Underwater Pelletizing Systems Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441890 | Date : Feb, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Underwater Pelletizing Systems Market Size

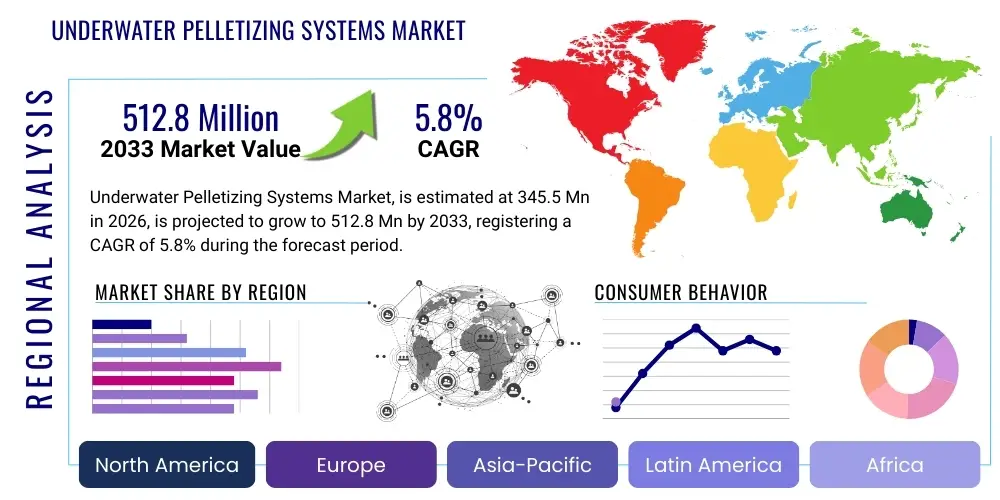

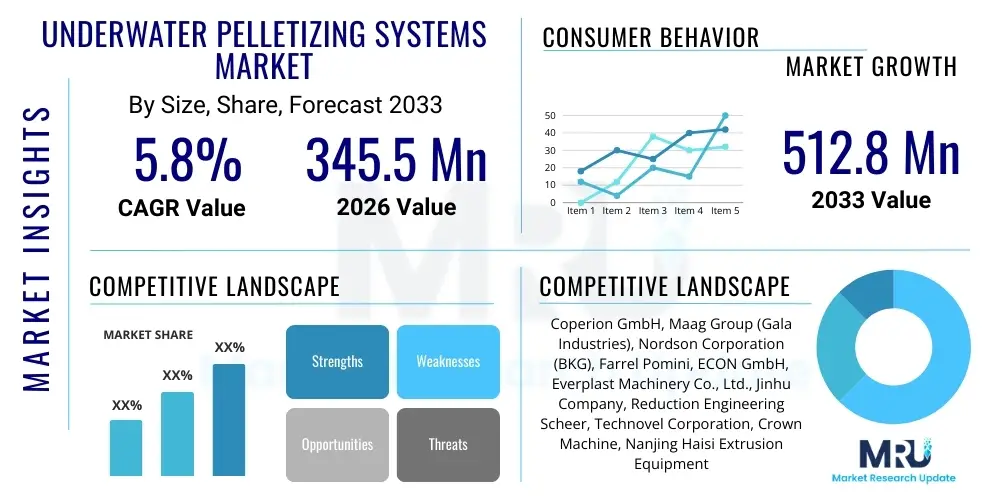

The Underwater Pelletizing Systems Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 345.5 Million in 2026 and is projected to reach USD 512.8 Million by the end of the forecast period in 2033. This substantial expansion is primarily driven by the increasing global demand for high-quality polymer pellets used across critical industries such as automotive, packaging, and construction. Efficiency improvements, coupled with stringent quality standards for thermoplastic materials, are compelling manufacturers to adopt advanced pelletizing technologies that ensure uniform size, shape, and moisture content, positioning underwater systems as the preferred method for high-throughput polymer processing.

Underwater Pelletizing Systems Market introduction

The Underwater Pelletizing Systems Market encompasses specialized machinery designed to convert molten polymers into uniform, solid pellets through a highly controlled process involving underwater cutting and cooling. This advanced technology is crucial in the polymer manufacturing and compounding industry, handling a diverse range of materials including thermoplastics, engineering plastics, and bio-polymers. The system fundamentally operates by extruding the molten polymer through a die plate, where it is immediately cut by rotating blades submerged in tempered water. This instantaneous cooling and cutting process ensures spherical, dust-free pellets with superior bulk density and consistency, attributes highly valued in downstream manufacturing processes such as injection molding and extrusion.

Major applications of these systems are concentrated in large-scale polymer production facilities, compounding operations customizing material properties, and recycling plants focused on high-quality recovered materials. Specifically, they are indispensable for handling sticky or low-viscosity polymers like polyethylene (PE), polypropylene (PP), and thermoplastic elastomers (TPEs), where air-cooling or traditional strand pelletizers often fail to maintain pellet quality or cause material fusion. The primary benefit derived from these systems is the ability to achieve exceptional pellet uniformity, rapid cooling, and dust minimization, leading to higher product yield and reduced operational complexity in material handling. Furthermore, the compact footprint of underwater pelletizers compared to strand systems makes them appealing for modern production environments prioritizing spatial efficiency.

Driving factors for market growth include the robust expansion of the global plastics industry, particularly in Asia Pacific, coupled with a consistent shift towards high-performance engineering plastics that necessitate precise processing. Regulatory mandates promoting circular economy models and encouraging high-grade plastic recycling also favor underwater systems, as they are highly effective at processing recycled and contaminated feeds while maintaining pellet integrity. Technological advancements focused on automation, improved die plate heating, and optimized water filtration circuits are further enhancing the efficiency and reliability of these systems, thereby accelerating their adoption across established and emerging industrial economies.

Underwater Pelletizing Systems Market Executive Summary

The global Underwater Pelletizing Systems Market is characterized by intense technological innovation centered on achieving higher throughput capacity, reduced energy consumption, and enhanced automation. Business trends indicate a strong focus on modular designs that allow for flexible integration into existing extrusion lines, catering specifically to compounding facilities that frequently switch between different polymer types and batch sizes. Key manufacturers are investing heavily in optimizing die plate metallurgy and cutter design to extend operational life and minimize maintenance downtime, leading to a competitive landscape dominated by specialized engineering firms offering tailored solutions for niche applications like highly filled materials or specialized bio-polymers. Geographically, market expansion is centered in the Asia Pacific region, driven by massive investments in new polymer capacity expansion and the modernization of manufacturing infrastructure in countries like China, India, and Southeast Asia. North America and Europe maintain a strong demand, particularly for high-end systems tailored for precision compounding and advanced recycling processes that demand stringent quality control.

Regional trends highlight that while APAC leads in volume deployment due to primary resin production, European and North American markets exhibit higher demand for technologically advanced, integrated systems featuring sophisticated process controls and real-time monitoring capabilities. The emphasis in developed markets is increasingly shifting towards systems capable of handling complex feedstock, including post-consumer and post-industrial recycled content (PCR/PIR), aligning with sustainability goals. Segmentation trends underscore the dominance of high-capacity systems (over 1000 kg/hr) in primary polymer production, while smaller, highly flexible systems are gaining traction in R&D and specialized compounding sectors. Furthermore, the increasing adoption of hot face cut technology, characterized by immediate cutting at the die plate exit, over traditional alternatives is a defining segmental trend, offering superior pellet consistency and throughput efficiency across the board.

Overall, the market trajectory is highly correlated with global GDP growth and the performance of end-use industries, particularly packaging and automotive, which are the largest consumers of materials processed by these systems. Sustainability initiatives are acting as a powerful long-term driver, compelling processors to upgrade older equipment with energy-efficient underwater systems that support higher levels of recycled content integration. Strategic partnerships between equipment manufacturers and resin producers are crucial for co-developing customized pelletizing solutions that address the specific processing challenges of next-generation polymers, ensuring the market remains robust and technologically progressive throughout the forecast period.

AI Impact Analysis on Underwater Pelletizing Systems Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Underwater Pelletizing Systems Market frequently revolve around optimizing process parameters, predictive maintenance capabilities, and enhancing pellet quality consistency. Common questions explore how AI algorithms can manage the delicate balance between water temperature, cutter speed, and polymer melt flow rates in real-time to maximize throughput while minimizing energy usage and material defects. Users are highly interested in the feasibility of utilizing machine learning models to predict die plate fouling or cutter wear before failure occurs, aiming to transition from time-based maintenance to condition-based predictive maintenance. Furthermore, there is significant curiosity about AI’s role in anomaly detection, specifically identifying deviations in pellet shape or size distribution instantly, thereby ensuring superior end-product quality without constant human intervention.

The convergence of AI with Industrial Internet of Things (IIoT) sensors is transforming underwater pelletizing operations from reactive processes into highly adaptive and self-optimizing systems. AI algorithms analyze vast datasets generated by pressure transducers, temperature sensors, flow meters, and video inspection systems installed within the pelletizer and cooling circuit. This data analysis allows for highly nuanced control adjustments, optimizing the cooling intensity and cutting frequency relative to the specific polymer grade being processed. Such optimized control not only enhances energy efficiency by reducing unnecessary heating or excessive cooling but also significantly improves material properties by minimizing thermal degradation and moisture absorption during the critical processing phase. This shift towards intelligent process control is expected to be a major differentiator for advanced pelletizer manufacturers.

The primary concern users express centers on the complexity and cost of implementing AI infrastructure, including the necessary computational power and the expertise required to manage and interpret complex machine learning models. However, the long-term benefits, such as reduced waste, extended equipment lifespan, and the ability to maintain uniform pellet quality even when processing variable feedstock (common in recycling), outweigh the initial investment for high-volume producers. AI integration represents the next evolutionary step in pelletizing technology, moving towards "lights-out" manufacturing where the system automatically calibrates itself based on external conditions or changes in raw material viscosity, ensuring peak operational performance 24/7 and substantially elevating the standard of production efficiency in polymer manufacturing.

- Real-time Parameter Optimization: AI algorithms adjust cutter speed, water temperature, and pressure dynamically to maximize quality and throughput.

- Predictive Maintenance: Machine learning models forecast component wear (e.g., die plates, knives) based on operational data, minimizing unplanned downtime.

- Quality Control Automation: AI-powered vision systems analyze pellet morphology for immediate defect detection and sorting.

- Energy Efficiency Management: Optimization of cooling and heating cycles based on melt flow, leading to reduced power consumption.

- Process Anomaly Detection: Immediate identification of irregularities caused by feedstock variability or equipment malfunction, ensuring stable operations.

DRO & Impact Forces Of Underwater Pelletizing Systems Market

The dynamics of the Underwater Pelletizing Systems Market are governed by a robust interplay of driving forces, inherent restraints, and emerging opportunities, collectively shaping its impact forces. The primary driver is the accelerating global demand for high-performance plastics and specialized compounds across industries like automotive, where lightweight materials are crucial for fuel efficiency, and packaging, necessitating high barrier properties. Opportunities are largely dictated by the transition to a circular economy, as these systems excel in handling complex recycled materials, offering pathways for enhanced sustainability and resource efficiency. However, the market faces restraints primarily related to the high capital investment required for these sophisticated systems and the operational complexity involved in managing the intricate water circuit and die plate maintenance, particularly for smaller compounding operations.

Driving Forces (D): The market is strongly propelled by the need for superior pellet quality, especially in processes involving high filler concentrations (e.g., mineral-filled compounds) or those requiring ultra-low moisture content, which underwater systems effectively address through rapid and uniform cooling. The expansion of virgin polymer production capacity, particularly in the APAC region, provides a fundamental demand base. Furthermore, the growth of the thermoplastic elastomer (TPE) sector, requiring specialized pelletizing techniques due to material stickiness, significantly boosts the adoption of underwater technology over traditional alternatives. The continuous drive towards automation and integration into larger extrusion lines also favors these modern systems, which often come equipped with sophisticated control interfaces and connectivity features essential for Industry 4.0 environments.

Restraints (R): Significant restraints include the high initial purchasing cost of underwater pelletizing lines compared to simpler strand or air-ring systems, acting as a barrier to entry for smaller-scale manufacturers. Operational challenges such as managing water filtration and temperature control—critical to preventing pellet agglomeration and ensuring quality—require specialized expertise and continuous monitoring. Maintenance of the cutting knives and die plate, which are subjected to high wear, contributes significantly to operational expenditure. Additionally, the inherent power consumption of the complex pumping and cooling systems presents a financial hurdle, although technological improvements are gradually mitigating this concern through energy recovery solutions and more efficient component designs.

Opportunities (O): Key opportunities stem from the burgeoning plastic recycling industry, where underwater pelletizers are indispensable for high-throughput reprocessing of difficult-to-handle recycled resins (e.g., flexible films or highly contaminated feedstock). The development of sustainable bio-polymers and compostable materials, which often require delicate processing conditions that are best managed by controlled underwater cutting, opens up new market niches. Furthermore, geographical expansion into emerging economies undergoing rapid industrialization provides significant growth avenues. The opportunity to integrate advanced sensor technologies and AI for enhanced diagnostics and optimization represents a substantial long-term growth trajectory for manufacturers of these high-tech systems.

Impact Forces: The combined effect of these factors creates significant impact forces. The high capital cost (Restraint) is partially offset by the superior product quality (Driver) and the ability to process high-value, specialized compounds (Opportunity), making the total cost of ownership acceptable for high-volume producers. The dominant impact force is the regulatory pressure for sustainable plastic management, compelling the industry to invest in high-efficiency recycling equipment, thereby positioning underwater pelletizers as mission-critical assets. The necessity for precise, high-volume production of specialty compounds reinforces the demand for these technologically advanced systems, ultimately accelerating market value growth despite cost constraints.

Segmentation Analysis

The Underwater Pelletizing Systems Market is comprehensively segmented based on System Type, Capacity, Polymer Type, and Application, reflecting the diverse requirements of the polymer processing industry. This segmentation is crucial for understanding specific market dynamics, technological preferences, and procurement trends across various end-user segments. System Type segmentation differentiates between established hot face cut systems, which dominate the market due to their efficiency and versatility, and specialized cold cut or hybrid systems used for unique applications. Capacity segmentation is fundamental, distinguishing between high-throughput lines crucial for primary resin manufacturers and low-to-medium capacity systems utilized by compounders and R&D labs. The polymer type processed, ranging from high-volume polyolefins to specialized engineered plastics and elastomers, dictates the necessary equipment specifications, particularly regarding die plate design and materials of construction.

The Application segment highlights the varied end-use sectors, with compounding being the largest user base, followed by virgin polymer production, and increasingly, plastic recycling. Compounding facilities rely heavily on underwater systems to incorporate fillers, additives, and colorants precisely, demanding robust systems capable of handling abrasive or highly viscous melts. In the recycling sector, the ability of underwater pelletizers to produce highly uniform pellets from diverse waste streams is a key driver for adoption. Analyzing these segments reveals that while volume growth is driven by commodity plastics capacity expansion, value growth is increasingly concentrated in advanced compounding and the burgeoning recycling sector, which demands higher-specification, durable equipment capable of complex melt handling.

Strategic analysis of these segmentations enables market players to tailor their product portfolios and go-to-market strategies. For instance, focusing on the high-capacity segment in the Asia Pacific region targets primary resin producers requiring maximum output and minimal downtime. Conversely, targeting the low-to-medium capacity segment in Europe and North America focuses on specialized compounders and masterbatch producers who prioritize flexibility, rapid material changeover, and stringent quality control protocols. The continuous evolution of polymer chemistry, particularly the introduction of new bio-plastics and complex polymer blends, ensures that demand for highly specialized and adaptable underwater pelletizing solutions remains consistently high across all major market segments.

- System Type:

- Hot Face Underwater Pelletizers (Dominant)

- Peripheral Underwater Pelletizers

- Eccentric Underwater Pelletizers (Used for specific applications)

- Capacity:

- Low Capacity (<500 kg/hr)

- Medium Capacity (500-1000 kg/hr)

- High Capacity (>1000 kg/hr)

- Polymer Type:

- Polyolefins (PE, PP)

- Engineered Plastics (PA, PC, PET, PBT)

- Thermoplastic Elastomers (TPEs, TPUs)

- Bio-polymers and Composites

- Application:

- Virgin Polymer Production

- Compounding

- Masterbatch Production

- Recycling (Post-Consumer and Post-Industrial)

Value Chain Analysis For Underwater Pelletizing Systems Market

The value chain for the Underwater Pelletizing Systems Market begins with upstream raw material suppliers, predominantly specialized metal component manufacturers providing corrosion-resistant materials for die plates, cutting knives, and cooling tank components, alongside suppliers of precision control systems and industrial pumps. Upstream efficiency and material quality are critical, as the performance and lifespan of the pelletizer heavily depend on the durability of components exposed to high heat, pressure, and potentially abrasive materials. Key upstream activities involve advanced metallurgy and the production of highly engineered components like specialized valves and filtration units necessary for the complex water circuit management. Strategic alliances with these component providers ensure a stable supply of high-quality, durable parts, crucial for maintaining the operational reliability of high-throughput systems.

Midstream activities involve the core functions of research, design, manufacturing, and assembly of the pelletizing systems by Original Equipment Manufacturers (OEMs). This stage focuses on technological innovation, including optimizing the hydrodynamic design of the cutting chamber, developing proprietary die plate heating systems, and integrating sophisticated process control software. Distribution channels are typically a mix of direct sales and indirect channels. Direct sales are favored for large, custom-engineered, high-capacity systems sold to global polymer producers, allowing for closer technical consultation and integration support. Indirect channels, involving regional distributors and agents, are often used for standard or medium-capacity systems, leveraging local expertise for installation, servicing, and spare parts supply in diverse geographical markets.

Downstream, the market is defined by the end-users: primary resin manufacturers, custom compounders, masterbatch producers, and recycling operations. These buyers utilize the systems to produce final pelletized material which then feeds secondary manufacturing processes (e.g., injection molding, blown film extrusion). The quality and consistency of the pellets are paramount to the downstream manufacturing success, placing high value on reliable and precise pelletizing technology. Post-sales support, including maintenance contracts, rapid spare part delivery, and technical training, forms a critical part of the downstream value proposition, ensuring high operational uptime for these capital-intensive processing lines.

Underwater Pelletizing Systems Market Potential Customers

Potential customers for Underwater Pelletizing Systems are diverse, primarily spanning the chemical and plastics processing industries, where material conversion and preparation are essential steps. The largest segment of end-users consists of major global chemical companies and large-scale polymer producers (e.g., polyolefin manufacturers) who require high-capacity, continuous systems for converting their molten resin output into transportable and manageable pellets. These facilities prioritize maximum throughput, operational robustness, and seamless integration into their entire production complex, viewing the pelletizer as a critical bottleneck component that must not fail. The procurement decision in this segment is highly technical, focusing on proven reliability and minimal specific energy consumption per kilogram of output.

A second crucial customer segment comprises custom compounders and specialty plastics manufacturers. These companies modify base resins by incorporating reinforcing agents, flame retardants, or specialty additives to create customized materials tailored for demanding applications (e.g., automotive interior parts, medical devices). For compounders, flexibility, rapid material changeover capabilities, and the system’s ability to handle highly filled or abrasive melts without excessive wear are key purchasing criteria. They often require medium-capacity, highly flexible systems that can process a wide variety of polymer chemistries efficiently, minimizing contamination risks between batches.

The rapidly growing recycling sector forms a third, increasingly significant customer base. Facilities focused on chemical recycling or mechanical recycling of post-consumer and post-industrial waste (PCR/PIR) rely on underwater systems to homogenize and re-pelletize the recovered materials, often dealing with inconsistent and complex feedstocks. These customers seek durable, robust systems optimized for high moisture tolerance and capable of producing high-quality pellets from inherently variable material streams, enabling the recycled content to meet the stringent quality standards required for brand owner applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 345.5 Million |

| Market Forecast in 2033 | USD 512.8 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Coperion GmbH, Maag Group (Gala Industries), Nordson Corporation (BKG), Farrel Pomini, ECON GmbH, Everplast Machinery Co., Ltd., Jinhu Company, Reduction Engineering Scheer, Technovel Corporation, Crown Machine, Nanjing Haisi Extrusion Equipment Co., Ltd., Wuxi Jinyi Extrusion Machinery Co., Ltd., Kawata Mfg. Co., Ltd., Qingdao Hegu Wood-Plastic Machinery Co., Ltd., Hangzhou Shuangda Plastic Machinery Co., Ltd., GMT-Maschinenbau, Jiangsu Nanji Machinery Co., Ltd., Lianshuo Machinery Co., Ltd., Shandong Tongjia Machinery Co., Ltd., Suzhou Polytime Machinery Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Underwater Pelletizing Systems Market Key Technology Landscape

The technological landscape of the Underwater Pelletizing Systems Market is defined by continuous innovation focused on optimizing the critical interface between the die plate, the molten polymer, and the submerged cutting knives. The core technology centers around the Hot Face Cut method, where the polymer melt is extruded through the die and immediately cut while still molten against the face of the die plate, which is kept consistently hot. Technological advancements in this area focus heavily on improving the die plate design, incorporating advanced thermal management systems (often utilizing electrical cartridge heaters or external fluid heating) to ensure precise and uniform temperature profiles across the die face, which is vital for preventing freeze-off and maintaining pellet consistency, particularly for temperature-sensitive polymers.

A significant trend involves the development of specialized cutter hub and knife designs. Modern systems utilize advanced, wear-resistant materials like carbide inserts for cutting blades to extend the operational lifespan, especially when processing abrasive materials such as glass-filled or highly mineral-filled compounds common in engineering plastics. Furthermore, pneumatic or hydraulic pressure systems for adjusting the knife pressure against the die face have become standard, allowing for real-time calibration and automatic compensation for wear, thereby maximizing the uniformity of the spherical pellets. This precision in cutter engagement minimizes dust generation and reduces energy consumption associated with excessive friction, enhancing both product quality and operational efficiency across high-capacity lines.

Beyond the cutting mechanism, critical auxiliary technology components are rapidly evolving. The water management system, including sophisticated filtration, cooling, and circulating units, is fundamental. Advanced water systems now feature multi-stage filtration (e.g., sieve filters, hydrocyclones) to ensure water clarity and prevent fines or debris from contaminating the pellets or recirculating into the die plate, potentially causing blockages or surface defects. Furthermore, the integration of specialized drying technology, such as high-efficiency centrifugal dryers and subsequent vibratory screens, ensures the final pellets have minimal residual moisture, a prerequisite for many downstream molding processes, thus completing the technological advancement cycle from melt to final dry product packaging.

Regional Highlights

The regional dynamics of the Underwater Pelletizing Systems Market exhibit substantial variation based on industrial maturity, regulatory environment, and the concentration of polymer manufacturing capabilities. Asia Pacific (APAC) dominates the global market in terms of installed capacity and production volume, primarily driven by China and India, which are hubs for both virgin polymer resin manufacturing and rapid expansion in compounding and recycling infrastructure. The demand here is characterized by the need for high-throughput, reliable systems to support massive petrochemical production sites and meet the surging material requirements of local manufacturing sectors, including automotive and electronics. Government support for industrial expansion and relatively lower operational costs continue to attract significant investment in advanced polymer processing machinery, positioning APAC as the engine of quantitative market growth.

Europe and North America represent mature markets distinguished by a strong emphasis on high-value, specialized compounding and stringent environmental regulations favoring advanced recycling technologies. These regions are leaders in the adoption of technically sophisticated pelletizing systems featuring advanced automation, process visualization, and energy recovery solutions. European regulations, particularly those promoting circular economy models, create sustained demand for underwater pelletizers capable of efficiently reprocessing post-consumer plastics into high-quality secondary raw materials. The regional market focus is less on volume expansion and more on technological optimization, material diversification (e.g., complex engineering plastics, bio-polymers), and reducing the environmental footprint of polymer processing operations. North America, influenced by the robust automotive sector and the need for specialty compounds, demonstrates consistent investment in modernizing existing lines with highly flexible and precise equipment.

Latin America and the Middle East & Africa (MEA) are emerging markets showing promising growth, albeit from a smaller base. In MEA, investments are strongly linked to the expansion of petrochemical industries, particularly in the Gulf Cooperation Council (GCC) countries which are focused on diversifying their downstream production capabilities and becoming global exporters of specialized polymer products. This region demands high-capacity systems for primary resin production. Latin America’s growth is more localized, driven by packaging and construction sector demand, leading to increasing adoption of medium-capacity systems for compounding and recycling activities. Overall, while global demand remains strong, the strategic focus shifts regionally: high-volume capacity in APAC and MEA, and high-specification, sustainable technology deployment in Europe and North America.

- Asia Pacific (APAC): Leading market share due to large-scale virgin polymer production expansion in China, India, and Southeast Asia. Characterized by high-volume capacity demand and rapid technological adoption in localized compounding centers.

- Europe: High demand for advanced, highly automated systems driven by stringent recycling targets and specialization in high-performance engineering plastics and bio-polymers. Focus on energy efficiency and low-downtime operation.

- North America: Stable market driven by robust automotive and construction sectors demanding specialized compounds. Strong focus on integrating AI/IIoT for operational efficiency and embracing domestic recycling capacity build-out.

- Middle East & Africa (MEA): Emerging growth tied to the expansion of regional petrochemical industries diversifying into downstream processing and polymer conversion, driving demand for new, high-capacity installations.

- Latin America: Growing market spurred by local manufacturing needs, particularly in packaging and construction materials, resulting in steady demand for reliable, mid-range pelletizing solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Underwater Pelletizing Systems Market.- Coperion GmbH

- Maag Group (Gala Industries)

- Nordson Corporation (BKG)

- Farrel Pomini

- ECON GmbH

- Reduction Engineering Scheer

- Technovel Corporation

- Everplast Machinery Co., Ltd.

- Jinhu Company

- Crown Machine

- Kawata Mfg. Co., Ltd.

- Nanjing Haisi Extrusion Equipment Co., Ltd.

- Wuxi Jinyi Extrusion Machinery Co., Ltd.

- Qingdao Hegu Wood-Plastic Machinery Co., Ltd.

- Hangzhou Shuangda Plastic Machinery Co., Ltd.

- GMT-Maschinenbau

- Jiangsu Nanji Machinery Co., Ltd.

- Lianshuo Machinery Co., Ltd.

- Shandong Tongjia Machinery Co., Ltd.

- Suzhou Polytime Machinery Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Underwater Pelletizing Systems market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of underwater pelletizing over strand pelletizing?

Underwater pelletizing offers superior pellet shape uniformity (spherical), significantly reduces dust and fines generation, and provides immediate, controlled cooling, which is crucial for processing low-viscosity or sticky materials like TPEs and certain polyolefins, leading to higher product quality and bulk density.

Which polymer types are best suited for processing using underwater pelletizing systems?

Underwater pelletizers are optimally suited for a wide range of thermoplastic materials, including high-volume polyolefins (PE, PP), complex engineering plastics (PA, PET, PC), and thermoplastic elastomers (TPEs, TPUs). They are essential for materials that tend to clump or deform when cooled via traditional air or strand methods.

How does the integration of Industry 4.0 technologies affect underwater pelletizer operations?

Industry 4.0 integration, leveraging IIoT sensors and AI, enables predictive maintenance, real-time optimization of cutter speed and water temperature, and remote diagnostics. This leads to reduced downtime, optimized energy use, and enhanced consistency in final pellet quality across continuous production cycles.

What is the typical lifespan and maintenance requirement for the die plate and cutting knives?

The lifespan of die plates and cutting knives varies significantly based on the processed material; abrasive compounds (e.g., highly filled plastics) cause faster wear. Maintenance involves regular inspection, precise knife pressure adjustments, and periodic replacement of carbide-tipped knives, usually every few weeks or months, depending on throughput and material hardness.

What impact does the growth of plastic recycling have on the demand for underwater pelletizing systems?

The plastic recycling sector is a major growth driver. Underwater systems are highly effective at processing varied and often contaminated recycled feedstock (PCR/PIR), converting it into uniform, high-quality pellets suitable for reintroduction into high-specification manufacturing, thereby directly supporting circular economy goals.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager