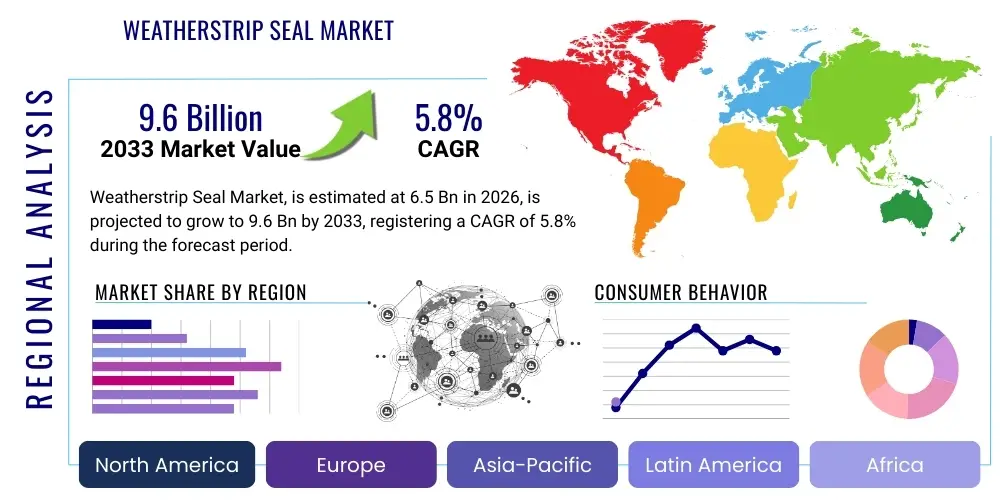

Weatherstrip Seal Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441737 | Date : Feb, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Weatherstrip Seal Market Size

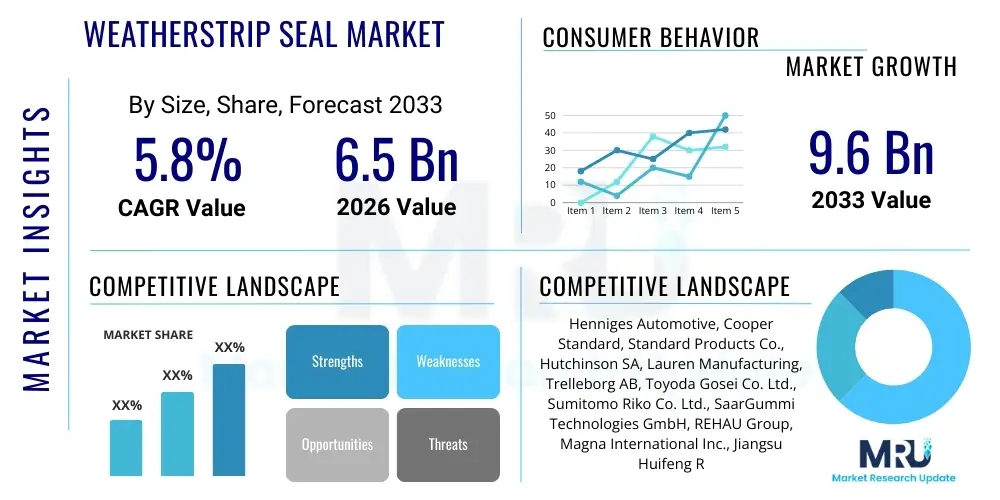

The Weatherstrip Seal Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 6.5 Billion in 2026 and is projected to reach USD 9.6 Billion by the end of the forecast period in 2033.

Weatherstrip Seal Market introduction

The Weatherstrip Seal Market encompasses the production and distribution of sealing components designed primarily to prevent the ingress of environmental elements—such as water, air, dust, and noise—into enclosed spaces, while simultaneously maintaining controlled climates and enhancing energy efficiency. These critical components are predominantly utilized in the automotive and building & construction sectors, serving as crucial barriers in doors, windows, and movable joints. Modern weatherstrip seals are engineered from advanced polymer materials, including Ethylene Propylene Diene Monomer (EPDM) rubber, Thermoplastic Elastomers (TPE), and Polyvinyl Chloride (PVC), selected based on their resistance to UV radiation, temperature extremes, and chemical exposure, ensuring long-term performance and durability in varied operating conditions.

The core application of weatherstrip seals in the automotive industry involves improving vehicle acoustics, enhancing occupant comfort, and contributing significantly to the overall structural integrity and fuel efficiency of vehicles. For the building sector, these seals are paramount in achieving stringent green building certifications and energy performance standards by minimizing air leakage and thermal bridging, which directly impacts heating, ventilation, and air conditioning (HVAC) load. The evolving demand for quieter interiors in both residential buildings and electric vehicles (EVs) is pushing manufacturers toward developing highly sophisticated, multi-material co-extruded seals that offer superior compression set resistance and sealing capabilities compared to traditional monolithic designs.

Key market benefits driving adoption include compliance with increasingly strict energy conservation codes globally, such as Title 24 in California and various European Directives focused on near-zero energy buildings (NZEBs). Furthermore, the substantial increase in global vehicle production, particularly the expansion of the Electric Vehicle (EV) segment which demands lightweight, high-performance sealing solutions to compensate for the absence of engine noise, serves as a primary driver. The continuous innovation in material science, focusing on recyclable and bio-based polymers, is also shaping the market landscape, offering opportunities for manufacturers to position their products as sustainable solutions in both B2B and B2C segments.

Weatherstrip Seal Market Executive Summary

The global Weatherstrip Seal Market is characterized by robust growth underpinned by strong industrial and construction activity, especially in the Asia Pacific region. Business trends show a significant pivot towards advanced, sustainable materials like TPE and bio-based rubbers, driven by Original Equipment Manufacturers (OEMs) seeking lightweight components for enhanced fuel economy and reduction of carbon footprint. Strategic mergers, acquisitions, and technological collaborations focusing on enhancing co-extrusion capabilities and integrating smart materials are defining the competitive landscape, with major players investing heavily in optimizing manufacturing processes for cost-efficiency and quality consistency, particularly in high-volume automotive production lines.

Regionally, the market dynamics are highly influenced by governmental regulatory frameworks. North America and Europe exhibit mature market characteristics, with growth propelled by stringent building energy codes and the rapid transition to electric vehicles, requiring specialized sealing solutions for battery enclosures and cabin insulation. Conversely, the Asia Pacific region, led by China and India, is the fastest-growing market segment, fueled by massive urbanization, infrastructure development projects, and the expansion of domestic automotive manufacturing bases. These regions are prioritizing affordability alongside performance, leading to diverse material adoption patterns and intense price competition among local and international suppliers.

Segmentation trends highlight the dominance of the EPDM material segment due to its excellent durability and cost-effectiveness, although TPE is gaining momentum rapidly owing to its superior recyclability and lightweight characteristics, making it highly preferred in modern automotive design. The application segment continues to be led by the automotive sector, specifically the OEM sub-segment, which demands high volumes of standardized and custom seals for new vehicle platforms. However, the building and construction segment is witnessing accelerated demand for high-performance window and door seals as energy conservation becomes a global priority, ensuring steady and diversified revenue streams across the forecast period.

AI Impact Analysis on Weatherstrip Seal Market

Common user questions regarding AI's influence on the Weatherstrip Seal Market primarily revolve around how artificial intelligence can optimize the complex polymer compounding and extrusion processes, how it assists in predicting material fatigue and product lifespan, and its role in managing the intricate global supply chains characterized by fluctuating raw material prices. Users are particularly interested in AI's capacity to enhance quality control during high-speed manufacturing, minimizing defects in co-extruded products that require precision blending of multiple materials. This analysis reveals a consensus that AI is seen not as a threat, but as an enabling technology essential for achieving the next generation of performance, efficiency, and sustainability goals in a traditionally high-volume, low-margin industry, especially concerning the development of smart, adaptive weather seals.

The implementation of AI and Machine Learning (ML) algorithms is fundamentally reshaping R&D efforts in material science for weatherstrip seals. By simulating millions of polymer formulations and processing conditions, AI accelerates the discovery of novel materials that exhibit improved durability, lower compression set, and better adhesion properties, specifically tailored for demanding applications like electric vehicle battery packs or high-rise building facades. Furthermore, predictive maintenance programs powered by AI are being integrated into extrusion lines, allowing manufacturers to anticipate equipment failure, optimize tooling changes, and ensure consistent product quality, thus dramatically reducing waste and operational downtime, which is critical for meeting stringent OEM supply timelines.

In the commercial aspect, AI-driven analytics are being deployed for sophisticated demand forecasting and inventory management, critical given the high volatility in the prices of key raw materials such as ethylene, propylene, and various plasticizers. These tools enable manufacturers to optimize purchasing strategies, hedge against price risks, and manage highly complex, Just-In-Time (JIT) supply chains globally. Additionally, AI-powered quality inspection systems, utilizing computer vision, provide real-time, highly accurate flaw detection along the production line, ensuring that the manufactured seals meet the tight dimensional tolerances and surface finish requirements stipulated by automotive and aerospace clients, thereby enhancing overall market credibility and reducing warranty claims.

- AI optimizes polymer compounding through predictive modeling, reducing material waste by up to 15%.

- Machine Learning enhances quality control by utilizing computer vision for real-time defect detection in complex co-extruded profiles.

- Predictive maintenance algorithms minimize manufacturing downtime and extend the lifespan of extrusion equipment.

- AI accelerates R&D for new TPE and bio-based seal formulations, meeting stringent performance and sustainability metrics faster.

- Demand forecasting powered by AI improves inventory management and shields businesses from raw material price volatility.

- Generative Design tools aid in optimizing seal geometry for specific application requirements (e.g., lightweighting for EVs).

DRO & Impact Forces Of Weatherstrip Seal Market

The Weatherstrip Seal Market is primarily driven by rigorous regulatory requirements concerning energy efficiency in the building sector and the global surge in automotive production, particularly in emerging economies and the accelerating shift toward Electric Vehicles (EVs). Stringent mandates like Europe's Energy Performance of Buildings Directive (EPBD) necessitate superior sealing solutions to minimize air infiltration in construction, directly boosting demand for high-performance perimeter seals. In the automotive sphere, the focus on reducing cabin noise (Noise, Vibration, and Harshness – NVH) and improving aerodynamic efficiency compels OEMs to adopt specialized, high-quality weatherstripping. However, the market faces significant restraints, chiefly related to the volatility and upward pressure on prices of key petrochemical-derived raw materials, such as synthetic rubbers and plastics, which directly compress manufacturer profit margins and necessitate constant efforts in cost optimization and process efficiency.

Opportunities in the market are abundant, particularly with the growth of niche high-performance applications and sustainability mandates. The development of 'smart' weather seals incorporating embedded sensors for monitoring air leakage or temperature changes presents a promising avenue for high-value products, especially in smart building architectures. Furthermore, the increasing consumer preference for sustainable products is creating a substantial opportunity for manufacturers investing in bio-based, recycled, or easily recyclable polymers like specialized TPEs and TPVs, positioning them favorably in the corporate sustainability strategies of major buyers. The large and growing global aftermarket, driven by replacement cycles for older buildings and vehicles, also provides a stable revenue stream less susceptible to new construction or production cycles.

The impact forces within this sector are multifaceted. Supplier power is moderate to high, as the raw material supply chain (petrochemicals) is concentrated, leading to significant leverage over manufacturers, especially during periods of global supply chain disruption. Buyer power, particularly from large Automotive OEMs, is extremely high, as they demand high volumes, precise specifications, and competitive pricing, often requiring suppliers to co-locate and adhere to strict quality standards (e.g., IATF 16949). The threat of new entrants is relatively low due to the high capital investment required for precision extrusion machinery and the necessity of establishing long-term quality certifications, while the threat of substitutes is also moderate, primarily arising from advanced foam sealants or alternative materials that could potentially replace traditional rubber profiles in certain low-stress applications.

Segmentation Analysis

The Weatherstrip Seal Market is meticulously segmented based on material, application, and end-use, allowing for detailed analysis of underlying demand drivers across various industries. Material segmentation is crucial as performance characteristics such as temperature resistance, flexibility, and longevity are dictated by the base polymer used. EPDM remains the volume leader due to its excellent weathering properties and cost balance, while the rapidly growing TPE segment caters to demands for lightweight, sustainable, and easily recyclable solutions favored by modern automotive and construction designers. Analysis by application confirms the automotive sector’s dominance, driven by new vehicle production cycles and stringent NVH requirements, contrasted by the building and construction sector's steady growth focused on energy conservation compliance.

Further segmentation by end-use reveals the distinction between the original equipment manufacturer (OEM) market and the aftermarket. The OEM segment, characterized by high volume, customized designs, and long-term contracts, is highly sensitive to overall economic cycles affecting manufacturing. In contrast, the aftermarket segment provides resilience, relying on maintenance, repair, and replacement demand, particularly in regions with aging building stock or vehicle fleets. The complexity of seal profiles, ranging from simple bulb seals to complex co-extruded composite seals, also serves as an important differentiator, influencing pricing and technical expertise required by manufacturers.

This structured segmentation enables market participants to tailor their product offerings and strategic investments. Manufacturers focusing on TPE solutions target premium automotive and green building projects, leveraging sustainability claims and lightweighting advantages. Those specializing in PVC and lower-cost EPDM target high-volume applications in emerging markets or the general construction segment where cost optimization is paramount. Understanding these nuanced demands across materials and end-users is vital for effective market positioning and predicting future technological adoption curves, particularly as specialized sealing requirements for electric vehicle battery enclosures gain prominence.

- By Material:

- Ethylene Propylene Diene Monomer (EPDM)

- Thermoplastic Elastomers (TPE)

- Polyvinyl Chloride (PVC)

- Silicone

- Others (e.g., TPV, Natural Rubber)

- By Application:

- Automotive (Doors, Windows, Hood, Trunk, Sunroof, Battery Enclosures)

- Building & Construction (Doors, Windows, Glazing Systems)

- Aerospace & Defense

- Marine

- Industrial

- By End-Use:

- Original Equipment Manufacturer (OEM)

- Aftermarket (Replacement/Repair)

- By Distribution Channel:

- Direct Sales

- Distributors/Wholesalers

- Retail

Value Chain Analysis For Weatherstrip Seal Market

The value chain for the Weatherstrip Seal Market begins with the upstream segment, primarily involving the procurement and production of raw materials, which are largely petrochemical derivatives. Key inputs include monomers (ethylene, propylene), vulcanizing agents, plasticizers, and specialty additives required for compounding EPDM, TPE, and PVC. The chemical industry suppliers hold significant influence in this initial phase due to the capital intensity of monomer production and susceptibility to global oil price fluctuations. Manufacturers engage in compounding, converting these raw materials into specialized polymer compounds tailored for specific sealing properties (e.g., UV stability, low temperature flexibility), a process that requires advanced chemical engineering and quality control expertise.

The core manufacturing stage involves the extrusion and molding processes, where the compounded materials are shaped into complex profiles. Co-extrusion technology, combining different materials (such as a rigid base and a soft sealing lip) into one profile, is a key value-added step, ensuring superior performance characteristics. This stage demands precision tooling, efficient energy usage, and rigorous quality inspection to meet the tight dimensional tolerances specified by OEM clients. Finished seals are then subjected to assembly, cutting, and application of adhesives or flocking (surface treatments) before moving into the distribution phase. Optimization of this manufacturing stage, often through automation and lean principles, is crucial for maintaining competitive pricing.

The downstream segment is dominated by sophisticated distribution channels tailored to the end-user requirements. For major Automotive OEMs, distribution is often direct (Just-In-Time delivery) to assembly plants globally, requiring suppliers to maintain stringent logistics and inventory management systems. For the building and construction sector, distribution relies more heavily on indirect channels, utilizing specialized distributors, building supply wholesalers, and retail chains like hardware stores, especially for standard-profile replacement seals in the aftermarket. Success in the downstream market depends on strong logistical networks, technical support capabilities, and the ability to efficiently service both high-volume OEM contracts and diverse aftermarket needs.

Weatherstrip Seal Market Potential Customers

The primary end-users and buyers of weatherstrip seals span across major industrial sectors, defined by their stringent requirements for sealing, NVH reduction, and climate control. Automotive Original Equipment Manufacturers (OEMs), including global giants producing passenger vehicles, commercial trucks, and specialized off-road equipment, constitute the largest and most demanding customer segment. These buyers prioritize custom-designed, high-precision seals that integrate seamlessly into complex vehicle architectures, requiring long-term partnership agreements, adherence to global automotive quality standards (e.g., IATF 16949), and substantial manufacturing capacity to handle high-volume demands for various platforms, including battery enclosures in electric vehicles.

The Building and Construction industry represents the second major customer base, encompassing commercial contractors, residential builders, window and door manufacturers (fenestration specialists), and large-scale infrastructure developers. This segment's purchasing criteria are strongly influenced by national and regional building codes focused on energy efficiency (e.g., U-factor, R-value requirements) and acoustic insulation. Buyers in this space seek durable, fire-resistant, and aesthetically pleasing seals that guarantee long operational life in diverse climatic conditions. The aftermarket demand from this sector, driven by property maintenance and renovation cycles aimed at upgrading energy performance, is consistent and robust, offering resilience against new construction downturns.

Beyond the core markets, niche potential customers include manufacturers in the Aerospace and Marine industries, where sealing requirements are extreme due to factors like high altitude, pressurized environments, saltwater exposure, and vibration. These sectors require seals made from highly specialized materials like silicone or proprietary fluorocarbon compounds. Furthermore, the industrial machinery sector, including manufacturers of HVAC systems, refrigerated transport units, and electrical cabinets, utilizes weatherstrip seals to protect sensitive internal components from environmental contaminants, representing crucial high-value, low-volume customer segments focused heavily on specific regulatory compliance and material certification.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 6.5 Billion |

| Market Forecast in 2033 | USD 9.6 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Henniges Automotive, Cooper Standard, Standard Products Co., Hutchinson SA, Lauren Manufacturing, Trelleborg AB, Toyoda Gosei Co. Ltd., Sumitomo Riko Co. Ltd., SaarGummi Technologies GmbH, REHAU Group, Magna International Inc., Jiangsu Huifeng Rubber and Plastic Co. Ltd., Meteor Gummiwerke K.H. Bette GmbH Co. KG, Jihong Manufacturing, Hi-Tech Seals Inc., Hebei Shida Seal Group, Ultrafab Inc., Z-Flex Sealed Unit Parts Ltd., Quanex Building Products Corporation, Schlegel International. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Weatherstrip Seal Market Key Technology Landscape

The technological evolution in the Weatherstrip Seal Market is centered around advanced material science and sophisticated manufacturing techniques, primarily aimed at enhancing performance, durability, and production efficiency. Multi-material co-extrusion technology is arguably the most critical process advancement, enabling manufacturers to combine materials with disparate physical properties—such as a rigid backbone for structural integrity (often polypropylene or harder TPE) and a soft, cellular rubber lip for superior sealing and low compression force—into a single, complex profile. This process minimizes assembly steps for OEMs and allows for precise control over the seal's flexibility, stiffness, and overall weight, a crucial factor in electric vehicle design where every component must contribute to energy efficiency and range extension.

Another significant technological focus is surface treatment and coating technologies. Flocking, which involves applying small textile fibers to the sealing surface, remains vital for reducing friction and minimizing operating effort for movable parts (like automotive windows or sliding doors). Newer advancements include specialized low-friction coatings and UV-resistant treatments that enhance the seal's longevity and aesthetics, preventing cracking or fading over time. Furthermore, the trend towards lightweighting is driving intensive research into micro-cellular extrusion, where the use of foaming agents creates seals with internal voids, reducing material density while maintaining high performance standards, directly appealing to automotive customers seeking component weight reduction.

In terms of materials, the landscape is shifting towards Thermoplastic Elastomers (TPEs) and Thermoplastic Vulcanizates (TPVs) as sustainable and high-performance alternatives to traditional EPDM. TPEs offer the advantage of being easily recyclable and processable using standard thermoplastic equipment, improving manufacturing yield and reducing scrap material. The integration of advanced polymer blends and nanotechnology additives is also becoming prevalent, aimed at imparting specific functionalities, such as enhanced thermal insulation for cold climates or specialized conductive properties for use in grounding applications, particularly around critical components in advanced vehicle systems. The adoption of Industry 4.0 principles, including integrated robotics and IoT sensors in the extrusion lines, ensures precision and traceability throughout the manufacturing process.

Regional Highlights

- North America: The North American market is characterized by mature automotive manufacturing and exceptionally stringent building energy codes, particularly in states like California, driving demand for high-performance seals. The market is highly competitive, dominated by established players and focused on complex, high-margin products like those used in luxury vehicles and high-efficiency commercial buildings. Growth is strongly linked to the rapid expansion of EV production capacity and governmental incentives promoting zero-emission vehicles, necessitating specialized seals for battery pack thermal management and quiet cabin design. The construction sector also sees steady demand due to replacement and renovation activities aimed at achieving net-zero energy standards.

- Europe: Europe is a sophisticated market heavily influenced by environmental legislation, including REACH regulations and directives promoting circular economy principles. This region is a leader in adopting bio-based and recyclable TPEs, driven by strong OEM sustainability mandates. The automotive sector, particularly premium German and French manufacturers, demands superior NVH characteristics, leading to high usage of complex multi-durometer and flocked seals. Furthermore, the European Union's focus on insulating its existing building stock provides a consistent, strong aftermarket demand, supplemented by new construction adhering to near-zero energy building (NZEB) requirements.

- Asia Pacific (APAC): APAC represents the fastest-growing and largest regional market globally, fueled by rapid urbanization, massive infrastructure spending, and the exponential growth of automotive production, especially in China, India, and Southeast Asia. The region’s demand structure is two-tiered: high-volume, cost-effective EPDM seals dominate general construction and mass-market vehicles, while sophisticated TPE/TPV seals are increasingly adopted by international OEMs and high-end residential projects. China’s dominance in electric vehicle manufacturing positions it as the primary driver for technological adoption in high-performance sealing solutions for EV platforms and battery cooling systems, creating intense competition and local innovation.

- Latin America (LATAM): The LATAM market, while smaller, shows significant potential tied to infrastructure investments in countries like Brazil and Mexico. Automotive demand is steady, driven by local assembly plants serving regional consumption. Cost competitiveness is a major factor, often favoring PVC and standard EPDM seals. The construction segment experiences cyclical demand influenced by economic stability and commodity prices, with opportunities emerging from efforts to standardize building codes and improve basic energy efficiency across commercial and residential developments.

- Middle East and Africa (MEA): The MEA market presents unique challenges and opportunities due to extreme climate conditions (intense heat, UV exposure, dust). Demand is highest for specialized materials (often silicone or highly stabilized EPDM) that can withstand these harsh environments without degradation. Major infrastructure projects and real estate developments in the Gulf Cooperation Council (GCC) countries, focusing on premium, energy-efficient buildings, drive demand for superior sealing systems, while the African market focuses primarily on essential, cost-effective solutions for general construction and basic vehicle maintenance.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Weatherstrip Seal Market.- Henniges Automotive

- Cooper Standard

- Standard Products Co.

- Hutchinson SA

- Lauren Manufacturing

- Trelleborg AB

- Toyoda Gosei Co. Ltd.

- Sumitomo Riko Co. Ltd.

- SaarGummi Technologies GmbH

- REHAU Group

- Magna International Inc.

- Jiangsu Huifeng Rubber and Plastic Co. Ltd.

- Meteor Gummiwerke K.H. Bette GmbH Co. KG

- Jihong Manufacturing

- Hi-Tech Seals Inc.

- Hebei Shida Seal Group

- Ultrafab Inc.

- Z-Flex Sealed Unit Parts Ltd.

- Quanex Building Products Corporation

- Schlegel International

Frequently Asked Questions

Analyze common user questions about the Weatherstrip Seal market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary material driving growth in the Weatherstrip Seal Market?

While EPDM currently holds the largest market share by volume due to its durability and cost-effectiveness, Thermoplastic Elastomers (TPE) and Thermoplastic Vulcanizates (TPV) are the fastest-growing segments. TPEs are preferred for new automotive platforms, especially electric vehicles, because of their lightweight properties, excellent recyclability, and ease of processing, which aligns with global sustainability mandates and lightweighting objectives.

How do weatherstrip seals contribute to energy efficiency in buildings?

Weatherstrip seals are critical for minimizing air leakage and thermal bridging around windows and doors, the two primary sources of energy loss in building envelopes. By creating a continuous seal, they prevent conditioned air from escaping and unconditioned air from entering, significantly reducing the load on HVAC systems and helping buildings comply with stringent energy performance and green building codes globally.

What is the major difference between OEM and Aftermarket demand for weatherstrip seals?

Original Equipment Manufacturer (OEM) demand is characterized by high volume, customized design specifications, and long-term contracts, driven by new vehicle production or construction projects. Aftermarket demand is focused on replacement and repair, involving standardized profiles and specialized kits, providing a more stable revenue stream less dependent on new market production cycles.

What is the impact of Electric Vehicles (EVs) on weatherstrip seal technology?

The EV shift necessitates specialized sealing solutions due to the absence of engine noise, making NVH reduction paramount. Furthermore, complex seals are required for protecting high-voltage battery enclosures from moisture and temperature fluctuations, driving demand for advanced, multi-material co-extruded TPE and silicone seals with enhanced thermal and fire-resistant properties.

Which geographical region dominates the Weatherstrip Seal Market?

The Asia Pacific (APAC) region currently dominates the Weatherstrip Seal Market in terms of volume and exhibits the highest growth rate. This dominance is attributed to rapid urbanization, massive government investment in infrastructure development, and the region's leading role in global automotive manufacturing, especially in high-volume markets like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager