Water Blocking Yarn Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440745 | Date : Feb, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Water Blocking Yarn Market Size

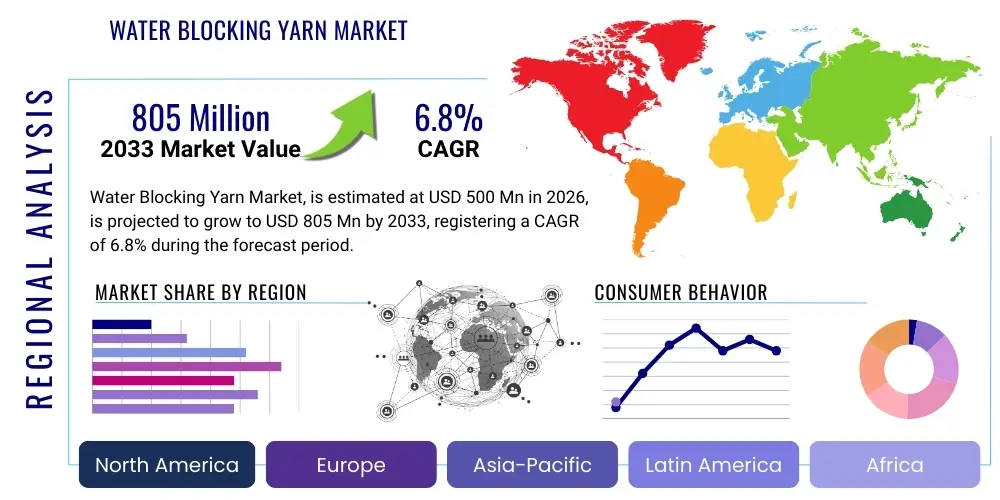

The Water Blocking Yarn Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 700 Million by the end of the forecast period in 2033.

Water Blocking Yarn Market introduction

The Water Blocking Yarn market is a specialized segment within the broader textile and cable component industries, focusing on advanced materials designed to prevent water ingress in various cable structures. These yarns are crucial for enhancing the reliability, longevity, and performance of sensitive electrical and optical cables, especially those deployed in harsh environments. The core function of water blocking yarn is to swell rapidly when it comes into contact with moisture, effectively sealing off the cable and preventing water from traveling longitudinally along its length, thereby protecting the internal conductors or optical fibers from damage.

Products in this market primarily include swellable yarns, often infused or coated with super absorbent polymers (SAPs), and hydrophobic yarns that repel water. Major applications span critical infrastructure sectors such as telecommunications, where they safeguard fiber optic cables against moisture-induced signal loss; energy and utilities, protecting power cables from short circuits and corrosion; and marine and subsea applications, where environmental resilience is paramount for umbilical and communication cables. The inherent benefits of these yarns include significantly extended cable service life, reduced maintenance costs, improved data transmission integrity, and enhanced safety by preventing electrical faults.

Driving factors for this market's growth are primarily rooted in the global surge in demand for high-speed internet connectivity, the extensive rollout of 5G networks, and the proliferation of smart city infrastructure, all of which necessitate robust and reliable cabling solutions. Additionally, the increasing investment in renewable energy projects, particularly offshore wind farms, and the expansion of subsea communication networks contribute substantially to the demand for advanced water blocking solutions. These macro trends underscore the critical role water blocking yarns play in modern industrial and communication ecosystems, highlighting their importance in safeguarding essential infrastructure against environmental degradation.

Water Blocking Yarn Market Executive Summary

The Water Blocking Yarn Market is experiencing robust growth, propelled by relentless global digitalization and the expansion of critical infrastructure. Business trends indicate a strong focus on innovation, with manufacturers investing heavily in developing more efficient, eco-friendly, and application-specific water blocking solutions. This includes the integration of advanced super absorbent polymers (SAPs) and novel hydrophobic coatings that offer superior swelling rates and barrier properties. There is also a discernible trend towards customization, as cable manufacturers demand tailored yarn specifications to meet diverse performance requirements for everything from compact data cables to large power transmission lines. Sustainability is emerging as a significant driver, with increasing pressure on suppliers to offer greener manufacturing processes and recyclable materials.

Regional trends highlight Asia-Pacific as the dominant and fastest-growing market, primarily due to aggressive infrastructure development, rapid urbanization, and extensive fiber optic network expansion in countries like China, India, and Southeast Asian nations. North America and Europe represent mature markets with a strong emphasis on upgrading existing infrastructure, deploying subsea cables for international connectivity, and integrating renewable energy sources, thereby sustaining a steady demand for high-performance water blocking yarns. Latin America, the Middle East, and Africa are showing promising growth, fueled by increasing investment in telecommunications and energy infrastructure projects, although these regions are more susceptible to economic volatilities and geopolitical factors.

Segmentation trends reveal that the fiber optic cable application segment continues to hold the largest market share, driven by the insatiable demand for bandwidth and high-speed internet. However, the power cable segment is anticipated to witness significant growth, especially with the global push towards smart grids, electric vehicle charging infrastructure, and the interconnection of renewable energy sources. Material-wise, polyester and polypropylene based yarns, often enhanced with advanced SAPs, remain prevalent due to their cost-effectiveness and performance attributes. The market is characterized by intense competition among a few established players and several niche providers, all vying for market share through product differentiation and strategic partnerships, ultimately contributing to a dynamic and evolving competitive landscape.

AI Impact Analysis on Water Blocking Yarn Market

The integration of Artificial Intelligence (AI) holds transformative potential for the Water Blocking Yarn market, addressing key challenges and unlocking new efficiencies across the value chain. Common user questions revolve around how AI can enhance product quality, streamline manufacturing, and optimize supply chains. Users are keen to understand if AI can lead to the development of more intelligent and responsive water blocking materials, predict material performance under various environmental stresses, and contribute to faster research and development cycles. Concerns often include the cost of AI implementation, the need for specialized data, and the potential for job displacement, alongside expectations for significant improvements in production accuracy and material innovation.

AI's influence is anticipated to profoundly impact several aspects, from raw material sourcing to final product application. In material science, AI algorithms can analyze vast datasets of polymer structures and additive combinations, accelerating the discovery of novel super absorbent polymers (SAPs) or hydrophobic coatings with enhanced swelling properties, durability, and eco-friendliness. This can lead to the development of "smart" yarns that offer superior water blocking capabilities and extended operational lifetimes for critical infrastructure. Furthermore, AI-driven simulations can accurately predict how different yarn compositions will perform under specific environmental conditions, reducing the need for extensive physical prototyping and speeding up the innovation pipeline.

Within manufacturing, AI-powered systems can optimize production parameters, leading to higher efficiency, reduced waste, and improved consistency in yarn quality. Predictive maintenance for machinery, enabled by AI, can prevent costly downtime and ensure continuous operation. In terms of supply chain management, AI algorithms can forecast demand more accurately, optimize inventory levels, and enhance logistics, leading to reduced operational costs and improved responsiveness to market fluctuations. The ability of AI to process and interpret complex data from various stages of the product lifecycle will ultimately lead to a more resilient, responsive, and technologically advanced Water Blocking Yarn market, delivering higher-quality products to end-users.

- AI-driven material discovery accelerates the development of novel super absorbent polymers and hydrophobic coatings.

- Predictive analytics enhance yarn performance modeling, reducing R&D cycles and optimizing material formulations.

- AI-powered quality control systems improve manufacturing consistency and reduce defects in yarn production.

- Optimized production lines through AI increase efficiency, minimize waste, and lower operational costs.

- AI-enabled supply chain management improves demand forecasting, inventory optimization, and logistics for raw materials and finished products.

- Implementation of AI in monitoring cable health can lead to proactive maintenance, extending cable lifespan.

- Data-driven insights from AI can inform customization strategies for specific cable applications.

DRO & Impact Forces Of Water Blocking Yarn Market

The Water Blocking Yarn Market is shaped by a confluence of powerful drivers, inherent restraints, and promising opportunities, all subjected to various impactful forces. Primary drivers include the escalating global demand for high-speed data transmission and reliable power infrastructure, which necessitates robust and resilient cabling solutions for fiber optic and power cables. The rapid deployment of 5G networks, expansion of submarine communication cables, and significant investments in renewable energy infrastructure, particularly offshore wind farms, are creating an unprecedented need for advanced water blocking technologies. Additionally, the growing focus on enhancing the longevity and reliability of critical infrastructure to reduce maintenance costs and ensure uninterrupted service fuels the adoption of these specialized yarns, highlighting their indispensable role in modern technological ecosystems.

However, the market also faces notable restraints. Fluctuations in the prices of raw materials, such as polyester, polypropylene, and specialized super absorbent polymers, can impact manufacturing costs and profitability, leading to price volatility for end products. The market is also sensitive to the economic cycles of the telecommunications and energy sectors, with potential slowdowns in infrastructure spending impacting demand. Furthermore, stringent regulatory standards for cable performance and material safety, while ensuring quality, can impose significant compliance costs and development challenges for manufacturers. Competition from alternative water blocking methods or materials, though currently limited in high-performance applications, also presents a perpetual challenge for market players.

Opportunities for growth are abundant, particularly in emerging markets across Asia-Pacific, Latin America, and Africa, where infrastructure development is booming, creating new avenues for market penetration. The increasing demand for specialized applications in sectors like automotive (for electric vehicle cabling), medical devices, and advanced aerospace components presents niche market expansion possibilities. Moreover, continuous innovation in sustainable and eco-friendly water blocking solutions, driven by environmental concerns and regulatory pressures, offers a significant opportunity for product differentiation and market leadership. The convergence of these drivers, restraints, and opportunities is further influenced by external forces such as rapid technological advancements in material science, evolving global trade policies, and shifts in geopolitical landscapes, all of which dynamically shape the market's trajectory and competitive environment.

Segmentation Analysis

The Water Blocking Yarn market is intricately segmented to reflect the diverse applications, materials, and technological approaches employed in safeguarding various cable types. This segmentation allows for a granular understanding of market dynamics, enabling stakeholders to identify key growth areas, competitive landscapes, and evolving customer needs. Analyzing these segments provides crucial insights into product development strategies, regional market preferences, and the overall trajectory of the industry, particularly in response to technological advancements and infrastructure demands across different end-use sectors.

- By Type

- Swellable Yarn (Super Absorbent Polymer (SAP) based)

- Hydrophobic Yarn (Non-SAP based)

- Hybrid Yarn

- By Material

- Polyester

- Polypropylene

- Aramid Fiber

- Glass Fiber

- Others (e.g., Nylon, Specialty Polymers)

- By Application

- Fiber Optic Cables

- Power Cables

- Umbilical Cables

- Subsea Cables

- Telecommunication Cables

- Others (e.g., Automotive Cables, Medical Cables)

- By End-Use Industry

- Telecommunications

- Energy & Utilities

- Marine & Offshore

- Oil & Gas

- Aerospace & Defense

- Automotive

- Others

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Water Blocking Yarn Market

The value chain for the Water Blocking Yarn market encompasses a series of interconnected stages, beginning with raw material extraction and culminating in the end-use application within various cable systems. Upstream analysis involves the procurement of essential raw materials, primarily petrochemical derivatives like polyester and polypropylene polymers, alongside specialty chemicals such as super absorbent polymers (SAPs) and various hydrophobic coatings. Key players at this stage include chemical manufacturers and polymer producers who supply the fundamental building blocks for yarn production. The quality and cost of these raw materials significantly influence the final product's performance and market price, making strong supplier relationships and efficient sourcing critical for yarn manufacturers.

Midstream activities are centered on the yarn manufacturing process itself, where raw polymers are spun into fibers and then processed with water blocking agents. This stage involves complex textile engineering, including spinning, weaving, coating, and sometimes twisting processes, to create yarns with the desired swelling characteristics, tensile strength, and hydrophobic properties. Manufacturers often employ proprietary technologies and specialized machinery to produce high-performance yarns that meet stringent industry standards. Research and development is also a crucial midstream activity, focusing on enhancing material properties, improving manufacturing efficiency, and developing new yarn formulations to cater to evolving cable demands and environmental regulations.

Downstream activities involve the distribution and application of water blocking yarns into finished cable products. The primary customers are cable manufacturers specializing in fiber optic, power, telecommunication, and subsea cables. Distribution channels can be both direct, through long-term contracts and partnerships between yarn manufacturers and large cable producers, and indirect, through specialized distributors or agents who serve smaller cable manufacturers or specific regional markets. The effectiveness of these channels, alongside robust technical support and customer service, is vital for ensuring timely delivery and successful integration of the yarns into complex cable designs. Ultimately, the efficiency and synergy across this entire value chain are paramount for delivering high-quality, cost-effective water blocking solutions to the global market.

Water Blocking Yarn Market Potential Customers

The primary potential customers for Water Blocking Yarn are entities deeply involved in the manufacturing, deployment, and maintenance of various types of cables that require protection against water ingress. At the forefront are global and regional cable manufacturers, who integrate these specialized yarns directly into their cable designs to enhance durability, reliability, and performance. These manufacturers produce a wide array of cables, including high-capacity fiber optic cables for telecommunications, robust power transmission cables for energy grids, and specialized subsea cables for marine and offshore applications, all of which critically depend on effective water blocking solutions to prevent operational failures and extend service life. Their continuous demand is driven by infrastructure expansion, technological upgrades, and the need to meet stringent industry standards.

Beyond the direct cable manufacturers, a significant segment of potential customers includes large-scale infrastructure developers and utility companies. Telecommunication companies, for instance, are major end-users, investing heavily in fiber optic networks and 5G infrastructure, which rely on water-protected cables to ensure uninterrupted connectivity and data integrity. Similarly, national and private energy utility providers require water blocking yarns for their power distribution and transmission cables, especially in underground and overhead systems exposed to environmental moisture. These entities often collaborate closely with cable manufacturers to specify the exact performance requirements, driving demand for innovative and high-quality water blocking yarns tailored to their specific operational environments.

Furthermore, specialized industries such as marine and offshore, oil and gas, and aerospace and defense represent crucial niche markets. Companies involved in laying subsea communication and power cables, developing offshore wind farms, or constructing advanced marine vessels and oil rigs require water blocking yarns for umbilical cables, control cables, and power lines that operate in extremely harsh, saline, and pressurized underwater environments. The aerospace and defense sectors utilize these yarns in mission-critical applications where cable integrity is paramount for safety and performance. These diverse end-users collectively underscore the broad utility and essential nature of water blocking yarns across a multitude of industries, highlighting a robust and expanding customer base seeking reliable moisture protection for their critical cable infrastructure.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 700 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Toyobo Co., Ltd., Kuraray Co., Ltd., Unitika Ltd., Teijin Limited, Lenzing AG, BASF SE, Evonik Industries AG, Mitsubishi Chemical Corporation, Sumitomo Electric Industries, Ltd., Corning Incorporated, Nexans SA, Prysmian Group, Fujikura Ltd., Furukawa Electric Co., Ltd., ZTT (Zhongtian Technology), Changzhou Water Blocking Material Co., Ltd., JDR Cable Systems Ltd., Qingdao Hanming Textile Co., Ltd., Shenzhen Sanxing Textile Co., Ltd., Jiangsu Aoshen Textile Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Water Blocking Yarn Market Key Technology Landscape

The technology landscape for the Water Blocking Yarn market is characterized by continuous innovation in material science and textile engineering, focusing on enhancing performance, durability, and environmental sustainability. A cornerstone of this landscape is the advanced development of Super Absorbent Polymers (SAPs). These polymers, often integrated into polyester or polypropylene fibers through various coating, impregnation, or compounding techniques, are engineered to swell rapidly and significantly upon contact with water. Recent advancements in SAP technology include the development of super-fast swelling SAPs, bio-based SAPs, and SAPs with improved thermal stability and resistance to various chemicals, ensuring their effectiveness in diverse and challenging cable environments, from extreme temperatures to corrosive liquids.

Alongside SAP-based solutions, hydrophobic coating technologies play a crucial role, particularly for non-swellable water blocking yarns. These coatings create a water-repellent barrier on the yarn surface, preventing water from penetrating the cable structure. Innovations in hydrophobic coatings involve the use of fluoropolymers, siloxanes, and other specialty chemicals that provide superior water repellency, abrasion resistance, and long-term stability. The integration of nanotechnology is also emerging in this space, with researchers exploring the application of nanomaterials to create ultra-hydrophobic surfaces that offer enhanced protection while maintaining yarn flexibility and strength. These advancements are critical for applications where minimal swelling is desired or where extreme water pressure is a factor, such as in deep-sea subsea cables.

Furthermore, the market benefits from sophisticated yarn manufacturing and processing techniques. This includes precision spinning technologies that ensure consistent fiber diameter and uniform distribution of water blocking agents, thereby guaranteeing reliable performance along the entire length of the yarn. Advanced extrusion processes allow for the creation of composite yarns with layered structures, optimizing both mechanical strength and water blocking efficacy. The ongoing focus on automation and quality control in manufacturing is paramount, utilizing sensors and data analytics to monitor production parameters in real-time, ensuring that each batch of water blocking yarn meets the rigorous specifications required by cable manufacturers for critical infrastructure projects. These technological synergies are driving the evolution of the Water Blocking Yarn market towards more resilient, efficient, and intelligent solutions.

Regional Highlights

- Asia Pacific (APAC): This region dominates the Water Blocking Yarn Market, primarily driven by extensive infrastructure development, rapid urbanization, and massive investments in telecommunications networks, particularly 5G deployment and fiber-to-the-home initiatives in countries like China, India, and Southeast Asian nations. The region is also a major manufacturing hub for cables, leading to high localized demand for water blocking yarns. Government initiatives supporting smart cities and digital connectivity further fuel market expansion, making APAC the fastest-growing and largest market segment.

- North America: The market in North America is characterized by mature infrastructure, with demand primarily stemming from upgrades and maintenance of existing power grids and telecommunication networks. Significant investments in renewable energy projects, especially offshore wind farms, and the expansion of subsea communication cables are key drivers. Emphasis on high-quality, durable, and reliable cable solutions for critical infrastructure, coupled with stringent industry standards, supports the adoption of advanced water blocking yarns.

- Europe: Similar to North America, Europe is a mature market focused on modernizing its digital and energy infrastructure. The strong push for sustainable energy sources, particularly inter-country power grids and offshore wind energy, alongside continuous investments in expanding fiber optic broadband, drives demand. European regulations for environmental safety and material quality also influence product development, pushing for eco-friendly and high-performance water blocking solutions.

- Latin America: This region is an emerging market for water blocking yarns, with growth propelled by increasing investment in telecommunication infrastructure, including expanding internet penetration and 5G network rollout. Urbanization and industrial growth are also fostering demand for reliable power cables. However, economic stability and foreign investment play a crucial role in dictating the pace of market development across countries like Brazil, Mexico, and Argentina.

- Middle East & Africa (MEA): The MEA region presents significant growth opportunities, largely due to ongoing infrastructure development projects, including smart city initiatives (e.g., NEOM in Saudi Arabia), expansion of oil and gas exploration (requiring specialized offshore cables), and improving telecommunication networks. Investments in renewable energy and efforts to diversify economies away from fossil fuels are also contributing to the demand for advanced cable protection solutions, albeit with sensitivity to regional geopolitical and economic factors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Water Blocking Yarn Market.- Toyobo Co., Ltd.

- Kuraray Co., Ltd.

- Unitika Ltd.

- Teijin Limited

- Lenzing AG

- BASF SE

- Evonik Industries AG

- Mitsubishi Chemical Corporation

- Sumitomo Electric Industries, Ltd.

- Corning Incorporated

- Nexans SA

- Prysmian Group

- Fujikura Ltd.

- Furukawa Electric Co., Ltd.

- ZTT (Zhongtian Technology)

- Changzhou Water Blocking Material Co., Ltd.

- JDR Cable Systems Ltd.

- Qingdao Hanming Textile Co., Ltd.

- Shenzhen Sanxing Textile Co., Ltd.

- Jiangsu Aoshen Textile Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Water Blocking Yarn market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is water blocking yarn and how does it work?

Water blocking yarn is a specialized fiber used in cable manufacturing that prevents water ingress. It typically contains super absorbent polymers (SAPs) that swell rapidly upon contact with moisture, forming a gel barrier to block water from propagating along the cable, thereby protecting internal conductors or optical fibers from damage and extending cable lifespan.

What are the primary applications of water blocking yarn?

Its primary applications are in fiber optic cables for telecommunications, power cables for energy transmission and distribution, and specialized subsea and umbilical cables used in marine, offshore, and oil & gas industries. These applications demand high reliability and protection against moisture for critical infrastructure.

Why is water blocking yarn crucial for cable longevity and reliability?

Water blocking yarn is crucial because water ingress can lead to signal loss in fiber optic cables, short circuits and corrosion in power cables, and overall degradation of cable integrity. By effectively sealing off moisture, it prevents these issues, significantly extending the operational lifespan of cables, reducing maintenance costs, and ensuring uninterrupted service.

What are the key factors driving the growth of the Water Blocking Yarn Market?

Key drivers include the global expansion of high-speed internet and 5G networks, increasing investments in renewable energy projects (especially offshore wind), rapid urbanization and smart city development, and the growing demand for reliable and durable cabling infrastructure across various industries worldwide.

What are the future trends and innovations expected in the Water Blocking Yarn market?

Future trends involve the development of more sustainable and eco-friendly yarns, advancements in faster-swelling and higher-performance super absorbent polymers (SAPs), the integration of smart technologies like AI for material discovery and quality control, and the expansion into new specialized applications such as automotive and medical cables.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager