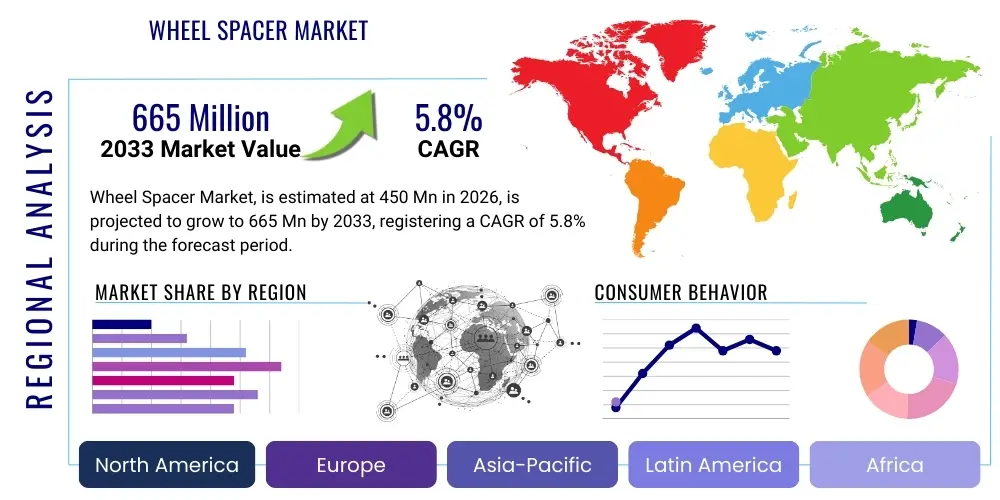

Wheel Spacer Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443261 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Wheel Spacer Market Size

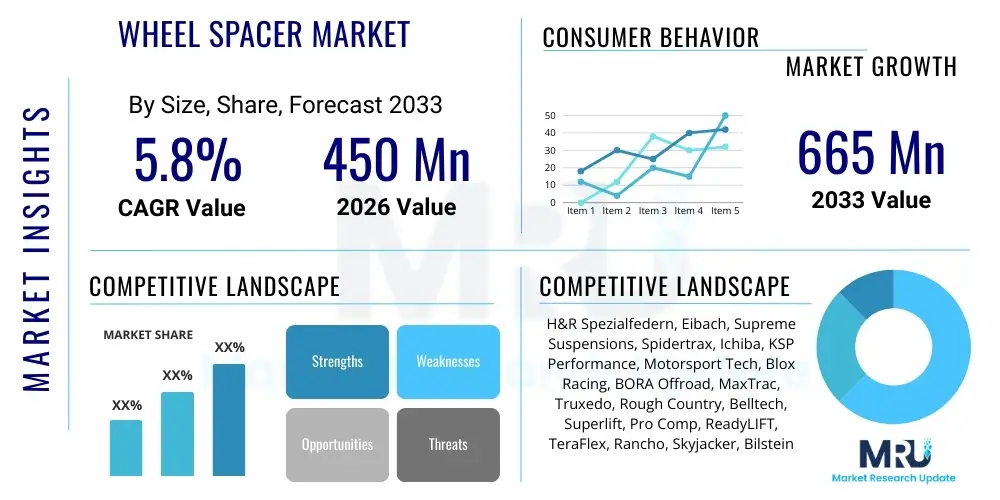

The Wheel Spacer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 665 Million by the end of the forecast period in 2033.

Wheel Spacer Market introduction

The Wheel Spacer Market encompasses the design, manufacturing, distribution, and sales of components primarily used to increase the offset between the vehicle wheel and the hub assembly. These components are generally disk-shaped devices manufactured from high-strength materials, predominantly aluminum alloys or steel, engineered to fit onto the vehicle's hub. The fundamental purpose of installing wheel spacers is multi-faceted: aesthetically, they provide a more aggressive stance by pushing the wheels out to align them better with the fender flares; functionally, they can improve handling characteristics by widening the vehicle’s track width, enhancing stability during cornering. Wheel spacers are crucial aftermarket accessories, especially popular among automotive enthusiasts engaged in performance tuning, off-roading, and cosmetic customization. They are essential for applications where larger brake calipers are installed, necessitating increased clearance, or when custom wheels with incorrect offset specifications are used, ensuring proper fitment and preventing tire rub against suspension components.

Product descriptions vary significantly based on design, primarily categorized into bolt-on and slip-on types. Bolt-on spacers are typically thicker and integrate their own set of studs, fastening directly to the hub, while the wheel then bolts onto the spacer itself. Slip-on spacers are thinner and simply slide over the existing studs, requiring longer lug nuts or studs for secure wheel attachment. Major applications span passenger vehicles, including sedans, SUVs, and sports cars, where cosmetic enhancements and minor handling improvements are sought, to specialized off-road vehicles and high-performance racing applications, where robust design and maximum track width extension are critical for stability and navigating demanding terrains. The growing trend of vehicle personalization and the strong performance aftermarket industry are the principal driving factors sustaining market growth.

Wheel Spacer Market Executive Summary

The global Wheel Spacer Market is characterized by robust business trends driven primarily by increasing consumer disposable income dedicated to vehicle customization and the persistent demand for performance enhancements in both developed and emerging economies. Key business trends include the emphasis on precision-engineered products certified for safety, particularly high-grade billet aluminum spacers manufactured using Computer Numerical Control (CNC) technology, which ensures critical dimensional accuracy and material integrity. Furthermore, e-commerce platforms have become pivotal distribution channels, facilitating direct-to-consumer sales and offering a wider variety of specialized products, thereby reducing barriers for smaller manufacturers to reach global consumers. Technological advancements in material science, focusing on reducing unsprung weight while maintaining superior strength and corrosion resistance, are defining competitive advantages among key market players. Safety and regulatory compliance, particularly regarding standardized load ratings and installation guidelines, are also becoming crucial factors influencing consumer purchasing decisions.

Regionally, North America remains the dominant market due to a deeply entrenched vehicle modification culture, high participation rates in motorsports, and a large population of off-road vehicle enthusiasts, particularly in the SUV and truck segments. Asia Pacific (APAC) is exhibiting the fastest growth trajectory, fueled by rapid urbanization, rising middle-class disposable income, and the burgeoning popularity of vehicle tuning communities in countries like China, India, and Japan. European markets maintain steady growth, influenced heavily by stringent regulatory standards regarding vehicle structural modifications, which often necessitate certified and type-approved wheel spacer kits. Segment trends highlight the dominance of the aluminum alloy segment due to its lightweight properties and superior heat dissipation characteristics, essential for performance applications. The bolt-on spacer type is increasingly preferred over slip-on variants for applications requiring greater thickness and enhanced structural safety, especially in high-torque and heavy-duty vehicles, driving significant revenue growth within this subsegment.

AI Impact Analysis on Wheel Spacer Market

Common user questions regarding AI’s impact on the Wheel Spacer Market generally revolve around manufacturing precision, supply chain optimization, and product personalization. Consumers and industry professionals frequently inquire whether AI-driven quality control systems can eliminate material defects and manufacturing variances, thereby enhancing product safety and longevity. There is significant interest in using predictive AI models to forecast demand for specific spacer sizes and materials across different geographic regions, streamlining inventory management and reducing lead times. Furthermore, users are keen to understand how AI algorithms can be employed in the design phase to simulate stress tests under various driving conditions, optimizing weight reduction without compromising structural integrity—a crucial factor for performance-oriented consumers. The overarching theme is the expectation that AI integration will lead to unprecedented levels of precision engineering, greater personalization options tailored to specific vehicle models and suspension setups, and a more resilient, responsive global supply chain, ultimately elevating product quality and reducing the risk of product failure.

- AI-driven Predictive Maintenance: Utilizing machine learning algorithms in CNC manufacturing equipment to monitor tool wear and operational variances, ensuring micron-level accuracy in spacer production and preventing dimensional errors before they occur.

- Generative Design Optimization: Employing AI to iterate through thousands of design variations for optimal stress distribution and minimal material usage, leading to ultra-lightweight yet robust wheel spacer designs tailored for specific load requirements (Unsprung Weight Reduction).

- Automated Quality Inspection: Implementation of computer vision systems integrated with AI to perform instantaneous, non-destructive testing and surface finish analysis on every produced unit, significantly exceeding the efficiency and accuracy of manual quality checks.

- Supply Chain and Inventory Management: Using sophisticated AI models to analyze global vehicle sales data, customization trends, and seasonal demands to predict necessary inventory levels for popular segment types (e.g., 5x114.3 bolt pattern, 25mm thickness), minimizing overstock and stockouts.

- Personalized Consumer Recommendations: AI-powered configurators on e-commerce platforms that suggest the optimal spacer size and type based on the user's vehicle model, current wheel offset, fender clearance measurements, and intended use (street, track, or off-road), enhancing customer satisfaction and reducing return rates due to improper fitment.

DRO & Impact Forces Of Wheel Spacer Market

The Wheel Spacer Market is propelled primarily by robust Drivers, specifically the burgeoning global market for vehicle personalization and customization, where aesthetic enhancement and aggressive vehicle stance are highly desired attributes, particularly among younger demographics and automotive enthusiasts. The continuous expansion of the aftermarket performance industry, focused on enhancing vehicle handling, stability, and braking clearance, provides a persistent source of demand. Simultaneously, the proliferation of specialized off-road vehicle communities and the requirement for wider tracks to accommodate larger tires and modified suspension systems significantly contribute to market upliftment. However, the market faces significant Restraints, chiefly the inherent safety concerns associated with improperly installed or low-quality spacers, which can lead to wheel detachment or premature component wear, generating regulatory scrutiny and consumer caution. Additionally, strict vehicle modification laws and inspection requirements in several mature economies, particularly in parts of Europe and Asia, limit the legal use or thickness of spacers, constraining potential sales volume.

Opportunities in the market center around technological innovation in material science, focusing on advanced lightweight composites and aerospace-grade aluminum alloys that offer enhanced strength-to-weight ratios, addressing safety concerns while boosting performance. Developing specialized, vehicle-specific hub-centric spacers that ensure perfect alignment and mitigate vibration issues presents a substantial market opportunity, differentiating premium products from generic alternatives. Impact Forces shaping the market include high leverage from consumer perception of product safety and brand reputation; manufacturers investing heavily in third-party testing and certification gain substantial competitive leverage. Furthermore, the dynamic nature of the automotive industry, characterized by rapid changes in original equipment manufacturer (OEM) wheel and suspension designs, necessitates continuous product adaptation and swift research and development cycles by spacer manufacturers to maintain compatibility and market relevance.

Segmentation Analysis

The Wheel Spacer Market is comprehensively segmented based on three critical factors: Material Type, which dictates performance characteristics and cost; Spacer Type, defining the installation method and suitability for various thickness requirements; and Application, specifying the end-use vehicle category. This multi-dimensional segmentation allows market players to accurately target specific consumer needs, ranging from the cost-conscious daily driver seeking a subtle aesthetic change to the high-performance racer demanding maximum strength and minimal weight. Understanding these segments is vital for developing targeted marketing strategies and investing in specialized manufacturing processes, such as high-precision CNC machining for aluminum products or heavy-duty forging for steel components used in commercial or rugged off-road applications. The segmentation highlights the market's diversity, indicating a mature yet continuously evolving aftermarket industry.

- By Material Type:

- Aluminum Alloy (6061-T6, 7075-T6)

- Steel (Carbon Steel, Alloy Steel)

- By Spacer Type:

- Bolt-on Spacers

- Slip-on Spacers

- By Application:

- Passenger Vehicles (Sedans, Hatchbacks, SUVs)

- Commercial Vehicles (Light Trucks, Vans)

- Off-Road and Performance Vehicles

- By Distribution Channel:

- Aftermarket Retail Stores

- Online Sales (E-commerce Platforms)

- Authorized Dealers/Workshops

Value Chain Analysis For Wheel Spacer Market

The value chain for the Wheel Spacer Market begins with the Upstream Analysis, dominated by raw material procurement, primarily high-grade aluminum billets (e.g., 6061-T6 or 7075-T6) and specialized alloy steel, which are sourced from primary metal producers. Material quality is paramount as it directly determines the safety and load-bearing capacity of the final product. Key upstream activities include material testing, certification, and establishing secure supply contracts to manage price volatility. Following procurement, the manufacturing stage involves high-precision CNC machining, surface treatments (anodizing for aluminum or zinc plating for steel to enhance corrosion resistance), and meticulous assembly, particularly for bolt-on spacers that require embedded high-tensile studs. Premium manufacturers often integrate in-house stress testing and quality assurance protocols at this stage to ensure compliance with international safety standards, adding significant value through verifiable quality.

The Downstream Analysis focuses on the distribution and end-user engagement. Distribution channels are highly fragmented but dominated by two primary paths: Direct and Indirect. Direct distribution includes sales through manufacturers' own specialized e-commerce platforms, allowing higher margins and direct consumer engagement, particularly for niche or customized products. Indirect distribution relies heavily on large-scale aftermarket retailers (both brick-and-mortar and online giants like Amazon or eBay), automotive parts distributors, and professional installation workshops. The choice of channel often depends on the segment, with high-volume, standard products favoring mass retail and specialized, high-performance parts relying more on direct channels or authorized tuning shops. Effective downstream marketing, emphasizing safety credentials, ease of installation, and performance benefits, is crucial for capturing consumer confidence and driving sales.

Wheel Spacer Market Potential Customers

The primary End-User/Buyers of wheel spacer products constitute a diverse group unified by the desire to modify or customize their vehicles for performance, aesthetic, or functional reasons. This highly engaged demographic includes automotive enthusiasts who perform modifications themselves, focusing on visual appeal, such as achieving a "flush" wheel-to-fender fitment, or minor handling improvements. A second major customer segment includes professional racing teams, track day participants, and performance tuning workshops, who utilize spacers as precision tools to fine-tune track width for optimal handling balance, cornering stability, and to clear large aftermarket brake systems. These buyers prioritize material strength, minimal tolerance levels, and adherence to specific homologation requirements, making them customers for premium, high-cost, hub-centric bolt-on spacers.

A rapidly expanding customer base resides within the off-road and truck modification community, particularly in North America and Australia. Owners of SUVs, 4x4 vehicles, and light trucks frequently install wheel spacers to accommodate significantly larger, wider off-road tires and lift kits. For these customers, functionality and rugged durability are paramount, ensuring the spacers can withstand extreme torsional stresses and exposure to harsh environmental elements. Finally, garage owners and general repair shops represent B2B customers, purchasing spacers in bulk to offer them as part of modification packages or as necessary components when fitting custom wheels with non-standard offsets. Targeting these different customer groups requires varied product strategies, ranging from highly durable, load-rated steel spacers for commercial applications to lightweight, anodized aluminum versions for passenger vehicle aesthetics.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 665 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | H&R Spezialfedern, Eibach, Supreme Suspensions, Spidertrax, Ichiba, KSP Performance, Motorsport Tech, Blox Racing, BORA Offroad, MaxTrac, Truxedo, Rough Country, Belltech, Superlift, Pro Comp, ReadyLIFT, TeraFlex, Rancho, Skyjacker, Bilstein |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Wheel Spacer Market Key Technology Landscape

The technological landscape of the Wheel Spacer Market is fundamentally defined by precision manufacturing processes, primarily Computer Numerical Control (CNC) machining. This technology is critical because the dimensional accuracy of a wheel spacer directly impacts vehicle safety and performance, specifically regarding vibration minimization and alignment integrity. High-end manufacturers utilize multi-axis CNC machines to mill wheel spacers from solid billets of high-strength materials, such as 6061-T6 or the even stronger 7075-T6 aluminum, ensuring tolerances are maintained within fractions of a millimeter. This precision is essential for hub-centric designs, where the spacer must perfectly match both the vehicle's hub lip diameter and the wheel's center bore, eliminating potential stress points and ensuring the load is borne correctly by the hub, not the wheel studs. Furthermore, the selection and integration of high-tensile strength studs and corresponding lug nuts in bolt-on applications represent a key technological focus, requiring robust material testing and certified heat treatment processes to withstand extreme shear forces and cyclical loads during vehicle operation.

Material science and surface treatment technologies are equally pivotal in advancing the market. Anodizing, a common surface treatment for aluminum spacers, is crucial not only for aesthetic appeal but primarily for creating a durable, corrosion-resistant oxide layer. Type III hard-coat anodizing is increasingly being adopted by premium brands as it provides superior wear resistance and hardness compared to standard Type II processes, extending the product's lifespan, especially in harsh environments encountered during off-roading or winter driving where road salts are prevalent. Manufacturers are also continuously researching and implementing alternative lightweight materials, including specialized magnesium alloys and reinforced composite materials, aiming to drastically reduce unsprung mass—a crucial factor in high-performance vehicles where every gram saved contributes to improved suspension responsiveness, braking efficiency, and overall dynamic handling characteristics. These technological advancements ensure that wheel spacers are not merely simple metal disks but complex, engineered components vital to vehicle dynamics.

Traceability and quality assurance technologies play a growing role, driven by the need to combat counterfeit products and uphold safety standards. Advanced manufacturers are integrating unique serialization and QR codes onto each spacer, leveraging laser etching technology. This allows for full traceability of the product, from the specific batch of raw material and the exact CNC machine used to the date of manufacturing and quality inspection results. This level of technological transparency provides crucial reassurance to both consumers and regulatory bodies, demonstrating adherence to certified manufacturing standards like ISO 9001 and enhancing brand trust. Moreover, digital measurement systems, often integrated with the CNC machines, provide real-time dimensional feedback, immediately identifying and isolating any parts that fall outside the specified engineering tolerances, representing a significant technological step in maintaining the highest levels of safety and precision in the highly competitive aftermarket accessory industry.

Regional Highlights

- North America: This region maintains its position as the market leader, characterized by a pervasive and deeply ingrained culture of vehicle customization, particularly within the truck, SUV, and muscle car segments. The strong presence of aftermarket tuning shops, accessible regulatory environment for modifications (compared to Europe), and a vast network of off-road enthusiasts drive consistently high demand for robust, high-offset wheel spacers. The U.S. and Canada benefit from high consumer disposable income allocated towards automotive upgrades and strong sales channels through major national retail chains and dedicated e-commerce platforms.

- Europe: The European market demonstrates steady, albeit more regulated, growth. Demand is highly concentrated in countries like Germany and the UK, driven by high-performance vehicle tuning and motorsports. However, stringent TÜV certification and specific national road traffic regulations concerning track width extension pose a significant challenge. Manufacturers must invest heavily in obtaining necessary homologation approvals, leading to higher average product prices but also guaranteeing superior quality and safety standards that appeal to discerning consumers who prioritize certified products.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, benefiting from rapid economic expansion, increasing vehicle ownership rates, and the emergence of vibrant car modification communities in countries such as Japan, Australia, China, and South Korea. Rising incomes allow middle-class consumers to increasingly engage in non-essential vehicle upgrades. While the Japanese market focuses on high-precision, track-oriented spacers, the Chinese and Southeast Asian markets are driven by volume sales of aesthetically motivated upgrades for passenger cars, presenting vast opportunities for both premium and value-segment manufacturers.

- Latin America (LATAM): This region shows nascent growth, primarily driven by economic stabilization and a growing demand for utilitarian vehicle customization, particularly in the pick-up truck and utility vehicle segments in countries like Brazil and Mexico. The market often favors cost-effective solutions, but growing awareness of safety and quality is slowly shifting demand towards certified, higher-quality aluminum spacers.

- Middle East and Africa (MEA): Growth in MEA is largely fueled by the high-end luxury vehicle segment and the strong tradition of off-roading and dune bashing, particularly in the Gulf Cooperation Council (GCC) countries. Consumers in these regions demand extremely durable, performance-oriented products capable of withstanding high temperatures and sandy environments, creating niche demand for specialized, corrosion-resistant spacer materials.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Wheel Spacer Market.- H&R Spezialfedern GmbH & Co. KG

- Eibach Springs, Inc.

- Supreme Suspensions

- Spidertrax Off-Road

- Ichiba USA

- KSP Performance

- Motorsport Tech

- Blox Racing

- BORA Offroad

- MaxTrac Suspension

- Truxedo, Inc.

- Rough Country Suspension Systems

- Belltech Suspension

- Superlift Suspension

- Pro Comp Suspension

- ReadyLIFT Suspension Inc.

- TeraFlex Inc.

- Rancho Performance Suspension and Shocks

- Skyjacker Suspensions

- Bilstein (ThyssenKrupp AG)

Frequently Asked Questions

Analyze common user questions about the Wheel Spacer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary safety concern associated with installing wheel spacers?

The chief safety concern is improper installation or the use of low-quality, non-hub-centric spacers, which can induce excessive stress on existing wheel studs, leading to potential stud failure, wheel vibration, and ultimately, wheel detachment. Premium, hub-centric, bolt-on spacers manufactured from certified materials are recommended to mitigate these risks by distributing load correctly.

How do hub-centric spacers differ from lug-centric spacers, and why is the difference important?

Hub-centric spacers are precision-machined to perfectly match the vehicle's hub and the wheel's center bore, ensuring the wheel is centered and supported by the hub flange, bearing the vehicle's weight. Lug-centric spacers rely solely on the wheel studs to center the wheel and bear the load, which can lead to vibration, stud shear stress, and premature failure. Hub-centric designs are critical for safety and smooth operation.

Which material type is dominating the Wheel Spacer Market, and why?

Aluminum Alloy, specifically high-grade 6061-T6 and 7075-T6 billet aluminum, dominates the market due to its superior strength-to-weight ratio. Aluminum spacers reduce unsprung weight, which improves vehicle handling and suspension performance, while offering adequate durability and excellent resistance to corrosion when anodized, making them ideal for performance and aesthetic applications.

Are wheel spacers legal for use on public roads in major regions like Europe and North America?

Legality varies significantly by region. In North America (US), they are generally permitted, though regulations differ by state regarding wheel protrusion. In Europe, especially countries like Germany, strict TÜV regulations mandate that spacers must be certified and type-approved for the specific vehicle model, often limiting the maximum permissible thickness and requiring professional installation and inspection to ensure road legality.

What are the main advantages of choosing bolt-on spacers over slip-on types?

Bolt-on spacers (typically 25mm or thicker) are generally safer and preferred for structural applications because they bolt securely to the hub and contain their own set of studs, ensuring full thread engagement for the wheel's lug nuts. Slip-on spacers, being thinner, require longer existing studs or extended lug nuts, which can sometimes compromise thread engagement, making the bolt-on type superior for stability and high-stress environments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager