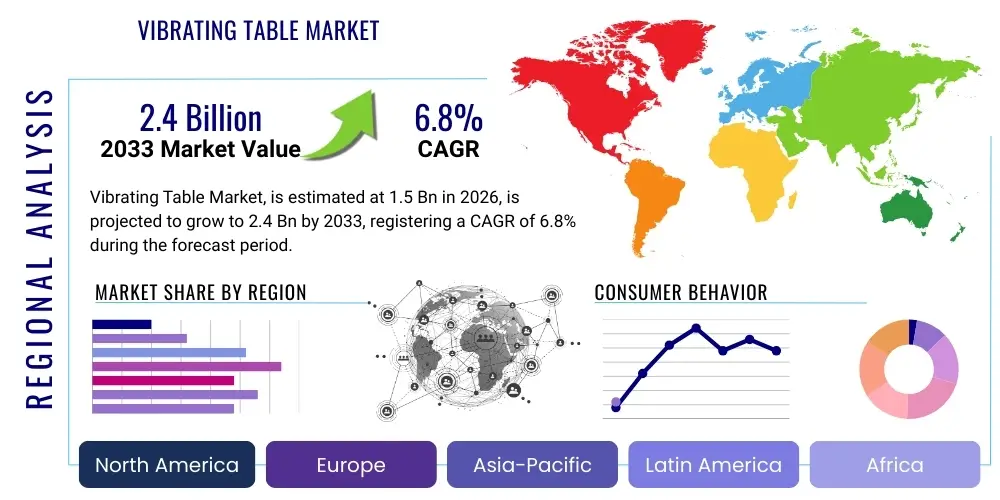

Vibrating Table Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441396 | Date : Feb, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Vibrating Table Market Size

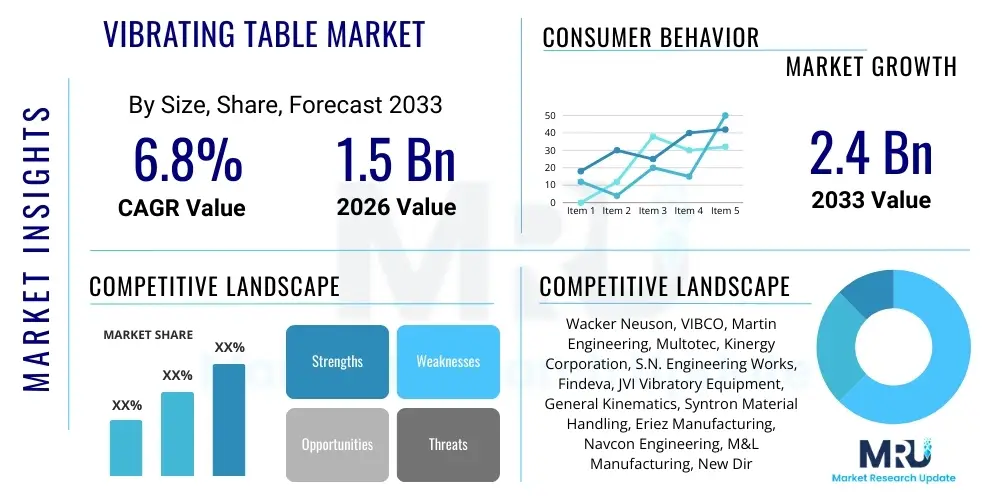

The Vibrating Table Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.4 Billion by the end of the forecast period in 2033.

Vibrating Table Market introduction

The Vibrating Table Market encompasses machinery designed to settle, compact, and de-aerate various materials, ranging from concrete and foundry sand to bulk powders and specialized chemicals, ensuring optimal density and structural integrity in final products or packaged goods. These tables utilize controlled vibrational forces, generated either mechanically, pneumatically, or electromagnetically, to eliminate voids and pockets within the material, thereby significantly improving efficiency in manufacturing processes. Key applications span high-volume construction projects, where precise concrete consolidation is essential for durability, and intricate packaging operations requiring maximum volume utilization and product settling before sealing. The market dynamics are largely driven by global infrastructure development, stringent quality control standards across industrial sectors, and the growing demand for automated material handling solutions that minimize manual labor.

The primary benefit of integrating vibrating tables into industrial workflows is the enhancement of material characteristics, leading directly to reduced waste, lower production costs, and superior product quality. The operational principle relies on tuning the frequency and amplitude of vibration to match the specific properties (density, viscosity, particle size) of the material being processed. Technological advancements are focusing on integrating variable frequency drives (VFDs) and sophisticated sensor feedback systems to optimize the compaction process automatically, catering to the diverse needs of end-users in sectors like pharmaceuticals and food processing, where hygiene and precision are paramount. The sustained growth of the market is intrinsically linked to industrial capacity expansion and the accelerating adoption of precision manufacturing techniques globally.

Driving factors propelling market expansion include the increasing scale of infrastructure projects, particularly in emerging economies, which necessitates high-capacity concrete consolidation equipment. Furthermore, the rising awareness regarding worker safety and ergonomic standards is pushing industries away from manual tamping methods toward automated vibrating solutions. The market also benefits from the continuous evolution of packaging standards, requiring precise filling and settling for materials sold by volume or weight, thereby minimizing air inclusion and improving logistical efficiency. These drivers collectively establish a robust foundation for consistent market growth throughout the forecast period.

Vibrating Table Market Executive Summary

The Vibrating Table Market is characterized by steady expansion, fueled primarily by robust growth in the construction and industrial packaging sectors. Current business trends indicate a strong move toward customized, high-frequency, low-amplitude vibrating tables, catering specifically to sensitive materials and high-precision tasks prevalent in the pharmaceutical and electronics industries. Key manufacturers are focusing their investment on developing smart vibrating solutions integrated with Industry 4.0 concepts, offering predictive maintenance capabilities and real-time operational diagnostics through IoT connectivity. Competition remains fragmented, with strong regional players specializing in specific technology types, although consolidation efforts are evident as global infrastructure players seek integrated material handling solutions. The emphasis on energy efficiency and noise reduction in newer models represents a critical differentiator in mature markets like North America and Europe.

Regional trends highlight Asia Pacific (APAC) as the dominant growth engine, driven by massive urbanization initiatives, large-scale public infrastructure investments (roads, bridges, ports), and the rapid expansion of the manufacturing base, particularly in China and India. North America and Europe, while mature, exhibit high demand for high-end, automated, and environmentally compliant electromagnetic tables used in specialized manufacturing applications. Segmentation trends reveal that mechanical vibrating tables continue to hold the largest market share due to their robustness and lower initial cost, especially in heavy construction and bulk material handling. However, the pneumatic and electromagnetic segments are accelerating their growth due to their superior precision, lower maintenance requirements, and quieter operation, making them preferred choices in hygienic and controlled environments such as food processing and pharmaceuticals. This bifurcation reflects the varied demands of a globally diverse industrial base.

AI Impact Analysis on Vibrating Table Market

User inquiries frequently center on how AI can optimize the compaction process, specifically asking about predictive maintenance schedules, automated amplitude adjustments, and the integration of machine learning algorithms for quality control in materials like concrete or specialized powders. Users are concerned about whether AI integration will significantly increase the cost of ownership but expect improved throughput and reduced energy consumption. The overarching theme is the transition from static, manually adjusted vibrating systems to dynamic, self-optimizing systems that use sensor data and historical performance metrics to achieve perfect compaction consistently, minimizing material heterogeneity and reducing structural failures. The expectation is that AI will transform vibrating tables from simple mechanical tools into intelligent consolidation stations, essential for high-specification manufacturing.

- AI-driven optimization of vibration parameters (frequency, amplitude) based on real-time material density sensor feedback, ensuring consistent quality.

- Implementation of predictive maintenance algorithms using vibration data analysis to anticipate motor or bearing failure, minimizing unexpected downtime.

- Enhanced quality control through machine vision and AI algorithms identifying surface defects or incomplete compaction instantly.

- Automated process tuning for handling variable material input characteristics (e.g., concrete slump variation or powder granularity changes).

- Integration with broader factory management systems (MES/ERP) for scheduling and throughput optimization driven by machine learning forecasts.

- Optimization of energy consumption by dynamically adjusting power input based on the precise energy required for consolidation.

DRO & Impact Forces Of Vibrating Table Market

The market's trajectory is primarily shaped by the synergy between accelerating industrialization and mandatory quality control regulations. Drivers include unprecedented investment in global infrastructure, particularly in developing nations, fueling demand for reliable concrete consolidation equipment, coupled with the increasing adoption of automated packaging systems across food and FMCG sectors. Restraints primarily involve the high initial capital expenditure associated with advanced, precision-engineered vibrating tables, particularly those utilizing electromagnetic technology, which can deter small and medium-sized enterprises (SMEs). Furthermore, the operational noise levels produced by traditional mechanical vibrating systems present a challenge in densely populated industrial areas, necessitating investment in specialized noise mitigation technologies, thereby increasing total implementation costs. Opportunities lie in the customization of tables for niche applications, such as lithium-ion battery manufacturing requiring precise settling of electrode materials, and the integration of IoT for remote diagnostics and enhanced operational efficiency, opening new service revenue streams for manufacturers.

Impact forces governing the market are primarily regulatory and competitive. Stringent safety and environmental regulations concerning dust suppression and noise pollution significantly influence product design and technology selection, favoring quieter electromagnetic and pneumatic systems. The threat of substitutes remains moderate; while alternative consolidation methods exist, vibrating tables offer a unique combination of speed, efficiency, and material handling capability that is difficult to replace entirely, especially in high-volume production. Supplier bargaining power is relatively low to moderate due to the availability of standardized components (motors, bearings), but high-tech specialized sensor and control system suppliers exert greater influence. Buyer bargaining power is significant, driven by the need for customized solutions and long-term maintenance contracts, forcing manufacturers to offer competitive pricing and superior after-sales service. These forces collectively push the market toward technological refinement and competitive pricing strategies to maintain margin stability.

Segmentation Analysis

The Vibrating Table Market is intricately segmented based on technology type, application across diverse industries, and the operational frequency range required for material processing. This detailed segmentation allows manufacturers to target specific end-user requirements, optimizing product features such as load capacity, vibration intensity, and overall footprint. The segmentation reflects the market's maturity, where generic solutions are being replaced by highly specialized equipment tailored for tasks ranging from heavy-duty concrete casting to gentle, high-precision pharmaceutical powder settling, ensuring market coverage across the entire spectrum of industrial demand.

Understanding these segments is crucial for strategic market positioning. For instance, the distinction between high-frequency and low-frequency tables directly impacts suitability for materials; low frequency is often preferred for heavy, dense aggregates like concrete, while high frequency is essential for fine powders requiring rapid de-aeration. Application segmentation further highlights market dynamics, with construction remaining the volume driver, whereas pharmaceutical and automotive applications command premium pricing due to stringent precision and certification requirements. The continuous evolution of manufacturing standards ensures that segmentation remains dynamic, adapting to new material sciences and industrial processes.

- By Type

- Electromagnetic Vibrating Tables

- Mechanical Vibrating Tables

- Pneumatic Vibrating Tables

- By Application

- Construction and Infrastructure

- Packaging and Logistics

- Food and Beverage Processing

- Chemical and Metallurgy

- Pharmaceutical and Cosmetics

- Automotive and Electronics

- By Frequency Range

- Low Frequency (Below 50 Hz)

- High Frequency (Above 50 Hz)

Value Chain Analysis For Vibrating Table Market

The value chain for the Vibrating Table Market begins with the upstream procurement of essential raw materials and standardized components, primarily high-grade steel and alloys for the table platform and frame, along with specialized components like electric motors, vibration exciters, springs, and advanced control systems (VFDs, sensors). Component suppliers wield moderate influence, especially those providing proprietary vibration control technologies. The manufacturing stage involves precision engineering, welding, and assembly, focusing heavily on quality control to ensure uniform vibration distribution and structural integrity under heavy loads. Operational efficiency at this stage is critical for cost management.

The downstream segment involves distribution and end-user deployment. Distribution channels are bifurcated into direct sales for large, complex, and customized systems, typically serving major construction companies or large industrial conglomerates, and indirect channels relying on specialized industrial equipment distributors and regional resellers for standardized models catering to SMEs. These distributors provide essential local technical support, installation, and maintenance services, which are critical value-adds. The market’s successful operation relies on robust after-sales support, encompassing spare parts provision and preventative maintenance contracts, which often constitute a significant long-term revenue stream for manufacturers.

The role of channel partners is increasingly important in providing application-specific consulting, helping clients select the optimal table type (e.g., high-amplitude for heavy aggregate vs. high-frequency for fine powder). Direct sales are highly effective for strategic accounts requiring bespoke integration into complex production lines. The shift toward digitalization and smart tables is enhancing the efficiency of the value chain, enabling remote diagnostics and faster resolution of operational issues, thus reducing reliance on intensive physical site visits. This modernization helps solidify manufacturer relationships with key end-users by enhancing total cost of ownership (TCO) predictability.

Vibrating Table Market Potential Customers

Potential customers for vibrating tables span a wide array of industrial and manufacturing sectors, fundamentally centered around any process requiring the compaction, settling, de-aeration, or density standardization of bulk materials. The largest consumer base resides within the heavy infrastructure sector, comprising concrete precast manufacturers, readymix concrete producers, and general construction contractors who utilize these tables to maximize the strength and longevity of concrete components such as pipes, beams, and blocks. Their procurement decisions are heavily influenced by table capacity, durability, and reliability under continuous, high-load operation.

A secondary, high-growth segment includes the packaging and logistics industries, where customers such as food processors, pharmaceutical companies, and chemical manufacturers require precise settling of powders, granules, and liquids to optimize container filling, meet minimum fill weight requirements, and improve shipping stability. These buyers prioritize hygienic design, precise amplitude control, and tables constructed from stainless steel to meet stringent regulatory standards (e.g., FDA, HACCP). The demand here is driven by the need for high-speed, automated production lines that minimize product giveaway and maximize package density.

Furthermore, specialized industrial customers, including automotive component suppliers (for core setting), foundry operators (for sand mold compaction), and electronics manufacturers (for specialized potting applications), represent niche but high-value segments. These end-users typically require custom-engineered tables with exceptionally low vibration noise and highly controlled G-forces to prevent damage to sensitive components while achieving critical compaction levels. The purchasing criteria for these segments revolve around certification, operational precision, and seamless integration with complex robotic material handling systems.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.4 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Wacker Neuson, VIBCO, Martin Engineering, Multotec, Kinergy Corporation, S.N. Engineering Works, Findeva, JVI Vibratory Equipment, General Kinematics, Syntron Material Handling, Eriez Manufacturing, Navcon Engineering, M&L Manufacturing, New Direction Equipment, Vibra-Max, BPS Bencor, Cleveland Vibrator Company, Airmaster Fan Company, Roto-Sieve, Inc., VIBRA SCHULTHEIS GMBH. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Vibrating Table Market Key Technology Landscape

The technology landscape of the Vibrating Table Market is characterized by a gradual shift from purely mechanical, eccentrically weighted systems toward more controllable and precise electromagnetic and pneumatic solutions. Mechanical tables, while still dominant in heavy-duty applications due to their durability and low acquisition cost, face limitations in terms of variable control and noise reduction. The latest advancements center on optimizing the excitation mechanism, utilizing high-frequency, low-amplitude vibration necessary for sensitive materials, often driven by sophisticated servo motors and Variable Frequency Drives (VFDs) which allow for immediate adjustment of vibrational force and direction based on load and material feedback, minimizing energy waste and maximizing compaction quality.

A critical technological evolution is the integration of sensor technology and IoT capabilities, transforming these tables into 'smart' industrial assets. Pressure sensors, accelerometers, and load cells are now commonly embedded to provide real-time data on the compaction process. This data feeds into proprietary control software, often leveraging basic AI algorithms, to achieve rapid process stabilization and highly repeatable results, a requirement for industries adhering to strict validation protocols like pharmaceuticals. Furthermore, design innovation focuses on material composition, utilizing specialized damping materials to isolate vibration to the platform only, significantly reducing noise levels and structural stress on surrounding machinery and facilities, thereby enhancing compliance with increasingly stringent workplace regulations.

The adoption of advanced materials, such as specific grades of stainless steel and corrosion-resistant coatings, is also prominent, especially for tables destined for the food, chemical, and offshore construction industries where environmental resistance and hygienic cleaning capabilities are non-negotiable. Manufacturers are actively pursuing modular designs, allowing end-users to easily adjust table size and capacity by adding or removing modular sections, thereby increasing the operational flexibility and lifespan of the equipment. This focus on modularity and smart control systems represents the forefront of technological development in this specialized machinery sector.

Regional Highlights

- Asia Pacific (APAC) Market Dominance: The APAC region is poised to maintain its status as the largest and fastest-growing market, primarily fueled by massive infrastructural projects in China, India, and Southeast Asian nations. High demand is observed from the concrete and construction sector, coupled with the rapid expansion of the manufacturing and processing industries, driving bulk procurement of mechanical and electromagnetic vibrating tables. Government policies promoting foreign direct investment in infrastructure are key catalysts for this sustained growth.

- North America Market Maturity and Technology Adoption: North America represents a mature market characterized by high regulatory standards and a strong preference for advanced, automated equipment. The demand is concentrated in high-precision segments, including advanced packaging, specialized chemical processing, and automotive manufacturing. The region shows rapid adoption of smart, IoT-enabled vibrating tables, prioritizing energy efficiency and reduced operational noise over low initial cost.

- Europe Market Focus on Sustainability and Precision: European market growth is steady, driven by stringent environmental and labor laws mandating low-noise and highly efficient industrial machinery. There is significant demand for sophisticated electromagnetic and pneumatic tables utilized in pharmaceutical manufacturing (especially cleanroom applications) and advanced precast concrete production requiring exceptional surface finish and structural uniformity. Investment is heavily skewed towards innovative, energy-saving designs.

- Latin America Market Recovery and Infrastructure Investment: The Latin American market is exhibiting promising recovery, with increasing governmental focus on revitalizing infrastructure projects, particularly in Brazil and Mexico. While pricing sensitivity is higher than in developed regions, there is a growing trend toward replacing aging, inefficient machinery with robust, mid-range mechanical tables suitable for heavy-duty construction applications, signaling sustained, albeit cautious, market expansion.

- Middle East and Africa (MEA) Oil & Gas and Urban Development: The MEA region's market is highly influenced by large-scale urban development projects (e.g., smart cities in the Gulf Cooperation Council nations) and investments in the petrochemical and construction industries. Demand is strong for durable, high-capacity tables capable of withstanding harsh operating conditions, predominantly serving concrete producers and material handling operations within the expansive oil and gas logistics sector.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Vibrating Table Market.- Wacker Neuson

- VIBCO

- Martin Engineering

- Multotec

- Kinergy Corporation

- S.N. Engineering Works

- Findeva

- JVI Vibratory Equipment

- General Kinematics

- Syntron Material Handling

- Eriez Manufacturing

- Navcon Engineering

- M&L Manufacturing

- New Direction Equipment

- Vibra-Max

- BPS Bencor

- Cleveland Vibrator Company

- Airmaster Fan Company

- Roto-Sieve, Inc.

- VIBRA SCHULTHEIS GMBH

Frequently Asked Questions

Analyze common user questions about the Vibrating Table market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected CAGR for the Vibrating Table Market between 2026 and 2033?

The Vibrating Table Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% during the forecast period of 2026 to 2033, driven by construction and packaging sector growth.

Which type of vibrating table technology is experiencing the fastest growth?

Electromagnetic and pneumatic vibrating tables are showing the fastest growth rate due to their superior precision, lower operational noise, and suitability for hygienic environments such and pharmaceuticals and food processing.

How is AI impacting the performance and efficiency of modern vibrating tables?

AI integration is enabling real-time optimization of vibration parameters, predictive maintenance scheduling, and advanced quality control through sensor feedback, leading to reduced downtime and consistent material compaction quality.

Which geographical region holds the largest market share in the global Vibrating Table Market?

The Asia Pacific (APAC) region currently holds the largest market share, predominantly driven by extensive governmental and private investment in massive infrastructure and large-scale manufacturing projects.

What are the primary applications driving the demand for high-precision vibrating tables?

High-precision vibrating tables, often electromagnetic, are primarily in demand across the pharmaceutical, specialized chemical, and electronics industries for precise powder settling, de-aeration, and component potting applications requiring stringent quality control.

Detailed Segment Analysis: By Type

The segmentation of the market by type—Electromagnetic, Mechanical, and Pneumatic—delineates the technological suitability of vibrating tables across various industrial needs, reflecting trade-offs between cost, durability, and control precision. Mechanical vibrating tables, relying on eccentric weights driven by motors, dominate in segments requiring sheer power and high load capacity, specifically heavy civil construction and bulk material handling. Their resilience and relatively straightforward maintenance procedures make them the workhorses of the industry, although they often present challenges regarding noise and precise frequency adjustment. Investment in this segment is focused on enhancing bearing life and material robustness to withstand extreme operational stress while improving dampening mechanisms.

Conversely, Electromagnetic vibrating tables offer highly controlled, high-frequency, low-amplitude vibration, making them ideal for handling finer materials where exact density is critical, such as pharmaceuticals, small component manufacturing, and intricate packaging. This segment is characterized by higher initial investment costs but offers superior precision and the ability to interface seamlessly with advanced automation systems. Their growth is propelled by industries moving toward lean manufacturing and quality assurance standards that demand highly repeatable processes. Pneumatic tables utilize compressed air to generate vibration, offering a robust, motor-free alternative, particularly valued in hazardous or explosive environments where electric motors pose a risk. Their inherent explosion-proof design secures a niche market, predominantly in specific chemical and mining operations.

The market trend indicates a bifurcation: volume is driven by cost-effective mechanical tables for primary consolidation tasks, while value growth is concentrating in the electromagnetic segment due to increasing demand for precision and automated control in specialty manufacturing. Manufacturers are strategically broadening their portfolios to offer hybrid solutions that combine the durability of mechanical frames with the precise control of electromagnetic actuators, targeting the mid-to-high capacity segment that demands both robustness and fine-tuning capabilities.

Detailed Segment Analysis: By Application

Construction and Infrastructure

The Construction and Infrastructure segment constitutes the largest consumer base for vibrating tables globally. These devices are indispensable for the consolidation of concrete mixtures used in the production of precast components such as barriers, pipes, slabs, and architectural elements. Effective vibration is crucial to eliminate air voids (entrained air), ensuring maximum density, strength, and durability of the finished concrete product, thereby extending its service life and minimizing defects. Large-scale mechanical vibrating tables, often operating at low to medium frequencies, are the primary technology deployed here due to their ability to handle heavy loads and large volumes efficiently. Growth in this segment is directly correlated with global government spending on public works and housing development initiatives.

The demand within this sector is evolving, moving beyond mere compaction towards aesthetic quality. Manufacturers are now developing high-amplitude tables capable of handling ultra-high-performance concrete (UHPC) and self-consolidating concrete (SCC), materials requiring sophisticated vibration profiles. The integration of sensors to monitor concrete slump and table G-force is becoming standard practice for quality assurance. The rapid urbanization in emerging economies, particularly in Asia and Africa, mandates continuous investment in high-capacity equipment, ensuring this application maintains its dominance throughout the forecast period.

Packaging and Logistics

The Packaging and Logistics application segment utilizes vibrating tables primarily for settling powders, granules, pellets, and other bulk materials into containers, bags, or cartons before sealing. This process, known as densification, maximizes the fill weight or volume within a standard package size, optimizing storage space, reducing transportation costs, and ensuring accurate product quantity distribution. The food and beverage industry relies heavily on these tables for filling products like flour, coffee, and spices, where consistent density is crucial for meeting regulatory labeling requirements.

Precision is the key requirement in this segment, favoring high-frequency electromagnetic tables capable of gentle but effective settling to prevent product damage while maximizing compaction. Automation is critical, with tables designed for seamless integration into high-speed conveyor systems. Furthermore, sanitary design requirements dictate the use of stainless steel construction and easy-to-clean features. The relentless growth of e-commerce and the need for efficient logistics drives continuous investment in advanced, automated settling stations to handle increased throughput and diverse product geometries.

Food and Beverage Processing

In the Food and Beverage sector, vibrating tables fulfill two primary roles: settling packaged goods and facilitating the screening or separation of raw materials. For packaging, the tables must meet strict hygienic standards, requiring food-grade materials and designs that eliminate crevices where contaminants could accumulate. High-frequency vibration is used to consolidate items like spices, grains, and frozen vegetables into their final packaging.

Beyond packaging, tables are sometimes integrated into processing lines for dewatering, grading, or conveying delicate food items. The adoption of advanced vibration technology here is governed by HACCP standards and consumer safety concerns. Manufacturers are emphasizing non-corrosive materials and quick-release mechanisms for thorough sanitation. The global trend towards processed and convenience foods ensures a stable and growing demand for specialized, hygienic vibrating equipment.

Chemical and Metallurgy

The Chemical and Metallurgy industries utilize vibrating tables for critical applications such as mold compaction in foundries, settling high-density chemical powders, and de-aerating specialized compounds before curing. In metallurgy, they are crucial for preparing sand molds, ensuring uniform density around complex patterns to achieve high-quality metal castings free of defects. This application typically requires heavy-duty mechanical tables capable of handling extreme loads and temperatures.

For the chemical industry, particularly in handling explosive or volatile powders, pneumatic vibrating tables are often mandated due to safety regulations. Precision is vital in pharmaceutical intermediate manufacturing and catalyst production, driving demand for high-control electromagnetic models. The continuous need for high structural integrity in metal parts and safe handling of sensitive chemical reagents sustains the demand for robust and certified vibration equipment in these heavy industries.

Pharmaceutical and Cosmetics

The Pharmaceutical and Cosmetics segment demands the highest levels of precision, cleanliness, and validation documentation. Vibrating tables are used for the highly controlled settling and de-aeration of powders during capsule filling, tablet production, and the consolidation of materials into vials or specialized containers. In cosmetics, they ensure uniform settling of makeup powders and creams.

Electromagnetic tables with extremely fine control over amplitude and frequency are standard here, often housed in cleanroom environments. Stainless steel construction (typically 316L) is mandatory, along with smooth, crevice-free surfaces for easy sterilization. Market growth is driven by increasing regulatory scrutiny (e.g., GMP guidelines) and the need for validation protocols that demonstrate repeatable compaction, making these systems highly specialized and consequently commanding premium prices.

Automotive and Electronics

In the Automotive and Electronics sectors, vibrating tables serve critical functions in highly specialized manufacturing processes. The automotive industry uses them for tasks like consolidating investment casting molds, settling foam or plastic components during manufacturing, and applying specialized coatings. The growing electric vehicle (EV) market is a new catalyst, as vibration technology is essential for the precise settling of electrode slurry materials within lithium-ion batteries to maximize energy density and structural integrity.

In electronics, vibrating tables are employed for potting and encapsulation—the process of filling an electronic assembly with a liquid resin or compound and then using vibration to remove trapped air bubbles. This ensures superior thermal dissipation and environmental protection. These applications require medium-to-high frequency electromagnetic tables with highly precise, low G-force operation to prevent damage to delicate circuits. The market growth here is directly tied to the expansion of EV battery manufacturing and the continuous demand for high-reliability consumer and industrial electronics.

Detailed Segment Analysis: By Frequency Range

Low Frequency (Below 50 Hz)

Low frequency vibrating tables are primarily engineered for processing heavy, high-density materials, such as concrete and coarse aggregates. Operating typically below 50 cycles per second, these tables deliver high amplitude vibration and significant G-force, making them exceptionally effective at overcoming the inertia of large, heavy particles and large volumes of viscous materials. Their robustness and structural simplicity mean they are predominantly mechanical tables, built to handle continuous, demanding operational cycles in outdoor or harsh industrial environments.

This segment is dominated by the construction and heavy manufacturing industries where the focus is on maximizing density and achieving deep consolidation rather than fine surface finishing. While offering high load capacities, the lower frequency often results in higher noise levels, which must be managed through specialized isolation mounting. Market stability is ensured by the unwavering global demand for basic infrastructure and precast concrete products.

High Frequency (Above 50 Hz)

High frequency vibrating tables operate above 50 Hz, often reaching several hundred Hertz, and are characterized by low amplitude vibration. This specific profile is optimal for processing fine powders, small granules, and highly sensitive materials, efficiently achieving de-aeration and settling without causing segregation or damage to the product structure. The rapid, gentle motion is critical for applications demanding high precision, repeatability, and superior surface finish.

The primary users of high-frequency tables include the pharmaceutical, cosmetics, food processing, and specialized electronics industries. These tables are predominantly electromagnetic or advanced pneumatic models, allowing for precise real-time adjustment of frequency and amplitude. The growth of this segment is driven by increasing product sophistication across these industries, requiring consolidation equipment that can integrate seamlessly with high-speed automated production lines and adhere to stringent quality control parameters.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager