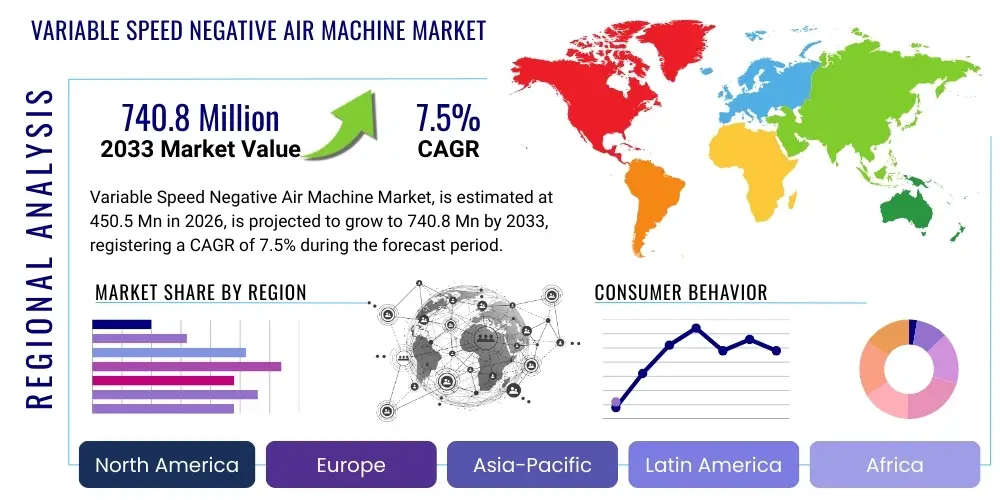

Variable Speed Negative Air Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441973 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Variable Speed Negative Air Machine Market Size

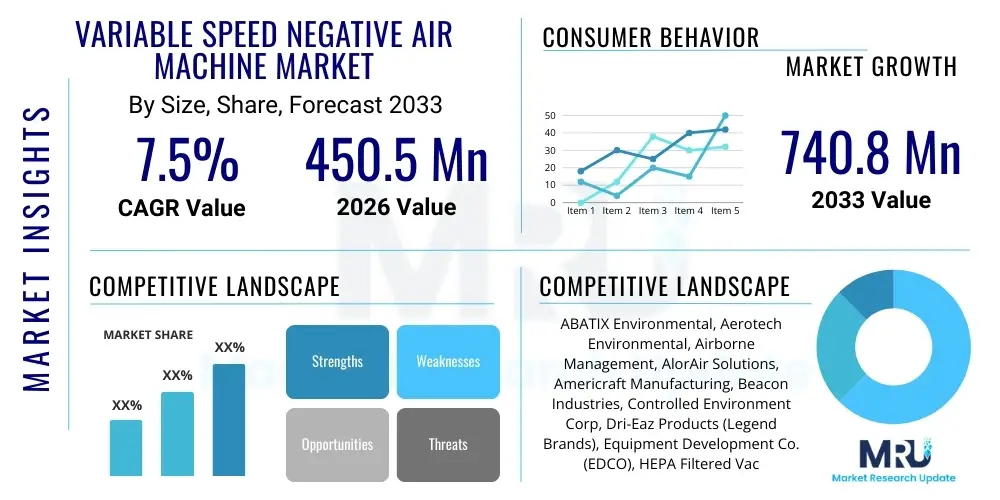

The Variable Speed Negative Air Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 450.5 million in 2026 and is projected to reach USD 740.8 million by the end of the forecast period in 2033.

Variable Speed Negative Air Machine Market introduction

The Variable Speed Negative Air Machine Market encompasses devices designed to create and maintain negative pressure differentials within controlled environments, primarily to prevent the migration of airborne contaminants out of a work zone. These specialized air movers utilize powerful fans coupled with high-efficiency particulate air (HEPA) filters to capture hazardous particles such as mold spores, asbestos fibers, dust, and pathogens. The key differentiator of variable speed models is their ability to precisely modulate airflow capacity, ensuring optimal negative pressure maintenance regardless of structural leaks or varying containment needs. This precision enhances energy efficiency and regulatory compliance, particularly in sensitive environments like healthcare facilities and highly regulated industrial sites, positioning these machines as indispensable tools for environmental remediation and critical air control.

Applications for variable speed negative air machines are extensive and highly critical across diverse sectors. In the construction industry, they are vital during demolition and renovation projects involving hazardous materials like lead or asbestos abatement, ensuring worker safety and external environmental protection. Healthcare utilizes these systems extensively for temporary or permanent infectious disease isolation rooms (IDIRs) and during facility upgrades to prevent cross-contamination in sterile areas. Furthermore, disaster recovery and mold remediation firms rely on the consistent and controlled air movement offered by these variable speed units to dry structures and extract biohazards efficiently. The market is characterized by stringent governmental regulations governing indoor air quality (IAQ) and occupational safety, driving continuous demand for reliable, high-performance containment solutions.

Key market benefits include superior containment integrity, reduced energy consumption compared to fixed-speed alternatives, and enhanced operational flexibility. The capability to adjust flow rates dynamically based on real-time pressure monitoring translates directly into significant cost savings and minimized risk of compliance violations. Driving factors influencing market expansion include the increasing global awareness of health risks associated with airborne contaminants, coupled with rising construction and infrastructure activities in developing economies. Additionally, the proliferation of aging infrastructure requiring hazardous material abatement and the need for enhanced biosafety protocols in post-pandemic healthcare settings further solidify the market's robust growth trajectory, pushing manufacturers towards developing smarter, IoT-enabled variable speed models.

Variable Speed Negative Air Machine Market Executive Summary

The Variable Speed Negative Air Machine Market is undergoing a rapid evolution driven by technological integration and stricter regulatory frameworks globally. Key business trends indicate a strong shift towards incorporating smart monitoring capabilities, such as remote diagnostics and pressure logging, which improve operational efficiency and simplify compliance reporting for end-users in abatement and healthcare sectors. Manufacturers are also prioritizing sustainability, embedding energy-efficient components like Electronically Commutated (EC) motors, which offer superior performance characteristics and reduced power consumption, appealing to environmentally conscious buyers and those focused on long-term operational costs. This focus on smart, energy-efficient design is consolidating market leadership among firms capable of offering integrated software platforms alongside robust hardware solutions, fostering intense competitive innovation.

Regionally, North America remains the dominant revenue generator, primarily due to rigorous asbestos and mold remediation regulations (e.g., OSHA, EPA guidelines) and a highly sophisticated healthcare infrastructure that routinely requires high-level air control for infection prevention. Europe follows closely, demonstrating strong growth spurred by national initiatives promoting energy conservation in commercial equipment and strict IAQ mandates in public buildings. However, the Asia Pacific (APAC) region is poised for the highest growth rate during the forecast period. This acceleration is attributed to massive ongoing infrastructure development projects, rapid urbanization leading to increased demand for mold remediation in dense living spaces, and significant investments in modernizing healthcare facilities to meet international biosafety standards, translating into substantial demand for effective negative air containment solutions.

Segment-wise, the market sees the highest traction in the HEPA filtration segment, which is mandatory for most critical applications like handling infectious agents or asbestos. Furthermore, the rental segment is experiencing robust expansion, particularly among smaller remediation companies and temporary construction sites that require flexible, capital expenditure-light solutions. Technological adoption is favoring larger capacity units (those exceeding 2,000 CFM) as project complexity and required containment volumes increase. These segment trends underscore a market demand for reliability, scalability, and adherence to the most demanding filtration standards, influencing manufacturers to increase the lifespan and robustness of both their filter media and variable speed fan components, ensuring market stability and continuous product refinement focused on operational endurance in challenging environments.

AI Impact Analysis on Variable Speed Negative Air Machine Market

User inquiries regarding the integration of Artificial Intelligence (AI) into the Variable Speed Negative Air Machine Market frequently center on predictive maintenance, autonomous pressure regulation, and optimization of energy usage in real-time. Users are keen to understand how AI algorithms can interpret vast streams of sensor data—including pressure differentials, filter loading, motor temperature, and ambient air quality—to predict equipment failure before it occurs, thereby maximizing uptime during critical containment operations. Furthermore, there is significant interest in AI’s capability to create self-adjusting systems that learn the optimal operational profile for specific environments, automatically adjusting fan speed and flow rates to maintain precise negative pressure with minimal human oversight. This self-optimization promises substantial efficiency gains, reduced manual intervention, and enhanced compliance assurance, fundamentally shifting the paradigm from reactive monitoring to proactive, intelligent containment management within the industry.

- AI enables predictive failure analysis for motors and filtration systems, minimizing unexpected downtime in critical operations.

- Machine learning algorithms optimize fan speed dynamically based on real-time environmental data, ensuring precise pressure differential maintenance while reducing power consumption.

- AI facilitates automated compliance reporting by logging and analyzing operational parameters against regulatory benchmarks, streamlining documentation processes.

- Integration with building management systems (BMS) allows AI-driven negative air machines to harmonize air control with HVAC systems for facility-wide optimization.

- Enhanced sensor data processing allows for early detection of containment breaches or filter saturation, triggering immediate alerts and adjustments.

- AI-powered remote diagnostics provide technicians with accurate root cause analysis, reducing repair times and maintenance costs significantly.

DRO & Impact Forces Of Variable Speed Negative Air Machine Market

The trajectory of the Variable Speed Negative Air Machine Market is significantly shaped by a confluence of driving forces (D), restrictive factors (R), and latent opportunities (O), collectively forming the market's impact forces. A primary driver is the stringent and escalating global regulatory environment mandating effective airborne contaminant control in industries ranging from asbestos abatement to sterile compounding in pharmaceuticals. This regulatory pressure, particularly from bodies like OSHA, EPA, and ISO, compels end-users to adopt reliable, certified containment technology. Concurrently, the increasing awareness regarding the health implications of indoor air pollutants, accelerated by global public health events, continuously fuels consumer and institutional demand for high-performance filtration and air exchange equipment. These factors are compounded by technological advancements in EC motors and IoT connectivity, which enhance the machines' performance and operational data visibility, offering strong value propositions to sophisticated buyers focused on total cost of ownership (TCO).

However, several restraints impede market penetration. The high initial capital investment required for professional-grade variable speed negative air machines, especially those equipped with high-efficiency HEPA filters and advanced controls, presents a substantial barrier, particularly for small-to-medium enterprises (SMEs) in developing regions. Furthermore, the operational challenge of ensuring proper maintenance and timely filter replacement—critical for performance validation—can be overlooked, leading to decreased efficiency or potential regulatory non-compliance, which tarnishes the perception of the technology's reliability. The market also faces restraint from the availability of cheaper, fixed-speed alternatives in lower-regulated markets, which, while less precise and efficient, often satisfy basic low-cost project requirements, thereby diluting the premium segment's potential volume growth.

Despite these barriers, significant opportunities for growth are emerging. The accelerating adoption of Negative Air Machines within the healthcare sector for pandemic preparedness and permanent isolation capabilities represents a massive, non-cyclical demand driver. The opportunity to integrate these machines into smart building infrastructure, utilizing AI and IoT for centralized, remote management and predictive maintenance, offers a compelling avenue for manufacturers to differentiate their products and establish long-term service contracts. Furthermore, geographic expansion into rapidly industrializing regions of Asia and Latin America, where infrastructure development and subsequent remediation needs are skyrocketing, provides untapped market potential. Developing modular, scalable systems that can adapt to various environmental conditions and regulatory tiers will be crucial for capitalizing on these burgeoning global opportunities, transforming containment services into managed environmental control solutions.

- Drivers: Stricter environmental and occupational health regulations; growing demand for biosafety in healthcare; technological advances in variable speed motor efficiency; increasing awareness of IAQ.

- Restraints: High initial investment cost; challenges associated with proper maintenance and verification of filter integrity; competition from low-cost fixed-speed alternatives; lack of standardization across global regulatory bodies.

- Opportunities: Expansion into developing APAC healthcare and infrastructure markets; integration of IoT/AI for predictive maintenance and remote operation; growth of the equipment rental market for specialized projects; emergence of green building certifications favoring energy-efficient air control.

Segmentation Analysis

The Variable Speed Negative Air Machine Market is comprehensively segmented based on critical operational and application characteristics, including air flow capacity, type of filter used, primary application sector, and distribution channel. Segmentation by capacity—ranging from small portable units (under 1000 CFM) to high-volume commercial systems (over 2500 CFM)—is crucial as it determines the machine's suitability for different project scales, from residential mold mitigation to large industrial cleanrooms. Filter type segmentation, primarily between standard filtration, HEPA (High-Efficiency Particulate Air), and ULPA (Ultra-Low Penetration Air), reflects the required level of particulate removal efficiency, directly correlating with the machine’s potential use in highly sensitive environments like pharmaceutical manufacturing or critical care isolation. Understanding these segments allows manufacturers to tailor product development to specific regulatory and performance needs across the global user base, maximizing market alignment.

- By Capacity (CFM):

- Low Capacity (Under 1000 CFM)

- Medium Capacity (1000 CFM to 2000 CFM)

- High Capacity (Above 2000 CFM)

- By Filter Type:

- HEPA Filters

- ULPA Filters

- Standard Pre-filters and Carbon Filters

- By End-Use Industry:

- Environmental Remediation (Asbestos/Mold Abatement)

- Healthcare (Infectious Disease Control, Renovation)

- Construction and Demolition

- Industrial Manufacturing and Cleanrooms

- Disaster Recovery Services

- By Distribution Channel:

- Direct Sales

- Distributors/Retailers

- Rental Services

Value Chain Analysis For Variable Speed Negative Air Machine Market

The value chain for the Variable Speed Negative Air Machine Market begins with upstream activities focused on the sourcing and manufacturing of specialized components. This critical stage involves procuring high-quality, energy-efficient Electronically Commutated (EC) motors, crucial for variable speed functionality and longevity, alongside durable casing materials, advanced digital controllers, and high-specification filter media, notably certified HEPA and ULPA filters. Key suppliers for these sophisticated components often operate in highly specialized technological niches, requiring stringent quality control checks to meet performance standards required for certification (e.g., DOP testing standards). Efficiency gains and cost reductions at this stage are primarily achieved through optimized component procurement logistics and forging long-term supplier relationships, which ensures a steady supply of high-performance variable speed motor technology essential for product differentiation and reliability in operation.

The midstream segment involves the core manufacturing, assembly, and rigorous testing of the negative air machines. This stage includes designing robust, portable housing, integrating the variable speed drive system, installing monitoring sensors, and performing factory acceptance testing (FAT) to verify proper negative pressure capability and filtration efficiency under various load conditions. Compliance and certification—including UL listings, CE marks, and adherence to specific air quality standards—are paramount here, often requiring substantial investment in specialized testing facilities and expert personnel. Differentiation is achieved through ergonomic design, features like integrated pressure monitoring displays, and connectivity options for remote management, all of which enhance user experience and compliance ease.

The downstream segment encompasses distribution channels and post-sales support. Distribution relies on a mix of direct sales to large institutional buyers (like major hospital networks or national abatement firms) and indirect distribution through specialized industrial equipment distributors and, crucially, equipment rental companies. The rental market plays a significant role, providing flexible access to high-cost machinery for short-term projects. Post-sales activities, including warranty provision, maintenance contracts, and the supply of consumable replacement filters (a high-margin business component), are vital for sustaining customer relationships and ensuring the long-term operational success and safety compliance of the installed base. The efficiency of the distribution network determines market reach and the speed of machine deployment in urgent environmental remediation or disaster scenarios.

Variable Speed Negative Air Machine Market Potential Customers

The primary end-users and potential customers for Variable Speed Negative Air Machines span multiple sectors demanding rigorous environmental containment and air quality control. Leading this group are specialized environmental remediation contractors focusing on hazardous material abatement, such as asbestos removal, lead paint mitigation, and complex mold remediation projects, where reliable negative pressure is non-negotiable for regulatory compliance and safety. The healthcare sector represents another critical customer base, encompassing hospitals, clinics, and temporary medical facilities that require controlled isolation environments, particularly for managing airborne infectious diseases and maintaining sterile conditions during facility renovations. Furthermore, commercial and industrial construction firms, especially those involved in high-end fit-outs or renovations of historic buildings, frequently rent or purchase these units to manage construction dust and debris, protecting adjacent occupied spaces, thereby showcasing a diverse and demanding clientele focused intensely on regulatory compliance and operational safety protocols.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 million |

| Market Forecast in 2033 | USD 740.8 million |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABATIX Environmental, Aerotech Environmental, Airborne Management, AlorAir Solutions, Americraft Manufacturing, Beacon Industries, Controlled Environment Corp, Dri-Eaz Products (Legend Brands), Equipment Development Co. (EDCO), HEPA Filtered Vacuum & Air Filtration Systems (HepaVac), IQAir, Nikro Industries, Phoenix Restoration Equipment, Pullman Ermator, Safety Clean. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Variable Speed Negative Air Machine Market Key Technology Landscape

The contemporary technology landscape of the Variable Speed Negative Air Machine Market is dominated by innovations aimed at improving efficiency, precision, and connectivity. The adoption of Electronically Commutated (EC) motor technology is perhaps the most significant recent development. Unlike traditional AC induction motors, EC motors utilize integrated electronics to control speed precisely and operate significantly more efficiently, resulting in lower power consumption, reduced heat generation, and extended motor lifespan. This efficiency is critical, as negative air machines often operate continuously for weeks or months during abatement projects. Furthermore, the variable speed capability inherent to these motors allows for the exact maintenance of specified air changes per hour (ACH) or pressure differential (e.g., -0.02 inches of water column), providing unparalleled control necessary for compliance validation in regulated environments, such as those governed by critical hospital standards or EPA guidelines.

Connectivity and smart features, powered by the Internet of Things (IoT), are rapidly becoming standard requirements, moving the machines beyond simple filtration units into sophisticated environmental control systems. Modern variable speed machines are increasingly equipped with integrated sensors for real-time monitoring of air pressure, filter load status, and operational hours. This data is often transmitted wirelessly via Wi-Fi or cellular networks to cloud-based dashboards, allowing project managers and facility engineers to remotely verify containment integrity, track filter life, and adjust fan speeds without needing to physically enter the contaminated zone. This remote monitoring capability enhances safety, simplifies documentation for regulatory bodies, and significantly reduces the operational expenditures associated with manual checks, positioning smart functionality as a key competitive differentiator in the premium segment of the market.

Filtration technology continues to advance, focusing on higher efficiency media and easier replacement mechanisms. While standard HEPA filters (rated 99.97% efficient at 0.3 microns) remain the benchmark for most applications, there is increasing adoption of ULPA filters (rated 99.999% efficient at 0.12 microns) for ultra-sensitive environments like compounding pharmacies or semiconductor manufacturing cleanrooms. Manufacturers are also innovating in pre-filtration stages, utilizing multi-stage filtration trains that include disposable coarse filters and carbon filters for odor control, thereby extending the life of the much more expensive primary HEPA filter. The development of differential pressure gauges and sensors that accurately predict the remaining lifespan of the HEPA filter based on pressure drop allows for proactive replacement scheduling, ensuring continuous optimal performance and minimizing the risk of containment failure due to filter overload or saturation during crucial operations.

Regional Highlights

Geographic market dynamics reflect varying levels of regulatory stringency, economic development, and infrastructure modernization priorities, resulting in differential growth rates and market maturity across key global regions. North America currently dominates the Variable Speed Negative Air Machine Market, largely due to established and rigidly enforced regulations concerning hazardous material handling (e.g., asbestos, mold) and robust investment in technologically advanced healthcare facilities, which demand sophisticated air containment systems. The culture of litigation associated with environmental exposure further compels contractors and facility managers to invest in certified, high-quality variable speed units to ensure comprehensive compliance and liability mitigation. The market here is highly mature but continues to grow through replacement demand and the adoption of newer, smart, IoT-enabled machines.

Europe represents a highly developed market characterized by strong emphasis on energy efficiency and sustainability. Regulations such as the EU Eco-design Directive influence product development, favoring machines equipped with EC motors and minimal energy footprints. Countries like Germany and the UK show high adoption rates, driven by extensive renovation projects in older buildings requiring lead and asbestos abatement, alongside a premium focus on indoor air quality standards in commercial spaces. The rental market is particularly strong in Europe, providing specialized equipment access to numerous small and medium-sized enterprises undertaking localized remediation projects across various member states, thus supporting steady, quality-driven market expansion.

The Asia Pacific (APAC) region is forecasted to exhibit the highest Compound Annual Growth Rate (CAGR) over the forecast period. This rapid growth is underpinned by explosive infrastructural expansion, urbanization, and subsequent environmental challenges, leading to increased demand for mold and moisture remediation services in densely populated areas. Crucially, vast investment in modernizing healthcare infrastructure across countries like China, India, and Southeast Asia, driven by the need for enhanced infectious disease control capabilities following recent pandemics, is creating substantial, non-cyclical demand for advanced variable speed air containment solutions. While price sensitivity remains a factor, the increasing implementation of international environmental and safety standards is accelerating the transition from basic filtration units to sophisticated variable speed models in this rapidly developing economic bloc.

- North America (Dominant Market): Driven by stringent environmental safety regulations (OSHA, EPA), mature abatement industry, and high adoption rates in healthcare facility construction and renovation projects.

- Europe (Energy Efficiency Focus): Growth supported by EU energy directives favoring EC motor technology, strong rental market, and widespread adoption in building remediation and compliance with strict IAQ standards.

- Asia Pacific (Highest Growth): Rapid urbanization and infrastructure development, increased foreign investment in modern hospitals, and rising awareness of biohazard control driving substantial demand for new containment equipment.

- Latin America & MEA (Emerging Markets): Expanding industrial sectors and nascent environmental regulations are slowly driving initial adoption, focusing primarily on industrial ventilation and basic construction dust control, representing future growth frontiers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Variable Speed Negative Air Machine Market.- ABATIX Environmental

- Aerotech Environmental

- Airborne Management

- AlorAir Solutions

- Americraft Manufacturing

- Beacon Industries

- Controlled Environment Corp

- Dri-Eaz Products (Legend Brands)

- Equipment Development Co. (EDCO)

- HEPA Filtered Vacuum & Air Filtration Systems (HepaVac)

- Herc Rentals Inc. (Rental Focus)

- IQAir

- Nikro Industries

- Novair (Novaire Systems)

- Phoenix Restoration Equipment

- Pullman Ermator

- Ruwac USA

- Safety Clean

- Sentry Air Systems

- Target Restoration Equipment

Frequently Asked Questions

Analyze common user questions about the Variable Speed Negative Air Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a variable speed negative air machine and why is variable speed important?

The primary function is to create a controlled negative pressure environment to prevent airborne contaminants from escaping a work zone, such as during asbestos abatement or infectious disease isolation. Variable speed capability is crucial because it allows operators to precisely match the fan output to the containment volume and leakage rate, maximizing energy efficiency, ensuring regulatory compliance, and maintaining consistent pressure differentials, which fixed-speed units cannot achieve.

Which end-use industries are driving the current demand for these machines?

Current demand is predominantly driven by the Environmental Remediation sector (mold, asbestos, lead abatement) due to strict governmental regulations, and the Healthcare sector, which requires these units for temporary patient isolation rooms, facility maintenance, and compliance with stringent biosafety protocols, especially post-pandemic preparedness efforts.

How is IoT technology impacting the operational efficiency of variable speed negative air machines?

IoT integration allows for remote monitoring of critical operational parameters, including real-time pressure differential, filter saturation levels, and run-time hours. This connectivity enables predictive maintenance scheduling, immediate alerts for containment failure, and simplifies regulatory documentation, resulting in enhanced uptime and reduced manual oversight costs for complex projects.

What is the main difference between HEPA and ULPA filtration in this market?

HEPA (High-Efficiency Particulate Air) filters are the standard, removing 99.97% of particles 0.3 microns and larger. ULPA (Ultra-Low Penetration Air) filters offer superior efficiency, removing 99.999% of particles 0.12 microns and larger. ULPA is typically required for ultra-sensitive environments like specialized pharmaceutical manufacturing cleanrooms, whereas HEPA suffices for most remediation and standard healthcare applications.

What are the key growth opportunities for manufacturers in the forecast period?

Key opportunities involve strategic geographic expansion into rapidly developing Asia Pacific markets, significant integration of Artificial Intelligence for autonomous control and diagnostic capabilities, and capitalizing on the burgeoning equipment rental segment, which provides accessible solutions for contractors facing high initial capital expenditure hurdles.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager