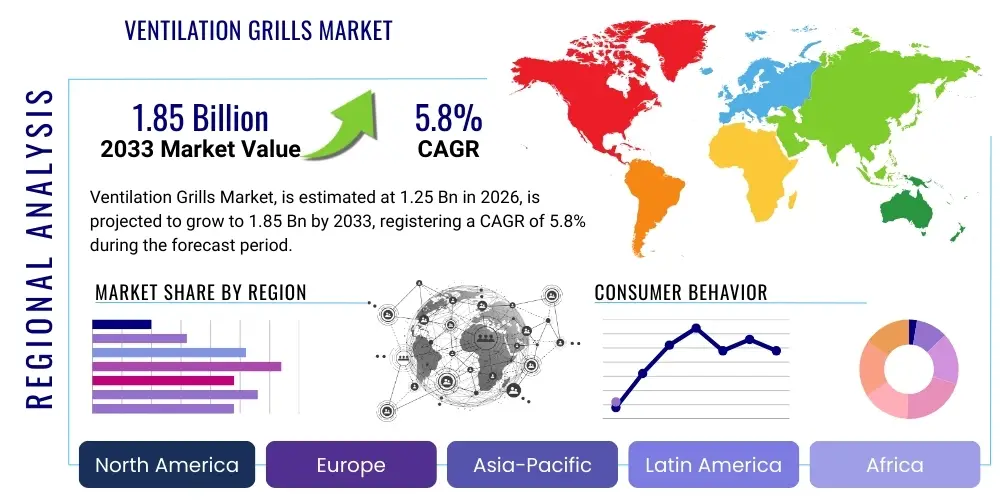

Ventilation Grills Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442485 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Ventilation Grills Market Size

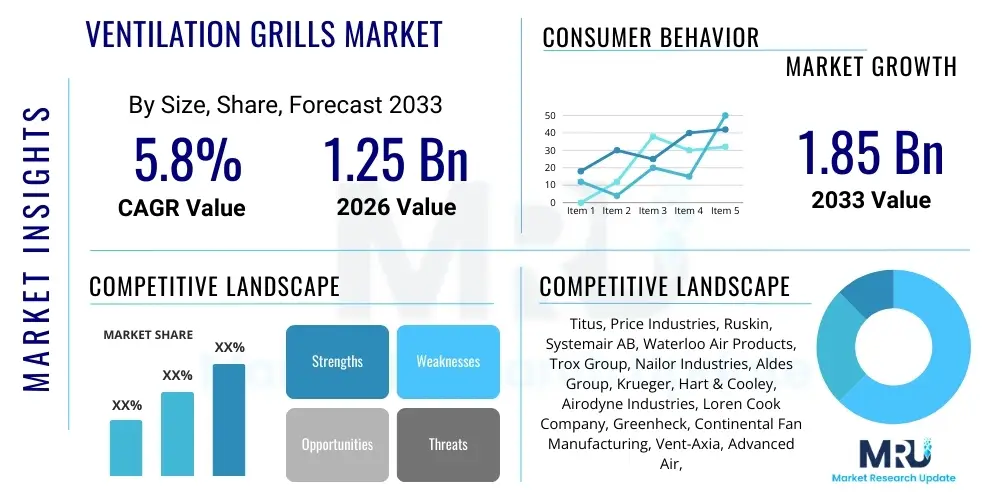

The Ventilation Grills Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.85 Billion by the end of the forecast period in 2033. This growth trajectory is fundamentally supported by the escalating focus on indoor air quality (IAQ) standards globally, coupled with stringent energy efficiency regulations being implemented across residential, commercial, and industrial construction sectors. The increasing adoption of advanced Heating, Ventilation, and Air Conditioning (HVAC) systems in developing economies is a primary catalyst expanding the demand for high-performance, aesthetically pleasing ventilation grills and diffusers, ensuring optimal air circulation and reducing energy waste across diverse building structures.

Ventilation Grills Market introduction

The Ventilation Grills Market encompasses the design, manufacture, and distribution of components used to cover air supply, return, and exhaust openings in HVAC systems, ensuring controlled airflow while preventing the ingress of foreign objects. These products, which include registers, diffusers, and louvers, are critical elements in maintaining thermal comfort and hygienic indoor environments. Major applications span residential buildings, commercial offices, industrial facilities, hospitals, and transportation infrastructure, where efficient air management is paramount. The primary benefit of sophisticated ventilation grills is their ability to precisely control air diffusion patterns, minimize noise generation, and enhance the overall architectural integration of the HVAC system. Key driving factors include the rapid urbanization trends, the modernization of existing infrastructure requiring system upgrades, and persistent technological innovation focused on materials science, particularly in corrosion resistance and fire safety attributes, positioning the market for sustained expansion.

Ventilation Grills Market Executive Summary

The global Ventilation Grills Market is characterized by robust business trends emphasizing smart ventilation systems, leading to a higher integration of adjustable and automated louver mechanisms that respond dynamically to environmental sensors. Manufacturers are increasingly prioritizing sustainable material sourcing, such as recycled aluminum and specialized plastics, to meet green building certifications and enhance corporate environmental responsibility profiles. Regionally, the Asia Pacific (APAC) stands out as the fastest-growing market, driven by massive infrastructure development and the increasing penetration of centralized air conditioning in nations like China and India, overshadowing mature markets in North America and Europe where demand is primarily driven by replacement and regulatory compliance. Segment trends indicate a strong shift toward aesthetically optimized linear slot diffusers and custom-designed architectural grills, particularly in the high-end commercial sector, while the residential sector maintains consistent demand for standard, cost-effective ceiling and sidewall registers. This confluence of technological innovation and geographical expansion defines the competitive landscape.

AI Impact Analysis on Ventilation Grills Market

User queries regarding the impact of Artificial Intelligence (AI) on the Ventilation Grills Market primarily revolve around how smart technology integrates with passive components, focusing on predictive maintenance, enhanced energy efficiency, and adaptive airflow optimization. Users are keen to understand if AI can make traditional, fixed components "smart," and how manufacturing processes might be automated or improved using machine learning algorithms. Key concerns include the potential obsolescence of purely mechanical components and the need for new skill sets in installation and maintenance. Expectations center on grills becoming sophisticated endpoints in a smart HVAC network, providing granular data on air quality, temperature gradients, and pressure differentials to centralized AI control systems, thereby achieving unparalleled comfort levels and operational cost savings.

AI’s influence is subtle yet transformative, extending beyond just the end-product into the entire lifecycle. In design, AI generative algorithms are assisting engineers in optimizing grill geometry—calculating precise blade angles and airflow resistance (K-factors) to maximize efficiency and minimize noise before physical prototyping, significantly reducing development time and material waste. Furthermore, AI-driven predictive maintenance models leverage data collected by integrated sensors (often placed near or within the grill) to diagnose potential issues in the broader HVAC system, such as filter clogging or fan wear, thereby shifting maintenance from reactive to proactive, ensuring system reliability and maximizing the lifespan of the entire ventilation infrastructure.

On the manufacturing floor, AI enhances precision and quality control. Computer Vision systems powered by deep learning scrutinize every finished grill for defects, misalignment, or surface imperfections at high speed, surpassing human capabilities and reducing the rate of flawed products entering the supply chain. Supply chain optimization, driven by AI, predicts raw material needs based on fluctuating construction demand forecasts, ensuring just-in-time inventory management for materials like aluminum, steel, and specialized polymers, thereby stabilizing production costs and improving responsiveness to sudden shifts in market demand for specialized or customized ventilation solutions.

- AI enables generative design for optimal airflow geometry (low noise, high efficiency).

- Predictive maintenance using AI analysis of integrated sensor data near the grill location.

- Enhanced quality control in manufacturing via AI-powered computer vision inspection systems.

- Optimization of HVAC system performance through AI-driven adaptive airflow adjustments coordinated by smart diffusers.

- AI assists in dynamic pricing and inventory management for customized grill orders.

DRO & Impact Forces Of Ventilation Grills Market

The dynamics of the Ventilation Grills Market are powerfully shaped by a combination of key drivers, fundamental restraints, and emerging opportunities, all interacting under significant internal and external impact forces. A primary driver is the accelerating stringency of building codes and air quality standards, particularly post-pandemic, compelling both new and existing structures to install or upgrade high-efficiency ventilation systems, thereby boosting demand for premium grills and diffusers designed for specific air changes per hour (ACH) requirements. Restraints include the inherent volatility of raw material prices, specifically steel and aluminum, which directly impacts manufacturing costs and profit margins, alongside the challenge posed by low-quality, inexpensive imports from unorganized sectors that exert downward pressure on overall market pricing and perceived value. Significant opportunities arise from the increasing adoption of smart building technologies, which necessitate specialized, sensor-integrated grills capable of dynamic airflow control and connectivity, offering higher margins and technological differentiation. The impact forces are characterized by moderate supplier power due to standardized raw material sourcing but high buyer power, especially in large-scale commercial projects, where customization and volume discounts dictate purchasing decisions, making innovation in material efficiency and smart features crucial for competitive differentiation and market positioning.

Segmentation Analysis

The Ventilation Grills Market is segmented across multiple dimensions, including Material Type, Product Type, Application, and End-User, reflecting the diverse requirements of the construction and HVAC industry. Understanding these segments is vital for manufacturers to tailor their product offerings and marketing strategies effectively. For instance, the segmentation by Material Type highlights the ongoing preference for durable, lightweight materials like aluminum and high-grade plastics, which offer excellent resistance to corrosion and moisture, particularly in humid or industrial environments, over traditional galvanized steel. The Product Type segmentation distinguishes between highly decorative and performance-focused components, ranging from simple stamped registers to complex VAV (Variable Air Volume) diffusers, each serving a distinct function in air distribution kinetics, directly impacting installation complexity and overall system efficiency.

Further analysis of the segmentation by Application reveals that commercial buildings, including offices, retail spaces, and hotels, typically demand high-aesthetic linear and architectural diffusers that blend seamlessly with interior design, prioritizing visual appeal alongside performance. Conversely, the industrial application segment focuses heavily on functional aspects, such as robust construction, large-volume airflow capability, and resistance to chemical exposure, often requiring specialized coatings or materials like stainless steel for demanding factory environments. These differences necessitate highly tailored production lines and distinct sales strategies. The End-User segmentation, focusing on new construction versus renovation projects, indicates that the replacement market, fueled by aging infrastructure and evolving regulatory mandates, represents a stable and high-volume demand stream, often seeking quick installation and standardized sizing.

The interaction between these segments defines market behavior. For example, the intersection of the Aluminum Material Type with the Commercial Application segment represents a high-growth area, driven by the need for lightweight, aesthetically superior, and corrosion-resistant solutions compliant with modern green building standards. Manufacturers capable of providing highly customizable, quick-turnaround aluminum linear grills for commercial retrofits are positioned to capture premium market share. Conversely, the Plastic Material Type segment, predominantly used in residential applications and specialized high-humidity zones like bathrooms, focuses on cost-efficiency, ease of installation, and mold resistance, often driving innovation in polymer compounds and injection molding techniques rather than complex mechanical controls.

- Material Type: Aluminum, Steel (Galvanized, Stainless), Plastic/Polymer (ABS, PVC), Wood/Composite.

- Product Type: Registers, Grilles, Diffusers (Ceiling, Floor, Wall), Louvers (Fixed, Adjustable), Dampers.

- Application: Supply, Return, Exhaust/Extraction.

- End-User: Residential, Commercial (Office, Retail, Hospitality), Industrial (Manufacturing, Warehousing), Institutional (Healthcare, Education).

Value Chain Analysis For Ventilation Grills Market

The value chain for the Ventilation Grills Market begins with the upstream procurement of primary raw materials, predominantly aluminum ingots, various grades of steel (galvanized and stainless), and specialized thermoplastic resins. The efficiency of this stage is crucial, as material costs constitute a significant portion of the final product cost, making stable long-term contracts and efficient supply chain logistics essential for mitigating price volatility. Material processing and component manufacturing involve precision processes such as extrusion for aluminum profiles, stamping and bending for sheet metal, and injection molding for plastic components. This stage adds significant value through high-tolerance fabrication, surface finishing (e.g., powder coating, anodizing), and assembly of functional parts like dampers and adjustable mechanisms, necessitating specialized machinery and skilled labor to ensure compliance with strict airflow performance specifications and noise criteria.

The downstream segment focuses on distribution, installation, and end-user application. Distribution channels are bifurcated into direct and indirect routes. Direct sales often involve large-scale customized orders placed by major HVAC contractors or Original Equipment Manufacturers (OEMs) who integrate the grills into larger systems for significant commercial or industrial projects, allowing manufacturers high control over product specifications and pricing. Indirect channels involve a layered network utilizing national and regional wholesale distributors, specialized HVAC supply houses, and retail hardware stores, which cater primarily to smaller contractors, maintenance professionals, and residential customers requiring standardized, off-the-shelf products. The installation phase, typically performed by mechanical contractors, links the product to the final end-user environment, requiring product compatibility with ductwork and wall/ceiling finishes.

Effective value chain management hinges on minimizing lead times and optimizing inventory across these channels. Manufacturers must maintain robust relationships with specialized component suppliers (e.g., damper controls, actuators) to ensure seamless assembly. The trend toward customized and semi-customized architectural grills has put pressure on the manufacturing stage to adopt flexible production systems. Furthermore, digital tools are increasingly integrated into the distribution phase, allowing contractors to use online configurators for custom orders, reducing errors and speeding up order fulfillment, thereby adding efficiency and improving customer satisfaction in a highly competitive and technically demanding market environment.

Ventilation Grills Market Potential Customers

Potential customers for the Ventilation Grills Market are diverse and can be broadly categorized across the construction ecosystem, primarily encompassing entities responsible for building infrastructure development, maintenance, and air quality management. The most significant end-users are large mechanical, electrical, and plumbing (MEP) contractors who execute major HVAC installations in commercial high-rises, institutional facilities, and sprawling industrial complexes. These customers prioritize high performance, certification compliance, and reliability, often demanding technical specifications regarding pressure drop and noise levels, making them highly receptive to premium and engineered product solutions offering documented performance data and sophisticated integrated features such as actuated dampers.

Another crucial customer segment includes HVAC Original Equipment Manufacturers (OEMs) that integrate grills and diffusers into pre-packaged air handling units, fan coil units, or terminal boxes. These buyers seek long-term supply agreements, highly consistent quality, and competitive pricing for standardized or semi-custom components used in mass production runs. The institutional sector, covering hospitals, schools, and government buildings, acts as a steady customer base, driven by regulatory compliance focused on critical applications, such as high-efficiency filtration and directional laminar flow requirements in operating theaters or laboratory environments, demanding specialized, hygienic ventilation products, often manufactured from stainless steel or specialized antimicrobial coatings.

Finally, the residential market segment, serviced primarily through wholesale distributors and retail outlets, consists of independent home builders, residential HVAC installers, and Do-It-Yourself (DIY) consumers undertaking renovation and replacement projects. This segment is highly sensitive to aesthetic appeal, ease of installation, and cost-effectiveness, favoring standard sizes, widely available finishes, and user-friendly materials like polymer or basic aluminum. Catering to this wide array of buyers requires manufacturers to maintain expansive product lines, ranging from basic utility products to highly engineered architectural components, ensuring broad market reach and stability across economic cycles in both new construction and aftermarket segments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.85 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Titus, Price Industries, Ruskin, Systemair AB, Waterloo Air Products, Trox Group, Nailor Industries, Aldes Group, Krueger, Hart & Cooley, Airodyne Industries, Loren Cook Company, Greenheck, Continental Fan Manufacturing, Vent-Axia, Advanced Air, Shoemaker Manufacturing, Air Conditioning Products, Regal Grille, FlaktGroup. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ventilation Grills Market Key Technology Landscape

The technology landscape within the Ventilation Grills Market is increasingly driven by advancements in material science, precision manufacturing, and integration capabilities with sophisticated building management systems (BMS). A key focus is the development of advanced polymer and composite materials offering superior fire ratings, antimicrobial properties, and lighter weight compared to traditional metals, thereby simplifying installation and maintenance in specialized environments such as healthcare and high-humidity zones. Furthermore, continuous investment in specialized extrusion and stamping technologies enables manufacturers to produce intricate, architecturally appealing linear slot diffusers and custom geometric patterns with exceptionally tight tolerances, minimizing air leakage and maximizing jet penetration effectiveness, which is crucial for achieving high comfort indexes in large commercial spaces.

The most significant technological shift involves smart ventilation components. This includes the development of active diffusers and Variable Air Volume (VAV) registers equipped with integrated micro-actuators, sensors (temperature, CO2, occupancy), and wireless communication modules (e.g., BACnet IP, Zigbee). These intelligent components allow for localized, zonal air delivery control, adjusting airflow dynamically based on real-time environmental data rather than fixed, system-wide settings. This capability directly enhances energy efficiency by ensuring that conditioned air is only delivered precisely where and when it is needed, moving the HVAC system closer to a demand-controlled ventilation (DCV) paradigm, which is a major regulatory and consumer trend.

Moreover, the integration of computational fluid dynamics (CFD) software during the product development phase represents a core technological tool. CFD simulations allow engineers to accurately model and predict air patterns, throw distances, and pressure drops for new grill designs before physical prototyping, significantly accelerating the innovation cycle and ensuring optimal performance validation. This technological reliance on simulation tools allows for highly specialized product development catering to unique architectural demands, such as displacement ventilation systems which require low-velocity air delivery diffusers placed near the floor level. The combined application of advanced materials, smart electronics, and simulation software is transforming passive grills into active, data-generating components of a modern, efficient HVAC infrastructure.

Regional Highlights

The global demand for ventilation grills exhibits distinct regional patterns influenced by climate, construction volume, and regulatory environments.

- Asia Pacific (APAC): Characterized by exponential growth in construction, particularly in China, India, and Southeast Asian nations. The demand here is driven by rapid urbanization, increasing disposable incomes leading to higher adoption of centralized HVAC systems, and a growing awareness of urban air pollution necessitating robust indoor ventilation solutions. Cost-effectiveness remains a strong factor, but there is an increasing shift toward high-efficiency, multi-zone systems in commercial development.

- North America: A mature market defined by strict energy efficiency standards (e.g., ASHRAE 90.1) and a high penetration of replacement and retrofit projects. Demand is concentrated on premium, technologically advanced products, including smart registers and architecturally concealed diffusers that enhance aesthetic appeal while offering superior zonal control. Innovation in material usage for fire safety and compliance is a major market driver.

- Europe: Highly regulated, focusing heavily on sustainability, low-energy buildings (NZEB), and mandatory IAQ monitoring (e.g., EU performance directives). The market favors manufacturers that offer certified components with documented environmental product declarations (EPDs). Demand is strong for displacement ventilation products and sophisticated façade-integrated louvers that manage natural light and airflow passively.

- Latin America (LATAM): Growth is steady, primarily concentrated in metropolitan areas of Brazil and Mexico. The market is price-sensitive, with a rising emphasis on basic, durable metal and plastic grills for both residential and smaller commercial applications. Infrastructure investment, especially in tourism and commercial centers, is gradually boosting demand for mid-range sophisticated HVAC components.

- Middle East and Africa (MEA): Dominated by extreme climatic conditions, necessitating high-performance, robust ventilation solutions designed for intense cooling loads and resistance to dust and corrosion. Major construction projects in the GCC region drive demand for high-volume air terminal devices and custom louvers for large-scale architectural projects, often requiring stringent standards adherence.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ventilation Grills Market, analyzing their product portfolios, geographical presence, and strategic initiatives.- Titus

- Price Industries

- Ruskin

- Systemair AB

- Waterloo Air Products

- Trox Group

- Nailor Industries

- Aldes Group

- Krueger

- Hart & Cooley

- Airodyne Industries

- Loren Cook Company

- Greenheck

- Continental Fan Manufacturing

- Vent-Axia

- Advanced Air

- Shoemaker Manufacturing

- Air Conditioning Products

- Regal Grille

- FlaktGroup

Frequently Asked Questions

Analyze common user questions about the Ventilation Grills market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between a grille, a register, and a diffuser in HVAC systems?

A grille is a basic air terminal device with fixed vanes used for return or exhaust air, offering minimal control over airflow. A register is essentially a grille that includes an integrated damper mechanism, allowing users to manually regulate the volume of air passing through it. A diffuser, conversely, is typically designed for supply air and utilizes specialized patterns and vanes to spread and mix the conditioned air across the occupied space, optimizing air distribution and minimizing drafts for thermal comfort.

How do smart ventilation grills contribute to energy efficiency in commercial buildings?

Smart ventilation grills, often termed active diffusers, contain embedded sensors (CO2, temperature, occupancy) and actuators that link directly to a Building Management System (BMS). They enhance energy efficiency by enabling Demand-Controlled Ventilation (DCV), meaning they adjust the supply air volume only to specific zones that require ventilation, rather than conditioning and delivering air uniformly across the entire building, thereby reducing the load on the main HVAC unit and lowering overall operational costs.

Which material type dominates the market and why is it preferred?

Aluminum dominates the market, particularly in commercial and high-end residential applications. Aluminum is favored for its excellent characteristics: it is lightweight, highly resistant to corrosion (unlike galvanized steel), and easily extruded, allowing manufacturers to create complex, aesthetically pleasing profiles like linear slot diffusers with high precision. Its ease of recycling also aligns with current sustainable building practices and green certifications.

What is the role of Computational Fluid Dynamics (CFD) in the design of modern ventilation grills?

CFD is crucial for modern grill design as it allows engineers to simulate and analyze complex air flow patterns, pressure drops, and noise generation characteristics before physical prototyping. This reduces development time and costs, ensuring that the final product meets rigorous performance standards concerning air distribution index (ADI), throw length, and compliance with noise criteria (NC) levels necessary for specific architectural applications.

What are the major regulatory standards impacting the manufacturing of ventilation grills globally?

Key regulatory standards include ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) standards, specifically ASHRAE 62.1 (Ventilation for Acceptable Indoor Air Quality) and ASHRAE 90.1 (Energy Standard for Buildings), which dictate performance requirements. European CE marking, particularly related to the Construction Products Regulation (CPR), and various national fire safety codes also mandate specific material flammability ratings and structural integrity, significantly influencing product specifications and market access.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager