemical industries and pharmaceutical production concentrated in Germany, Switzerland, and the UK. The market is highly regulated under frameworks like REACH, which strongly favors solid, safer reagents. Innovation in European flow chemistry centers further stimulates the use of TPG for highly controlled and efficient synthetic processes.

- Latin America, Middle East, and Africa (MEA): These regions represent emerging markets for Triphosgene. Growth in Latin America is tied to nascent domestic pharmaceutical production, requiring imported high-purity reagents. MEA demand, though smaller, is increasing due to foreign investment in specialty chemical facilities, particularly in polymer and resin production in the Gulf Cooperation Council (GCC) countries, driven by infrastructure development.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Triphosgene Market.- Merck KGaA

- TCI Chemicals

- Alfa Aesar (Thermo Fisher Scientific)

- BASF SE

- Santa Cruz Biotechnology

- Acros Organics

- J&K Scientific

- Shanghai Fuxin Chemical

- Jiangsu Huilong Synthetic Materials

- Strem Chemicals

- Angene International Limited

- HBCChem, Inc.

- Meryer (Shanghai) Chemical Technology

- Tokyo Chemical Industry Co., Ltd.

- Matrix Scientific

- Chem-Impex International

- BOC Sciences

- Wako Pure Chemical Industries

- CSPC Pharmaceutical Group Limited

- Suzhou Highfine Electronic Material Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Triphosgene market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Triphosgene and why is it preferred over Phosgene?

Triphosgene, or bis(trichloromethyl) carbonate, is a solid, safer substitute for highly toxic, gaseous phosgene (COCl2). It is preferred because its solid state dramatically simplifies handling, storage, and precise metering in chemical synthesis, significantly reducing the inherent safety risks associated with highly hazardous gas.

Which application segment drives the highest demand for Triphosgene?

The Pharmaceutical Synthesis application segment is the primary demand driver. Triphosgene is essential for introducing carbonyl groups in the synthesis of complex Active Pharmaceutical Ingredients (APIs) and critical intermediates, which require high yield and purity that TPG-mediated reactions reliably provide.

What is the Compound Annual Growth Rate (CAGR) projected for the Triphosgene Market?

The Triphosgene Market is projected to exhibit a steady Compound Annual Growth Rate (CAGR) of 6.8% between the years 2026 and 2033, driven by increasing global pharmaceutical production and stringent chemical safety regulations mandating its use.

How do regulatory requirements impact the Triphosgene market growth?

Strict global regulatory requirements, such as those imposed by EHS agencies and REACH, positively impact the TPG market. These regulations enforce the use of safer alternatives to hazardous gases like phosgene, compelling manufacturers to adopt TPG for compliant and sustainable chemical operations.

Which geographical region is showing the fastest growth in Triphosgene consumption?

The Asia Pacific (APAC) region is demonstrating the fastest growth in Triphosgene consumption. This surge is attributed to the rapid expansion of generic drug manufacturing, the proliferation of Contract Manufacturing Organizations (CMOs) in China and India, and rising specialty chemical production.

What challenges exist regarding the storage and handling of Triphosgene?

While safer than phosgene, TPG remains a highly reactive chemical that decomposes slowly upon contact with moisture. Challenges include the need for specialized, inert atmosphere storage (often refrigerated), strict inventory controls, and adherence to specific hazardous material transport regulations to maintain its quality and stability.

What key technological trend is influencing the use of Triphosgene?

The adoption of flow chemistry and continuous manufacturing processes is a key technological trend. Flow reactors allow for the safe, scalable, and highly precise use of TPG in phosgenation reactions, enhancing efficiency and minimizing operational hazards compared to traditional batch synthesis.

Is Triphosgene used in the Agrochemical industry?

Yes, Triphosgene is widely used in the Agrochemical industry. It serves as a vital reagent for the synthesis of advanced and proprietary intermediates required for the production of high-performance herbicides, insecticides, and fungicides, where precise carbonylation steps are necessary.

How does the purity grade of Triphosgene affect its end-use?

Purity grade directly dictates the end-use. High Purity Grade (>99.5%) is mandatory for pharmaceutical synthesis, ensuring minimal risk of contamination in Active Pharmaceutical Ingredients (APIs). Standard Grade (98-99%) is suitable for bulk chemical production, polymer chemistry, and non-API specialty chemical manufacturing.

What raw materials are critical for the production of Triphosgene?

The critical raw material for Triphosgene production is Chloroform (CHCl3). This is processed through specific reactions, typically involving chlorination and carbonylation steps, often using controlled oxidation or reaction with chlorinating agents to form the final product, bis(trichloromethyl) carbonate.

How does AI contribute to safety in Triphosgene-mediated synthesis?

AI contributes to safety by powering predictive models that analyze reaction conditions in real-time. These systems can forecast potential thermal runaways or unexpected side reactions during phosgenation processes, enabling automated adjustments or shutdown protocols to prevent accidents and ensure operational stability.

What are the main competitive factors in the Triphosgene market?

Key competitive factors include product purity and consistency (especially High Purity Grade certification), robust supply chain logistics for regulated chemicals, technical expertise in handling and application support, and global regulatory compliance capabilities. Price competitiveness is secondary to reliability and quality assurance in this specialized market.

Can Triphosgene be used for polymer manufacturing?

Yes, Triphosgene is utilized in polymer chemistry, particularly for specialized syntheses where controlled carbonylation is required. It is an effective agent for forming polycarbonates and certain polyurethane intermediates, contributing to the production of high-performance engineering plastics and resins.

What is the role of CMOs in the Triphosgene market demand?

Contract Manufacturing Organizations (CMOs) are crucial demand drivers. As pharmaceutical companies increasingly outsource the synthesis of complex intermediates and APIs, CMOs require reliable, high-purity TPG supplies to execute critical phosgenation steps under strict quality and safety standards.

How is the market influenced by green chemistry initiatives?

Green chemistry initiatives moderately influence the market by encouraging research into non-phosgenation routes (restraint). However, TPG itself is considered a 'greener' alternative compared to gaseous phosgene, allowing manufacturers to maintain high-efficiency carbonylation while adhering to safer, more sustainable practices, thereby supporting TPG adoption as a necessary compromise.

What is the expected market valuation of Triphosgene by 2033?

The Triphosgene market is projected to reach an estimated valuation of USD 71.9 Million by the end of the forecast period in 2033, reflecting consistent demand across specialized chemical and pharmaceutical sectors worldwide.

How does Triphosgene simplify laboratory procedures?

Triphosgene simplifies laboratory procedures by being a solid substance at room temperature, allowing for easy, precise weighing and dosing, unlike gaseous phosgene which requires specialized high-pressure handling systems, complex flowmeters, and rigorous containment protocols. Its stability makes it ideal for bench-scale synthesis.

What impact do raw material price fluctuations have on the market?

Fluctuations in the prices of critical raw materials, such as chloroform and chlorine derivatives, have a moderate impact on the market. Since TPG is a high-value specialty chemical, cost pass-through is possible, but extreme volatility can squeeze the margins of manufacturers, particularly those competing on price for Standard Grade TPG.

Why is Europe a significant consumer of Triphosgene?

Europe is a significant consumer due to its stringent regulatory environment (REACH), which strongly penalizes the use of highly hazardous substances, thereby institutionalizing the use of safer phosgenation agents like TPG. Additionally, the region hosts major specialty chemical and advanced material manufacturers that rely on TPG.

What are the typical packaging requirements for shipping Triphosgene?

Shipping Triphosgene requires specialized packaging due to its classification as a hazardous solid. It must be packaged in hermetically sealed, chemically resistant containers (often glass bottles or UN-approved drums) and shipped under conditions that minimize exposure to moisture or high temperatures, adhering strictly to international dangerous goods regulations.

What defines the High Purity Grade Triphosgene segment?

The High Purity Grade segment is defined by a purity level exceeding 99.5%. This grade necessitates advanced purification technologies, rigorous quality control checks (e.g., trace impurity analysis), and stringent batch-to-batch consistency required exclusively for synthesis steps in human pharmaceutical and high-end biotechnology products.

How is the Triphosgene market addressing sustainability concerns?

The market addresses sustainability by focusing on improving reaction efficiency using flow chemistry, thereby reducing waste and energy consumption in the synthesis process. Additionally, the inherent use of TPG as a replacement for the highly polluting gaseous phosgene contributes positively to operational safety and environmental management in end-user industries.

What role do Research Institutions play in the TPG market?

Research Institutions, including universities and government labs, are crucial for driving innovation. They consume smaller, specialized batches of TPG for developing novel synthetic methods, testing new catalysts, and scouting greener, more efficient carbonylation routes, often influencing future industrial adoption.

Does the availability of generic drugs influence TPG demand?

Yes, the rising global production of generic drugs significantly influences TPG demand, particularly in APAC. Generic drug synthesis often requires efficient, high-volume production of intermediates using reliable reagents like TPG, boosting demand in the Standard and High Purity Grade segments utilized by large-scale manufacturers.

What measures are taken to ensure the long-term stability of Triphosgene?

To ensure long-term stability, Triphosgene must be stored in cool, dark environments, often under refrigeration, and sealed under an inert atmosphere (e.g., nitrogen or argon) to prevent reaction with atmospheric moisture and oxygen, which can cause decomposition and loss of purity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager