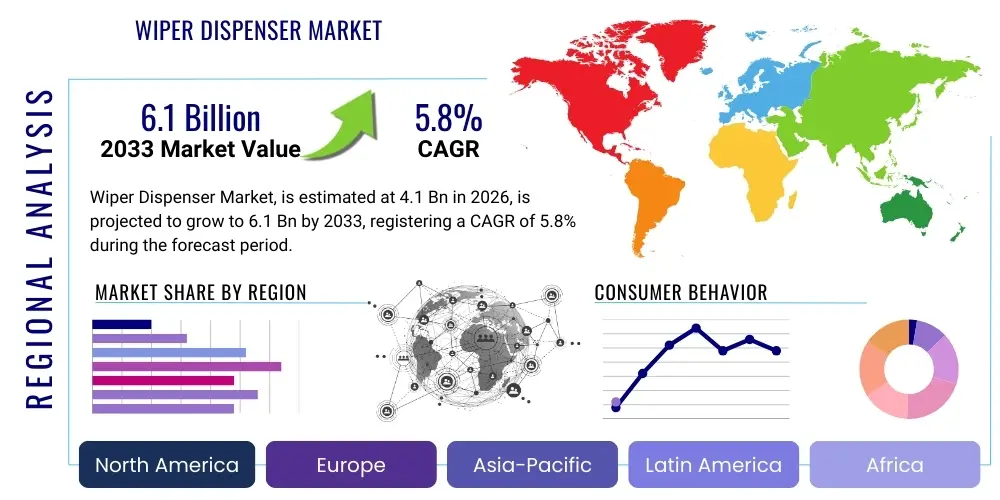

Wiper Dispenser Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442232 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Wiper Dispenser Market Size

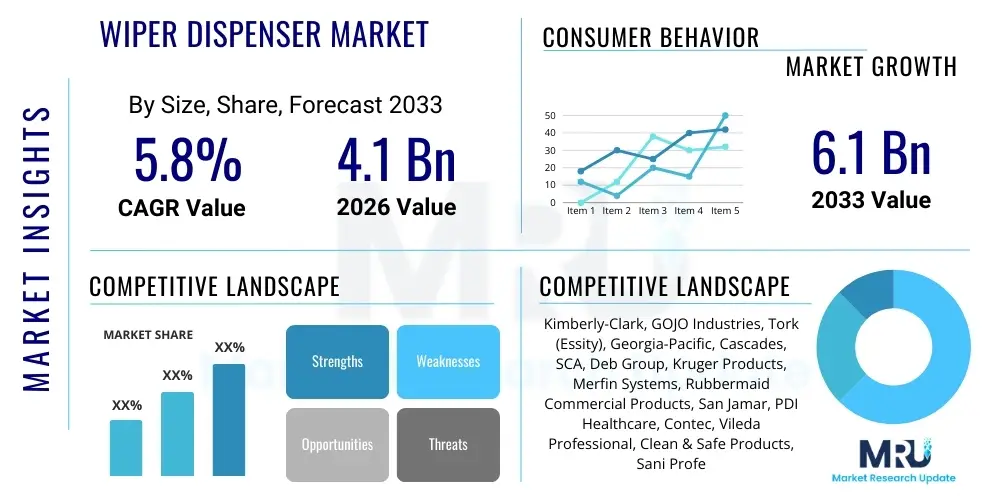

The Wiper Dispenser Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.1 Billion in 2026 and is projected to reach USD 6.1 Billion by the end of the forecast period in 2033. This consistent expansion is primarily fueled by stringent regulatory standards concerning hygiene and contamination control across critical sectors such as healthcare, food processing, and heavy-duty manufacturing. Modern wiper dispensers, designed for touchless operation and efficient material utilization, are becoming essential infrastructure in environments requiring high levels of sanitation and waste reduction.

Wiper Dispenser Market introduction

The Wiper Dispenser Market encompasses a range of devices designed to store, protect, and dispense various types of disposable and reusable wiping materials, including paper towels, non-woven wipes, and specialized industrial cloths. These dispensing systems are critical components of operational hygiene and efficiency across countless commercial, industrial, and institutional settings. Products range from basic wall-mounted mechanical units to advanced electronic, sensor-activated systems that control usage rates to minimize waste, ensuring that the integrity and saturation of the wiping material are maintained until the point of use. The primary function of these dispensers is not only accessibility but also contamination prevention, keeping unused wipers protected from airborne pathogens and surface contact.

Major applications for wiper dispensers span numerous high-growth sectors. In the healthcare industry, specialized dispensers are used for medical wipes, surface disinfectants, and patient care; the food and beverage industry utilizes them to maintain strict sanitation protocols in preparation areas; and the manufacturing sector, particularly aerospace and automotive, relies on heavy-duty industrial dispensers for handling solvents, cleaning intricate machinery, and managing spills. The widespread adoption is directly linked to the operational benefits they provide, which include enhanced user convenience, improved workplace safety by facilitating quick cleanup, and significant cost savings derived from controlled usage patterns and reduced consumption of wiping materials. Furthermore, the aesthetic and ergonomic design of modern dispensers contributes positively to facility management and perceived quality of service.

Key driving factors accelerating market expansion include the global post-pandemic emphasis on surface hygiene, which has institutionalized higher cleaning standards. The rapid growth of the global industrial sector, requiring specialized wiping solutions for oil, grease, and chemical residues, also contributes significantly. Simultaneously, innovations in dispenser technology, such as the integration of IoT for usage monitoring and low-battery alerts, enhance management efficiency, making advanced dispensing solutions an attractive investment for large corporations focused on operational excellence. The regulatory environment, particularly concerning HACCP (Hazard Analysis Critical Control Point) in food safety and OSHA standards in industrial settings, mandates the use of appropriate dispensing systems to maintain compliance, thereby sustaining demand.

Wiper Dispenser Market Executive Summary

The global Wiper Dispenser Market is exhibiting robust growth, largely driven by fundamental business trends emphasizing automation, sustainability, and heightened hygiene expectations. A significant business trend involves the shift towards subscription-based service models, where manufacturers provide dispensers free or at reduced cost alongside mandatory long-term contracts for proprietary wiper refills, ensuring recurring revenue and strong customer retention. Furthermore, the market is segmented by material type, with non-woven wipers gaining significant traction due to superior absorbency and durability in industrial contexts, contrasting with the high volume use of traditional paper products in commercial settings. Innovation focuses heavily on material science, developing biodegradable and recycled fiber-based wiping solutions that appeal to corporate sustainability goals, pushing the market toward technologically advanced, yet environmentally conscious, dispensing hardware.

Regionally, North America and Europe dominate the market, primarily due to established regulatory frameworks mandating stringent hygiene in sectors like healthcare and food processing, coupled with high awareness regarding cross-contamination risks. However, the Asia Pacific (APAC) region is projected to register the highest growth rate during the forecast period. This accelerated growth in APAC is attributable to rapid industrialization, increasing foreign direct investment in manufacturing hubs, and significant improvements in public health infrastructure and commercial real estate development in countries like China and India. These factors are creating massive new installation opportunities, particularly for standardized and high-volume dispenser models suitable for large factory settings and high-traffic public areas. Latin America and MEA continue to grow steadily, largely adopting proven technologies imported from North American and European market leaders, driven by localized needs for sanitation improvements in hospitality and localized manufacturing sectors.

Segment trends highlight the growing preference for touchless and sensor-based electronic dispensers over traditional mechanical systems. While mechanical dispensers remain cost-effective for low-traffic areas, the long-term operational cost savings, coupled with enhanced hygienic perception afforded by electronic systems, drive higher adoption rates in critical environments. By application, the industrial sector maintains the largest share, reflecting the sheer scale of specialized wiping tasks in heavy machinery maintenance, chemical handling, and electronics manufacturing. Conversely, the institutional segment, encompassing schools, government offices, and recreational facilities, represents a stable growth opportunity, focused primarily on bulk paper towel dispensing solutions. Manufacturers are adapting their product lines to offer modular and aesthetically diverse systems that can meet the dual requirements of hygiene and integration into modern commercial architectural designs.

AI Impact Analysis on Wiper Dispenser Market

Analysis of common user questions regarding the impact of Artificial Intelligence (AI) on the Wiper Dispenser Market reveals core themes centered on operational efficiency, predictive maintenance, and inventory management. Users frequently inquire about how AI can optimize refill schedules, prevent stock-outs, and analyze usage data to tailor product recommendations and optimize placement within large facilities. Key concerns revolve around the cost justification of integrating smart, AI-enabled sensors into traditionally low-cost dispensing equipment and the security protocols required for transmitting sensitive usage data across corporate networks. Expectations are high for AI to move dispensers beyond simple mechanical tools into interconnected endpoints that actively contribute to facility management analytics and sustainable resource allocation, driving a transition from reactive servicing to proactive hygiene maintenance strategies across multi-site operations.

The implementation of AI is expected to revolutionize the supply chain and maintenance protocols associated with wiper dispensers. AI algorithms, fed by usage data collected via IoT-enabled sensors embedded in smart dispensers, can accurately forecast demand variations based on time of day, day of the week, and facility occupancy patterns. This predictive capability allows facility managers and suppliers to move from fixed refill schedules to 'just-in-time' inventory replenishment, drastically reducing logistics costs, minimizing waste from expired or damaged stock, and ensuring zero instances of run-outs in critical areas such as surgical wards or food preparation zones. This shift transforms the dispenser from a passive product into an active data-generating asset essential for modern smart building management.

Beyond logistical improvements, AI is instrumental in enhancing the user experience and compliance. Advanced AI systems can analyze user interaction frequency and timing, identifying areas of low compliance or excessively high consumption, allowing managers to intervene with targeted training or equipment adjustment. For specialized industrial wipers used with chemicals or solvents, AI systems can link the dispenser usage directly to safety logs, ensuring that proper wiping materials are used for specific tasks, thereby mitigating compliance risks and ensuring worker safety. This proactive monitoring capability, enabled by machine learning on sensor data, establishes a new baseline for operational integrity and hygiene management, justifying the premium associated with 'smart' dispenser models across high-value applications.

- Predictive Inventory Management: AI algorithms forecast consumption rates based on real-time occupancy data, optimizing refill cycles and eliminating stock-outs.

- Usage Pattern Analysis: Machine learning identifies anomalies in usage, signaling potential equipment misuse, maintenance needs, or non-compliance areas.

- Automated Fault Diagnostics: Smart dispensers use AI to self-diagnose mechanical failures (e.g., jamming, low battery) and automatically dispatch maintenance tickets.

- Sustainable Resource Optimization: AI tracks material consumption per user/shift, providing data-driven insights to reduce waste and promote the use of environmentally friendly refills.

- Enhanced Hygiene Monitoring: Integration with facility management systems allows AI to correlate dispenser usage with infection control data, improving overall site hygiene compliance.

DRO & Impact Forces Of Wiper Dispenser Market

The Wiper Dispenser Market is driven by a powerful confluence of regulatory compliance, increasing global hygiene consciousness, and technological innovation. Key drivers include stringent governmental regulations in healthcare and food processing, which mandate dedicated dispensing solutions to prevent cross-contamination, particularly in developed economies. The rising industrial output globally, necessitating specialized wiping materials for complex machinery maintenance and technical cleanup, fuels the demand for durable and chemical-resistant dispensing systems. However, the market faces restraints, primarily the high initial cost associated with advanced sensor-activated and IoT-enabled dispensers, which can be prohibitive for small and medium-sized enterprises (SMEs). Furthermore, the lack of standardized refill sizes across the industry creates vendor lock-in, leading to frustration among large facility managers seeking supply chain flexibility, which acts as a minor constraint on market elasticity. The overall market trajectory, however, is significantly positive, weighted heavily by the sustained demand for enhanced sanitation solutions.

Opportunities for growth are abundant, particularly in emerging economies where public infrastructure and hygiene awareness are rapidly improving. The greatest opportunity lies in the development and proliferation of sustainable dispensing systems and recyclable/compostable wiping materials, aligning with global environmental, social, and governance (ESG) goals increasingly adopted by large corporations. Developing 'smart' dispensing solutions that integrate seamlessly into existing Building Management Systems (BMS) offers high-margin potential. Furthermore, expanding penetration into specialized industrial niches, such as microelectronics manufacturing cleanrooms or pharmaceutical laboratories, which require ultra-clean and precise dispensing of highly specialized wipes, represents untapped market potential. These opportunities allow key players to differentiate their product offerings beyond basic functionality and capture value through service and data provision.

The impact forces influencing the market are strong and predominantly positive. The increasing prevalence of infectious disease outbreaks and heightened global awareness regarding hygiene have created an irreversible upward pressure on sanitation standards, making robust dispensing solutions non-negotiable across public and private sectors. Economic factors, such as rising labor costs, force facility managers to seek efficient, waste-reducing dispensing technologies to lower operational expenditure, thereby favoring electronic, consumption-controlled models. The technology impact is continuously reshaping the landscape, as advancements in sensor technology and battery life make touchless dispensing more reliable and cost-effective. These forces collectively ensure sustained demand, transforming the wiper dispenser from a simple accessory into a critical piece of hygiene infrastructure essential for operational integrity and public safety in the modern world.

- Drivers:

- Increasing global focus on cross-contamination prevention and infection control protocols.

- Rapid expansion and industrial growth requiring specialized wiping solutions (e.g., solvents, heavy grease).

- Regulatory mandates (HACCP, OSHA, healthcare standards) enforcing controlled dispensing practices.

- Demand for usage efficiency and cost reduction via controlled dispensing mechanisms.

- Restraints:

- High upfront investment required for sophisticated electronic and IoT-enabled dispenser units.

- Proprietary refill systems leading to vendor lock-in and supply chain inflexibility.

- Environmental concerns regarding the disposal of plastic dispenser components and non-recyclable wiping materials.

- Opportunities:

- Development of fully biodegradable and sustainable wiping materials and dispenser hardware.

- Integration of smart technology (IoT, AI) for predictive maintenance and inventory optimization.

- Untapped market potential in emerging economies and expansion into highly specialized cleanroom applications.

- Impact Forces:

- Intensified public health awareness elevating hygiene standards permanently.

- Technological advancements reducing costs and increasing reliability of touchless dispensing.

- Economic pressure driving adoption of consumption control features to minimize operational waste.

Segmentation Analysis

The Wiper Dispenser Market is segmented comprehensively based on several critical factors, including the type of mechanism used, the material of the wiper being dispensed, the primary application environment, and the geographical location of deployment. This segmentation is essential for understanding market dynamics, as the requirements for a high-volume mechanical dispenser in a school restroom differ significantly from those for a specialized, chemical-resistant, touchless unit used in an aerospace manufacturing cleanroom. Key differentiations include the mechanism segment (Manual vs. Automatic/Sensor-based), which reflects the ongoing shift toward hygienic touchless solutions, particularly post-2020. Furthermore, the material segment (Paper vs. Non-woven vs. Specialty Cloth) dictates market value, as specialized non-woven and saturated wipes command higher prices and necessitate more robust dispensing systems to maintain saturation and integrity.

The market is predominantly structured around end-user segmentation, where industrial, healthcare, and commercial sectors represent the largest consumer bases. The industrial segment, encompassing heavy manufacturing, automotive, and oil & gas, demands high durability, solvent resistance, and bulk capacity, often favoring large wall-mounted or floor-standing dispensers for rolled or folded non-woven wipers. Conversely, the healthcare segment requires the highest hygiene standards, driving the adoption of touchless, tamper-proof dispensers for disinfectant wipes and standard paper products used in clinical and patient care areas. The commercial sector, including hospitality, retail, and office buildings, focuses on aesthetics, ease of use, and moderately priced, often proprietary, dispensing systems to manage high traffic and maintain brand image.

Sub-segmentation by mounting type further details the market landscape, distinguishing between wall-mounted, free-standing (floor), and portable dispensing units. Wall-mounted units are the standard for maximizing space and providing fixed access in commercial and industrial settings. Floor-standing dispensers, often large capacity units, are critical in manufacturing workshops or large public spaces where permanent wall installation is impractical. The growing demand for portability, particularly in mobile service industries, remote maintenance, and temporary worksites, is boosting the segment for small, mobile dispenser units designed for utility carts or temporary stands. This detailed segmentation allows manufacturers to target specific operational pain points with precision-engineered dispensing solutions tailored to both functional requirements and budgetary constraints.

- By Mechanism Type:

- Manual/Mechanical Dispenser

- Automatic/Sensor-Based (Touchless) Dispenser

- By Wiper Material:

- Paper Wipers (Rolls, Folded)

- Non-Woven Wipers (Spunlace, Meltblown)

- Specialty Wipes (Saturated, Chemical Resistant, Cleanroom Grade)

- By Capacity:

- High Capacity (Bulk Industrial Rolls)

- Standard Capacity (Commercial Folded)

- Low Capacity (Portable/Small Area)

- By Mounting Type:

- Wall-Mounted Dispenser

- Floor/Stand-Mounted Dispenser

- Portable/Benchtop Dispenser

- By End-Use Industry:

- Industrial & Manufacturing (Automotive, Aerospace, Electronics)

- Healthcare & Pharmaceutical (Hospitals, Clinics, Laboratories)

- Commercial & Institutional (Offices, Retail, Hospitality, Education)

- Food & Beverage Processing

Value Chain Analysis For Wiper Dispenser Market

The value chain for the Wiper Dispenser Market is intricate, spanning from raw material procurement for both the hardware and the consumable wipers, through manufacturing, distribution, and ultimately to the end-user deployment. The upstream segment involves the sourcing of critical materials: plastics (ABS, polypropylene) and metals (stainless steel) for the dispenser housing, and pulp, non-woven fibers (rayon, polyester), and chemical saturants for the wiper refills. Raw material quality is paramount, particularly for specialty and medical dispensers which must meet stringent regulatory standards for durability and chemical resistance. Manufacturing of the hardware is often outsourced to specialized plastic injection molders, while the key market players maintain control over design, quality assurance, and proprietary dispensing mechanisms, which are the main sources of intellectual property and competitive advantage.

The downstream component is heavily focused on the complex interplay between the dispenser hardware and the continuous, high-volume supply of consumable wipers. Since many leading manufacturers utilize proprietary locking mechanisms and refill sizes (vendor lock-in), the distribution of the consumables dictates the market flow. The distribution channel is bifurcated into direct sales to large industrial clients or major healthcare networks, and indirect sales through extensive networks of specialized janitorial supply distributors, facility management wholesalers, and e-commerce platforms. Distributors play a crucial role by providing local inventory, maintenance services, and integrated hygiene solutions, bundling the dispenser with other cleaning chemicals and services, effectively acting as the primary point of contact for most small to medium commercial customers. The efficiency of this downstream logistics network is vital for ensuring uninterrupted supply and maintaining customer satisfaction.

Direct distribution often targets major institutional contracts, allowing key players to install large quantities of dispensers under long-term service agreements, providing reliable, high-margin recurring revenue. Conversely, indirect channels are essential for penetrating the highly fragmented SME market and accessing regional industrial clusters. E-commerce platforms are increasingly gaining importance, especially for standard, non-proprietary dispenser models and generic wiper refills, driving price transparency and competition. Crucially, the final stage in the value chain involves installation, maintenance, and data management (for smart dispensers), services that often require specialized technical teams, ensuring the long-term functioning and effective use of the dispensed product at the point of application. Optimization efforts are focused on integrating supply chain data from smart dispensers back into the production and logistics planning stages, closing the loop and enhancing overall operational efficiency.

Wiper Dispenser Market Potential Customers

The potential customer base for the Wiper Dispenser Market is extremely diverse, spanning any facility or organization where surface cleaning, infection control, and specialized technical wiping are operational necessities. The primary end-users fall into three major categories: Healthcare, Industrial Manufacturing, and Commercial/Institutional sectors. Healthcare customers, including hospitals, outpatient clinics, dental offices, and long-term care facilities, are perhaps the most critical segment, requiring medical-grade, often saturated (disinfectant) wipes dispensed from touchless, highly reliable systems to adhere to rigorous sanitation protocols and prevent Healthcare-Associated Infections (HAIs). These buyers prioritize reliability, ease of disinfection, and compliance documentation, making them high-value, long-term contractual customers.

Industrial manufacturers constitute the largest volume consumers, particularly in the automotive, aerospace, oil and gas, and heavy machinery maintenance sectors. These customers require robust, heavy-duty dispensing systems designed to handle specialized non-woven wipers capable of absorbing solvents, oil, and grease without tearing. Their purchasing decisions are primarily influenced by durability, bulk capacity, resistance to harsh industrial environments, and the ability to minimize material waste during high-frequency use. Within this segment, specialized customers like electronics manufacturers also require ultra-cleanroom-compliant dispensing solutions for precision wiping tasks, driving demand for technologically advanced, non-linting products and dispensers.

The Commercial and Institutional segment represents the broadest customer base, including office buildings, retail chains, hospitality venues (hotels, restaurants), government buildings, and educational facilities. These buyers focus on balancing cost-effectiveness with aesthetic appeal and user experience. They generally favor standard paper towel and facial tissue dispensers, increasingly transitioning to electronic, automatic models to enhance hygiene perception among staff and guests. The food service industry (F&B) is a key subset, strictly requiring HACCP-compliant systems for both hand hygiene and surface preparation wipes, prioritizing ease of cleaning and materials that prevent cross-contamination in preparation areas. Effective marketing and sales strategies must be tailored to these distinct needs, recognizing the procurement cycles and regulatory pressures unique to each segment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.1 Billion |

| Market Forecast in 2033 | USD 6.1 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Kimberly-Clark, GOJO Industries, Tork (Essity), Georgia-Pacific, Cascades, SCA, Deb Group, Kruger Products, Merfin Systems, Rubbermaid Commercial Products, San Jamar, PDI Healthcare, Contec, Vileda Professional, Clean & Safe Products, Sani Professional, Dynarex, Hospeco, U.S. Wipers, Wausau Paper |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Wiper Dispenser Market Key Technology Landscape

The technology landscape of the Wiper Dispenser Market is rapidly evolving beyond simple mechanical delivery systems, driven primarily by the need for better hygiene control, usage efficiency, and data-driven facility management. The most significant technological shift involves the integration of Internet of Things (IoT) connectivity into dispenser units, transforming them into 'smart dispensers.' These devices utilize low-power sensors (e.g., infrared, ultrasonic, or capacitive sensors for touchless activation and usage monitoring) and wireless communication modules (Wi-Fi, Bluetooth Low Energy, or LoRaWAN) to report real-time status, including remaining material levels, battery life, and dispense frequency. This data is aggregated in cloud platforms, enabling predictive analytics for optimal maintenance scheduling and supply chain logistics, drastically improving efficiency in large, multi-site operations.

Another crucial technological advancement is focused on enhancing the mechanics of dispensing itself, particularly for specialized industrial and medical wipes. Innovations here involve developing anti-jamming mechanisms and single-sheet dispensing systems that prevent material waste and ensure the integrity of pre-saturated or delicate non-woven materials. Furthermore, there is significant research and development into material science for the dispenser housing, focusing on the use of antimicrobial plastics (often infused with silver ions) that actively inhibit bacterial growth on the dispenser surface. This directly addresses hygiene concerns in sensitive environments like hospitals and food processing plants, where the dispenser itself could otherwise become a source of secondary contamination.

The push for sustainability is also driving technological innovation in refill materials and packaging. Manufacturers are investing heavily in technologies that allow for the safe and effective use of post-consumer recycled plastics in dispenser hardware and the creation of highly absorbent, yet biodegradable or compostable, wiper fibers. This includes specialized packaging technology for wipes, ensuring that volatile chemical saturants (like disinfectants) maintain their efficacy over long shelf lives, coupled with innovative core-less or compressed refill formats that reduce packaging waste and logistical weight. The convergence of digital sensing capabilities, antimicrobial materials, and sustainable supply chain optimization defines the current state of the art in the Wiper Dispenser Market, positioning the products as high-tech components of modern facility infrastructure.

Regional Highlights

Regional dynamics within the Wiper Dispenser Market are characterized by maturity and high technological adoption in developed regions, contrasted with rapid infrastructural growth and increasing hygiene awareness in emerging markets. North America, particularly the United States, commands the largest market share, driven by strict occupational safety and health regulations (OSHA), advanced healthcare spending, and a high rate of adoption of smart, IoT-enabled dispensing solutions. The market here is highly competitive, focusing heavily on proprietary systems, sustainability reporting, and comprehensive service contracts, making the operational expenditure model highly attractive to large corporate clients.

Europe represents the second-largest market, exhibiting a strong emphasis on ecological responsibility and high-quality, durable dispensing hardware. European demand is bolstered by stringent regulations like the EU Biocidal Products Regulation and rigorous food safety standards, which favor specialized non-woven and saturated wipe dispensing systems. Countries such as Germany, the UK, and France are leaders in implementing sustainable practices, driving the adoption of dispensers made from recycled materials and requiring certified biodegradable wiper refills, shaping global trends towards green hygiene solutions.

The Asia Pacific (APAC) region is projected to be the fastest-growing market globally. This exponential growth is fueled by massive urbanization, the rapid expansion of industrial manufacturing bases (especially in electronics and automotive sectors in China, India, and Southeast Asia), and significant government investment in public health infrastructure development. While APAC initially favors cost-effective, high-capacity mechanical dispensers, the rising middle class and increasing penetration of multinational corporations are quickly accelerating the demand for touchless, premium hygiene solutions. This region presents substantial opportunities for market players willing to localize production and establish robust distribution networks capable of handling rapid volume scaling.

- North America (NA): Dominant market share; highest adoption of IoT-enabled smart dispensers; stringent healthcare and industrial regulatory environment.

- Europe (EU): Strong focus on sustainability and eco-certified products; high demand in food processing and pharmaceutical sectors; established market maturity.

- Asia Pacific (APAC): Highest CAGR forecast; rapid industrialization and infrastructural development; growing hygiene awareness driving switch from manual to automatic systems.

- Latin America (LA): Moderate growth driven by tourism and expanding localized manufacturing; gradual adoption of international hygiene standards.

- Middle East & Africa (MEA): Growth concentrated in commercial and hospitality sectors (GCC countries); increasing government initiatives to improve public health and sanitation.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Wiper Dispenser Market.- Kimberly-Clark Corporation

- GOJO Industries, Inc.

- Tork (Essity AB)

- Georgia-Pacific LLC

- Cascades Inc.

- SCA Hygiene Products AB

- Deb Group (a part of SC Johnson Professional)

- Kruger Products L.P.

- Merfin Systems

- Rubbermaid Commercial Products, Inc.

- San Jamar

- PDI Healthcare, Inc.

- Contec, Inc.

- Vileda Professional

- Clean & Safe Products

- Sani Professional

- Dynarex Corporation

- Hospeco Brands Group

- U.S. Wipers

- Wausau Paper (now part of SCA)

Frequently Asked Questions

Analyze common user questions about the Wiper Dispenser market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is driving the shift from manual to automatic wiper dispensers?

The primary driver is the post-pandemic emphasis on reducing contact surface transmission of pathogens, increasing infection control compliance, and minimizing operational waste. Automatic dispensers ensure touchless usage and control the sheet length dispensed, reducing overall material consumption and enhancing hygiene perception.

How is sustainability impacting the Wiper Dispenser Market?

Sustainability is a major influence, forcing manufacturers to innovate using recycled content for dispenser hardware and prioritizing the development of biodegradable, compostable, or sustainably sourced fiber wipes. Consumers increasingly prefer brands that offer verifiable waste reduction and environmental certifications.

Which end-user segment holds the largest market share for wiper dispensers?

The Industrial and Manufacturing sector typically holds the largest volume share due to the sheer scale and frequency of specialized wiping tasks involving solvents, grease, and chemicals. However, the Healthcare sector drives the highest demand for premium, specialized, and touchless dispensing technologies necessary for critical infection control.

What role does IoT technology play in modern wiper dispenser systems?

IoT integration transforms dispensers into 'smart devices' that use sensors to monitor real-time usage, inventory levels, and battery status. This data feeds into facility management systems, enabling predictive maintenance, automated refill orders (preventing stock-outs), and optimized staffing schedules, leading to significant operational savings.

What are the main regional growth opportunities for wiper dispenser manufacturers?

The Asia Pacific (APAC) region offers the highest growth opportunities, spurred by rapid industrialization, massive commercial infrastructure expansion, and improving hygiene standards across countries like China and India. Manufacturers are focusing on localized product offerings and expanding distribution networks in these high-growth urban centers.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager