Wire Brushes Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441544 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Wire Brushes Market Size

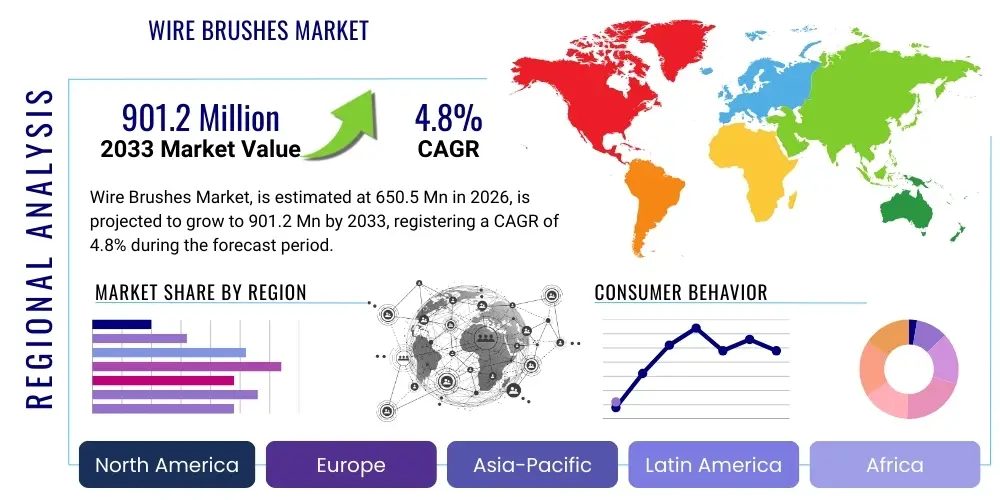

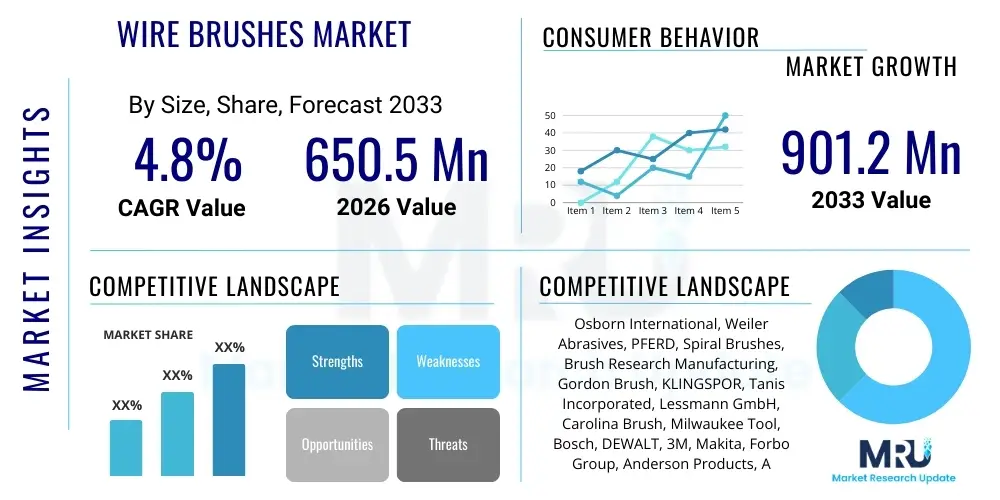

The Wire Brushes Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 650.5 Million in 2026 and is projected to reach USD 901.2 Million by the end of the forecast period in 2033.

Wire Brushes Market introduction

The Wire Brushes Market encompasses a diverse range of abrasive tools crucial for industrial cleaning, surface preparation, deburring, polishing, and welding applications across numerous sectors. Wire brushes, fundamentally designed with bristles made of materials such as steel, stainless steel, brass, nylon, or abrasive nylon, are categorized based on their application mechanism—manual, mounted on power tools (like angle grinders or drills), or integrated into automated machinery. Their core function is the mechanical removal of material, including rust, paint, scale, slag, and general contaminants, providing a superior finish and preparing surfaces for subsequent treatments like coating or bonding. The enduring demand for these tools is driven by the necessity for high-quality surface integrity in capital-intensive industries.

Major applications for wire brushes span the entirety of the manufacturing and maintenance lifecycle, prominently featuring in the automotive sector for engine part cleaning and bodywork preparation, in construction for masonry and structural steel maintenance, and within general fabrication shops for weld cleaning and component finishing. The benefits associated with utilizing wire brushes include cost-effectiveness, versatility across different substrates (metal, wood, concrete), and the ability to achieve various levels of aggressiveness in surface treatment depending on the wire material and diameter chosen. Furthermore, specific applications, such as internal pipe cleaning or complex geometry deburring, rely almost exclusively on specialized wire brush configurations due to their mechanical adaptability.

Driving factors propelling market expansion are fundamentally linked to global industrial output, increasing infrastructure spending, and the rising emphasis on preventative maintenance programs across mature and emerging economies. As manufacturing processes become more precise, the demand for highly specialized, high-performance wire brushes—particularly those utilizing heat-treated or coated wires—is intensifying. The aftermarket segment, driven by repair and maintenance (MRO) activities, constitutes a stable base for market growth, ensuring consistent demand regardless of short-term volatility in new capital expenditure projects. Innovations in brush design, focusing on ergonomics for manual tools and enhanced durability for automated applications, further solidify their market position against chemical alternatives.

- Product Description: Mechanical abrasive tools featuring clustered metal or synthetic filaments used for surface conditioning, cleaning, and material removal.

- Major Applications: Weld cleaning, rust and scale removal, surface deburring, paint stripping, concrete texture finishing, and industrial polishing.

- Key Benefits: Non-chemical material removal, adaptability to various power tools, high durability, and ability to process high-temperature surfaces.

- Driving Factors: Growth in automotive and aerospace manufacturing, increasing MRO activities, stringent quality standards for surface preparation, and global infrastructure development.

Wire Brushes Market Executive Summary

The Wire Brushes Market is undergoing a transformation characterized by dual growth pathways: robust demand in traditional industrial sectors (like fabrication and construction) and accelerated uptake of specialized, automated brush systems in high-tech manufacturing (such as aerospace and precision engineering). Current business trends indicate a critical shift towards sustainability, pushing manufacturers to develop wire brushes with longer operational lifespans and reduced material waste. Furthermore, supply chain resilience has become a major strategic priority following global disruptions, leading companies to prioritize domestic or near-shored production capabilities, particularly in North America and Europe. Investment in automation-compatible brush heads and robotic integration tooling is a core element of competitive advantage, reflecting the wider trend of Industry 4.0 adoption.

Regionally, Asia Pacific (APAC) remains the dominant engine of growth, fueled by rapid industrialization, massive infrastructure investments, and the relocation of global manufacturing bases, particularly in countries like China, India, and Southeast Asian nations. North America and Europe, while growing at a steadier pace, are characterized by a strong focus on high-performance materials (e.g., stainless steel and specialized abrasive nylon) driven by stringent regulatory standards in aerospace and medical device manufacturing. The Middle East and Africa (MEA) region is exhibiting potential growth, primarily driven by expanding oil and gas infrastructure maintenance requirements and diversification efforts in non-oil industrial sectors, necessitating reliable surface preparation tools.

Analysis of market segmentation reveals that the professional/industrial segment, utilizing heavy-duty mounted brushes (such as wheel and cup brushes), generates the largest revenue share due to high frequency of use and the need for premium quality tools. However, the DIY/Household segment is experiencing rapid volume growth, supported by increased consumer interest in home improvement and lower-cost, readily available brush kits distributed through e-commerce platforms. In terms of fill material, stainless steel wire brushes are witnessing above-average growth rates, attributed to their indispensable role in environments requiring corrosion resistance and contamination control, particularly within the food processing and pharmaceutical industries.

AI Impact Analysis on Wire Brushes Market

Common user questions regarding AI's impact on the Wire Brushes Market typically revolve around whether automation, driven by AI and machine learning (ML), will render traditional manual brushes obsolete, how AI optimizes manufacturing processes, and if AI can select the optimal brush for a specific application. Users are keenly interested in the integration of predictive maintenance systems that utilize AI to monitor brush wear and tear, thereby minimizing unplanned downtime. The underlying expectation is that AI will enhance efficiency and precision, rather than displacing the physical tool itself. Key concerns focus on the initial investment costs associated with adopting robotic systems and the necessity for specialized training to operate and maintain AI-driven surface finishing cells.

The most significant current impact of AI is not in the design of the brush itself, but in the optimization of its usage within robotic and CNC environments. AI algorithms are being deployed to analyze sensor data from automated finishing cells, enabling dynamic adjustment of brush pressure, speed, and trajectory based on real-time surface feedback. This precision allows for consistent quality control, crucial in industries requiring extremely low tolerances, such as aerospace turbine manufacturing. Furthermore, ML models are enhancing inventory management and predictive failure analysis by forecasting the precise lifecycle of brushes based on usage patterns and material stress, transforming the MRO supply chain from reactive to proactive, ensuring optimal stock levels and timely replacements.

- AI-driven Robotic Integration: Enables highly precise, consistent surface finishing by controlling brush parameters (speed, force, angle).

- Predictive Maintenance: ML algorithms analyze vibration and usage data to forecast brush failure, reducing unexpected downtime in industrial operations.

- Quality Control Automation: Vision systems augmented by AI verify surface preparation quality post-brushing, ensuring adherence to strict industrial specifications.

- Design Optimization: Computational models use AI to simulate wire stress and wear patterns, leading to the development of more durable and efficient brush filament geometries.

DRO & Impact Forces Of Wire Brushes Market

The Wire Brushes Market is shaped by a balance of persistent drivers and structural restraints, yielding specific opportunities that define strategic direction. Primary drivers include sustained global growth in the construction and infrastructure sectors, which rely heavily on durable tools for site preparation and maintenance, coupled with the mandatory requirement for highly specific surface treatments in regulated industries such as aerospace and defense. Restraints often center on intense price competition, particularly from low-cost manufacturers in Asia, which pressures margins for established players focusing on high-quality specialized brushes. Furthermore, the substitution threat from advanced chemical cleaning solutions or laser ablation technologies presents a long-term challenge, although these alternatives often lack the versatility and mechanical efficacy of wire brushes in heavy-duty applications.

Opportunities for expansion are evident through geographic market penetration into emerging industrial hubs, particularly in Southeast Asia and Latin America, where industrial output is escalating. Product innovation presents a major opportunity, focusing on developing brushes made from exotic or specialized abrasive materials (e.g., silicon carbide filaments or ceramic-coated wires) designed for new composite materials and hardened alloys. The shift toward specialized, application-specific brushes for robotic arms offers high-margin growth, moving away from commoditized standard brushes. Furthermore, focusing on the ergonomics and safety of manual brushes can appeal to the DIY and professional trades markets by reducing operator fatigue and increasing efficiency.

The impact forces within this market are predominantly technological and economic. Economic forces—such as fluctuating steel and brass commodity prices—directly influence production costs and pricing strategies. Technological forces, specifically the rise of automated manufacturing (Industry 4.0), dictate that future wire brush products must be robust, balanced, and compatible with high-speed, high-precision robotics, moving the market away from purely manual tool design. Social impact forces include increasing worker safety regulations, prompting demand for brushes that minimize particulate emission or vibration. These intersecting forces ensure that while the core product remains simple, the market dynamics require continuous adaptation regarding material science, manufacturing automation, and supply chain management.

Segmentation Analysis

The Wire Brushes Market segmentation provides a crucial framework for understanding the diverse applications and end-user needs that define market demand. Segmentation is typically categorized based on Product Type, identifying the mechanical configuration of the brush; Fill Material, specifying the abrasive or cleaning medium; End-Use Industry, detailing the primary sectors driving consumption; and Distribution Channel, outlining the route to market. The dominance of the market stems from the necessity to cater to highly distinct operational requirements, where a specialized brush type or material is indispensable for achieving the required surface finish or cleanliness standard, necessitating detailed product specialization by manufacturers.

The product type segment, encompassing wheel, cup, end, and strip brushes, is highly reflective of the machinery compatibility and specific task requirements. Wheel brushes are dominant due to their versatile use on bench grinders and portable angle grinders for general surface cleaning. Conversely, end brushes are critical for accessing confined spaces and internal geometries, often utilized in automotive engine block maintenance. The Fill Material segment is strategically important, as the choice between high-tensile carbon steel, non-corrosive stainless steel, softer brass, or non-marring synthetic nylon dictates the suitability for specific substrates and the level of abrasive aggression desired.

Analyzing the End-Use Industry segment highlights key revenue streams, with the Manufacturing and Automotive sectors representing the largest consumers due to continuous processes requiring preparation, deburring, and welding cleanup. The Construction and Infrastructure sectors provide cyclical demand tied to maintenance projects. Furthermore, the segmentation by Distribution Channel emphasizes the split between traditional industrial supply houses (Offline) serving professional users with bulk orders and specialized consultation, and the rapid expansion of e-commerce platforms (Online), which cater efficiently to the high-volume, low-margin DIY segment and smaller professional shops seeking quick procurement.

- By Product Type:

- Wheel Brushes

- Cup Brushes

- End Brushes

- Strip Brushes

- Hand Brushes

- By Fill Material:

- Carbon Steel

- Stainless Steel

- Brass

- Bronze

- Nylon (Abrasive and Non-Abrasive)

- By End-Use Industry:

- Automotive and Transportation

- Aerospace and Defense

- Construction and Infrastructure

- Manufacturing and Fabrication

- Marine

- DIY and Household

- By Distribution Channel:

- Offline (Industrial Distributors, Retail Stores)

- Online (E-commerce Platforms, Company Websites)

Value Chain Analysis For Wire Brushes Market

The value chain for the Wire Brushes Market begins with upstream activities, primarily sourcing and processing raw materials. This includes procuring high-quality wire stock (steel, stainless steel, brass) and synthetic filaments (nylon, polypropylene). Material quality is paramount, as the performance and longevity of the brush are directly dependent on the tensile strength and metallurgical properties of the wire used. Upstream suppliers specializing in drawing and heat-treating specialized wire are critical partners. Fluctuations in global commodity prices for steel and non-ferrous metals introduce significant variability at this stage, impacting manufacturer margins and final pricing. Efficiency in material purchasing and inventory management is a core competitive factor for brush manufacturers.

The core manufacturing process involves precision machinery for forming, crimping, and securely mounting the filaments into various brush bases (cups, wheels, strips). Companies focus heavily on manufacturing efficiency and quality control, ensuring optimal balance for high-speed operation, which is essential for safety and performance, especially in power tool applications. Downstream analysis focuses on effective distribution and market access. The distribution channels are bifurcated: Direct sales are often utilized for large industrial clients and custom automation solutions, allowing manufacturers to provide specialized technical consultation. Indirect sales, which utilize robust networks of industrial supply distributors, hardware wholesalers, and e-commerce platforms, manage the high-volume flow of standardized products to a broad customer base.

The distribution network is complex, heavily relying on industrial distributors (Offline) who offer technical support and maintain local inventory for MRO clients, ensuring rapid fulfillment. The rise of e-commerce (Online) has streamlined the purchasing process for smaller workshops and DIY customers, increasing price transparency but also intensifying competition. Success in the downstream market hinges on strong relationships with established distributors and effective utilization of digital channels, ensuring product availability and providing detailed product specifications to aid in selection. The effectiveness of the value chain is measured by the ability to move specialized, quality products from raw material input to the precise point of industrial application efficiently.

Wire Brushes Market Potential Customers

The potential customer base for wire brushes is extraordinarily broad, encompassing nearly every industry that involves metal fabrication, surface treatment, or structural maintenance. The primary end-users are large-scale manufacturing operations, particularly within the automotive sector, which uses specialized brushes for engine component cleaning, gasket surface preparation, and pre-welding treatment of body panels. Aerospace and Defense companies represent high-value customers, requiring extremely consistent, contamination-free brushes (often stainless steel or brass) for critical processes like turbine blade polishing and structural integrity preparation, where quality specifications are non-negotiable and safety-critical.

A second major segment consists of the Construction and Infrastructure industries. Contractors and maintenance teams utilize heavy-duty wire brushes for cleaning concrete forms, removing rust and old coatings from structural steel elements (bridges, buildings), and preparing surfaces for anti-corrosion applications. Shipyards and the Marine industry constitute another specialized user group, demanding resilient brushes capable of handling harsh, corrosive environments for hull preparation and scale removal. These industrial buyers typically purchase in bulk through specialized industrial distributors and prioritize product durability, performance consistency, and compatibility with heavy-duty pneumatic or electric tools.

The final, rapidly expanding customer segment is the DIY and Small Trades sector. These end-users, including plumbers, electricians, home renovators, and small welding shops, require general-purpose hand brushes and smaller mounted brushes compatible with standard household power tools. This segment is characterized by high price sensitivity and relies heavily on accessibility through retail hardware stores and major online marketplaces. Targeting this segment requires robust packaging, clear application guidance, and competitive pricing, contrasting with the technical sales approach necessary for large industrial clients.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650.5 Million |

| Market Forecast in 2033 | USD 901.2 Million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Osborn International, Weiler Abrasives, PFERD, Spiral Brushes, Brush Research Manufacturing, Gordon Brush, KLINGSPOR, Tanis Incorporated, Lessmann GmbH, Carolina Brush, Milwaukee Tool, Bosch, DEWALT, 3M, Makita, Forbo Group, Anderson Products, Apex Tool Group, Norton Abrasives, PPG Industries |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Wire Brushes Market Key Technology Landscape

The technology landscape for the Wire Brushes Market is centered less on radical invention and more on sophisticated material science, enhanced manufacturing precision, and integration capabilities for automated systems. A crucial technological focus is on improving wire consistency and durability through advanced heat treatment processes and specialized coatings. Manufacturers are increasingly utilizing high-tensile strength carbon and stainless steel wires that resist premature breaking and maintain filament aggressiveness for longer operational periods, directly addressing end-user demands for increased tool lifespan and reduced replacement frequency. Furthermore, the development of abrasive filaments, where nylon is embedded with silicon carbide or aluminum oxide grit, provides controlled abrasive action for sensitive materials like aluminum and composites without the risk of wire breakage contamination, broadening the application scope.

Another significant technological advancement lies in the manufacturing methods themselves, specifically the dynamic balancing of mounted brushes (cup and wheel types). As industrial power tools and robotic systems operate at increasingly high rotational speeds (RPMs), any imbalance in the brush assembly can lead to excessive vibration, tool chatter, rapid wear, and safety hazards. Precision automated tufting and crimping techniques, coupled with computerized balancing during the production phase, ensure that brushes maintain stability even under extreme operating conditions. This technological requirement is essential for penetrating the high-end aerospace and automotive manufacturing segments that demand superior consistency and finishing quality.

Integration technology represents the third pillar of innovation, focusing on seamless compatibility with industrial automation and robotic arms. This involves designing brushes with standardized mounting interfaces and specific geometry optimized for robotic handling, ensuring minimal setup time and maximum repeatability. Furthermore, the utilization of sophisticated manufacturing technologies allows for the creation of brushes with varying densities and trim lengths within a single tool (Zonal Brushing), enabling complex surface preparation tasks in a single pass. This focus on system integration—from the filament material to the robotic interface—is driving premium pricing and competitive differentiation in the advanced industrial segment.

Regional Highlights

The Asia Pacific (APAC) region currently dominates the Wire Brushes Market, driven primarily by robust manufacturing expansion, significant government investments in infrastructure development, and the concentration of major automotive production hubs. Countries like China, India, Japan, and South Korea are heavy consumers due to continuous high-volume production activities across fabrication, construction, and electronics sectors. The APAC market is characterized by strong demand for both high-performance professional brushes and cost-effective standard wire brushes, reflecting the diverse scale of industrial operations present in the region. The sheer scale of MRO requirements across rapidly expanding industrial zones ensures APAC's leadership position in consumption volumes and market growth trajectory.

North America and Europe represent mature markets defined by a high propensity for adopting high-quality, specialized products and an intense focus on automation and safety standards. Growth in these regions is stable and driven by technology-intensive industries, notably aerospace, medical devices, and precision engineering, where stainless steel, non-contaminating, and abrasive nylon brushes are preferred. Manufacturers in North America and Europe typically emphasize product innovation related to ergonomics (for manual tools), durability, and compliance with stringent environmental and worker safety regulations. The aftermarket MRO segment in these regions is highly stable, supported by continuous maintenance requirements for aging but complex industrial infrastructure.

Latin America (LATAM) and the Middle East and Africa (MEA) are emerging regions exhibiting considerable potential. LATAM's growth is tied to resurgent construction activities and automotive manufacturing investments in countries like Mexico and Brazil. The MEA region's demand is largely dictated by the ongoing maintenance and expansion of the oil, gas, and petrochemical sectors, which require robust surface preparation tools for pipeline integrity and plant safety. Economic diversification efforts in the Gulf Cooperation Council (GCC) countries, focusing on non-oil manufacturing and tourism infrastructure, are creating new, albeit smaller, pockets of specialized demand for industrial abrasive tools, including high-specification wire brushes.

- Asia Pacific (APAC): Market leader fueled by massive manufacturing output, rapid infrastructure growth, and high demand in automotive and construction sectors. Key markets include China and India.

- North America: Strong demand for high-performance, precision brushes driven by aerospace, defense, and stringent MRO standards. Focus on automated application compatibility.

- Europe: Stable market characterized by high regulatory standards, strong focus on specialty materials (stainless steel, specialized nylon), and efficient distribution channels serving highly developed industrial bases (Germany, UK).

- Latin America (LATAM): Growth driven by commodity processing, localized manufacturing, and infrastructure projects, necessitating general-purpose and heavy-duty wire brushes.

- Middle East and Africa (MEA): Demand concentrated in oil, gas, and petrochemical maintenance, along with emerging demand from new industrial diversification and construction projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Wire Brushes Market.- Osborn International

- Weiler Abrasives

- PFERD

- Spiral Brushes

- Brush Research Manufacturing

- Gordon Brush

- KLINGSPOR

- Tanis Incorporated

- Lessmann GmbH

- Carolina Brush

- Milwaukee Tool

- Bosch

- DEWALT

- 3M

- Makita

- Forbo Group

- Anderson Products

- Apex Tool Group

- Norton Abrasives

- PPG Industries

Frequently Asked Questions

Analyze common user questions about the Wire Brushes market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the key drivers of demand in the Wire Brushes Market?

The primary drivers are escalating global industrial maintenance, repair, and overhaul (MRO) activities, coupled with significant infrastructure and construction spending globally. The stringent surface preparation requirements in high-value manufacturing sectors like aerospace and automotive also fuel specialized demand.

How does the choice of fill material impact brush performance?

The fill material critically determines the brush's aggressiveness and suitability. Carbon steel offers maximum abrasion for rust and scale removal; stainless steel is required for non-contaminating finishes (e.g., food/medical); and nylon or brass are used for gentler cleaning or polishing on softer materials.

Which segment holds the largest market share by product type?

Wheel Brushes typically hold the largest market share by product type. They are highly versatile, easily adaptable to various bench and angle grinders, and are used across nearly all industrial and DIY applications for general surface preparation and weld cleaning.

Is the Wire Brushes Market affected by advancements in automation and robotics?

Yes, automation significantly impacts the market by increasing demand for highly durable, dynamically balanced, and standardized mounted brushes specifically designed for integration with robotic arms. This shift emphasizes precision and consistency over manual dexterity.

What is the competitive strategy for manufacturers in mature markets like North America and Europe?

Manufacturers in mature markets focus on high-margin specialization, emphasizing superior material quality, product longevity, ergonomic design, and full compliance with industry-specific safety and quality certifications, rather than competing solely on price.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager