Tyre Curing Press Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442163 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Tyre Curing Press Market Size

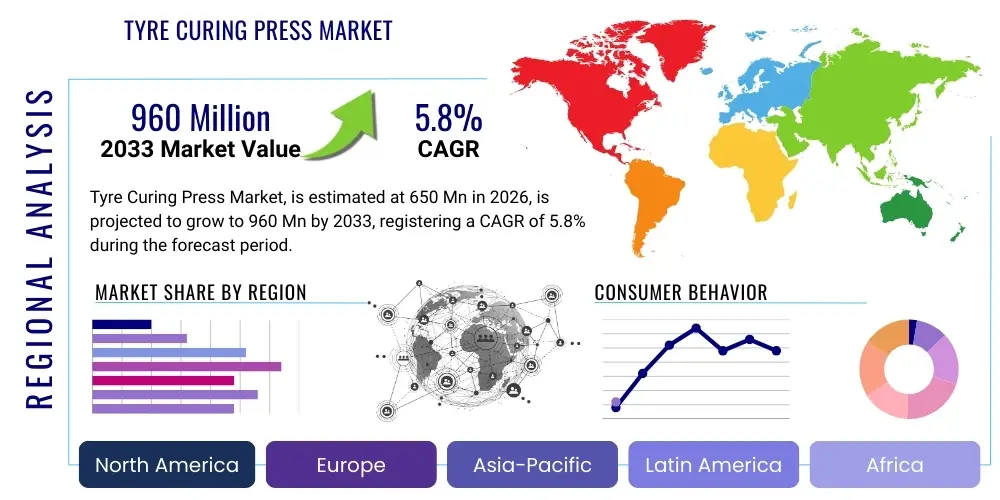

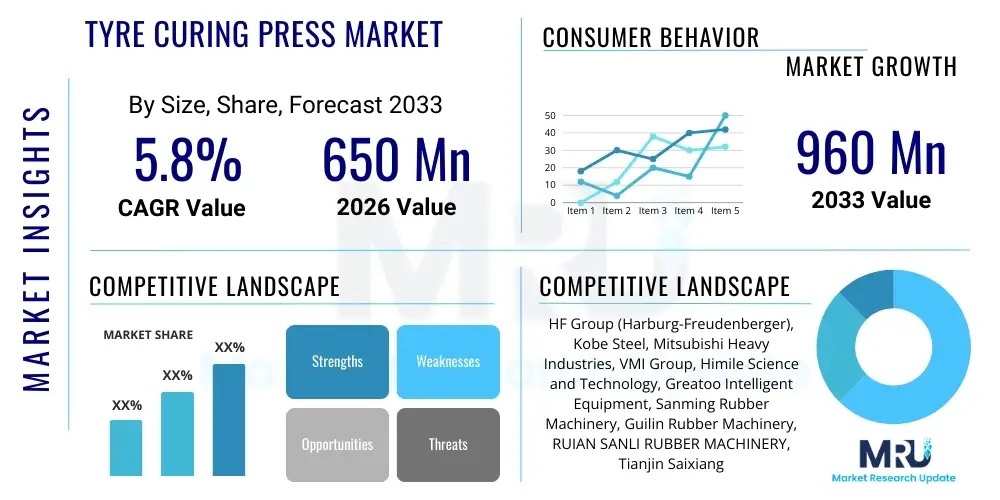

The Tyre Curing Press Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 650 Million in 2026 and is projected to reach USD 960 Million by the end of the forecast period in 2033.

Tyre Curing Press Market introduction

The Tyre Curing Press Market encompasses the global trade of specialized machinery essential for the final manufacturing stage of vehicle tires. Tyre curing presses are high-precision industrial systems designed to transform a 'green tire' (an uncured, built-up assembly of rubber components) into a finished tire by applying controlled heat, pressure, and time. This critical process, known as vulcanization or curing, chemically cross-links the rubber polymers, giving the tire its final shape, tread pattern, sidewall details, and, most importantly, its durable physical properties necessary for safe operation, such as resilience, traction, and resistance to wear and tear. The technology employed in these presses is constantly evolving, focusing on energy efficiency, reducing cycle times, and ensuring uniformity across production batches, which is paramount for safety and performance standards in the automotive industry.

Major applications of tyre curing presses span the entire spectrum of vehicular transport, including passenger cars, trucks and buses (TBR), aircraft, agricultural machinery, and specialized off-the-road (OTR) vehicles. The industry is segmented primarily based on the actuation mechanism—hydraulic or mechanical presses—and the degree of automation. Benefits derived from advanced curing press technology include enhanced operational safety due to precise temperature and pressure control, improved energy conservation through efficient heating methods like steam, nitrogen, or superheated water, and flexibility to handle diverse tire sizes and constructions. Manufacturers are increasingly integrating IoT capabilities into these systems for real-time diagnostics and predictive maintenance, contributing significantly to operational uptime.

The market is primarily driven by the consistent growth in the global automotive sector, particularly the rising demand for replacement tires and original equipment (OE) tires in emerging economies across Asia Pacific. Furthermore, regulatory shifts mandating stricter performance standards for tires (e.g., rolling resistance requirements for fuel efficiency and wet grip specifications for safety) compel tire manufacturers to invest in newer, more precise curing technologies. The need to produce high-performance, complex tire structures, coupled with the industry's sustained focus on reducing manufacturing carbon footprints, acts as a primary catalyst for innovation and market expansion in the Tyre Curing Press sector.

Tyre Curing Press Market Executive Summary

The global Tyre Curing Press Market exhibits robust growth, propelled by accelerating automotive production rates and a sustained global demand for high-quality replacement tires, particularly in high-growth regions like China, India, and Southeast Asia. Key business trends indicate a strong industry shift towards fully automatic mechanical presses, favored for their enhanced precision, faster cycle times, and superior energy efficiency compared to traditional hydraulic systems. This transition is also supported by the increasing adoption of automated material handling and mold maintenance systems integrated within the curing process, optimizing overall manufacturing throughput and reducing manual intervention.

Regionally, Asia Pacific maintains market dominance, driven by extensive domestic tire manufacturing capacities and significant foreign direct investment aimed at capturing regional automotive growth. North America and Europe, while mature, focus intensely on technological upgrades, emphasizing presses capable of handling specialized, high-performance, and larger tire formats, such as those used in electric vehicles (EVs) and advanced trucks. Segments trends highlight that the Mechanical Curing Press segment is projected to achieve the highest CAGR, primarily due to its operational superiority and reduced maintenance complexity. Simultaneously, the application segment focused on Truck and Bus Radial (TBR) tires continues to generate substantial revenue, owing to massive infrastructure projects and high freight volumes worldwide requiring durable commercial vehicle tires.

Overall market dynamics suggest that competitive advantage will increasingly depend on the integration of digitalization and advanced control systems (Industry 4.0 principles) within curing presses. Suppliers providing solutions that maximize uptime, minimize energy consumption (specifically steam usage), and offer flexibility for quick mold changes are positioning themselves strategically. While initial capital expenditure remains a restraint, the long-term operational savings and adherence to stringent quality controls provided by advanced curing technology justify the investment for major tire manufacturers globally.

AI Impact Analysis on Tyre Curing Press Market

Common user questions regarding AI's influence in the Tyre Curing Press Market typically center on how artificial intelligence can optimize the curing process, minimize defects, and predict equipment failure. Users are specifically concerned about AI’s capability to manage the complex, multi-variable curing algorithms (temperature, time, pressure profiles) in real-time to achieve optimal quality uniformity (CQI). Furthermore, there is significant interest in using machine learning (ML) models to analyze historical curing data, correlate process parameters with final tire quality metrics (e.g., uniformity, balance, weight variation), and provide prescriptive adjustments to press settings, thereby moving beyond traditional statistical process control (SPC). Expectations also revolve around AI integrating with predictive maintenance systems to forecast component wear in high-stress areas like bladders and mold segments, significantly improving overall equipment effectiveness (OEE).

- AI-driven optimization of curing profiles for reduced cycle time and energy consumption.

- Predictive quality control (PQC) achieved through ML correlation of input parameters (green tire weight, moisture) with final vulcanization outcomes.

- Enhanced predictive maintenance (PdM) analyzing sensor data (vibration, temperature logs) to prevent unexpected downtime of complex mechanical components.

- Automated fault detection and diagnosis in press operations, minimizing the incidence of curing defects (e.g., porous rubber, insufficient adhesion).

- Supply chain optimization for press components and consumables (molds, bladders) based on predicted usage patterns derived from operational data.

DRO & Impact Forces Of Tyre Curing Press Market

The Tyre Curing Press Market is fundamentally influenced by a complex interplay of global automotive demand, technological requirements, and sustainability mandates. Key drivers include the exponential increase in radial tire manufacturing, which necessitates advanced press technology for precise handling and uniform vulcanization, coupled with the mass adoption of automated manufacturing systems (Industry 4.0). Restraints primarily stem from the high initial capital investment required for state-of-the-art curing presses and the volatility in raw material costs, particularly steel and specialized alloys required for mold construction. Opportunities are vast in the domain of eco-friendly manufacturing, specifically the development and marketing of energy-efficient presses that significantly reduce steam consumption—a major energy drain in tire plants—and the growing demand for presses tailored to handle the unique specifications of heavy-duty and electric vehicle tires, which often require different curing cycles and pressure applications.

Impact forces within the market are predominantly driven by technological shifts and competitive intensity. The shift from hydraulic to mechanical presses represents a significant internal impact force, altering the competitive landscape and raising the performance benchmark for new equipment acquisitions. External forces include governmental regulations regarding tire performance standards (e.g., EU tire labeling requirements) and safety mandates, which accelerate the obsolescence of older, less precise press models. Furthermore, the consolidated structure of the global tire manufacturing industry means that procurement decisions by major tire makers (Tier 1 players) significantly impact the order books and technological direction of press manufacturers, leading to continuous pressure on innovation and customization capabilities.

The market faces constant pressure from technological requirements related to producing tires with thinner sidewalls, complex internal structures, and advanced materials. This necessitates presses offering tighter tolerances and multi-zone temperature control capabilities. The intense focus on minimizing waste (scrap tires) and maximizing energy efficiency serves as a sustained driver for replacing legacy equipment, ensuring that even in mature markets, there remains a cyclical demand for advanced, highly automated curing solutions that guarantee operational cost reductions and superior end-product quality.

Segmentation Analysis

The Tyre Curing Press Market segmentation provides critical insights into the preferred technological solutions utilized by global tire manufacturers, categorized primarily by the operational mechanism, level of automation, and the specific application or type of tire being cured. Analyzing these segments helps stakeholders understand investment patterns, technological evolution, and regional consumption differences. The segmentation reveals a growing preference for technologically advanced, energy-efficient solutions, especially within the mechanical press and fully automatic operational categories, driven by the desire for optimized cycle times and repeatable quality.

- By Type:

- Hydraulic Curing Press

- Mechanical Curing Press

- By Operational Technology:

- Automatic

- Semi-Automatic

- By Application:

- Passenger Car Tyre (PCR)

- Truck & Bus Radial Tyre (TBR)

- Off-the-Road (OTR) Tyre

- Aircraft & Specialty Tyre

- By Heating Medium:

- Steam Curing Press

- Hot Water/Nitrogen Curing Press

Value Chain Analysis For Tyre Curing Press Market

The value chain of the Tyre Curing Press Market begins with upstream activities involving the sourcing of high-grade raw materials, primarily specialized steel alloys, high-precision hydraulic and pneumatic components, advanced control systems, and complex mold components. Critical upstream suppliers include metal fabricators, industrial automation providers (PLC and HMI manufacturers), and specialized component makers responsible for bladders and heating elements. Ensuring consistent quality and timely delivery of customized, high-tolerance components is crucial, as the performance and longevity of the curing press directly depend on the precision of these inputs. Press manufacturers then engage in complex design, precision machining, assembly, and rigorous testing phases before deployment.

The distribution channel is predominantly direct, especially for large, custom-built mechanical or hydraulic presses. Due to the high capital cost, complexity, and installation requirements, original equipment manufacturers (OEMs) typically engage directly with Tier 1 and Tier 2 tire producers. This direct model allows for tailored solutions, comprehensive after-sales service, installation support, and specialized training, which are critical competitive factors. Indirect channels, involving authorized distributors or sales agents, are occasionally used for selling standard spare parts, consumables, or smaller, specialized presses to niche markets or smaller regional tire plants.

Downstream analysis focuses on the end-users: the global tire manufacturing facilities. Key activities at this stage include installation, commissioning, integration with existing material handling systems, continuous maintenance, and modernization/retrofitting of older presses. The aftermarket segment, involving replacement parts (bladders, molds, heating coils) and specialized service contracts, constitutes a significant, stable revenue stream for press OEMs, reflecting the long operational lifecycle of these heavy machines. The efficiency and reliability of the press directly impact the tire producer's operational efficiency, making post-sale support a critical link in the value chain.

Tyre Curing Press Market Potential Customers

Potential customers for Tyre Curing Presses are predominantly large-scale, international tire manufacturing corporations and specialized rubber product processors requiring vulcanization capabilities. These entities are characterized by significant capital expenditure budgets and a relentless focus on improving production efficiency, reducing energy consumption, and maintaining strict compliance with global quality standards. The primary purchasing drivers for these end-users are not merely replacement cycles but capacity expansion plans driven by surging vehicle production, the strategic need to localize manufacturing in key consumer markets (especially APAC), and the necessity to adopt advanced press technology capable of handling the demands of next-generation tires, such as those designed for electric vehicles (EVs) that require higher load ratings and specialized compounds. Key buyers also include specialty manufacturers focusing on aviation, mining, and agricultural tires, where curing presses must handle extremely large diameters and specialized compounds under severe operational tolerances.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650 Million |

| Market Forecast in 2033 | USD 960 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | HF Group (Harburg-Freudenberger), Kobe Steel, Mitsubishi Heavy Industries, VMI Group, Himile Science and Technology, Greatoo Intelligent Equipment, Sanming Rubber Machinery, Guilin Rubber Machinery, RUIAN SANLI RUBBER MACHINERY, Tianjin Saixiang Technology, Meccanica Fracasso, Surendra Engineering, MRP (Modern Rubber Products), Sinyang Mechanical Press Co. Ltd., Shandong Buluoze Machinery, Qingdao Doublestar Group, Simatec Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Tyre Curing Press Market Key Technology Landscape

The technology landscape of the Tyre Curing Press Market is defined by the ongoing transition from traditional hydraulic systems to advanced mechanical presses, coupled with significant advancements in heating mechanisms and automation controls. Mechanical presses offer inherent benefits in terms of superior force distribution, precision alignment, and reduced energy consumption, largely because they eliminate the inefficiencies associated with hydraulic fluid power units. Modern presses utilize high-precision servo drives and sophisticated linkage systems to ensure near-perfect parallelism between mold halves, which is vital for tire uniformity and maximizing quality consistency, thereby significantly improving the Cure Uniformity Index (CUI) score of the manufactured tires.

A crucial technological development is the shift away from steam-based curing towards environmentally friendlier and more energy-efficient methods utilizing nitrogen or superheated water as the heating medium. Nitrogen curing presses, in particular, offer rapid heating and cooling cycles, contributing to shorter curing times and substantial energy savings, directly addressing the industry’s push toward sustainable manufacturing practices. Furthermore, the integration of bladder shaping technology—where the green tire is precisely shaped prior to curing—and automated dual-cavity mold systems allows for the simultaneous curing of two different tire sizes or patterns, drastically increasing production flexibility and output within the same physical footprint.

The incorporation of Industry 4.0 elements, including advanced sensors, real-time data acquisition (SCADA systems), and IoT connectivity, is now standard for leading press manufacturers. This technology enables continuous monitoring of critical parameters like mold surface temperature, bladder pressure, and ram velocity. This collected data facilitates predictive maintenance, allowing operators to anticipate equipment failure and schedule repairs proactively, dramatically increasing OEE. Furthermore, advanced Human-Machine Interfaces (HMIs) and remote diagnostics capabilities are enhancing operational ease and serviceability, solidifying the trend toward fully digitized curing plants.

Regional Highlights

The global Tyre Curing Press Market exhibits distinct regional dynamics, driven by varying levels of automotive production, regulatory environments, and manufacturing maturity.

- Asia Pacific (APAC): Dominates the market owing to massive tire manufacturing hubs in China, India, and ASEAN nations. The region benefits from lower operating costs and burgeoning domestic automotive demand, driving sustained capital investment in new tire plants and capacity expansions. APAC is both a major consumer and producer of press equipment.

- Europe: Characterized by high technological adoption and replacement demand. European manufacturers focus heavily on high-specification presses capable of handling premium, ultra-high-performance (UHP) and EV tires, driven by stringent EU regulations concerning safety and rolling resistance. Emphasis is placed on energy efficiency and automation.

- North America: A mature market focused on replacing legacy equipment with advanced mechanical and hot water curing presses. Demand is strongly correlated with the production of light trucks, SUVs, and commercial vehicle tires. Adoption of digital twin technology for process simulation is high.

- Latin America (LATAM): Exhibits moderate growth, primarily driven by replacement demand and moderate expansion in countries like Brazil and Mexico, which serve as regional manufacturing hubs for international tire companies. Price sensitivity remains a key factor in equipment procurement decisions.

- Middle East and Africa (MEA): Represents an emerging market with gradual investment in new tire production facilities, supported by infrastructure development and government initiatives aimed at establishing regional manufacturing independence. Growth is localized and generally focused on standard radial tire production capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Tyre Curing Press Market.- HF Group (Harburg-Freudenberger)

- Kobe Steel, Ltd.

- Mitsubishi Heavy Industries, Ltd.

- VMI Group

- Himile Science and Technology Co., Ltd.

- Greatoo Intelligent Equipment Inc.

- Sanming Rubber Machinery Co., Ltd.

- Guilin Rubber Machinery Co., Ltd.

- RUIAN SANLI RUBBER MACHINERY Co., Ltd.

- Tianjin Saixiang Technology Co., Ltd.

- Meccanica Fracasso S.r.l.

- Surendra Engineering Co. Pvt. Ltd.

- MRP (Modern Rubber Products)

- Sinyang Mechanical Press Co. Ltd.

- Shandong Buluoze Machinery Co., Ltd.

- Qingdao Doublestar Group Co., Ltd.

- Simatec Group

- L&T Rubber Processing Machinery (Larsen & Toubro)

Frequently Asked Questions

Analyze common user questions about the Tyre Curing Press market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between hydraulic and mechanical curing presses?

Hydraulic presses use fluid power to close the mold and apply curing force, offering high flexibility and control over large forces, but often consuming more energy. Mechanical presses utilize servo motors and linkage systems, providing superior precision, faster cycle times, and significantly higher energy efficiency, making them the preferred choice for high-volume radial tire production today.

How is the growth of the electric vehicle (EV) sector affecting the demand for curing presses?

The EV sector necessitates specialized curing presses capable of handling larger, heavier tires designed for higher torque and heavier battery packs. These tires require specific compound characteristics and precise curing parameters, driving demand for advanced, highly automated presses with enhanced temperature and pressure uniformity controls.

Which segment of the Tyre Curing Press Market is anticipated to grow the fastest?

The Mechanical Curing Press segment is projected to exhibit the highest Compound Annual Growth Rate (CAGR). This acceleration is driven by the industry’s push for increased automation, reduced operational costs, and the superior quality consistency achieved by mechanical systems compared to older hydraulic counterparts.

What role does Industry 4.0 play in modern tyre curing technology?

Industry 4.0 integrates advanced IoT sensors, real-time diagnostics, cloud connectivity, and sophisticated control systems (SCADA) into curing presses. This enables predictive maintenance, real-time process optimization, remote monitoring, and data-driven quality adjustments, maximizing OEE and minimizing production defects.

What are the main regional drivers for market growth in Asia Pacific (APAC)?

APAC growth is fueled by robust demand from emerging economies for vehicle tires, extensive capital investment in establishing new greenfield tire manufacturing plants, and favorable government policies supporting localization of automotive and industrial production, making it the largest market both for consumption and manufacturing capacity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager