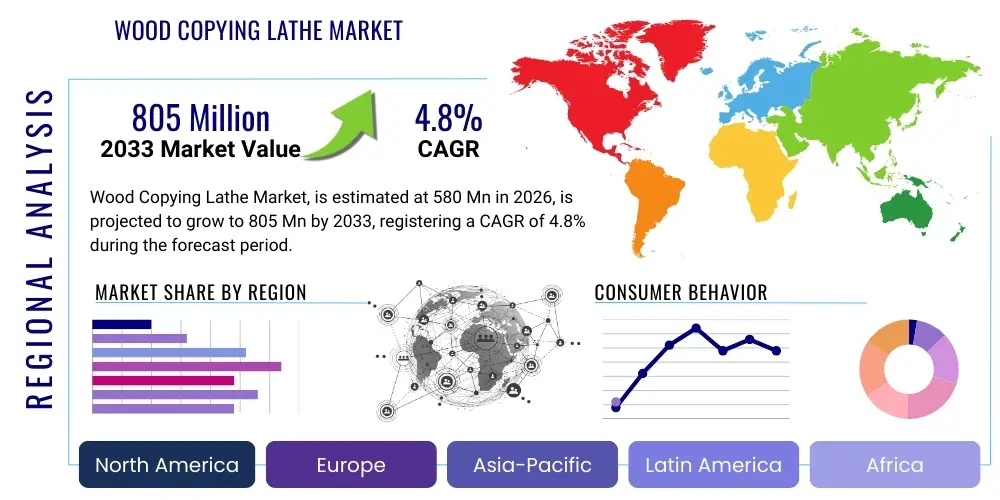

Wood Copying Lathe Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442220 | Date : Feb, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Wood Copying Lathe Market Size

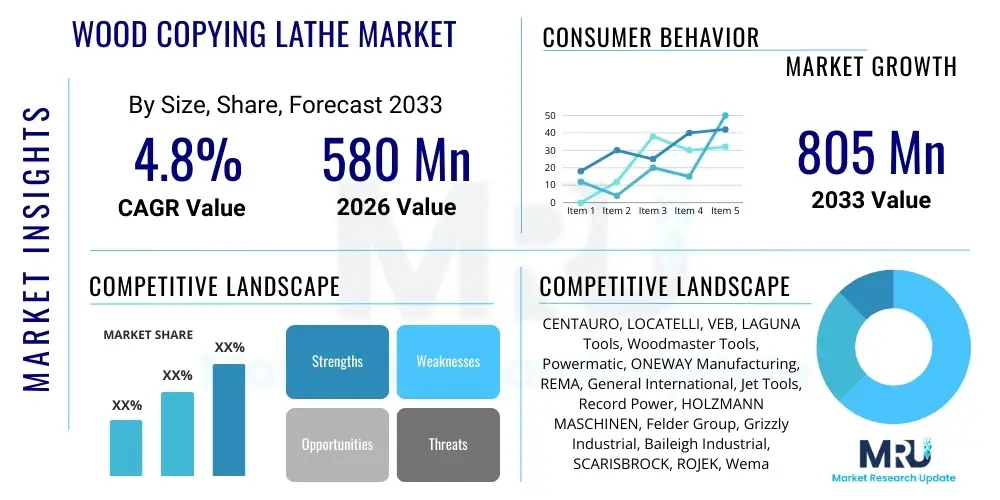

The Wood Copying Lathe Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at $580 Million in 2026 and is projected to reach $805 Million by the end of the forecast period in 2033.

The consistent growth trajectory in the Wood Copying Lathe Market is fundamentally driven by the escalating global demand for bespoke and semi-custom wooden furniture and architectural elements. Wood copying lathes offer a crucial balance between highly skilled manual turning and expensive, complex CNC machining, making them the preferred choice for small to mid-sized workshops specializing in replication and batch production of identical components like stair spindles, chair legs, and decorative columns. The inherent efficiency and reliability of these machines, particularly the hydraulic and electronic tracer models, allow manufacturers to significantly reduce production time and minimize material waste associated with manual errors, thereby bolstering operational profitability across various woodworking segments, including cabinet making and interior design.

Furthermore, the increased focus on historical restoration and the preservation of traditional craftsmanship, particularly in established markets across Europe and North America, contributes significantly to sustained market demand. Restoration projects often require the precise duplication of intricate, antique wooden components, a task for which copying lathes are uniquely suited due to their ability to trace and reproduce existing profiles accurately. Technological advancements, such as the integration of digital scanning technologies with traditional copying mechanisms, are broadening the application scope of these machines, enabling faster setup times and higher precision levels, thus appealing to a wider industrial client base seeking efficiency gains in high-volume replication tasks.

Wood Copying Lathe Market introduction

The Wood Copying Lathe Market encompasses the manufacturing, distribution, and utilization of specialized machinery designed to automatically reproduce complex turned shapes in wood based on a template, master pattern, or digital file. These machines range from manual tracer systems to sophisticated electronic copying systems that utilize advanced servo motors and optical readers. The primary function of a wood copying lathe is to efficiently produce identical wooden components in batches, significantly reducing the labor intensity and variability associated with purely manual wood turning. Key applications span the furniture industry, where components such as table legs, chair rails, and decorative knobs are mass-produced, and the architectural millwork sector, focusing on staircase balusters, porch posts, and custom moldings required for large-scale construction or renovation projects.

The intrinsic benefits of adopting wood copying lathes include substantial improvements in production throughput, unparalleled consistency in component dimensions and profiles, and a lower requirement for highly specialized manual turning skills compared to traditional methods. These factors are major driving forces in a manufacturing environment increasingly pressured by labor shortages and tight delivery schedules. The market is also propelled by rising disposable incomes globally, particularly in developing economies, which fuels the demand for high-quality, aesthetically pleasing wooden interior furnishings and decorative items. As manufacturers seek competitive edges, the precision and speed offered by modern copying lathes become essential tools for scaling operations without compromising on the fidelity of complex designs.

Modern copying lathes often feature robust construction, high spindle speeds, and increasingly intuitive controls, making them accessible to a broader range of woodworking businesses, from small bespoke shops to large industrial facilities. The continuous integration of electronic control systems allows for precise feed rates and depth control, further enhancing the quality of the finished product. This technological evolution ensures that the wood copying lathe remains a critical piece of equipment in the specialized wood processing ecosystem, supporting both traditional craft replication and contemporary mass production requirements. The market environment is characterized by steady innovation focused on automation and ease of use, ensuring long-term relevance in the specialized machinery sector.

Wood Copying Lathe Market Executive Summary

The Wood Copying Lathe Market exhibits robust growth, primarily fueled by global urbanization, a resurgent demand for artisanal and customized wooden goods, and technological advancements integrating digital scanning and electronic control into traditional machinery. Business trends indicate a strong shift toward highly automated electronic copying lathes that minimize setup time and enhance replication accuracy, catering specifically to medium-volume, high-mix production environments. Manufacturers are strategically focusing on modular designs that allow for quick tooling changes and the incorporation of multi-axis capabilities, expanding the range of profiles that can be accurately duplicated. Regional trends reveal North America and Europe maintaining leadership due to established furniture manufacturing sectors and high demand for historical preservation, while the Asia-Pacific (APAC) region, driven by massive infrastructure growth and rapid industrialization in countries like China, India, and Vietnam, is emerging as the fastest-growing market, primarily importing advanced electronic copying systems to meet global export demands. This regional disparity is driving differentiated pricing and distribution strategies across multinational lathe producers.

Segmental analysis highlights that hydraulic copying lathes continue to dominate in terms of volume due to their durability and lower initial investment cost, making them attractive to smaller workshops, whereas electronic copying lathes are gaining traction rapidly in industrial settings requiring superior precision and seamless integration with existing digital workflows. The end-user segment is dominated by the Furniture Manufacturing industry, particularly manufacturers of seating and decorative items, followed closely by the architectural Millwork sector, which requires complex, repetitive components for residential and commercial construction. Key market players are engaging in vertical integration and expanding their service networks globally to provide comprehensive technical support and specialized training, recognizing that the complexity of modern machinery necessitates robust after-sales service. The competitive landscape is moderately fragmented, with specialized European manufacturers leading in high-end electronic models and Asian manufacturers gaining ground in cost-effective hydraulic variants.

Overall, the market is poised for significant expansion, contingent upon resolving restraints such as the high initial capital expenditure required for advanced electronic systems and the need for skilled operators capable of managing the sophisticated digital templates and calibration processes. Opportunities abound in developing customized software interfaces specific to regional wood types and design aesthetics, offering localized solutions that enhance efficiency. Strategic initiatives focusing on sustainable manufacturing practices, including the utilization of low-power components and minimized material waste during the copying process, are also expected to differentiate market leaders. The continued push for standardization in components across various product lines further solidifies the long-term utility and profitability of the wood copying lathe sector.

AI Impact Analysis on Wood Copying Lathe Market

User queries regarding AI in the Wood Copying Lathe Market typically revolve around themes of automation efficacy, predictive maintenance capabilities, quality control precision, and integration challenges within traditional woodworking machinery. Users are primarily concerned with whether AI can eliminate the need for physical templates entirely, transition from tracer-based systems to purely digital, adaptive manufacturing, and how machine learning algorithms can optimize cutting paths to maximize material yield and minimize tool wear. There is a strong expectation that AI will standardize and automate the often-laborious setup and calibration phases, allowing operators to focus on oversight rather than complex manual adjustments. Concerns also include data security for proprietary design files and the upfront cost and complexity of implementing sophisticated AI-driven vision systems for real-time defect detection in turned components, thereby shaping future investment decisions toward smart, interconnected machinery platforms.

The influence of Artificial Intelligence (AI) on the Wood Copying Lathe Market is transforming operational efficiency, primarily through enhanced diagnostic capabilities and optimized production planning. AI algorithms, when integrated with machine sensors, can analyze vibration data, temperature fluctuations, and power consumption patterns to predict mechanical failures long before they occur. This transition from reactive to predictive maintenance significantly reduces unexpected downtime, a critical factor in high-volume furniture production. Furthermore, AI-driven software can analyze the wood grain structure and density in real-time, dynamically adjusting the lathe's speed and feed rate to ensure a cleaner cut and prevent tear-out, which is particularly challenging when working with varied or complex wood types. This level of adaptive control is impossible with traditional fixed-parameter copying systems, offering a significant leap in component quality consistency.

Beyond diagnostics, AI is also revolutionizing the design-to-production pipeline. Machine learning models are being developed to analyze 3D scans of original components and automatically generate optimized toolpaths and templates, eliminating the manual drafting or physical template creation step. This process enhancement drastically accelerates prototyping and small-batch customization. Additionally, AI-powered vision systems, utilizing high-resolution cameras and computer vision, are being deployed for real-time quality inspection. These systems can instantly compare the dimensions and surface finish of newly turned components against the digital master file, identifying deviations or defects at the source, thus improving overall quality assurance processes and reducing the volume of rejected parts. This integration positions wood copying lathes as key components within Industry 4.0 environments.

- AI-driven predictive maintenance forecasts component failure, minimizing costly downtime.

- Machine learning optimizes cutting parameters based on real-time wood characteristics (density, grain).

- Computer vision systems enable automated, high-speed quality control and defect detection.

- AI accelerates digital template generation from 3D scans, bypassing physical pattern creation.

- Optimization algorithms enhance material yield by calculating minimum necessary stock removal.

- Automated calibration reduces setup time and dependence on highly skilled machine operators.

DRO & Impact Forces Of Wood Copying Lathe Market

The dynamics of the Wood Copying Lathe Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities, which collectively exert significant Impact Forces on market progression and technological adoption. Primary drivers include the unrelenting global demand for customized wooden products, which necessitates efficient component replication, and the sustained growth of the housing and renovation sectors worldwide. However, the market faces considerable restraints, notably the substantial initial investment required for sophisticated electronic copying systems and the growing scarcity of skilled labor capable of operating and maintaining advanced woodworking machinery, which restricts adoption among smaller workshops. Opportunities primarily lie in the rapid technological advancement of digital scanning integration and the potential for market expansion in emerging economies where industrialization is fueling the construction of new manufacturing facilities, offering high-impact growth prospects.

Drivers: The fundamental driver is the intrinsic need for high-volume, precision replication of turned wood components, especially within the vast global furniture industry. As consumer preferences shift toward unique and aesthetically detailed products, manufacturers are increasingly relying on copying lathes to produce complex designs quickly and uniformly. The second major driver is the productivity gain realized by utilizing these machines; they allow for continuous operation once set up, drastically lowering the cost per piece compared to manual turning. Furthermore, stringent quality control standards in international markets mandate uniformity, a requirement that modern copying lathes meet effectively through electronic control and consistent tracing mechanisms, thereby solidifying their position as essential manufacturing assets.

Restraints: The most significant restraint is the high capital expenditure associated with purchasing and installing advanced wood copying lathes, particularly those utilizing electronic tracing and CNC integration. This cost factor often places the equipment out of reach for smaller, traditional woodworking businesses. Additionally, the learning curve associated with mastering complex digital interfaces and ensuring precise calibration for highly detailed work acts as a barrier to entry, exacerbating the restraint caused by the global shortage of trained woodworking machine operators. Economic uncertainties and volatile raw material prices for wood also introduce variability in production planning, which can temporarily dampen investment in new machinery, compelling businesses to extend the lifespan of older, less efficient equipment.

Opportunities: Significant growth opportunities exist in integrating advanced digital technologies, such as 3D scanning and CAD/CAM software, directly into the lathe interface, making the replication process faster and less reliant on physical templates. The untapped potential in developing and emerging markets, particularly Southeast Asia and Latin America, represents a vast opportunity for sales of both new and refurbished hydraulic and electronic models, driven by localized infrastructure development and increasing domestic demand for furnishings. Furthermore, the development of compact, versatile, and highly automated copying lathes tailored for educational institutions and smaller custom workshops presents a niche opportunity for market penetration outside of traditional industrial manufacturing environments.

Segmentation Analysis

The Wood Copying Lathe Market is comprehensively segmented based on product type, technology, application, and end-user, providing a granular view of market dynamics and adoption patterns across diverse industrial ecosystems. Segmentation by product type primarily differentiates between standard lathes equipped with simple tracing attachments, dedicated copying lathes built specifically for replication, and integrated CNC turning centers that incorporate copying capabilities. The technology segment distinguishes between traditional mechanical tracer systems, robust hydraulic copying systems offering high power, and high-precision electronic copying systems utilizing stepper or servo motors for template following. Analyzing these segments helps stakeholders understand where technological investment is concentrated and which features are prioritized by specific user groups based on production scale and required tolerance levels.

Segmentation by application reveals the dominance of basic component replication, such as producing uniform cylindrical parts, versus complex profile replication involving intricate curves and varying diameters, often required for high-end decorative elements. The end-user analysis provides critical insights into the primary consumption hubs, dominated by the Furniture Manufacturing industry due to its constant need for standardized parts like legs, spindles, and posts. This segment is followed by the Millwork and Architectural elements industry, which focuses on larger, custom components like columns and balustrades. Understanding these user requirements allows manufacturers to tailor machine specifications, offering higher spindle capacities for millwork and faster cycle times for high-volume furniture production, thus aligning product development with documented market needs.

The strategic importance of effective segmentation lies in identifying specific underserved niches, such as automated tooling systems for quick changeovers in high-mix environments, or developing entry-level, cost-effective electronic copying solutions for small and medium enterprises (SMEs). The market's future growth is increasingly tied to the adoption rate of electronic copying technology, which offers superior precision necessary for modern, interlocking furniture designs that require tight tolerances. Moreover, regional segmentation (detailed elsewhere) highlights geographic variations in technology preference, with mature markets opting for high-end electronic systems while emerging markets favor durable and easy-to-maintain hydraulic systems, influencing localized marketing and distribution strategies.

- Product Type:

- Standard Lathes with Copying Attachment

- Dedicated Wood Copying Lathes (Single-Spindle, Multi-Spindle)

- CNC Wood Turning Centers with Copying Functionality

- Technology:

- Mechanical Tracer Systems

- Hydraulic Copying Systems

- Electronic (Servo/Stepper Motor) Copying Systems

- Application:

- Standard Cylindrical Replication

- Complex Profile Replication (Fluting, Twisting, Oval Turning)

- End-User Industry:

- Furniture Manufacturing (Seating Components, Tables, Beds)

- Architectural Millwork (Stair Balusters, Columns, Posts)

- Decorative Woodware and Craft Production

- Wooden Toy Manufacturing

Value Chain Analysis For Wood Copying Lathe Market

The Value Chain for the Wood Copying Lathe Market begins with the Upstream activities, focusing on the sourcing and manufacturing of critical components, including high-grade specialized steel for the machine beds and spindles, advanced electronic control units (ECUs), servo motors, hydraulic systems, and sophisticated precision measuring equipment used for template tracing. Key upstream suppliers include electrical component specialists, bearing manufacturers, and specialized metal fabrication firms. Efficiency in this stage is crucial, as the reliability and longevity of the lathe are directly dependent on the quality of these sourced inputs. Manufacturers must maintain robust supply chain relationships to ensure timely delivery of high-precision parts, especially electronic components, which are subject to global supply fluctuations and rapidly evolving technical standards. Cost optimization at this stage is achieved through strategic bulk purchasing and stringent quality control protocols enforced on all incoming raw materials.

The midstream phase involves the core manufacturing process, encompassing design engineering, assembly, calibration, and rigorous testing of the copying lathes. Leading manufacturers invest heavily in R&D to improve tracing accuracy, reduce vibration, and enhance operational safety features. Advanced processes include precision machining of the machine frame, integration of tracing mechanisms (whether mechanical, hydraulic, or electronic), and the installation of complex software necessary for electronic copying. The Downstream phase focuses heavily on effective Distribution Channels. Direct sales models are often employed for large industrial clients requiring custom configurations and specialized integration services, ensuring personalized technical consultation and installation. Conversely, indirect channels, such as authorized dealers and regional distributors, are utilized to penetrate smaller local markets and provide localized maintenance and spare parts inventory, which is essential for minimizing customer downtime.

The success of the value chain is increasingly reliant on effective post-sale services. Given the complexity of modern electronic and hydraulic copying systems, comprehensive technical support, operator training programs, and the readily availability of proprietary spare parts are crucial differentiating factors. Distribution channel effectiveness is measured not only by speed but also by the technical expertise of the sales agents, who often double as initial troubleshooters. The shift towards electronic copying also demands seamless integration with customers’ existing CAD/CAM ecosystems, making software support a non-negotiable part of the downstream offering. Optimized logistics, minimizing shipping damage for heavy industrial equipment, completes the value delivery process, ensuring customer satisfaction and repeat business.

Wood Copying Lathe Market Potential Customers

The primary End-Users and Buyers of Wood Copying Lathes are typically characterized by a need for high-volume, repetitive production of identical turned wooden components that adhere to strict dimensional tolerances. The most dominant segment is the Furniture Manufacturing Industry, encompassing large-scale producers of residential and commercial furniture, including manufacturers of chairs, tables, beds, and specialized cabinetry. These businesses rely on copying lathes to efficiently produce components such as chair and table legs, decorative spindles, and structural elements, often requiring thousands of identical pieces per production run. The transition from mass-produced, standardized designs to semi-custom product lines further reinforces the need for flexible, high-precision copying technology that can handle frequent changeovers with minimal template adjustment.

The secondary, yet highly critical, customer base resides within the Architectural Millwork and Building Construction sectors. This group focuses on producing larger, intricate components used in interior and exterior design, such as custom stair balustrade systems, decorative columns, porch posts, and specialized wood trim. Buyers in this segment prioritize machines with high stability, large turning capacities, and exceptional accuracy to meet architectural specifications, often involving historical replication or high-end bespoke designs for luxury residential projects. Furthermore, small to medium-sized custom woodworking shops and craft producers, specializing in custom woodware, toys, and restoration projects, represent a viable customer segment, typically favoring durable, smaller-footprint hydraulic copying lathes due to lower operating complexity and moderate initial investment.

A smaller, but growing segment includes vocational training centers and educational institutions that require reliable, functional lathes for teaching fundamental wood turning and replication techniques. These entities prioritize safety features and robust, easy-to-maintain mechanical systems. For all customer segments, the decision to purchase a wood copying lathe is based on a clear Return on Investment (ROI) calculation, factoring in reduced labor costs, increased production speed, and minimized scrap rate compared to purely manual alternatives. Therefore, potential customers are businesses looking to scale production, improve quality consistency, and reduce reliance on increasingly scarce, highly skilled manual labor.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $580 Million |

| Market Forecast in 2033 | $805 Million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | CENTAURO, LOCATELLI, VEB, LAGUNA Tools, Woodmaster Tools, Powermatic, ONEWAY Manufacturing, REMA, General International, Jet Tools, Record Power, HOLZMANN MASCHINEN, Felder Group, Grizzly Industrial, Baileigh Industrial, SCARISBROCK, ROJEK, Wema Probst. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Wood Copying Lathe Market Key Technology Landscape

The technological landscape of the Wood Copying Lathe Market is defined by a progressive transition from purely mechanical and hydraulic tracer systems towards sophisticated electronic and integrated digital solutions, drastically enhancing accuracy and production flexibility. Hydraulic copying lathes, while robust and powerful, utilize oil pressure to control the cutting depth based on a follower tracing a physical template. These systems remain prevalent due to their reliability in high-throughput, rough turning operations. However, the cutting-edge technology is centered around Electronic Copying Lathes, which replace the hydraulic or mechanical tracer arm with electronic sensors (optical or contact) and servo-driven control systems. These electronic systems translate the template profile into digital signals, which then precisely control the movement of the cutting tool carriage, offering unparalleled fidelity and allowing for faster changeovers between different profiles stored digitally, positioning them as the future standard for precision woodworking.

A significant advancement involves the seamless integration of 3D Scanning Technology directly into the workflow. Instead of relying on a physical template (a wooden master piece or a metal profile), modern electronic copying lathes can utilize a laser or structured light scanner to capture the geometry of an existing part, generating a digital CAD profile instantly. This digital file is then fed directly to the machine's CNC or electronic control unit, eliminating the labor and time required to prepare or repair physical templates. This capability is particularly vital for restoration and custom manufacturing where the original part may be damaged or irregular. The increasing adoption of Computer Numerical Control (CNC) features, even in dedicated copying machines, is enabling operators to program complex profiles that standard tracing systems cannot handle, such as fluting, twisting, or multi-axis turning, broadening the machine's functional versatility and increasing overall market value.

Furthermore, the focus on spindle and tool innovation is contributing significantly to technological evolution. High-speed, variable-frequency drive (VFD) controlled spindles provide better surface finishes and allow for optimization based on wood hardness. Automated tool changers are also being integrated, particularly in CNC-enabled copying centers, minimizing idle time and maximizing throughput. The software used to manage these lathes is becoming increasingly user-friendly, incorporating graphical interfaces and diagnostic tools that simplify calibration and maintenance. This continuous pursuit of enhanced precision, faster cycle times, and reduced reliance on manual intervention through advanced electronic and software integration is the defining characteristic of the current Wood Copying Lathe technology landscape.

Regional Highlights

The global Wood Copying Lathe Market exhibits distinct regional dynamics driven by local manufacturing capabilities, consumer demand for furniture, and investment levels in industrial machinery.

- North America (NA): Characterized by a high demand for advanced, electronically controlled copying lathes due to high labor costs and stringent quality requirements. The market is primarily driven by the residential construction and renovation boom, leading to strong demand for architectural millwork (stair parts, columns). Companies prioritize machinery that offers maximum automation and integration with existing digital design workflows (CAD/CAM). Market penetration for large-capacity, multi-spindle copying lathes is significant in established woodworking hubs.

- Europe: This region maintains a strong market presence, particularly in Germany, Italy, and Scandinavia, which are globally renowned for their precision woodworking machinery manufacturing and high-quality furniture production. The European market leans towards sophisticated, high-end electronic copying systems and those emphasizing energy efficiency and ergonomic design. Demand is sustained by tradition, including historical restoration projects requiring exact replicas, and a strong export-oriented furniture industry that mandates extremely accurate component production.

- Asia Pacific (APAC): APAC is the fastest-growing market, primarily fueled by the massive expansion of the furniture and wood processing industries in China, Vietnam, Indonesia, and India. While price sensitivity remains a factor, driving demand for cost-effective hydraulic copying lathes, there is a rapidly increasing shift towards electronic and CNC-integrated systems to meet the precision demands of international export markets. Government initiatives supporting manufacturing infrastructure and technology upgrades are key drivers in this region, resulting in high import volumes of advanced machinery.

- Latin America (LATAM): The LATAM market is characterized by moderate growth, heavily influenced by local economic conditions and fluctuating investment in infrastructure and housing. Demand is primarily centered on durable, robust hydraulic copying lathes that are easy to maintain and repair locally. Key markets include Brazil and Mexico, driven by domestic furniture consumption and growing specialized export markets for unique wood products. The adoption of high-end electronic technology is slower compared to North America and Europe due to higher upfront costs and infrastructure challenges.

- Middle East and Africa (MEA): This region represents a niche but emerging market, with growth concentrated in the Gulf Cooperation Council (GCC) countries due to substantial investments in high-end construction and luxury interior projects. The demand here is highly focused on quality architectural elements, often requiring specialized, large-capacity lathes. African markets are slower, relying mostly on imported, often used, machinery, though industrialization efforts in South Africa and Nigeria are beginning to drive investment in newer equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Wood Copying Lathe Market.- CENTAURO (Italy)

- LOCATELLI (Italy)

- VEB (Germany)

- LAGUNA Tools (USA)

- Woodmaster Tools (USA)

- Powermatic (USA)

- ONEWAY Manufacturing (Canada)

- REMA (Poland)

- General International (USA)

- Jet Tools (USA)

- Record Power (UK)

- HOLZMANN MASCHINEN (Austria)

- Felder Group (Austria)

- Grizzly Industrial (USA)

- Baileigh Industrial (USA)

- SCARISBROCK (UK)

- ROJEK (Czech Republic)

- Wema Probst (Germany)

Frequently Asked Questions

Analyze common user questions about the Wood Copying Lathe market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between a hydraulic and an electronic wood copying lathe?

Hydraulic copying lathes use pressurized fluid to control the cutting action based on a mechanical tracer arm following a physical template, offering high power and durability. Electronic copying lathes utilize servo motors and optical/electronic sensors to follow a digital or physical template, offering superior precision, faster setup times, and easier integration with digital design files, albeit at a higher initial cost.

Which industry is the largest consumer of wood copying lathes globally?

The Furniture Manufacturing Industry is the largest consumer, relying heavily on copying lathes for the efficient, high-volume, and precise replication of standardized components such as chair and table legs, stair spindles, and decorative parts, ensuring uniformity across product lines.

How does technological integration, such as 3D scanning, benefit the wood copying process?

3D scanning significantly benefits the process by eliminating the need for physical templates. A scanner captures the geometry of an existing object and creates a digital profile (CAD file), which the electronic lathe can follow directly, streamlining prototyping, custom replication, and restoration work, and reducing template creation time.

What are the main restraints hindering the market growth of advanced wood copying lathes?

The main restraints are the high initial capital expenditure required for purchasing sophisticated electronic and CNC-integrated models, which poses a barrier for small and medium-sized enterprises (SMEs), and the persistent shortage of skilled operators capable of managing and maintaining complex automated woodworking machinery.

Is the Wood Copying Lathe Market expected to be replaced entirely by CNC machining centers?

While CNC machining centers offer greater versatility, the Wood Copying Lathe Market is not expected to be entirely replaced. Dedicated copying lathes offer a significantly lower operational cost, faster cycle times for repetitive turning tasks, and simpler programming specific to cylindrical replication, maintaining a crucial niche in specialized high-volume production.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager