Vaccine Refrigerators Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441949 | Date : Feb, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Vaccine Refrigerators Market Size

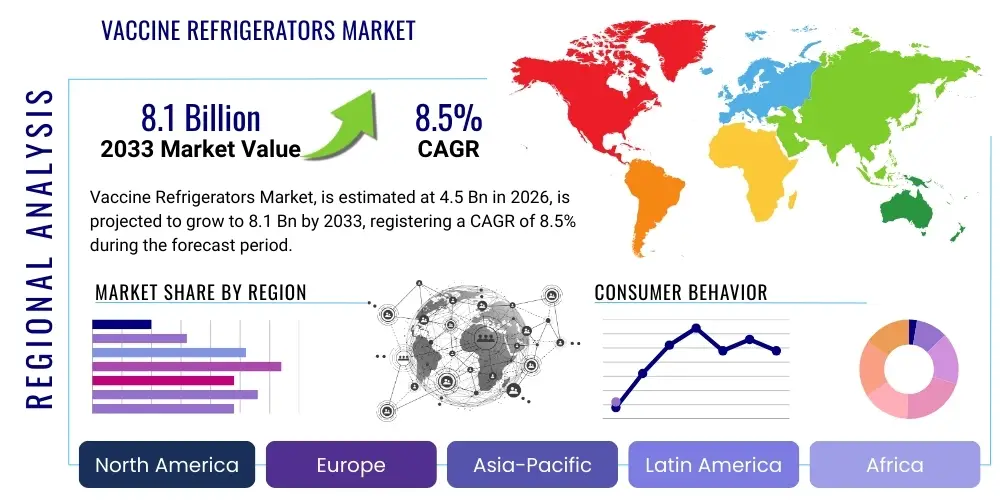

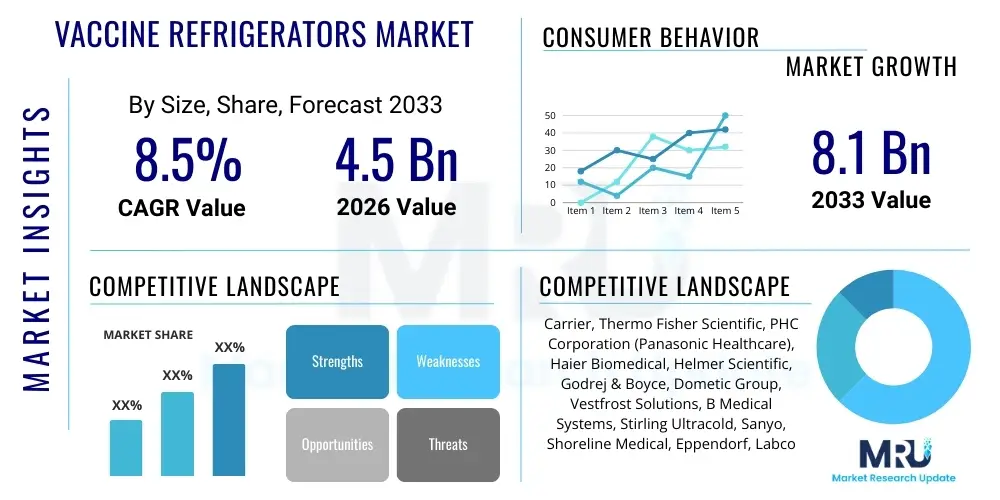

The Vaccine Refrigerators Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 8.1 Billion by the end of the forecast period in 2033.

Vaccine Refrigerators Market introduction

The Vaccine Refrigerators Market encompasses specialized cold chain equipment essential for maintaining the viability and efficacy of vaccines, biological samples, and other temperature-sensitive pharmaceutical products. These refrigeration systems are meticulously engineered to provide precise temperature control, typically within the critical range of 2°C to 8°C, or significantly lower for ultra-low temperature (ULT) requirements, often reaching -80°C. The fundamental design considerations include superior insulation, highly reliable cooling mechanisms, redundant safety features, and stringent adherence to global regulatory standards such as those mandated by the World Health Organization (WHO) and regional regulatory bodies. The importance of these devices escalated dramatically following global immunization initiatives, particularly the distribution of temperature-sensitive mRNA vaccines, necessitating advanced cold chain infrastructure capable of maintaining consistent and verified temperatures across diverse geographical and logistical environments. This market segment is crucial for public health infrastructure worldwide.

Product descriptions within this market vary significantly, ranging from small, portable refrigerators utilized in mobile vaccination clinics or remote areas to large, fixed-site pharmaceutical-grade units used in central storage facilities and hospitals. Key features increasingly incorporated include digital monitoring systems, alarm functions for temperature deviations, battery backup systems for power failures, and data logging capabilities to ensure regulatory compliance and traceability throughout the distribution lifecycle. Major applications span prophylactic vaccination programs, research and development involving biological material storage, blood banking, and general pharmaceutical storage in clinical settings. The reliability and accuracy of temperature maintenance directly correlate with patient safety and public health outcomes, making technological innovation in energy efficiency and temperature consistency paramount for manufacturers operating in this domain.

The primary driving factors propelling the market expansion include the sustained growth in global immunization coverage, driven by government initiatives and the increasing prevalence of infectious diseases demanding extensive vaccination campaigns. Furthermore, the rising complexity of new vaccine formulations, many of which require ultra-low temperature storage (e.g., specific COVID-19 vaccines), fuels demand for technologically advanced and robust ULT freezers. Technological advancements, such as the integration of Internet of Things (IoT) sensors for real-time monitoring and predictive maintenance capabilities, enhance operational security and efficiency across the cold chain. These advancements, coupled with stringent regulatory mandates concerning vaccine storage protocols, incentivize healthcare providers and logistics companies to upgrade existing outdated equipment to compliant, high-performance refrigeration solutions, thereby sustaining the robust growth trajectory of the Vaccine Refrigerators Market.

Vaccine Refrigerators Market Executive Summary

The Vaccine Refrigerators Market is experiencing significant dynamic shifts characterized by heightened investment in pharmaceutical cold chain logistics and a transition towards smart, energy-efficient refrigeration technologies. Business trends are dominated by strategic partnerships between equipment manufacturers and logistics providers to offer end-to-end cold chain solutions, especially in emerging economies where infrastructure gaps persist. Furthermore, companies are prioritizing product differentiation through superior temperature uniformity, lower energy consumption (critical for off-grid applications like solar-powered units), and integrated compliance features such as automated data logging and validation protocols. The competitive landscape is becoming increasingly focused on providing tailored solutions, ranging from high-capacity centralized storage facilities to lightweight, durable solutions for last-mile delivery. Sustainability initiatives are also influencing business decisions, pushing manufacturers to adopt natural refrigerants and modular designs that reduce environmental impact and improve long-term operational costs.

Regionally, the market growth is bifurcated, with developed regions like North America and Europe demonstrating strong demand for advanced, ultra-low temperature freezers due to intensive R&D activities and high regulatory compliance standards. Conversely, the Asia Pacific (APAC) and Middle East & Africa (MEA) regions are the fastest-growing markets, driven primarily by mass immunization programs, expansion of healthcare access into rural areas, and substantial public sector investment in strengthening national immunization supply chains (NIS). Governments and NGOs in these regions show a preference for ice-lined refrigerators (ILRs) and solar direct drive (SDD) systems, which offer reliable cooling in areas with unstable or non-existent power grids. Latin America is also showing robust growth, particularly in urban centers where modern hospital infrastructure requires high-precision pharmaceutical storage units, moving away from conventional commercial refrigeration towards dedicated medical-grade solutions.

Segment trends reveal a strong shift toward Ultra-Low Temperature (ULT) freezers, reflecting the complexity of modern biological medicines and vaccines. While standard 2°C to 8°C refrigerators remain foundational, the demand for equipment capable of operating below -40°C has surged, directly influencing product development cycles. Another significant trend is the rise of IoT-enabled refrigerators within the monitoring segment, facilitating remote temperature verification, predictive maintenance scheduling, and immediate alert notification to prevent catastrophic cold chain breaches. End-user trends show hospitals and large vaccination centers remaining the core consumers, but pharmaceutical companies and specialized logistics providers are increasingly investing in proprietary cold storage assets to maintain control and quality assurance over their high-value products until the point of administration. This emphasis on stringent monitoring and specialized temperature profiles is reshaping overall market investment priorities.

AI Impact Analysis on Vaccine Refrigerators Market

Analysis of common user questions reveals significant interest regarding how Artificial Intelligence (AI) can enhance the reliability and efficiency of vaccine cold chain management. Key user themes center around predictive failure detection—asking if AI can forecast equipment breakdowns before they occur—and optimization of large-scale vaccine distribution logistics. Concerns are often raised about the cost of integrating AI tools into existing legacy refrigeration infrastructure and the cybersecurity risks associated with networked, smart cold storage units. Users express high expectations for AI’s ability to minimize temperature excursions, thereby reducing vaccine spoilage and ensuring optimal inventory management across decentralized storage locations. The overarching query is how AI transcends simple data logging to provide actionable, real-time intelligence that strengthens the integrity of the fragile cold chain.

AI is beginning to revolutionize the vaccine refrigerator market primarily through sophisticated data analysis models applied to sensor data. By continuously monitoring parameters such as compressor cycles, interior and exterior temperatures, door opening frequency, and power consumption, AI algorithms can establish baseline operational norms. Any subtle deviation from these norms, even before standard alarm thresholds are breached, can be flagged by the AI system as an indicator of potential mechanical failure, allowing maintenance teams to intervene proactively. This transition from reactive repair to predictive maintenance drastically reduces the risk of equipment failure and subsequent high-value vaccine loss, offering significant cost savings and compliance benefits to healthcare organizations and public health bodies.

Furthermore, AI plays a pivotal role in optimizing energy efficiency, a critical factor, particularly for regions relying on intermittent power sources or solar power. AI models can learn usage patterns and environmental conditions to dynamically adjust cooling cycles, minimizing electricity consumption while rigorously maintaining the required temperature profile. In large distribution networks, AI algorithms are used for logistics optimization, determining the optimal placement and inventory levels for refrigerators based on predicted vaccination demand, population density, and logistical constraints. This holistic application of AI transforms the vaccine cold chain from a passive storage system into an intelligent, self-optimizing network, significantly improving global access to viable vaccines and ensuring greater public health security.

- AI enables predictive maintenance by analyzing sensor data to forecast potential component failures, ensuring proactive service intervention.

- Optimizes energy consumption by dynamically adjusting cooling cycles based on real-time operational data and external environmental factors.

- Enhances inventory management across distributed networks by using machine learning for demand forecasting and optimal stock placement.

- Improves cold chain integrity through sophisticated anomaly detection, identifying temperature deviations faster than static alarm systems.

- Streamlines regulatory compliance by automating data verification and generating comprehensive audit trails based on continuous operational monitoring.

DRO & Impact Forces Of Vaccine Refrigerators Market

The dynamics of the Vaccine Refrigerators Market are predominantly shaped by robust public health mandates and significant technological pressure to enhance reliability and sustainability. The primary drivers include the escalating global birth rates and associated mandatory infant immunization schedules, coupled with the increasing necessity for adult booster shots and seasonal vaccinations, such as influenza. Furthermore, the global readiness required to combat potential future pandemics, emphasizing decentralized, highly reliable cold storage capacity, continues to spur substantial investment from governments and multilateral organizations like the WHO and GAVI. Restraints mainly center on the high initial capital expenditure associated with purchasing sophisticated, pharmaceutical-grade refrigeration units, especially ultra-low temperature freezers, and the logistical challenges inherent in deploying, maintaining, and providing stable power to these units in remote, underserved areas of developing countries. These financial and infrastructural hurdles often slow the rate of market penetration in critical areas.

Opportunities for market expansion are abundant, particularly in the realm of advanced technology and sustainable solutions. The shift towards solar-powered vaccine refrigerators (Solar Direct Drive or SDD systems) presents a massive opportunity to circumvent unstable electrical infrastructure in Africa and parts of Asia, simultaneously addressing sustainability goals. There is a burgeoning market for intelligent, IoT-enabled systems that offer advanced data logging, remote diagnostics, and improved compliance assurance, meeting the stringent quality control requirements of pharmaceutical companies. Furthermore, the growing pharmaceutical R&D sector necessitates robust storage solutions for clinical trials and novel drug components, driving demand for specialized cryogenic and ULT storage beyond vaccine applications. Developing cost-effective, easily maintainable, and highly durable systems designed specifically for harsh environmental conditions represents a key area of growth and differentiation for manufacturers.

The market is impacted by several potent forces, including high regulatory stringency and continuous pressure for operational efficiency. Impact forces are derived from the critical nature of the stored products; any failure can lead to massive financial loss and severe public health risks, placing intense pressure on manufacturers to guarantee near-perfect reliability and redundancy. Competition is fierce, focusing on energy efficiency and compliance certifications (e.g., WHO PQS). The shift toward environmentally friendly refrigerants (such as R600a and R290) in response to global environmental agreements acts as a major external force driving redesign and innovation across product lines. Lastly, geopolitical factors, including trade restrictions and global supply chain disruptions, significantly impact the availability and cost of key components, affecting manufacturing scalability and overall market pricing stability. Manufacturers must navigate this complex interplay of public health demands, technological innovation, and regulatory compliance to maintain a competitive edge and ensure market relevance.

Segmentation Analysis

The Vaccine Refrigerators Market segmentation provides a granular view of diverse product offerings tailored to specific temperature requirements, logistical constraints, and end-user operational needs. Segmentation is primarily based on Product Type, which defines the cooling mechanism and temperature range; End-User, which determines the scale and regulatory environment of deployment; and Temperature Range, which is critical for vaccine viability. This detailed categorization allows manufacturers to target their R&D efforts and marketing strategies effectively, addressing distinct market demands, such as the need for rugged, high-capacity storage versus portable, battery-operated units for mobile health services. Understanding these segments is vital for tracking differential growth rates and assessing the impact of new technologies like solar power integration.

The Product Type segment is dynamic, encompassing Ice-Lined Refrigerators (ILRs), which use frozen water packs to maintain temperature stability during power outages; Solar Direct Drive (SDD) units, which utilize solar power for autonomous operation; and conventional electric compression refrigerators, including specialized Ultra-Low Temperature (ULT) freezers necessary for highly sensitive vaccines. ILRs and SDD units dominate procurement strategies in developing regions due to their resilience and low operational dependency on grid electricity. Conversely, sophisticated hospitals and research centers in developed markets drive the demand for electronically controlled, pharmaceutical-grade upright and chest freezers offering precise digital control and monitoring capabilities crucial for clinical compliance and research integrity.

The End-User analysis reveals that institutional buyers, primarily public and private hospitals, major pharmaceutical distributors, and government vaccination centers, constitute the largest share of the market due to the sheer volume of vaccines they handle. However, smaller clinics, community pharmacies, and specialized blood banks represent rapidly growing segments, increasingly upgrading from general-purpose cooling equipment to certified medical-grade refrigerators to minimize liability and comply with tightening regulatory guidelines. The differentiation in segment growth highlights the dual focus of the market: high-volume, precision storage in urban centers, and resilient, infrastructure-independent solutions for peripheral healthcare services, ensuring that the cold chain is robust and accessible globally.

- By Product Type:

- Ice-Lined Refrigerators (ILR)

- Solar Direct Drive (SDD) Refrigerators

- Compressor-Based Refrigerators (Electric)

- Ultra-Low Temperature (ULT) Freezers (-40°C to -86°C)

- Cryogenic Storage Equipment (Below -150°C)

- Portable/Transport Refrigerators and Coolers

- By Temperature Range:

- 2°C to 8°C (Standard Vaccine Storage)

- -20°C to -40°C (Deep Freezing)

- Below -40°C (Ultra-Low Temperature)

- By Storage Capacity:

- Under 50 Liters

- 50 Litters – 200 Liters

- Above 200 Liters

- By End-User:

- Hospitals and Clinics

- Blood Banks

- Research Laboratories and Universities

- Pharmaceutical and Biotechnology Companies

- Retail Pharmacies

- Government Agencies/Public Health Organizations

Value Chain Analysis For Vaccine Refrigerators Market

The value chain for the Vaccine Refrigerators Market is characterized by a high degree of specialization and stringent quality control at every stage, reflecting the critical nature of the final product’s function. Upstream activities involve the sourcing of specialized components, including highly efficient compressors (often variable speed drives), advanced insulation materials (such as vacuum insulated panels or polyurethane foam), precise digital temperature controllers, and sophisticated monitoring sensors (IoT components). Suppliers in this upstream segment must adhere to strict quality standards as component failure directly translates to cold chain breaches. The complexity of ULT freezers requires specialized component manufacturers, often leading to reliance on a few key global suppliers for specific high-performance parts, creating potential supply chain vulnerability that companies actively seek to mitigate through diversification and vertical integration efforts.

Midstream activities encompass the manufacturing, assembly, and rigorous testing of the refrigeration units. Manufacturers must invest heavily in R&D to develop systems that offer superior temperature uniformity and recovery characteristics, minimizing temperature fluctuations caused by door openings or ambient environmental changes. Certification and validation are critical steps; products often require WHO PQS (Performance, Quality, and Safety) verification or other regulatory approvals (like FDA/CE marking), which act as significant barriers to entry. The manufacturing process involves integrating cooling systems, digital interfaces, and data logging capabilities, followed by comprehensive quality assurance checks to guarantee performance under various stress conditions, simulating real-world deployment scenarios across different climates.

Downstream activities focus on distribution, installation, maintenance, and end-user training. Distribution channels are typically a mix of direct sales to large hospital networks or government tenders (especially for mass immunization programs) and indirect distribution through specialized medical equipment suppliers and cold chain logistics firms. Direct channels allow for better control over complex ULT equipment installation and validation. The role of specialized third-party logistics (3PL) providers is crucial, as they often handle the final mile delivery and setup, ensuring the refrigerator is correctly calibrated and documented upon arrival. Post-sale services, including scheduled maintenance, emergency repair services, and compliance audits, form a high-value component of the downstream segment, contributing significantly to manufacturer revenue and customer loyalty, especially for complex systems requiring highly technical support.

Vaccine Refrigerators Market Potential Customers

The primary consumers and end-users of vaccine refrigerators span the entire spectrum of healthcare and public health infrastructure, with demand concentrated heavily among large institutional purchasers. Hospitals, particularly those with major surgical units or extensive outpatient immunization programs, are foundational customers, requiring a mix of standard 2°C to 8°C units and specialized ULT freezers for advanced therapies. Government public health departments and national immunization programs (NIPs) represent major volume buyers, often procuring through large, centrally managed tenders. These governmental entities drive demand for robust, easily deployable, and often solar-powered equipment to support nationwide vaccination efforts and ensure equity of access in remote communities, often setting the standard for minimum acceptable performance via international guidelines.

Another rapidly expanding segment of potential customers includes pharmaceutical and biotechnology companies. These entities require high-precision, reliable cold storage solutions not only for the final commercial vaccine products but also for storing raw materials, cell lines, and research samples during the R&D and clinical trial phases. The increasing complexity of biologic drugs necessitates specialized, controlled environments, driving demand for high-capacity, highly monitored ULT storage. These customers often prioritize data security, detailed audit trails, and integration with laboratory information management systems (LIMS) over cost, leading them to purchase premium, fully automated systems from established market leaders known for reliability and regulatory compliance expertise.

Furthermore, specialized medical service providers such as blood banks, which require precise control over blood plasma and other components, and retail pharmacy chains, which are increasingly involved in community vaccination programs, represent significant potential customer bases. Retail pharmacies, benefiting from centralized purchasing power, are upgrading their refrigeration infrastructure to meet stricter state and national storage guidelines to handle complex vaccines, moving away from conventional small refrigerators. Lastly, specialized cold chain logistics and 3PL companies invest heavily in transportable, high-efficiency refrigeration units and temporary storage depots to facilitate the movement of vaccines across international borders and diverse climates, acting as crucial intermediary customers who prioritize durability, transport certifications, and remote tracking capabilities.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 8.1 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Carrier, Thermo Fisher Scientific, PHC Corporation (Panasonic Healthcare), Haier Biomedical, Helmer Scientific, Godrej & Boyce, Dometic Group, Vestfrost Solutions, B Medical Systems, Stirling Ultracold, Sanyo, Shoreline Medical, Eppendorf, Labcold, Arctiko, Fiocchetti, BINDER, Kirby Lester, Nor-Lake Scientific, Accucold |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Vaccine Refrigerators Market Key Technology Landscape

The technological landscape of the Vaccine Refrigerators Market is rapidly evolving, driven by the need for superior reliability, energy independence, and advanced monitoring capabilities. A cornerstone technology is the deployment of highly efficient, often variable-speed compressors and advanced refrigeration cycles that optimize cooling performance while drastically minimizing power consumption. This efficiency is paramount, especially for mobile and off-grid applications where battery life or solar panel output is limited. Furthermore, the adoption of environmentally friendly, natural refrigerants like isobutane (R600a) and propane (R290) is becoming standard practice, driven by global phase-down mandates for harmful hydrofluorocarbons (HFCs), pushing manufacturers to redesign their systems for optimal performance with these sustainable alternatives.

Digitalization and connectivity are transforming basic storage units into smart, networked devices. The integration of Internet of Things (IoT) sensors and connectivity modules (Wi-Fi, cellular, or satellite) enables continuous, real-time temperature monitoring and remote diagnostics. This allows healthcare facilities to receive immediate alerts regarding power outages, temperature excursions, or component malfunctions, ensuring compliance and preventing high-value vaccine loss. Data logging capabilities are crucial, with technologies ensuring tamper-proof records accessible via cloud platforms for auditing and regulatory submissions. These smart technologies are central to AEO, providing immediate, verified answers about the stored product’s temperature history and cold chain integrity, critical for complex global supply routes.

In ultra-low temperature environments, technological innovation focuses on insulation and cascade refrigeration systems. Advanced insulation materials, such as Vacuum Insulated Panels (VIPs), significantly reduce heat transfer, maintaining stable temperatures even in high-ambient conditions or during prolonged power failures. For ULT freezers, cascade systems utilizing two independent refrigeration circuits are standard, offering redundancy and achieving temperatures reliably below -80°C. Furthermore, new developments include specialized door-sealing mechanisms and automatic or manual vacuum relief systems designed to combat ice buildup, which typically degrades performance and increases maintenance burden, thereby enhancing the overall long-term durability and operational effectiveness of these critical storage assets.

Regional Highlights

North America represents a mature yet high-value market segment for vaccine refrigerators, characterized by stringent regulatory environments (FDA/CDC guidelines) and high healthcare expenditure. The demand here is primarily focused on advanced, high-capacity Ultra-Low Temperature (ULT) freezers and pharmaceutical-grade units with sophisticated monitoring and compliance features. Major hospitals, research institutions, and large pharmaceutical manufacturing hubs in the US and Canada are continuously investing in upgrading their cold chain infrastructure to handle novel biological drugs and complex clinical trials. The focus is on redundancy, data security, and integration with hospital management systems, driving innovation towards automated inventory tracking and high-performance, energy-efficient cooling solutions. The rapid scale-up witnessed during the COVID-19 pandemic solidified the requirement for robust regional cold chain hubs, ensuring sustained market investment in high-end equipment.

Europe exhibits strong growth driven by widespread national immunization programs (NIPs) and significant investment in biotechnology research across key countries such as Germany, the UK, France, and Switzerland. European markets are particularly sensitive to energy efficiency and environmental sustainability, strongly favoring refrigerators using natural refrigerants (like R600a and R290) to align with EU environmental mandates. Regulatory bodies, including the EMA, impose rigorous standards for pharmaceutical storage, necessitating sophisticated data logging and temperature mapping capabilities in all purchased units. While Western Europe demands highly specialized, compliant ULT units, Eastern European markets, which are modernizing their public health infrastructure, are seeing increased procurement of standard medical-grade refrigerators (2°C to 8°C) to replace outdated commercial equipment, fueling steady volume growth in this segment.

Asia Pacific (APAC) is projected to be the fastest-growing region globally, fueled by vast populations, expanding access to basic healthcare, and significant governmental investment in infrastructure modernization, especially in India, China, and Southeast Asia. The heterogeneity of the region dictates demand for a diverse product mix. In developed APAC economies like Japan and South Korea, demand mirrors North America, focusing on advanced research ULT freezers. However, in emerging and densely populated nations, the emphasis is heavily placed on resilient, off-grid solutions, leading to massive demand for Ice-Lined Refrigerators (ILRs) and Solar Direct Drive (SDD) units to ensure vaccines reach rural populations without viable electrical grids. China's extensive manufacturing base also significantly influences global supply dynamics, while the sheer volume of governmental tender activity across the region guarantees robust market expansion throughout the forecast period.

Latin America (LATAM) and Middle East & Africa (MEA) represent critical growth frontiers, characterized by high population growth and ongoing infrastructure development aimed at increasing immunization coverage. In LATAM, market growth is concentrated in major urban centers (Brazil, Mexico) where modern hospitals are upgrading to certified medical-grade refrigeration units. The MEA region, particularly Sub-Saharan Africa, is the primary global deployment area for solar cold chain technology. Significant procurement is driven by international NGOs and global health initiatives (GAVI, WHO) focusing on establishing reliable cold chain networks in remote settings. The demand profile is highly skewed towards durable, easy-to-maintain SDD and ILR systems designed to withstand high ambient temperatures and unreliable power, making system longevity and WHO PQS certification crucial purchasing criteria in this geographically challenging, yet high-potential, market area.

- North America: Dominates the ULT freezer segment due to expansive biotech R&D and strict regulatory compliance (FDA/CDC). High market value focused on smart, integrated hospital solutions.

- Europe: Driven by environmental mandates and NIPs. Strong preference for natural refrigerants and high-efficiency standard medical-grade units across the 2°C to 8°C range.

- Asia Pacific (APAC): Fastest-growing market, characterized by large-scale government procurement of both sophisticated ULT freezers (China, Japan) and resilient SDD/ILR units for rural outreach (India, SEA).

- Latin America (LATAM): Growth centered around healthcare infrastructure upgrades in urban centers and increasing government focus on expanding public vaccination program capacity.

- Middle East & Africa (MEA): Critical market for off-grid solutions; demand heavily influenced by international aid organizations procuring Solar Direct Drive (SDD) systems for reliable, infrastructure-independent vaccine storage.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Vaccine Refrigerators Market.- Carrier

- Thermo Fisher Scientific

- PHC Corporation (Panasonic Healthcare)

- Haier Biomedical

- Helmer Scientific

- Godrej & Boyce

- Dometic Group

- Vestfrost Solutions

- B Medical Systems

- Stirling Ultracold

- Sanyo

- Shoreline Medical

- Eppendorf

- Labcold

- Arctiko

- Fiocchetti

- BINDER

- Kirby Lester

- Nor-Lake Scientific

- Accucold

Frequently Asked Questions

Analyze common user questions about the Vaccine Refrigerators market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary temperature range for standard vaccine refrigerators?

The universally mandated temperature range for storing most conventional vaccines, as established by the WHO and regulatory bodies, is strictly maintained between 2°C and 8°C (35°F and 46°F). Maintaining this precise range is critical for vaccine potency, necessitating pharmaceutical-grade refrigeration equipment with superior temperature uniformity and recovery speed.

How do Solar Direct Drive (SDD) refrigerators differ from standard units?

SDD refrigerators operate autonomously using energy directly from solar panels without requiring traditional electricity or battery banks for daily function. They utilize thermal energy storage (ice or phase change material) to maintain stable temperatures overnight or during cloudy periods, making them ideal, reliable, and sustainable solutions for off-grid or remote cold chain implementation.

What is an Ultra-Low Temperature (ULT) freezer and why is it increasingly needed?

A ULT freezer maintains temperatures typically ranging from -40°C down to -86°C. The increasing demand for ULT freezers is driven by the development and distribution of highly complex biological products, such as mRNA vaccines and specific advanced cell therapies, which require extremely cold environments to preserve their molecular integrity and efficacy over time.

What are the key compliance standards for medical-grade vaccine refrigerators?

Key compliance standards include the World Health Organization Performance, Quality, and Safety (WHO PQS) certification, which validates performance robustness for global deployment, particularly in developing nations. Additionally, compliance with national health authority guidelines, like the CDC’s Vaccine Storage and Handling Toolkit in the US, mandates features such as continuous monitoring, digital data logging, and alarm systems.

How does the integration of IoT technology benefit vaccine cold chain management?

IoT technology integrates sensors and connectivity into refrigerators, enabling real-time, remote monitoring of internal temperature, door status, and power consumption. This provides immediate notification of excursions, facilitates predictive maintenance planning through data analytics, and automatically generates required compliance logs, significantly enhancing the security and integrity of the vaccine cold chain.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager