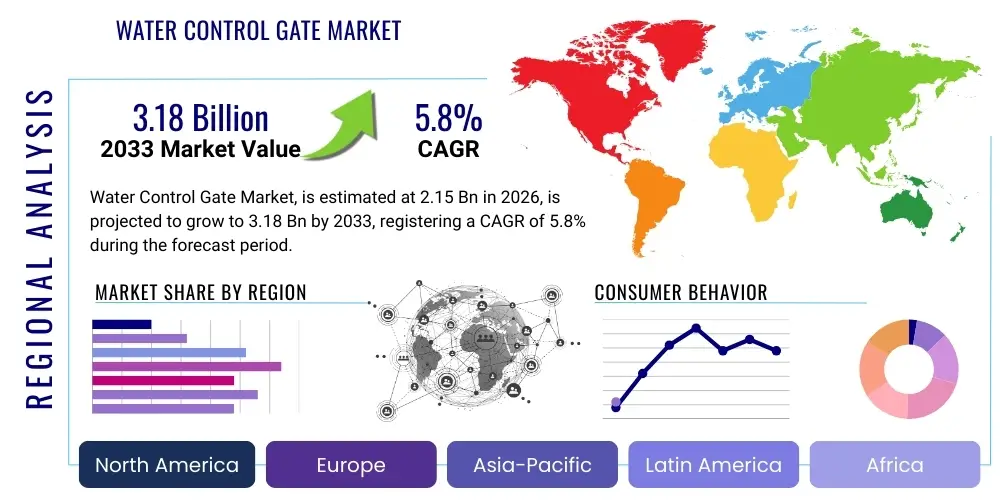

Water Control Gate Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441231 | Date : Feb, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Water Control Gate Market Size

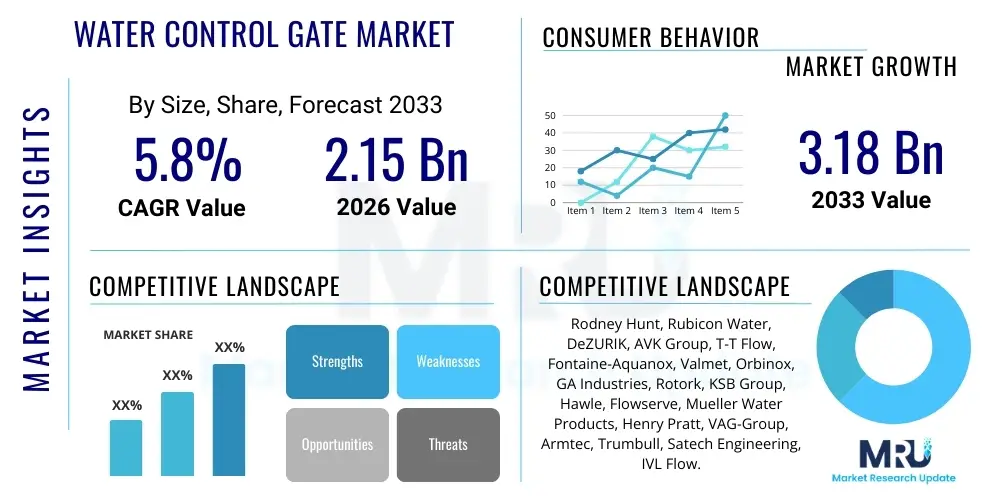

The Water Control Gate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $2.15 Billion in 2026 and is projected to reach $3.18 Billion by the end of the forecast period in 2033.

Water Control Gate Market introduction

The Water Control Gate Market encompasses the design, manufacturing, and installation of mechanical structures used to regulate, divert, or stop the flow of water in various infrastructure projects such as dams, reservoirs, irrigation systems, flood defenses, and wastewater treatment facilities. These crucial components are engineered to withstand significant hydrostatic pressures and environmental wear, ensuring reliable water management and safety. The primary function of these gates—including slide gates, radial gates, and sluice gates—is to maintain operational efficiency and environmental balance by precisely controlling water levels and flow rates across diverse terrains and climatic conditions. Technological advancements are steadily integrating smart actuation systems and corrosion-resistant materials, enhancing durability and reducing maintenance overheads for municipal and industrial operators globally.

Major applications for water control gates span across essential public services and industrial operations. In municipal water infrastructure, they are indispensable for inflow regulation at water treatment plants and effluent control in sewerage systems. For agricultural sectors, precision gates facilitate optimized irrigation schedules, minimizing water waste and maximizing crop yields. Furthermore, in the context of renewable energy, high-performance gates are vital for the efficient operation of hydroelectric power plants, controlling the water head and discharge necessary for turbine operations. The growing global focus on sustainable water resource management and the urgent need for robust flood mitigation strategies following extreme weather events are accelerating the demand for advanced water control infrastructure.

Driving factors for this market growth include rapid urbanization, leading to expanded municipal water and wastewater networks, and significant government investments in upgrading aging water infrastructure, particularly in developed economies. Simultaneously, emerging economies are initiating large-scale hydraulic projects, such as new irrigation canals and flood protection barriers, to support economic development and climate resilience. The inherent benefits of modern water control gates—such as their capacity for remote operation, fail-safe design, and reduced leakage rates due to improved seal technology—further solidify their adoption. These elements collectively contribute to improved operational safety, reduced environmental impact, and superior asset longevity, positioning the market for sustained expansion throughout the forecast period.

Water Control Gate Market Executive Summary

The Water Control Gate Market is characterized by robust growth, driven primarily by escalating concerns over water scarcity, increased regulatory focus on flood management, and the imperative need to modernize global water infrastructure. Business trends indicate a strong shift toward automation and smart gate solutions, incorporating sensors and IoT connectivity for real-time monitoring and predictive maintenance, thereby maximizing operational uptime. Key manufacturers are focusing on material innovation, utilizing advanced stainless steels and composites to offer products with superior resistance to corrosion and abrasion, extending lifecycles in harsh environments like coastal flood barriers and highly abrasive sewage systems. Consolidation activities, particularly among specialized suppliers focusing on unique actuation mechanisms (e.g., hydraulic cylinders or electric linear actuators), are shaping the competitive landscape, pushing smaller players to specialize or integrate within larger diversified infrastructure conglomerates.

Regionally, Asia Pacific maintains market dominance due to massive infrastructure development projects, especially in China and India, focusing on irrigation, dam construction, and rapid expansion of urban water supply systems. North America and Europe are pivotal markets for infrastructure replacement and technological adoption, emphasizing precision control for environmental compliance and disaster risk reduction, particularly in coastal and riverine flood control. The Middle East and Africa are experiencing high growth driven by critical investments in desalination plants and essential water conveyance systems, necessitating specialized, robust gates for regulating high salinity and fluctuating water volumes. These regional dynamics highlight a bifurcated demand pattern: high volume sales in developing regions and high-value, technologically sophisticated sales in mature markets.

Segment trends reveal that the Slide Gate and Sluice Gate segments, favored for their versatility and robust sealing capabilities, account for the largest market share, essential across almost all end-use sectors including water treatment and irrigation. The Hydraulic operation segment is seeing rapid uptake due to its reliability, high torque capabilities, and suitability for large-scale gates in critical infrastructure like dams and major flood barriers. Furthermore, the End-Use segmentation confirms that the Irrigation and Flood Control sectors are the fastest-growing applications, stimulated by climate change impacts demanding more adaptive and responsive water management infrastructure. Material trends emphasize the increasing adoption of composites for lighter, corrosion-resistant structures, especially in environments where traditional cast iron or carbon steel require constant protective coatings and maintenance cycles.

AI Impact Analysis on Water Control Gate Market

User inquiries regarding AI's influence in the Water Control Gate Market primarily revolve around predictive maintenance capabilities, the optimization of water resource distribution, and the potential for autonomous operation in remote or hazardous locations. Users are keen to understand how AI algorithms can analyze historical flow data, weather patterns, and structural integrity sensor readings (vibration, pressure, strain) to predict equipment failure before it occurs, thereby reducing costly unplanned downtime. A common concern is the integration complexity and the cybersecurity risks associated with connecting critical civil infrastructure to cloud-based AI platforms. Furthermore, there is significant interest in how AI can optimize the synchronized operation of multiple gates across a large river basin or irrigation district to maximize water efficiency, minimize flood risk, and respond dynamically to sudden environmental shifts, moving beyond fixed operational schedules towards a truly adaptive management framework.

- AI-driven Predictive Maintenance: Utilizing machine learning algorithms to analyze sensor data from gate mechanisms (actuators, gearboxes, seals) to forecast component failure and optimize maintenance scheduling, enhancing reliability.

- Optimized Resource Allocation: Implementing AI models to process complex hydrometeorological data (rainfall, runoff, soil moisture) for precise, real-time control of gate openings, optimizing water distribution for irrigation and hydropower generation.

- Autonomous Flood Management: Deployment of AI systems that can autonomously assess flood risk based on real-time river levels and predicted storm surges, enabling rapid and coordinated gate adjustments across interconnected flood defense networks.

- Enhanced Cybersecurity Monitoring: Utilizing AI for anomaly detection in operational data and network traffic, safeguarding critical gate control systems against cyber threats and unauthorized operational interference.

- Design Optimization: AI and Generative Design aiding engineers in optimizing gate structures and flow channels for maximum hydraulic efficiency and material use, reducing manufacturing costs and improving performance.

- Remote Monitoring and Digital Twins: Creation of AI-powered digital twins of large gate installations, allowing operators to simulate various scenarios (e.g., extreme weather events) and test control strategies before deployment in the physical world.

DRO & Impact Forces Of Water Control Gate Market

The market dynamics are shaped by substantial Drivers, Restraints, and Opportunities, collectively determining the impact forces on the water control infrastructure sector. Key drivers include accelerating climate change impacts, which necessitate urgent investment in resilient flood control systems, and the global imperative to replace aging water infrastructure constructed primarily during the mid-20th century. However, the market faces significant restraints, notably the high initial capital expenditure associated with custom-engineered gates and the complexity of integration with legacy SCADA and control systems often found in older treatment and distribution networks. Opportunities are abundant in the smart infrastructure domain, particularly in developing countries adopting advanced, modular gate solutions, and the increasing demand for sustainable, non-corrosive materials like fiberglass-reinforced plastic (FRP) and specialized composite alloys for specific demanding applications.

Impact forces on the Water Control Gate Market are primarily driven by regulatory frameworks, climate mandates, and technological advancements. Regulatory forces, such as stricter water quality standards and dam safety guidelines (e.g., requiring higher seismic resistance), compel end-users to upgrade or replace existing gates. Climate change acts as a massive impact force, transforming operational requirements by demanding gates capable of handling more extreme and rapid fluctuations in water levels, often requiring robust, faster-acting actuation mechanisms. Furthermore, the decreasing cost of high-precision sensors and connectivity modules significantly impacts market adoption, making sophisticated remote monitoring and control accessible for a wider range of projects, shifting the industry from reactive maintenance to proactive asset management.

The balance between the high upfront cost of specialized engineered solutions (Restraint) and the long-term operational savings derived from reduced maintenance and improved water efficiency (Driver/Opportunity) dictates purchasing decisions. Geopolitical instability and supply chain fragility, particularly for specialized metal components and complex electronic actuators, also act as external impact forces, influencing project timelines and overall cost structures. Successful market participants are those who leverage modular design to mitigate cost barriers while capitalizing on the rising demand for integrated, smart gates that meet stringent safety and environmental performance criteria mandated by both municipal and private sector stakeholders.

Segmentation Analysis

The Water Control Gate Market segmentation provides a detailed structural view based on product type, material composition, mechanism of operation, and critical end-use applications, reflecting diverse functional requirements across the globe. This analysis highlights areas of concentrated growth, particularly within the specialized gates segment catering to high-pressure environments, and the rapidly expanding adoption of durable, lightweight materials like composites. Understanding these segments is crucial for strategic planning, allowing manufacturers to tailor their product offerings—from robust radial gates used in large hydroelectric dams to specialized flap gates for tidal control—to specific sector needs, ensuring optimal hydraulic performance and structural integrity under varying operational stresses and environmental conditions.

- By Type:

- Sluice Gates (Slide Gates)

- Radial Gates (Tainter Gates)

- Weir Gates

- Flap Gates (Check Gates)

- Roller Gates

- Stoplogs and Bulkhead Gates

- By Material:

- Cast Iron

- Stainless Steel

- Carbon Steel

- Aluminum

- Composites (FRP/GRP)

- By Operation/Actuation:

- Manual/Handwheel Operated

- Hydraulic Operated

- Electric Operated (Motorized)

- Pneumatic Operated

- By End-Use Application:

- Water Treatment Plants (WTP)

- Wastewater Treatment Plants (WWTP)

- Irrigation and Agriculture

- Flood Control and Coastal Defense

- Hydropower Generation

- Dams and Reservoirs

Value Chain Analysis For Water Control Gate Market

The value chain for the Water Control Gate Market begins with upstream activities focused on raw material sourcing and primary component manufacturing. This stage involves the procurement of high-grade metals (steel, cast iron, aluminum) and advanced composites (fiberglass reinforced polymers), which are then processed into robust structural components, specialized coatings, and sealing materials. Reliability and quality control at this stage are paramount, as the durability of the final product hinges on the material properties, particularly their resistance to corrosion, cavitation, and hydrostatic stress. Key upstream players include specialized metal foundries and composite material suppliers that meet stringent infrastructure standards and certifications, driving innovation in longevity and reducing the environmental footprint of the final gate structure.

Midstream activities encompass the actual design, engineering, and manufacturing of the gates and their associated operating systems (actuators, gearboxes, control panels). Due to the custom-engineered nature of many large-scale water control projects, precise hydraulic modeling and site-specific structural analysis are critical components of the midstream value proposition. Manufacturers often maintain specialized fabrication facilities capable of handling large-scale welding and precise machining required for reliable sealing surfaces. The integration of advanced actuation technologies (hydraulic or electric) and sophisticated sensor packages defines value addition in this stage, ensuring the gate meets operational efficiency requirements and safety standards mandated by infrastructure operators and regulatory bodies.

Downstream activities include distribution, installation, commissioning, and crucial post-sale services such as maintenance and repair. Direct distribution channels are often preferred for highly customized, large-scale projects, involving direct engagement between the manufacturer's specialized engineering team and the end-user (e.g., government water authorities or major construction contractors). Indirect distribution involves a network of specialized local distributors and system integrators who handle smaller, standard gate sales, spares, and local support. Given the long operational lifecycle of water control gates (often 30+ years), the maintenance and spares market represents a significant and stable revenue stream, emphasizing the importance of robust service networks and readily available replacement parts to minimize infrastructure downtime.

Water Control Gate Market Potential Customers

The primary consumers of water control gates are governmental and municipal entities responsible for public water infrastructure and safety. These include national, regional, and local water authorities, irrigation boards, public works departments, and flood management agencies. These customers require robust, certified, and long-life gates for critical applications such as reservoirs, urban storm drainage systems, and municipal water treatment and distribution networks. Purchasing decisions in the public sector are heavily influenced by stringent specifications, compliance with environmental regulations, demonstrated reliability, and adherence to competitive bidding processes, favoring suppliers with strong track records and comprehensive support services.

A second major segment comprises private sector entities involved in infrastructure operation, industrial processes, and power generation. This includes operators of hydroelectric power plants, large-scale industrial facilities requiring process water control (e.g., mining, paper mills), and private agricultural enterprises managing extensive irrigation schemes. Hydroelectric companies require specialized, large radial or roller gates capable of managing high flows and pressures efficiently. Industrial customers prioritize gates made from specific materials to resist chemical corrosion or abrasion inherent in their processes. These customers often seek integrated, automated control solutions that offer high operational flexibility and reduced personnel involvement, driving demand for smart, remotely operable gates.

Furthermore, major international and local engineering, procurement, and construction (EPC) firms act as significant buyers, procuring gates as part of large-scale infrastructure turnkey projects commissioned by governments or private developers. These firms prioritize suppliers who can deliver complex gate packages on time, integrate seamlessly with broader construction schedules, and provide detailed technical documentation and installation support. The demand from EPCs is highly cyclical and project-dependent but represents the largest transactional volume for high-value custom-engineered gate systems globally.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $2.15 Billion |

| Market Forecast in 2033 | $3.18 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Rodney Hunt, Rubicon Water, DeZURIK, AVK Group, T-T Flow, Fontaine-Aquanox, Valmet, Orbinox, GA Industries, Rotork, KSB Group, Hawle, Flowserve, Mueller Water Products, Henry Pratt, VAG-Group, Armtec, Trumbull, Satech Engineering, IVL Flow. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Water Control Gate Market Key Technology Landscape

The technological evolution within the Water Control Gate Market is rapidly transitioning from purely mechanical components to highly integrated, electro-mechanical and smart hydraulic systems. A critical shift involves the adoption of advanced actuation technologies, moving away from labor-intensive manual operation toward precision electric and hydraulic cylinders. These modern systems offer significantly enhanced torque, faster response times, and highly accurate positioning capabilities, essential for dynamic water level management. Furthermore, the development of sophisticated sealing mechanisms, often incorporating specialized polymer and elastomeric compounds, has drastically reduced leakage rates, improving overall water conservation and operational efficiency, particularly vital in drought-prone regions or sensitive environmental applications.

Material science innovation is another cornerstone of the current technology landscape. The utilization of high-performance, corrosion-resistant materials, specifically Stainless Steel grades (e.g., Duplex and Super Duplex) and advanced Fiber Reinforced Polymer (FRP) composites, is growing rapidly. Composites offer the advantages of being lightweight, requiring minimal maintenance due to inherent corrosion resistance, and possessing high strength-to-weight ratios, making them ideal for coastal environments and harsh wastewater treatment facilities where traditional metals degrade rapidly. This material diversification helps extend the gate's lifecycle and reduces the long-term total cost of ownership (TCO) for end-users, aligning with sustainability objectives.

The most transformative technological trend is the integration of Information and Communication Technology (ICT) into gate operation, enabling the Internet of Things (IoT) and smart infrastructure. This involves embedding a network of high-precision sensors—measuring flow rate, gate position, vibration, pressure, and structural strain—which communicate wirelessly with Supervisory Control and Data Acquisition (SCADA) systems. This connectivity allows for centralized, remote operation and real-time data analysis. The data collected feeds into predictive maintenance algorithms and smart control loops, enabling automated optimization of water flow based on environmental inputs, thereby significantly improving the reliability and efficiency of large, distributed water networks, particularly those governed by complex regulatory requirements.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market due to massive investments in basic infrastructure development, driven by rapid urbanization, industrial growth, and the expansion of irrigation networks. Countries like China, India, and Southeast Asian nations are undertaking mega-projects (dams, reservoirs, flood channels) necessitating high volumes of standard and custom water control gates. The strong governmental push for modernizing outdated irrigation infrastructure to address food security concerns further fuels demand.

- North America: This region is characterized by infrastructure replacement and technological sophistication. The primary market driver is the urgent need to refurbish or replace aging civil infrastructure—some dating back over 50 years—to meet contemporary safety and environmental standards. Demand is high for high-precision, automated, smart gates equipped with IoT capabilities for remote diagnostics, crucial for compliance with dam safety regulations and optimizing water use efficiency in complex municipal systems.

- Europe: European market growth is stable and heavily focused on environmental compliance, climate change adaptation, and precision water management. Key activities include upgrading flood defense systems in coastal and riverine areas (e.g., using flap gates and tidal barriers) and improving efficiency in wastewater treatment plants. Strict EU directives regarding water quality and the resilience of critical infrastructure stimulate demand for specialized, high-quality, corrosion-resistant gates made to strict quality standards.

- Latin America (LATAM): Growth in LATAM is driven by regional investments in hydropower generation projects and expanding agricultural demands, particularly in Brazil, Mexico, and Chile. The market often favors cost-effective yet reliable hydraulic and electric gates for remote dam operations and irrigation system control. Economic volatility can sometimes slow large projects, yet the fundamental need for water resource development remains a consistent long-term driver.

- Middle East and Africa (MEA): This region exhibits high growth potential, strongly linked to water scarcity issues and massive investments in non-conventional water resources. Projects include large desalination plants, complex conveyance systems, and strategic water storage facilities, particularly in the Gulf Cooperation Council (GCC) countries. The demand is focused on highly durable, specialized materials (like Duplex Steel) capable of resisting the high salinity and corrosive environments typical of coastal and reclaimed water applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Water Control Gate Market.- Rodney Hunt

- Rubicon Water

- DeZURIK

- AVK Group

- T-T Flow

- Fontaine-Aquanox

- Valmet

- Orbinox

- GA Industries

- Rotork

- KSB Group

- Hawle

- Flowserve

- Mueller Water Products

- Henry Pratt

- VAG-Group

- Armtec

- Trumbull

- Satech Engineering

- IVL Flow

Frequently Asked Questions

Analyze common user questions about the Water Control Gate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What types of water control gates are most commonly used in municipal infrastructure projects?

Sluice gates (or slide gates) and flap gates are the most common in municipal settings, including water and wastewater treatment plants, due to their effective sealing capabilities and suitability for medium-pressure, corrosive environments, offering reliable flow diversion and isolation.

How is the adoption of composite materials influencing the design and maintenance of water control gates?

Composite materials, such as Fiberglass Reinforced Plastic (FRP), are increasingly used because they offer superior resistance to corrosion and chemical degradation compared to traditional metals, significantly extending the lifespan of gates, reducing weight, and lowering long-term maintenance costs in harsh environments.

What key technological innovations are driving efficiency improvements in gate operation?

Key innovations include the integration of hydraulic and electric actuators for precision control, combined with IoT sensors and SCADA systems for real-time remote monitoring, predictive maintenance, and optimized, automated flow regulation in large, distributed water networks.

Which geographical region holds the largest market share for water control gates and why?

The Asia Pacific (APAC) region currently holds the largest market share, primarily due to large-scale, ongoing infrastructure development, encompassing new dam construction, rapid urbanization requiring extensive wastewater management networks, and major investments in expanding critical irrigation systems.

What is the primary driver for the replacement and refurbishment of existing water control gate installations?

The primary driver is the need to replace aging infrastructure, much of which is past its intended operational lifespan, to comply with stricter modern safety regulations, improve operational efficiency (reduce leakage), and enhance resilience against increasingly severe and unpredictable climate-related flood events.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager