Vertical Hydroponic Lettuce Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443152 | Date : Feb, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Vertical Hydroponic Lettuce Market Size

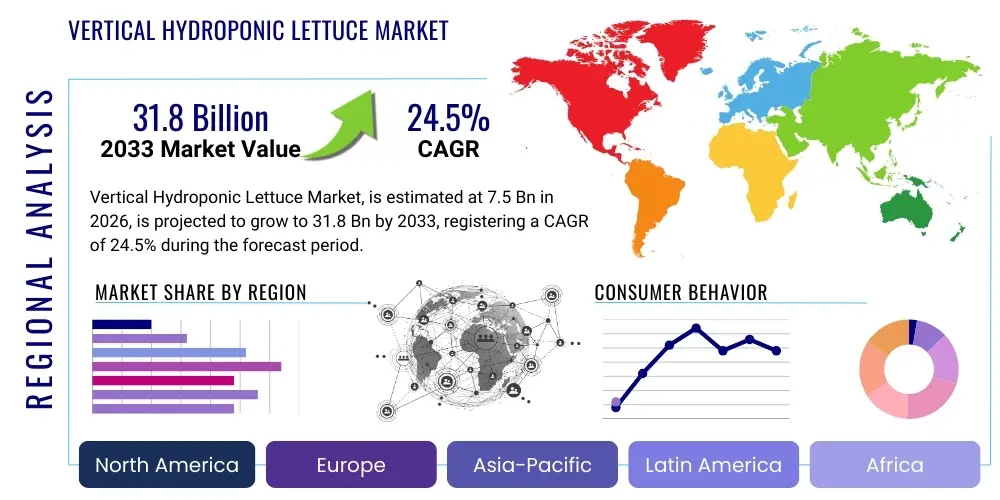

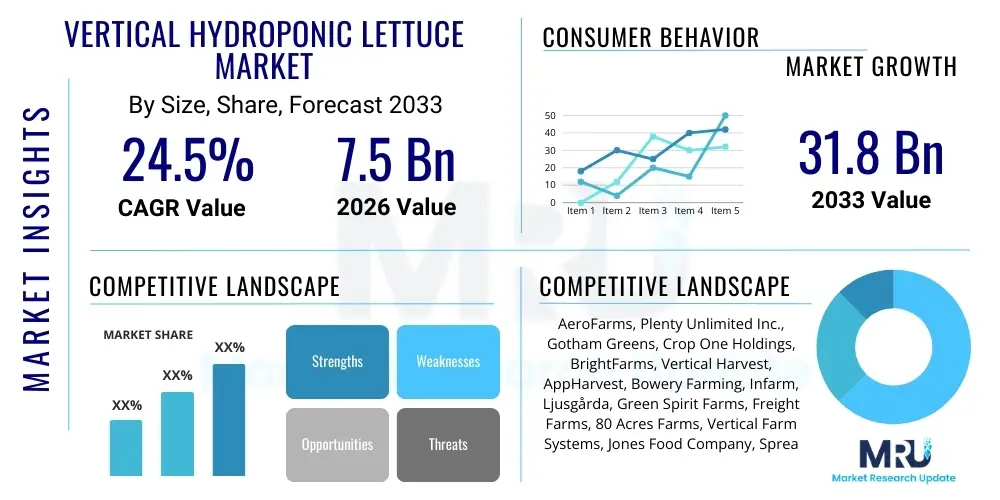

The Vertical Hydroponic Lettuce Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 24.5% between 2026 and 2033. The market is estimated at $7.5 Billion in 2026 and is projected to reach $31.8 Billion by the end of the forecast period in 2033.

Vertical Hydroponic Lettuce Market introduction

The Vertical Hydroponic Lettuce Market encompasses the cultivation of various lettuce varieties using soilless techniques within vertically stacked layers, typically indoors under controlled environmental agriculture (CEA) conditions. This methodology leverages systems like Deep Water Culture (DWC), Nutrient Film Technique (NFT), and Aeroponics to deliver nutrient-rich water directly to the plant roots, optimizing growth rates and resource efficiency compared to traditional field farming. The primary product is high-quality, pesticide-free, and locally sourced lettuce, addressing increasing consumer demand for sustainable and fresh produce, particularly in urban environments and regions facing water scarcity or unpredictable climate patterns.

Major applications for vertically farmed lettuce include direct consumer sales through grocery retail chains, specialized gourmet culinary establishments, and institutional food services, such as hospitals and corporate cafeterias that prioritize freshness and traceability. The inherent benefits of vertical hydroponics—such as year-round production regardless of external weather conditions, significantly reduced water usage (up to 95% less than conventional farming), and elimination of harmful pesticides—are key drivers accelerating market adoption. Furthermore, the capacity for high-density planting in urban centers drastically cuts down transportation costs and carbon emissions, promoting a sustainable local food system.

Driving factors propelling market expansion include rapid urbanization leading to shrinking agricultural land, technological advancements in LED lighting and environmental control systems (HVAC, sensors), and robust investment in agri-tech infrastructure. The growing recognition of food safety issues and the consumer desire for transparent supply chains further cement vertical hydroponics as a viable, scalable alternative. This convergence of resource efficiency needs and market demand for premium fresh produce positions the vertical hydroponic lettuce segment as a crucial component of future global food security strategies.

Vertical Hydroponic Lettuce Market Executive Summary

The Vertical Hydroponic Lettuce Market is experiencing transformative growth, primarily fueled by global shifts toward sustainable resource management and optimized urban food supply chains. Key business trends indicate significant investment concentration in automation technologies, particularly robotics for planting, harvesting, and packaging, aimed at reducing operational labor costs and enhancing scalability. Strategic partnerships between technology providers, construction firms specializing in CEA infrastructure, and major food distributors are crucial for expanding market penetration. Furthermore, companies are increasingly focusing on varietal optimization, utilizing genetic research to enhance lettuce types specifically for vertical farming environments, ensuring better yield density and improved flavor profiles to command premium pricing.

Regionally, North America and Europe currently dominate the market due to high consumer spending power, established technological infrastructure, and stringent food safety regulations favoring controlled environment agriculture. However, the Asia Pacific region, particularly China and Japan, is emerging as the fastest-growing market, driven by massive urbanization, limited arable land, and government mandates supporting localized food production to reduce reliance on imports. Latin America and the Middle East and Africa (MEA) represent substantial future growth opportunities, particularly where water stress and high energy costs necessitate highly efficient farming methods, positioning hydroponics as a vital long-term solution.

Segment trends highlight the dominance of the Nutrient Film Technique (NFT) and Deep Water Culture (DWC) systems due to their proven reliability and moderate cost efficiency, though Aeroponics is gaining traction for its high yield per square foot and maximum water efficiency. By variety, Butterhead and Romaine lettuce varieties hold significant market share, favored for their commercial appeal and robustness in CEA settings. The market structure remains fragmented but is moving toward consolidation as larger, well-funded ag-tech players acquire smaller regional farms to achieve economies of scale and standardize production protocols across multiple vertical farm locations globally.

AI Impact Analysis on Vertical Hydroponic Lettuce Market

User inquiries regarding the integration of Artificial Intelligence (AI) in the Vertical Hydroponic Lettuce Market frequently center on predictive analytics capabilities, optimization of resource use, and the concept of "autonomous farming." Key themes involve how AI can fine-tune microclimates (temperature, humidity, CO2 levels) in real-time to maximize crop health and minimize energy consumption. Users are deeply concerned with achieving perfect input ratios—water, nutrients, and light spectrum—and look to AI to eliminate human error and achieve consistent, predictable yields. Expectations are high that AI will transition vertical farms from automated systems to fully intelligent, self-correcting growth environments, leading to unprecedented operational efficiency and crop quality consistency previously unattainable in traditional agriculture.

AI adoption is profoundly affecting the operational landscape by enabling data-driven decision-making across the entire cultivation cycle, from seeding to harvesting. Machine learning algorithms process massive datasets collected by farm sensors—including leaf color, growth rate, nutrient absorption, and pest presence—to identify optimal growth recipes for specific lettuce varieties. This level of granular control ensures that environmental variables are constantly adjusted, preventing disease outbreaks before they manifest and drastically cutting down on waste. Moreover, AI-powered computer vision systems are revolutionizing quality control and harvesting processes, accurately identifying mature lettuce heads for robotic picking, thereby maintaining labor efficiency in large-scale operations.

The immediate consequence of AI integration is the shift from high-labor, complex manual management to streamlined, centralized digital oversight, significantly impacting profitability and scalability. By analyzing energy usage patterns and predicting peak electricity demand, AI scheduling systems allow farms to optimize lighting cycles during off-peak hours, substantially reducing the largest operating expenditure: energy. This technological evolution moves vertical farming beyond being just a novelty into a critical, economically viable component of global food supply infrastructure, making hyper-local, sustainable lettuce production scalable globally.

- Enhanced Yield Prediction and Optimization: AI algorithms predict harvest volume and optimize input parameters (light, nutrients, temperature) for maximum output density.

- Resource Efficiency Maximization: Machine learning fine-tunes irrigation schedules and nutrient delivery based on real-time plant needs, minimizing water and fertilizer wastage.

- Automated Climate Control: AI maintains ideal microclimates autonomously, compensating for external factors and reducing energy consumption through predictive HVAC management.

- Pest and Disease Detection: Computer vision systems identify initial signs of infestation or disease with high accuracy, enabling preemptive, localized intervention without human oversight.

- Robotic Harvesting and Quality Sorting: AI guides precision robots for non-destructive harvesting and automatically grades lettuce quality based on defined commercial standards.

DRO & Impact Forces Of Vertical Hydroponic Lettuce Market

The Vertical Hydroponic Lettuce Market is shaped by powerful Drivers, Restraints, and Opportunities (DRO), which collectively form the Impact Forces determining its trajectory. Key drivers include accelerating global population growth demanding sustainable food sources, coupled with technological maturation in CEA, specifically advancements in energy-efficient LED technology and sophisticated environmental control software. The opportunity lies in geographical expansion into food-insecure or water-scarce regions, along with developing proprietary lettuce varieties optimized for rapid vertical growth. These positive forces are currently exerting significant upward pressure on market valuation and adoption rates globally, especially as consumer preferences trend strongly toward locally sourced and pesticide-free produce.

Restraints, however, pose significant challenges to widespread adoption and profitability. The primary constraint is the exceptionally high initial capital expenditure required for establishing vertical farms, encompassing infrastructure, specialized equipment, and advanced climate control systems. Furthermore, high operational energy consumption remains a critical cost factor, particularly in regions with elevated electricity tariffs, although this is being partially mitigated by renewable energy adoption and AI-driven optimization. Regulatory hurdles related to zoning, building codes, and integrating these novel food production methods into existing agricultural supply chains also slow down market entry for smaller players, leading to consolidation among firms with access to large funding rounds.

The overarching impact forces thus create a dynamic environment where efficiency and scale dictate success. The necessity for achieving significant economies of scale quickly pushes market players towards rapid technological adoption and strategic mergers. Success is measured not just by yield, but by the energy usage per pound of lettuce produced. The market is positioned at a tipping point where increasing consumer awareness and government subsidies (Opportunity) are rapidly overcoming the hurdles posed by high CapEx and OpEx (Restraints), ensuring sustained double-digit growth (Drivers) over the forecast period, provided that technological advancements continue to drive down operational costs, making the final product competitive with high-quality conventional imports.

Segmentation Analysis

The Vertical Hydroponic Lettuce Market is meticulously segmented based on System Type, Component, Variety, and End-Use, providing a comprehensive understanding of the market structure and investment prioritization. Segmentation by system type reveals crucial insights into technological adoption, with proven techniques like Nutrient Film Technique (NFT) dominating due to ease of scalability, while emerging methods like Aeroponics offer higher resource efficiency. Component segmentation highlights the critical expenditure areas, such as HVAC systems and LED lighting, which are key targets for efficiency improvements and technological innovation to drive profitability across the value chain. Analysis across these segments allows stakeholders to tailor their product offerings, technological development, and market entry strategies to align with the most lucrative and rapidly evolving sub-sectors of the industry.

Variety segmentation underscores consumer preferences and farm operational choices. Common varieties like Romaine and Butterhead are chosen for their resilience and commercial popularity, while specialty greens cater to niche, high-value markets. End-Use segmentation confirms that Retail and Food Service sectors are the primary consumers, demanding consistent, high-quality lettuce year-round. Understanding these diverse segments is vital for predicting growth pockets, optimizing logistical planning, and mitigating supply chain risks associated with high-density, localized production. The dynamic interplay between technology components and specific lettuce varieties cultivated ultimately determines the farm’s overall yield and return on investment.

- By System Type

- Nutrient Film Technique (NFT)

- Deep Water Culture (DWC)

- Aeroponics

- Drip Systems

- Other Systems (e.g., Wick Systems)

- By Component

- Grow Lights (LED, HPS)

- Environmental Controls (HVAC, Sensors, Controllers)

- Growing Medium (Rockwool, Coco Coir, Peat Moss)

- Nutrient Delivery Systems (Pumps, Irrigation Lines)

- Racks and Shelving

- By Variety

- Butterhead

- Romaine

- Leafy (Green Leaf, Red Leaf)

- Crisphead (Iceberg – limited use)

- Specialty Greens (e.g., Frisee, Arugula, Mizuna)

- By End-Use

- Retail Stores (Supermarkets, Hypermarkets)

- Food Service (Hotels, Restaurants, Cafes)

- Institutional Feeding (Hospitals, Schools)

- Direct-to-Consumer (Online Subscriptions)

Value Chain Analysis For Vertical Hydroponic Lettuce Market

The value chain for the Vertical Hydroponic Lettuce Market is distinctly technology-centric and operates across several crucial stages, starting from upstream inputs to final downstream distribution. Upstream analysis involves the procurement and development of essential technological components, including high-efficiency LED lighting systems, sensors for environmental monitoring (pH, EC, humidity), and specialized nutrient formulations. This segment is characterized by high research and development intensity, driven by the need for customized inputs that maximize plant growth while minimizing energy consumption. Key players in the upstream segment include specialized agricultural technology firms and component manufacturers who provide the foundational hardware and software for farm construction and operation.

The midstream operation involves the actual construction and operation of the vertical farms, where controlled environment management and crop cycles take place. This stage relies heavily on automation and system integration, converting raw inputs (water, nutrients, energy, seeds) into marketable lettuce. Efficiency at this stage determines the overall cost structure and scalability. Downstream activities focus on post-harvest handling, packaging, and distribution. Given the short shelf life of fresh lettuce and the competitive advantage of localization, minimizing transit time is paramount. Direct distribution channels, where the farm supplies produce directly to nearby retail distribution centers or food service hubs, are highly favored to maintain freshness and capture higher margins.

Distribution channels are categorized into direct and indirect methods. Direct channels involve farm-to-table models, online subscription services, and direct contracts with high-end restaurants, emphasizing premium quality and immediate delivery. Indirect channels involve utilizing traditional retail supply chains, working through major distributors or wholesalers who handle large volumes and complex logistics to reach widespread retail points (supermarkets and hypermarkets). The effectiveness of the distribution strategy, especially the reliance on direct or localized networks, significantly influences market prices, brand perception regarding freshness, and the overall competitiveness of the vertical farming entity within its operating region.

Vertical Hydroponic Lettuce Market Potential Customers

The primary potential customers and end-users of vertical hydroponic lettuce span a diverse range of commercial and institutional entities focused on sourcing high-quality, reliable, and locally grown produce year-round. The largest buyer segment is retail chains, including both large hypermarkets and smaller specialty grocery stores, which require consistent supply volumes, standardized product quality, and the marketing advantage associated with selling "local" and "pesticide-free" products. These retailers leverage vertical farm produce to minimize supply volatility caused by weather or seasonal changes affecting traditional agriculture, ensuring shelves are consistently stocked with premium lettuce.

The Food Service industry, encompassing hotels, upscale restaurants, and catering companies, represents another critical customer base. These entities demand specialized lettuce varieties and greens with exceptional texture and flavor profiles, and highly value the extended shelf life and guaranteed traceability offered by controlled environment farming. Corporate cafeterias and other institutional buyers are increasingly becoming key targets as they integrate sustainability mandates and prioritize locally sourced, healthy meal options for large populations, recognizing the environmental benefits of vertical farming.

Additionally, the direct-to-consumer segment, often facilitated through subscription boxes and online delivery platforms, is rapidly gaining traction, appealing to health-conscious urban dwellers willing to pay a premium for hyper-fresh, sustainably produced food delivered directly to their homes. These buyers prioritize transparency and minimal environmental footprint. Successful vertical farms often maintain a balanced portfolio, serving large retail anchors while also cultivating high-margin direct-to-consumer relationships.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $7.5 Billion |

| Market Forecast in 2033 | $31.8 Billion |

| Growth Rate | 24.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | AeroFarms, Plenty Unlimited Inc., Gotham Greens, Crop One Holdings, BrightFarms, Vertical Harvest, AppHarvest, Bowery Farming, Infarm, Ljusgårda, Green Spirit Farms, Freight Farms, 80 Acres Farms, Vertical Farm Systems, Jones Food Company, Spread Co. Ltd., Mirai Co. Ltd., Sananbio, Intelligent Growth Solutions (IGS), AGRICO. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Vertical Hydroponic Lettuce Market Key Technology Landscape

The operational efficiency and competitive viability of the Vertical Hydroponic Lettuce Market are fundamentally dependent on a sophisticated technology landscape dominated by Controlled Environment Agriculture (CEA) infrastructure. A core technological pillar is the advancement in LED grow lights, moving beyond simple illumination to spectral tuning. Modern LED systems allow growers to customize the light spectrum, intensity, and photoperiod precisely for specific lettuce varieties at different growth stages, optimizing photosynthesis and morphology. This level of precision maximizes yield while simultaneously driving down the single largest operating cost—electricity—making highly efficient spectral control crucial for profitability and scalability in vertical farms worldwide.

Environmental control systems, often managed by advanced software and sensor arrays, form the brain of the vertical farm. These systems meticulously regulate temperature, humidity, carbon dioxide enrichment, and airflow (HVAC), creating a stable, pest-free microclimate essential for predictable, year-round production. Furthermore, the integration of IoT sensors, coupled with cloud computing, provides real-time data feedback, allowing operators (or AI systems) to immediately detect and correct deviations from ideal growth parameters. This technological sophistication contrasts sharply with traditional agriculture, where external variables introduce significant risk and yield variation.

Another defining technology segment is the optimization of the hydroponic delivery systems themselves. While Nutrient Film Technique (NFT) and Deep Water Culture (DWC) remain standard, the drive for enhanced efficiency pushes innovation toward high-pressure Aeroponics, which maximizes oxygen delivery to the roots, resulting in faster growth and reduced water consumption. Furthermore, the increasing adoption of robotics and automation for high-throughput tasks—such as transplanting, monitoring, and harvesting—is streamlining labor, significantly improving operational throughput, and achieving the required quality consistency demanded by large-scale commercial buyers.

Regional Highlights

Regional analysis reveals that market leadership is concentrated in technologically advanced and highly urbanized regions, while the highest growth potential resides in areas facing acute climate or resource challenges.

- North America: This region holds the largest market share, driven by a mature investment landscape, rapid adoption of ag-tech innovation, and high consumer willingness to pay a premium for local, sustainable produce. The U.S. and Canada host several major vertical farming companies (e.g., AeroFarms, Bowery Farming), focusing heavily on scaling operations, reducing energy costs through green energy contracts, and penetrating mainstream retail channels.

- Europe: The European market is highly developed, spurred by stringent food safety standards, sustainability mandates, and the lack of suitable agricultural land in dense population centers (e.g., Netherlands, UK). Key growth is seen in Northern and Western Europe, where government incentives and large investments in automated, climate-neutral vertical farms are common. Innovation frequently centers on energy efficiency and system integration.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, primarily due to soaring demand in densely populated, land-scarce countries like China, Japan, and Singapore. These countries view vertical farming as critical national infrastructure for food security. Japan and Singapore are leaders in implementing high-tech vertical farming solutions, often with government backing, focusing on efficiency and high-yield per unit area.

- Middle East and Africa (MEA): This region presents significant opportunities driven by extreme water scarcity and arid climates, making traditional farming highly resource-intensive or impossible. Countries in the GCC, particularly the UAE and Saudi Arabia, are making massive capital investments in vertical farms to drastically reduce reliance on imported fresh produce, positioning hydroponics as a strategic priority for long-term food resilience.

- Latin America: The market here is nascent but growing, fueled by urbanization and the need for localized production to overcome logistical challenges associated with transporting produce across varied geographies. Adoption is currently focused on providing high-value crops to urban centers, with Brazil and Mexico showing early investment in both small- and large-scale vertical operations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Vertical Hydroponic Lettuce Market.- AeroFarms

- Plenty Unlimited Inc.

- Gotham Greens

- Crop One Holdings

- BrightFarms

- Vertical Harvest

- AppHarvest

- Bowery Farming

- Infarm

- Ljusgårda

- Green Spirit Farms

- Freight Farms

- 80 Acres Farms

- Vertical Farm Systems

- Jones Food Company

- Spread Co. Ltd.

- Mirai Co. Ltd.

- Sananbio

- Intelligent Growth Solutions (IGS)

- AGRICO

Frequently Asked Questions

Analyze common user questions about the Vertical Hydroponic Lettuce market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor limiting profitability in vertical hydroponic lettuce farms?

The most significant constraint on profitability is the high operational expenditure associated with electricity consumption required for sophisticated LED lighting and HVAC (climate control) systems. Reducing energy costs through advanced AI management and renewable energy integration is critical for achieving viable margins.

How much water does vertical hydroponic lettuce farming save compared to traditional methods?

Vertical hydroponic systems are engineered for maximum water efficiency, typically resulting in savings of 90% to 95% compared to conventional field agriculture. This significant reduction is achieved through closed-loop systems that recapture and reuse nutrient-rich water, minimizing evaporation and runoff.

Which technology system dominates the vertical hydroponic lettuce market?

The Nutrient Film Technique (NFT) and Deep Water Culture (DWC) systems currently hold the dominant market share due to their proven scalability, relative simplicity, and lower initial setup costs compared to more complex systems like high-pressure Aeroponics, although Aeroponics is growing rapidly.

Is vertical hydroponic lettuce considered organic?

Vertical hydroponic lettuce cannot typically be labeled "organic" under strict USDA standards because the farming method does not use soil. However, it is marketed as "pesticide-free," "locally grown," and "sustainable," meeting high standards for freshness and environmental stewardship valued by consumers.

Which geographical region is expected to demonstrate the highest growth rate for vertical hydroponic lettuce?

The Asia Pacific (APAC) region, driven by rapid urbanization, extreme land scarcity, and governmental focus on food security in countries like Singapore and China, is forecast to exhibit the highest Compound Annual Growth Rate (CAGR) during the forecast period of 2026–2033.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager