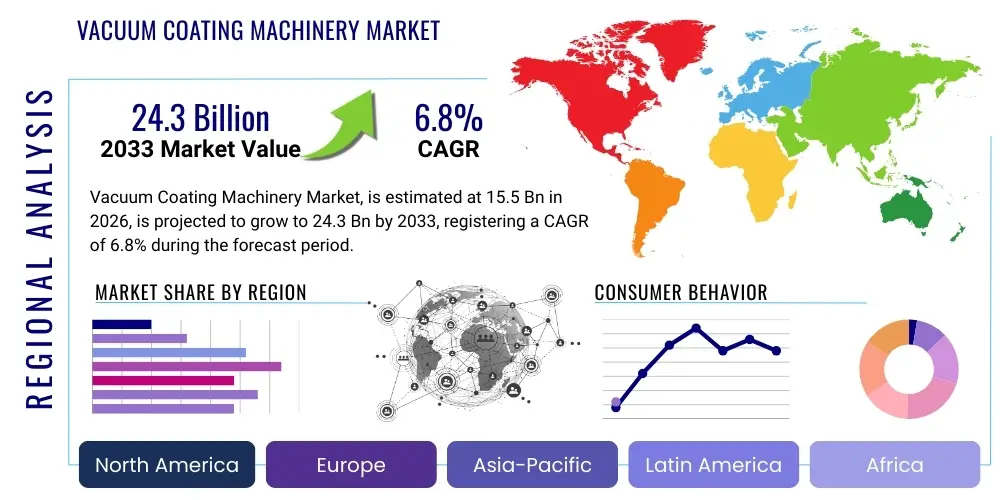

Vacuum Coating Machinery Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440923 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Vacuum Coating Machinery Market Size

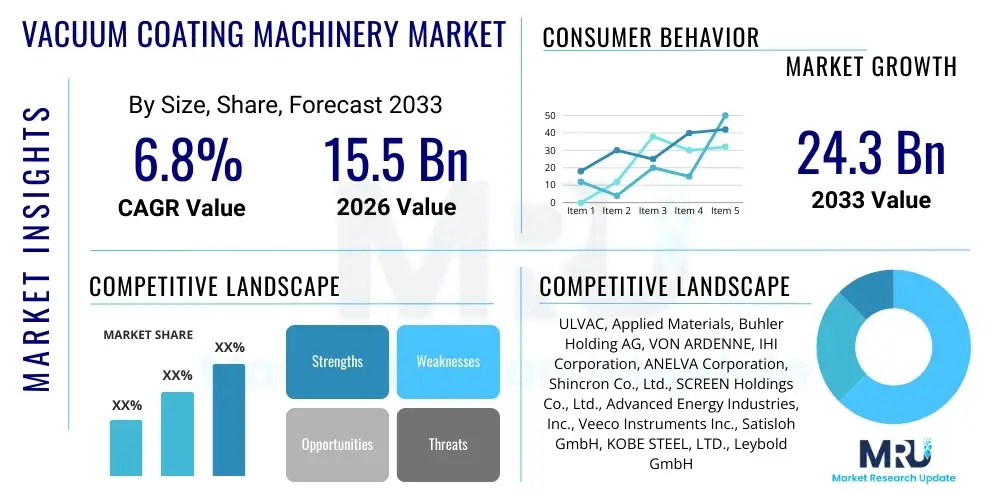

The Vacuum Coating Machinery Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 15.5 Billion in 2026 and is projected to reach USD 24.3 Billion by the end of the forecast period in 2033.

Vacuum Coating Machinery Market introduction

The Vacuum Coating Machinery Market encompasses specialized capital equipment used to deposit thin layers of material onto various substrates within a highly controlled vacuum environment. This critical process, vital for enhancing surface properties such as hardness, corrosion resistance, electrical conductivity, thermal performance, and aesthetic quality, relies on sophisticated techniques including Physical Vapor Deposition (PVD), Chemical Vapor Deposition (CVD), and Atomic Layer Deposition (ALD). These advanced machines are fundamental enablers across numerous high-technology industries, facilitating the precise manufacture of semiconductors, advanced optical filters, energy-efficient architectural glass, and protective coatings for automotive and aerospace components. The rigorous performance demands of modern products, especially concerning durability and component longevity in harsh environments, are directly met by the thin-film solutions provided by this machinery, positioning the market as a crucial component of global precision manufacturing infrastructure.

The applicability of vacuum coating machinery is vast and continuously expanding, driving sustained market investment. In the electronics sector, these systems are indispensable for the fabrication of integrated circuits, advanced memory chips, and high-resolution displays, where film thickness and purity are controlled at the atomic level. Automotive industries heavily utilize vacuum coatings for reflective headlight assemblies, decorative interior and exterior finishes, and functional coatings that reduce friction and wear on engine and transmission components, particularly in the growing electric vehicle (EV) segment. Furthermore, the deployment of large-area vacuum coaters in the architectural sector allows for the production of energy-saving Low-E (low-emissivity) glass, which significantly contributes to reduced energy consumption in buildings globally, offering both economic and environmental benefits derived from these enhanced material properties.

Key driving factors accelerating market growth include the exponential demand for sophisticated consumer electronics, particularly advanced smartphones, tablets, and wearable devices, all of which mandate high-precision PVD processes for functional and cosmetic coatings on screens, casings, and internal components. The massive global transition toward electrification and autonomous driving systems necessitates new types of protective, insulating, and electrically functional coatings for EV batteries, power electronics, and sensors. Additionally, stricter global environmental regulations are progressively pushing manufacturers away from traditional, often solvent-based, wet chemical coating processes toward cleaner, more sustainable vacuum-based deposition methods. Continued technological breakthroughs in specialized processes like High-Power Impulse Magnetron Sputtering (HiPIMS) and spatial ALD further enhance the productivity and broaden the industrial applicability of next-generation vacuum coating systems, assuring robust market expansion throughout the forecast period.

Vacuum Coating Machinery Market Executive Summary

The Vacuum Coating Machinery Market is experiencing significant expansion, primarily fueled by the accelerating convergence of digitization, sustainable manufacturing initiatives, and the need for enhanced material performance across major industrial sectors. Prevailing business trends underscore a strong industry focus on integrating sophisticated automation technologies, including advanced robotics for substrate handling and AI-driven process optimization tools, aimed at ensuring superior coating uniformity and maximizing equipment uptime. Market players are increasingly developing modular and highly customizable system architectures to quickly adapt to niche application requirements, such as those found in advanced packaging, flexible electronics, and specialized medical device coatings. The competitive landscape is being shaped by strategic consolidation efforts, including key mergers and acquisitions, coupled with aggressive R&D spending focused on developing deposition systems capable of high throughput and atomic-level precision, particularly in the ALD and advanced sputtering domains.

Regional dynamics clearly position the Asia Pacific (APAC) as the primary engine of market growth and the largest revenue generator, driven by extensive investments in semiconductor fabrication, high-volume consumer electronics assembly, and the rapidly expanding EV battery supply chain in nations like China, South Korea, and Taiwan. North America and Europe, while maintaining slower volume growth, focus strategically on the high-value, research-intensive segments, including specialized aerospace coatings, certified medical device surface treatments, and advanced optical components, spurring demand for high-cost, ultra-precise, and often custom-engineered PVD and ALD solutions. These developed markets prioritize long-term reliability and specialized application capabilities over sheer mass production capacity, leading to sustained but focused demand for premium machinery and comprehensive service agreements.

Analysis of segment trends indicates that the Physical Vapor Deposition (PVD) segment retains the largest historical market share, owing to its widespread versatility in applying wear-resistant, decorative, and functional coatings across the automotive and tooling industries. However, the Atomic Layer Deposition (ALD) segment is forecasted to achieve the highest Compound Annual Growth Rate (CAGR), reflecting its indispensable role in the continuous scaling and manufacturing precision required by advanced semiconductor architectures, particularly in 3D NAND and next-generation logic chips. Within the end-user segments, the electronics and semiconductor industry remains the most crucial revenue stream, requiring continuous technology upgrades, closely followed by the automotive sector, which is increasingly adopting complex vacuum coatings for lightweighting, thermal management, and improved durability of critical powertrain components in electric vehicles.

AI Impact Analysis on Vacuum Coating Machinery Market

User queries regarding the integration of Artificial Intelligence (AI) and Machine Learning (ML) into vacuum coating machinery frequently highlight concerns about process variability and the need for autonomous quality assurance. Common questions explore how AI algorithms can effectively analyze complex, multi-sensor data streams—such as plasma emission spectra, film stress monitors, and residual gas analysis—to dynamically adjust deposition parameters (e.g., power, pressure, gas flow) in real-time, thereby maintaining tighter control over coating thickness and composition than traditional control systems. Users are keenly interested in leveraging ML for predictive maintenance, seeking systems that can forecast the precise optimal time for high-cost consumable replacement (e.g., sputtering targets or pump seals) to minimize operational disruption. The overarching expectation is that AI will be the key differentiator enabling next-generation coating facilities to achieve unprecedented levels of yield, material efficiency, and near-zero defect rates in high-precision, high-volume production environments.

The transformative influence of AI is rapidly reshaping the control and monitoring infrastructure of high-end vacuum coating machinery, facilitating a shift from standardized, static recipes to dynamic, self-optimizing deposition processes. By processing vast quantities of historical and real-time operational data gathered from dozens of embedded sensors, AI systems can instantly recognize subtle process drifts or incipient instabilities that precede coating defects. This allows the system to implement micro-adjustments to deposition parameters proactively, ensuring superior film uniformity and consistency across large substrate batches. This capability is particularly crucial in highly sensitive manufacturing environments, such as the fabrication of advanced microprocessors or complex medical stents, where slight deviations in film purity or thickness translate directly into substantial component rejection rates and major financial losses. Consequently, intelligent process control reduces scrap and optimizes material utilization, providing a clear competitive advantage.

Furthermore, AI plays an indispensable role in enhancing the reliability and longevity of vacuum coating equipment, which are characterized by high capital costs and sensitivity to internal component wear. ML-driven predictive maintenance modules analyze machine telemetry—including vibration signatures, temperature fluctuations across cooling loops, and power supply characteristics—to accurately predict potential mechanical or electrical failures. This allows facility operators to schedule maintenance precisely when necessary, shifting away from inefficient, time-based maintenance schedules. By minimizing unplanned and costly downtime, AI integration significantly boosts the overall equipment effectiveness (OEE) and provides comprehensive diagnostic feedback. The data generated through these intelligent systems also accelerates research and development, enabling engineers to quickly correlate machine behavior with coating performance, leading to faster development cycles for novel coating materials and deposition techniques.

- Real-time process control and self-correction utilizing complex sensor data fusion and machine learning algorithms.

- Predictive maintenance deployment to maximize system uptime and optimize the replacement of high-cost components.

- Automated defect recognition and classification employing deep learning models analyzing in-situ optical or physical measurements.

- Accelerated optimization of coating recipes, reducing R&D cycle times for new materials and functional films.

- Enhanced energy management through dynamic power and gas flow regulation based on immediate process needs.

- Integration of robotics and automation for high-precision, low-contamination substrate handling managed by intelligent systems.

DRO & Impact Forces Of Vacuum Coating Machinery Market

The market development is driven by robust demand for performance-enhancing materials in critical sectors, while simultaneously facing constraints related to investment hurdles and technical complexity. Key drivers include the accelerated global rollout of 5G and subsequent generations of consumer electronics, which mandate extremely thin, high-performance films, coupled with the mass adoption of electric vehicles demanding durable battery and thermal management coatings. Restraints on growth primarily stem from the enormous initial capital outlay required to procure advanced, high-precision vacuum coating systems, necessitating extensive specialized facility infrastructure, and the persistent shortage of personnel trained to operate and maintain these complex machines. Strategic opportunities emerge from the expansion into renewable energy (advanced solar cells, hydrogen fuel cell components) and the medical device industry, alongside the commercialization of novel, high-speed ALD and advanced plasma etching technologies. These market forces collectively dictate the innovation trajectory and geographical distribution of manufacturing capacity.

Significant growth drivers sustaining the market expansion are intrinsically tied to global technological trends. The mandated miniaturization in semiconductor technology dictates that films must be deposited with atomic-level precision and high conformality, which only advanced CVD and ALD systems can reliably achieve. Furthermore, escalating regulatory pressures worldwide, particularly concerning the reduction of Volatile Organic Compound (VOC) emissions, favor vacuum-based deposition methods as inherently cleaner, solvent-free alternatives to traditional electroplating or liquid-based coating processes. The rapid technological evolution in display technology, transitioning toward flexible OLED and micro-LED screens, necessitates large-area, high-throughput roll-to-roll vacuum coaters capable of applying highly effective moisture and oxygen barrier films. These systemic demands solidify the critical, non-substitutable role of vacuum coating machinery in future high-tech manufacturing, ensuring sustained investment cycles from major global players.

Despite the powerful drivers, several key restraints impede broader market access and rapid proliferation. The investment barrier is substantial; a high-end PVD or ALD system for semiconductor manufacturing can cost tens of millions of dollars, placing it out of reach for many smaller enterprises and requiring significant financial planning even for large corporations. Operational complexity is another major limiting factor; maintaining the ultra-high vacuum environment and ensuring process repeatability requires specialized training, precise material management (high-purity targets and gases), and frequent, expert calibration, contributing significantly to high operational expenses. Moreover, the global supply chain for critical vacuum components, such as sophisticated turbo pumps, power generators, and precursor delivery systems, remains concentrated among a few key suppliers, making the market vulnerable to geopolitical and logistical disruptions that can delay equipment delivery and maintenance timelines, further challenging end-users.

The most compelling opportunities for market stakeholders lie in pioneering solutions for next-generation energy and medical applications. The massive scale-up of battery gigafactories globally presents an immediate need for coating machinery specialized in modifying electrode and separator surfaces to enhance energy density and safety, representing a lucrative new revenue stream outside of traditional electronics. In the medical sector, the demand for biocompatible, anti-microbial, and friction-reducing coatings for implants and surgical instruments is rapidly expanding, requiring precision systems capable of meeting stringent validation and regulatory standards. Furthermore, the development of integrated, fully automated deposition cells that combine coating, metrology, and cleaning processes into a single, seamless workflow offers manufacturers a pathway to significantly reduce labor costs and increase the overall cost-effectiveness of vacuum coating technology, opening doors to broader industrial adoption in non-traditional fields.

Segmentation Analysis

The Vacuum Coating Machinery Market is meticulously segmented across multiple dimensions, including the fundamental deposition technology, the specific process method, the core end-user industry, and geographical classification. This segmented analysis provides essential insights into where technological investment is concentrated and how different industrial sectors prioritize coating capabilities, whether for high-speed mass production or ultra-precision, low-volume applications. Understanding these breakdowns allows market participants to accurately gauge competitive positioning, allocate resources for R&D on emerging technologies like spatial ALD, and tailor their product offerings to meet the specific technical requirements of dominant segments such as electronics or the rapidly growing EV component sector, ensuring optimized strategic planning and market penetration.

- By Technology Type:

- Physical Vapor Deposition (PVD) Equipment (E-Beam, Thermal, Sputtering)

- Chemical Vapor Deposition (CVD) Equipment (Atmospheric, Low-Pressure, Plasma-Enhanced)

- Atomic Layer Deposition (ALD) Equipment (Thermal, Plasma, Spatial)

- Hybrid and Other Specialized Coating Systems (e.g., Pulsed Laser Deposition, Plasma Surface Treatment)

- By Process Type:

- Magnetron Sputtering (DC, RF, Reactive, HiPIMS)

- Evaporation Techniques (Thermal Evaporation, Electron Beam Evaporation)

- Plasma-Enhanced Chemical Vapor Deposition (PECVD)

- Ion Plating and Ion Beam Assisted Deposition (IBAD)

- By End-User Industry:

- Electronics and Semiconductors (Wafers, Displays, Photovoltaics)

- Automotive and Transportation (Lighting, Components, Battery Foils)

- Optics and Photonics (Lenses, Filters, Coatings for Lasers)

- Aerospace and Defense (Turbine Blades, Composites, Sensor Coatings)

- Medical Devices and Biomedical (Implants, Surgical Tools)

- Architectural Glass and Energy (Low-E Glass, Solar Panels)

- Tool and Mold Manufacturing (Cutting Tools, Dies, Injection Molds)

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, U.K., France, Italy, Rest of Europe)

- Asia Pacific (China, Japan, South Korea, Taiwan, India, Southeast Asia)

- Latin America (Brazil, Argentina, Rest of LATAM)

- Middle East and Africa (UAE, Saudi Arabia, South Africa)

Value Chain Analysis For Vacuum Coating Machinery Market

The inception of the value chain involves the highly specialized upstream procurement and manufacturing of critical components necessary for ultra-high vacuum operation. This includes high-purity metal and ceramic sputtering targets, highly volatile and sensitive precursor chemicals (for CVD/ALD), specialized power supplies capable of generating stable plasma, and high-precision vacuum generation and measurement equipment (turbomolecular pumps, cryopumps, gauges). Upstream suppliers are global leaders in material science and precision engineering, and their proprietary technologies often dictate the final performance specifications of the coating machine. The challenge in this stage is managing the complex logistics and ensuring consistent, ultra-high quality standards for materials that must function flawlessly in high-vacuum, high-temperature, or high-plasma flux environments.

The midstream segment is dominated by Original Equipment Manufacturers (OEMs) who design, engineer, and integrate these complex components into complete vacuum coating systems. Success in this phase relies heavily on intellectual property pertaining to chamber geometry optimization, robotic substrate handling, and proprietary software algorithms for advanced process control and monitoring (including AI/ML integration). Machinery distribution utilizes a dual-channel approach. Large, complex, or highly customized systems (e.g., for major semiconductor fabs or aerospace clients) are typically sold via direct channels, involving in-house sales teams and dedicated technical specialists for seamless integration and training. Standardized or smaller R&D-scale systems may leverage indirect channels, utilizing specialized regional distributors or system integrators who provide local sales presence and first-line technical support, often focusing on tool coating or general industrial customers.

Downstream activities are defined by system installation, critical process commissioning, and long-term after-sales support, which is often a major revenue component for OEMs. End-users (the final buyers) demand maximum system uptime and consistent coating quality, making prompt and effective servicing indispensable. Direct service ensures the OEM maintains control over proprietary spare parts and highly specialized technical knowledge, reinforcing the long-term customer relationship. Indirect distribution channels require robust certification programs for service partners to guarantee the quality of maintenance and repair operations, especially in geographically fragmented or emerging markets. Furthermore, the constant demand for replacement consumables (targets, precursors, pump oil, filters) represents a stable, ongoing revenue stream that links the end-user tightly to the machinery provider throughout the operational lifecycle of the equipment.

Vacuum Coating Machinery Market Potential Customers

The core potential customers for vacuum coating machinery are high-volume, high-precision manufacturers across technologically demanding sectors where surface functionality is paramount to product performance and reliability. These customers represent industrial giants, specialized component suppliers, and advanced research entities that utilize thin-film technology as a critical competitive differentiator. The buying decision is usually strategic, involving significant capital allocation and multi-year planning, driven by the need for superior coating adhesion, uniformity, and the ability to process unique or temperature-sensitive substrates, requiring highly collaborative purchasing cycles between the end-user and the equipment manufacturer.

The largest customer cohort is situated within the electronics and semiconductor ecosystem, including companies involved in wafer fabrication (for memory, logic, and analog chips), panel manufacturers producing high-end displays (OLED, QLED), and solar cell producers. These organizations continuously require the latest generation of ALD and PECVD equipment to keep pace with Moore’s Law and display advancements, ensuring films are deposited with perfect conformality and minimized defects at high throughputs. The automotive industry represents a rapidly growing segment, driven by the transition to EVs. Customers here include Tier 1 and Tier 2 suppliers purchasing PVD and specialized coating systems for battery components, lightweight structural parts, sensor housings, and durable decorative finishes, where enhanced thermal and abrasion resistance is essential.

Beyond electronics and automotive, significant customer segments include the tooling industry (e.g., manufacturers of precision cutting tools and dies), who invest in PVD systems to apply super-hard coatings (nitrides, diamond-like carbon) to vastly extend tool life and enhance machining performance. The aerospace and defense sectors are premium customers, requiring certified machinery for complex coating tasks on turbine blades, optical sensors, and stealth material applications. Lastly, medical device manufacturers represent a high-value customer group demanding vacuum coaters for biocompatible and wear-resistant coatings on implants, stents, and surgical tools, where regulatory compliance and absolute reliability are non-negotiable purchasing criteria, cementing the crucial role of coating technology in life-critical applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 15.5 Billion |

| Market Forecast in 2033 | USD 24.3 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ULVAC, Applied Materials, Buhler Holding AG, VON ARDENNE, IHI Corporation, ANELVA Corporation, Shincron Co., Ltd., SCREEN Holdings Co., Ltd., Advanced Energy Industries, Inc., Veeco Instruments Inc., Satisloh GmbH, KOBE STEEL, LTD., Leybold GmbH, Intevac, Inc., Hanil Vacuum Co., Ltd., Platit AG, Hauzer Techno Coating B.V., CemeCon AG, Mustang Vacuum Systems, Inc., Optorun Co., Ltd., Ferrotec Holdings Corporation, Evatec AG, CVD Equipment Corporation, Pfeiffer Vacuum GmbH, Müller-Weingarten AG, KUKA AG (Robotics Integration). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Vacuum Coating Machinery Market Key Technology Landscape

The technology landscape governing the Vacuum Coating Machinery Market is characterized by rapid innovation centered on enhancing process efficiency, deposition control, and material versatility while drastically reducing thermal budget requirements for sensitive substrates. Physical Vapor Deposition (PVD) remains highly relevant, with significant advancements in High-Power Impulse Magnetron Sputtering (HiPIMS) which delivers extremely dense, smooth films with superior adhesion and customized material microstructures compared to conventional sputtering. Manufacturers are also developing complex multi-source PVD architectures that enable co-deposition of multiple materials, creating functionally graded coatings and novel alloy compositions with highly tailored properties. Crucial technological efforts are focused on refining linear and rotating cathode designs to maximize target utilization and ensure highly uniform coating thickness over large substrate areas, which is essential for architectural glass and large-format display production.

Chemical Vapor Deposition (CVD), particularly Plasma-Enhanced CVD (PECVD), is continually being optimized for the semiconductor industry, facilitating the deposition of high-quality dielectric and conductive layers at significantly reduced temperatures, preventing damage to existing chip structures. However, the most disruptive technology remains Atomic Layer Deposition (ALD), which offers unmatched precision by sequentially exposing the substrate surface to different chemical precursors, achieving perfect step coverage (conformality) even on complex, high aspect ratio features. Current ALD research is heavily invested in increasing the deposition speed through techniques like spatial ALD and developing plasma-based ALD processes that enable the use of a wider variety of materials and reduce the reliance on thermal energy. This focus on high-speed, low-temperature, and high-conformal deposition is critical for scaling next-generation semiconductor devices and enabling flexible electronics.

Furthermore, the modern technological trend is towards deep systems integration, transforming vacuum coating machines into sophisticated, multi-process platforms. These platforms often combine several deposition techniques—PVD, CVD, and plasma etching/cleaning—within a single high-vacuum environment to produce complex, multi-layer stack coatings without breaking vacuum, thereby minimizing contamination and maximizing interface quality. The adoption of advanced in-situ metrology tools, such as spectroscopic ellipsometers and thin-film thickness monitors, provides real-time data feedback, crucial for AI-driven process control and ensuring quality assurance in line with Industry 4.0 standards. Innovations in high-vacuum pump technology, offering greater pumping speeds and reduced vibration, also play a vital role in enabling the purity and repeatability demanded by the most advanced coating applications in fields like advanced optics and quantum technology.

Regional Highlights

The Asia Pacific (APAC) region continues its firm dominance in the Vacuum Coating Machinery Market, primarily driven by its massive and rapidly expanding manufacturing base across key technological sectors. China, South Korea, and Taiwan lead global production in semiconductors, advanced display panels (OLED and micro-LED), and high-volume consumer electronics, mandating aggressive, recurring investment in state-of-the-art coating equipment. China’s strategic national industrial policies, specifically focused on achieving technological self-sufficiency in high-value components, are fueling multi-billion dollar expansion cycles for domestic semiconductor foundries and display factories, thereby creating continuous, enormous demand for ALD, CVD, and large-area PVD systems. Japan remains a crucial contributor, concentrating on the development and export of highly specialized, ultra-precision deposition systems and the proprietary precursor materials necessary for cutting-edge applications.

North America and Europe constitute mature markets characterized by sustained, high-value demand focused on niche, R&D-intensive, and highly regulated industries such as aerospace, defense, and medical devices. These regions prioritize quality, customization, and long-term reliability over sheer volume. The United States drives innovation in optical coatings for high-power lasers, sensor technology, and R&D-scale ALD systems for emerging fields like quantum computing and micro-electromechanical systems (MEMS). European demand, particularly in Germany and Italy, is robust in the tool manufacturing and industrial component sectors, where PVD systems are essential for applying specialized wear-resistant and anti-friction coatings. Regulatory pressures concerning environmental standards also push European manufacturers towards adopting cleaner vacuum coating solutions, sustaining steady investment in advanced, compliant machinery.

The Latin America (LATAM) and Middle East & Africa (MEA) regions, while smaller in market share, are demonstrating accelerated growth potential due to specific sectoral investments. Growth in LATAM is closely tied to the regional automotive industry's modernization and retooling efforts, particularly in Brazil and Mexico, creating steady demand for functional and decorative coating systems. The MEA region’s expansion is heavily influenced by monumental infrastructure and architectural projects in the Gulf Cooperation Council (GCC) countries, which necessitate high-volume large-area coaters for the production of energy-efficient, reflective architectural glass to manage extreme desert climates. Furthermore, economic diversification initiatives across major MEA nations are fostering localized manufacturing capabilities, gradually increasing the procurement of general industrial and specialized coating machinery to support fledgling high-tech sectors and defense industries.

- Asia Pacific (APAC): Leads globally, fueled by semiconductor fab expansion (China, Taiwan, South Korea), high-volume display manufacturing, and foundational support for the EV battery supply chain. Focus is on high-throughput and high-precision systems.

- North America: Strong market for high-performance, certified systems for aerospace, defense, and specialized R&D applications; key investment in advanced optical and ALD technology.

- Europe: Mature market concentrating on tooling, medical devices, and high-quality industrial coatings; driven by regulatory compliance and demand for energy-efficient processes.

- Latin America (LATAM): Emerging demand linked to automotive sector upgrading and local industrial component manufacturing, primarily seeking PVD and basic CVD solutions.

- Middle East and Africa (MEA): Growth driven by large architectural glass coating projects and government initiatives aimed at industrial diversification and establishing local high-tech manufacturing hubs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Vacuum Coating Machinery Market.- ULVAC, Inc.

- Applied Materials, Inc.

- Buhler Holding AG

- VON ARDENNE GmbH

- IHI Corporation

- ANELVA Corporation

- Shincron Co., Ltd.

- SCREEN Holdings Co., Ltd.

- Advanced Energy Industries, Inc. (Component Provider)

- Veeco Instruments Inc.

- Satisloh GmbH

- KOBE STEEL, LTD.

- Leybold GmbH (A part of Atlas Copco)

- Intevac, Inc.

- Hanil Vacuum Co., Ltd.

- Platit AG

- Hauzer Techno Coating B.V.

- CemeCon AG

- Mustang Vacuum Systems, Inc.

- Optorun Co., Ltd.

- Ferrotec Holdings Corporation

- Evatec AG

- CVD Equipment Corporation

- Pfeiffer Vacuum GmbH

- Müller-Weingarten AG

- KUKA AG (Robotics Integration)

- Singulus Technologies AG

- CHA Industries

- PVD Products Inc.

Frequently Asked Questions

Analyze common user questions about the Vacuum Coating Machinery market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the growth of the Vacuum Coating Machinery Market?

The central driver is the relentless demand from the electronics and semiconductor sectors for higher performance, miniaturized components, requiring ultra-precise thin-film deposition achievable only through advanced vacuum coating technologies like ALD and HiPIMS, alongside the massive investment in the electric vehicle supply chain.

Which geographical region dominates the sales of vacuum coating equipment?

The Asia Pacific (APAC) region holds the largest market share, predominantly due to the high concentration of global manufacturing for consumer electronics, display panels, and massive investments in semiconductor fabrication facilities (fabs) across China, South Korea, and Taiwan, which demand high-volume machinery procurement.

How does PVD technology differ from CVD in industrial applications?

PVD (Physical Vapor Deposition) uses physical processes (like sputtering or evaporation) to deposit material, often resulting in hard, wear-resistant, and decorative coatings for tools and automotive parts. CVD (Chemical Vapor Deposition) uses chemical reactions of gaseous precursors, critical for high-purity, conformal coatings essential in microelectronics and certain barrier applications.

What is the impact of Artificial Intelligence (AI) on vacuum coating operations?

AI significantly enhances operational efficiency by enabling predictive maintenance, real-time process monitoring, and closed-loop control systems. This minimizes machine downtime, optimizes coating recipes dynamically based on sensor feedback, and dramatically improves film uniformity and yield rates in production.

What are the key restraint challenges facing vacuum coating machinery adoption?

The main challenges include the very high initial capital expenditure (CapEx) required for sophisticated vacuum systems, the specialized technical expertise needed for their continuous operation and maintenance, and inherent process complexities demanding high-purity precursor materials and sensitive environmental controls.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager