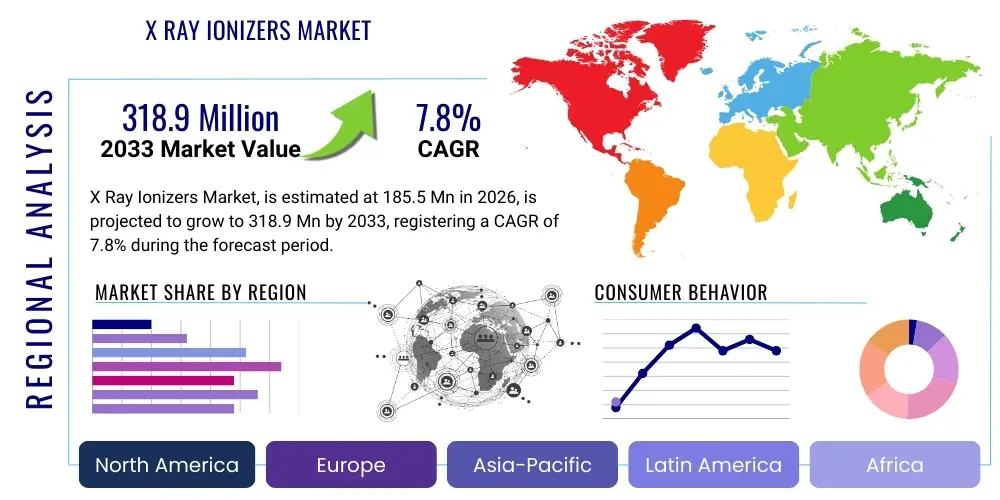

X Ray Ionizers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441474 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

X Ray Ionizers Market Size

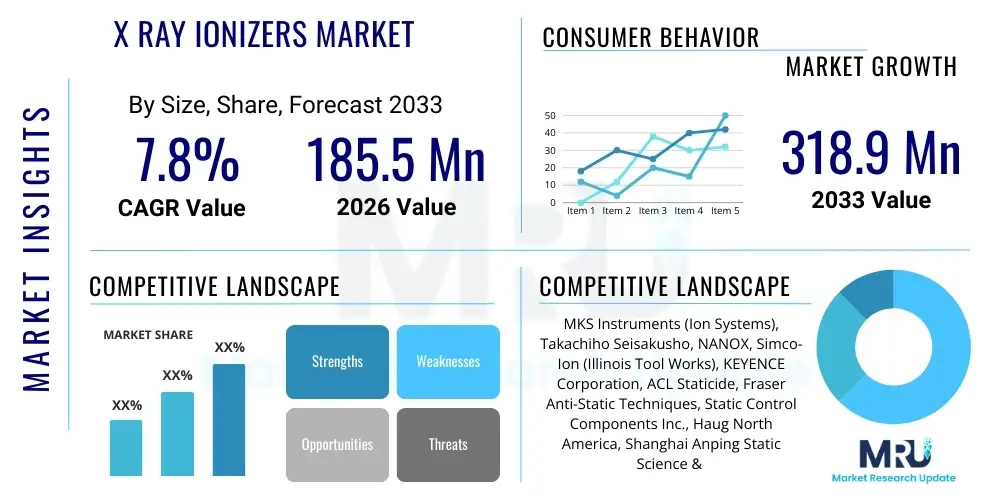

The X Ray Ionizers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 185.5 million in 2026 and is projected to reach USD 318.9 million by the end of the forecast period in 2033.

X Ray Ionizers Market introduction

The X-Ray Ionizers Market encompasses advanced electrostatic discharge (ESD) control equipment designed to neutralize static charges in highly sensitive manufacturing and controlled environments, particularly those where conventional corona discharge ionizers are unsuitable due to particle generation or insufficient ionization range. X-ray ionizers utilize soft X-rays to generate positive and negative air ions throughout a defined space or directed area, providing highly effective and ultra-clean static neutralization without physical contact or the need for constant calibration. This technology is critical for processes operating at nanoscale tolerances, offering superior performance in environments demanding zero contamination and precise charge balancing.

These specialized ionizers are primarily deployed in semiconductor fabrication facilities, advanced electronics assembly lines, and environments producing highly sensitive microelectronic components such as microchips, sensors, and flat panel displays (FPDs). The core product description involves a shielded X-ray source that emits controlled radiation into the air stream, generating the necessary ion density to neutralize static buildup which can otherwise cause defects, material handling issues, and equipment damage. The major benefit of using X-ray ionization lies in its intrinsic cleanliness, speed of neutralization, and ability to achieve deep penetration into complex structures and non-conductive materials, crucial for high-yield manufacturing processes.

The driving factors for market growth include the relentless miniaturization of semiconductor geometries (moving below 10nm), increasing demand for advanced flat panel displays (OLED, micro-LED), and the stringent quality requirements in medical device manufacturing. As production tolerances decrease, the risk associated with electrostatic discharge dramatically increases, making the passive or less effective static control methods obsolete. X-ray ionizers address this technological gap, ensuring higher throughput and reduced scrap rates, thereby justifying their premium cost structure in critical applications globally.

X Ray Ionizers Market Executive Summary

The X Ray Ionizers Market is poised for substantial expansion driven by the escalating complexity and sensitivity of advanced manufacturing processes, particularly within the semiconductor and microelectronics sectors. Business trends show a strong focus on developing smaller, more robust, and highly integrated X-ray sources that require less maintenance and offer enhanced energy efficiency, moving towards smart, networked ionization systems compatible with Industry 4.0 initiatives. Key market players are investing heavily in improving shielding mechanisms and increasing the ion density output while ensuring compliance with global radiation safety standards, cementing X-ray ionizers as the premium solution for ultra-clean static control.

Regionally, the Asia Pacific (APAC) segment dominates the market landscape, primarily fueled by massive capital expenditure in semiconductor fabrication plants (fabs) located in countries like China, South Korea, Taiwan, and Japan. These regions are the global hubs for microchip and FPD manufacturing, necessitating the highest level of ESD control. North America and Europe, while representing mature markets, exhibit steady growth driven by the expansion of niche high-end applications, advanced research facilities, and stringent quality control mandates in aerospace and medical device production. Regulatory adherence to ESD standards (like ANSI/ESD S20.20) further mandates the adoption of high-performance ionization solutions across these developed economies.

In terms of segmentation, the Soft X-Ray Ionizers segment holds the largest market share due to its efficiency in neutralizing charges over short to medium distances, which is ideal for wafer processing tools and localized assembly areas. Application-wise, Semiconductor Manufacturing remains the dominant consumer, although the Flat Panel Display (FPD) segment is experiencing the fastest growth rate, fueled by the transition to larger, higher-resolution displays requiring immaculate production environments. Future segment trends indicate rising adoption in automated precision robotics and advanced packaging technologies where traditional air ionizing bars cannot perform effectively due to space constraints or air flow limitations.

AI Impact Analysis on X Ray Ionizers Market

User inquiries regarding AI's influence on the X Ray Ionizers Market commonly revolve around predictive maintenance, optimization of ionization parameters, and the integration of static monitoring data with broader fab automation systems. Users are keen to understand how AI can minimize downtime associated with X-ray source wear and regulatory checks, and whether machine learning algorithms can dynamically adjust ionization levels based on real-time particulate counts, humidity, and production material throughput. The key themes emerging from user concerns center on integrating complex, high-reliability equipment like X-ray ionizers into smart factory ecosystems without compromising safety or data integrity, ultimately seeking enhanced operational efficiency and preemptive failure detection.

The practical application of Artificial Intelligence within this market is focused on transforming reactive maintenance into predictive servicing. AI algorithms process historical operational data, sensor inputs (such as beam current, gas pressure, and ambient environmental data), and neutralization performance metrics to predict component degradation, particularly concerning the X-ray tube life. This capability allows manufacturers to schedule tube replacements during planned downtime, maximizing utilization rates and preventing catastrophic failures that could halt multi-million-dollar production lines. Furthermore, AI contributes to compliance management by automatically logging and analyzing operational parameters against regulatory benchmarks for radiation safety and performance.

Beyond maintenance, AI integration enhances the precision of static control itself. By analyzing the unique electrical properties of specific wafers or components moving through a process, AI can fine-tune the output energy and pulse frequency of the X-ray ionizers in real-time. This dynamic charge balancing ensures optimal neutralization speed and minimizes residual voltage, which is crucial for yielding devices at the smallest nodes. This level of responsiveness significantly surpasses the capabilities of traditional static control systems, positioning AI as a vital tool for achieving zero-defect goals in advanced manufacturing environments.

- AI enables predictive maintenance scheduling for X-ray tube replacement, reducing unexpected downtime.

- Machine learning optimizes ionization output parameters (frequency, intensity) based on real-time process data and ambient conditions.

- Integration with fab-wide automation systems allows for centralized monitoring and control of ESD performance metrics.

- Automated anomaly detection identifies subtle shifts in ionization efficiency or potential radiation leaks proactively.

- AI analyzes material movement and throughput to dynamically ensure optimal charge balance across varying production speeds.

- Enhanced compliance logging and automated generation of performance reports meet stringent regulatory requirements.

DRO & Impact Forces Of X Ray Ionizers Market

The X Ray Ionizers Market is shaped by powerful industry drivers stemming from technological advances in microelectronics, countered by restraints related to cost and complexity, while opportunities emerge through geographical expansion and regulatory shifts. The primary impact force is the mandatory requirement for ultra-clean static elimination in semiconductor nodes below 14nm, where traditional methods introduce unacceptable particle counts. This necessity outweighs the higher initial investment, pushing market adoption forward.

Drivers include the rapid expansion of the semiconductor industry globally, particularly in advanced logic and memory manufacturing, which demands pristine, particle-free environments. The complexity and high value of modern semiconductor wafers mean that even minor static discharge events are economically disastrous, making X-ray ionizers an insurance policy for high yield. Furthermore, the stringent quality controls enforced by industries like aerospace, pharmaceuticals, and medical devices necessitate the superior performance and stability offered by X-ray ionization technology. However, restraints present substantial barriers; the high initial capital cost associated with X-ray ionizers, the perceived safety concerns related to X-ray exposure (even soft X-rays), and the regulatory hurdles requiring specialized certification and maintenance staff often deter smaller manufacturing operations.

Opportunities for growth are significant, particularly through market penetration into emerging application areas such as advanced battery manufacturing, display assembly, and precision additive manufacturing processes where static poses significant quality issues. Technological advancements focusing on miniaturization, portability, and enhanced radiation shielding will broaden the potential customer base. Moreover, the long-term trend toward automated, highly controlled manufacturing environments ensures that solutions offering precision and reliability, like X-ray ionizers, will increasingly replace less stable alternatives. The complex interplay of these forces ensures sustained market growth focused on high-value, high-reliability applications.

- Drivers: Miniaturization of semiconductor components (sub-10nm nodes), increasing complexity and value of microchips, zero-defect requirements in FPD manufacturing, and demand for ultra-clean static neutralization solutions.

- Restraints: High initial investment and maintenance costs, regulatory compliance and certification requirements for X-ray equipment, perceived user hesitancy regarding radiation exposure, and competition from advanced plasma and alpha source ionizers.

- Opportunities: Expansion into new applications (e.g., advanced battery manufacturing, precision optics), development of integrated, modular ionization systems, and growth in emerging APAC markets driving new fab construction.

- Impact Forces: Technological necessity (high impact), Regulatory burden (medium impact), Cost sensitivity (high impact).

Segmentation Analysis

The X Ray Ionizers Market is systematically segmented based on Type, Application, and End-User, reflecting the diverse requirements of static control across various industrial sectors. This segmentation helps manufacturers tailor their product offerings—ranging from soft X-ray emitters suitable for localized, confined spaces to hard X-ray variants used for broader area coverage or penetrating complex structures—to specific industrial needs. The dynamic growth of segments like Flat Panel Displays and specialized electronics assembly underscores the market's reliance on ultra-clean ESD solutions as production standards become increasingly demanding.

By Type, the market is differentiated primarily by the energy level of the X-ray source, which dictates the penetration depth and effective range of the ions produced. Soft X-Ray Ionizers are dominant due to their localized effectiveness, lower energy consumption, and common use within closed process tools like photolithography and etching chambers. Hard X-Ray Ionizers, while less common, are utilized where deep penetration or ionization across large, enclosed conveyor systems is necessary. The technological differentiation emphasizes achieving superior charge neutralization efficiency (ion balance) with minimal environmental impact and guaranteed safety.

Application-wise, the segmentation highlights the market's dependence on high-tech manufacturing, where ESD control directly impacts product yield and quality. Semiconductor manufacturing remains the cornerstone, encompassing wafer handling, probing, and packaging. The rapid expansion of organic light-emitting diode (OLED) and other advanced FPD technologies significantly drives demand in the Display segment. Analyzing these segments is crucial for strategic market positioning, allowing companies to focus on regions and industries undergoing significant capital investment and requiring compliance with the highest standards of electrostatic control.

- By Type:

- Soft X-Ray Ionizers

- Hard X-Ray Ionizers

- Pulsed X-Ray Ionizers

- By Application:

- Semiconductor Manufacturing (Wafer Processing, Backend Packaging)

- Electronics Assembly and Testing (PCBs, Components)

- Flat Panel Displays (FPD) and OLED Production

- Medical Device Manufacturing (Micro-sensors, Implants)

- Precision Optics and Lens Manufacturing

- By End-User:

- Cleanrooms (ISO Class 1 to 5)

- Automated Manufacturing Facilities

- Research and Development Laboratories

- ESD-Sensitive Industrial Environments

Value Chain Analysis For X Ray Ionizers Market

The value chain for the X Ray Ionizers Market is highly specialized, beginning with the critical upstream supply of core components, primarily the X-ray sources (tubes) and high-voltage power supplies, which require advanced physics and engineering expertise. Manufacturers of the ionizer units focus on integration, ensuring precise shielding, control mechanisms, and regulatory compliance. The upstream phase is characterized by a limited number of specialized suppliers providing patented technology necessary for stable, long-life soft X-ray emission, making the ionizer producers dependent on this niche component supply chain.

In the midstream, ionizer manufacturers assemble, calibrate, and certify the final products, often customizing them for integration into specific production tools (e.g., lithography scanners or automated handlers). This phase also involves rigorous quality control, calibration testing, and adherence to strict radiation safety standards (e.g., IEC 61010). The complexity of integrating X-ray technology means that the value addition at the manufacturing stage is substantial, covering proprietary software for monitoring and remote diagnostics, crucial for performance optimization in 24/7 manufacturing environments.

Downstream distribution predominantly relies on specialized technical distributors and direct sales channels, particularly for large semiconductor or FPD fabs that require direct manufacturer support for installation and validation. Indirect channels are utilized for smaller R&D labs or less demanding industrial environments. The service and support segment is a critical downstream component, encompassing regular calibration, tube replacement, and performance audits. Given the high capital cost and technical nature of the equipment, long-term service contracts form a significant part of the total revenue generation, ensuring ongoing functional integrity and regulatory adherence for the end-user.

X Ray Ionizers Market Potential Customers

Potential customers and primary buyers of X Ray Ionizers are entities deeply invested in high-precision, contamination-sensitive manufacturing where traditional ESD measures are inadequate or contribute to yield loss. The primary end-users are large multinational semiconductor corporations, known as Integrated Device Manufacturers (IDMs) and pure-play foundries, which require X-ray ionization integrated directly into their lithography, inspection, and deposition tools to protect delicate wafers.

Another significant customer group consists of manufacturers specializing in advanced electronic displays, particularly those producing large-format OLED and high-resolution LCD panels. These processes involve handling large, non-conductive substrates that are extremely sensitive to static charge build-up, demanding fast, particle-free ionization solutions. Furthermore, specialized manufacturers in the aerospace, defense, and high-end medical device sectors represent crucial, albeit smaller, customer bases, valued for their stringent quality requirements and willingness to adopt high-cost, high-reliability equipment to ensure compliance and product integrity.

The purchasing decisions in these customer segments are driven by total cost of ownership (TCO) weighed against potential yield increase, rather than just initial unit cost. Procurement involves collaboration between equipment engineers, process specialists, and environmental health and safety (EHS) managers, ensuring both performance and regulatory compliance are met. The ultimate buyers are process managers and engineering teams responsible for maintaining high throughput and minimizing defect rates in ISO-certified cleanrooms.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 185.5 million |

| Market Forecast in 2033 | USD 318.9 million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | MKS Instruments (Ion Systems), Takachiho Seisakusho, NANOX, Simco-Ion (Illinois Tool Works), KEYENCE Corporation, ACL Staticide, Fraser Anti-Static Techniques, Static Control Components Inc., Haug North America, Shanghai Anping Static Science & Technology, Meech International, Exair Corporation, Static Clean International, Elco, and TREK, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

X Ray Ionizers Market Key Technology Landscape

The technological landscape of the X Ray Ionizers Market is dominated by advancements aimed at increasing ion output, minimizing maintenance intervals, and enhancing safety protocols. The core technology involves highly efficient, sealed X-ray tubes (typically soft X-ray emitters) that generate ions without physical contact or the need for a high-velocity air stream, unlike traditional corona ionizers. Recent innovations focus heavily on micro-focus X-ray tubes that allow for more compact designs and precise targeting of ionization zones within increasingly intricate process equipment. This miniaturization is crucial for integrating ionizers directly into the tight spaces found in modern semiconductor fabrication machinery.

A major area of technological differentiation is the integration of proprietary beam control and shielding mechanisms. Manufacturers are continuously improving the stability of the X-ray emission to ensure a constant, highly balanced ion flow (often maintaining less than ±5V offset voltage), which is paramount for protecting sensitive components. Furthermore, advanced monitoring systems utilizing embedded sensors and diagnostic software are becoming standard. These systems provide real-time data on the X-ray tube life, ion balance, and environmental factors such as temperature and humidity, enabling closed-loop control and remote monitoring necessary for automated, high-throughput manufacturing lines.

The market is also witnessing a shift towards pulsed X-ray ionization technology, offering advantages in energy efficiency and control over ion dispersal, especially in areas with complex air flow dynamics. While Soft X-ray systems remain the standard for cleanroom environments due to their particle-free operation, continuous development aims to further reduce the regulatory burden associated with X-ray use through highly engineered shielding and fail-safe mechanisms. The future of the technology landscape involves enhanced connectivity, moving towards smart X-ray ionizers that communicate seamlessly with factory execution systems (MES) and utilize AI for self-calibration and predictive performance management.

Regional Highlights

- Asia Pacific (APAC): APAC stands as the undisputed leader in the X Ray Ionizers Market, commanding the largest market share due to its concentration of global semiconductor giants (TSMC, Samsung, SK Hynix) and major FPD producers. Countries like Taiwan, South Korea, China, and Japan are continuously investing billions in new fabrication facilities (fabs) and advanced assembly lines. The relentless push for smaller node technologies (7nm, 5nm, and below) necessitates the mandatory adoption of ultra-clean static control, fueling high sales volumes of X-ray ionizers in this region. This region is characterized by high production throughput and a strong competitive drive for manufacturing yield optimization.

- North America: North America represents a mature, high-value market driven by R&D intensity, aerospace, and medical device manufacturing, alongside significant reshoring efforts in specialized semiconductor production (e.g., advanced packaging). While smaller in volume compared to APAC, the demand here is focused on highly sophisticated, customizable ionization solutions for niche, high-reliability applications and university research cleanrooms. Compliance with ANSI/ESD S20.20 standards and safety regulations is extremely strict, prioritizing equipment with proven long-term stability and extensive safety certification.

- Europe: Europe is characterized by steady growth, supported by strong investments in industrial automation, automotive electronics, and precision engineering. Germany, France, and Ireland are key markets. The focus is increasingly shifting toward integrating X-ray ionizers within automated production cells (Industry 4.0), ensuring static control throughout complex robotics and conveyor systems. The European market values energy efficiency and robust, compliant design, driven by stringent environmental and safety regulations (e.g., CE marking and specific regional radiation protection laws).

- Latin America, Middle East, and Africa (LAMEA): LAMEA currently holds a smaller share but exhibits emerging growth potential, particularly in countries developing localized electronics manufacturing capabilities and pharmaceutical production facilities. Adoption is slower due to higher capital costs, but increasing foreign direct investment in technology manufacturing hubs in countries like Mexico and Israel suggests rising future demand for high-end static control solutions in critical environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the X Ray Ionizers Market.- MKS Instruments (Ion Systems)

- Takachiho Seisakusho

- NANOX

- Simco-Ion (Illinois Tool Works)

- KEYENCE Corporation

- ACL Staticide

- Fraser Anti-Static Techniques

- Static Control Components Inc.

- Haug North America

- Shanghai Anping Static Science & Technology

- Meech International

- Exair Corporation

- Static Clean International

- Elco

- TREK, Inc.

- Terra Universal

- Desco Industries

- 3M Company (Industrial Business Group)

- AlphaLab, Inc.

Frequently Asked Questions

Analyze common user questions about the X Ray Ionizers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of X Ray Ionizers over traditional corona ionizers in cleanrooms?

X Ray Ionizers offer a particle-free, ultra-clean method of static neutralization, making them essential for ISO Class 1 environments. Unlike corona discharge ionizers, X-ray technology does not rely on high voltage points that generate particulate contamination, ensuring higher yield in sub-10nm semiconductor processing.

Are X Ray Ionizers safe, and what are the maintenance requirements?

Modern X Ray Ionizers are designed with extensive shielding and fail-safe mechanisms, emitting only soft X-rays which are safely contained, adhering to strict international radiation safety standards (e.g., IEC 61010). Maintenance primarily involves the periodic replacement of the internal X-ray tube, typically dictated by operating hours and confirmed via integrated diagnostic monitoring systems.

Which manufacturing sectors are the largest consumers of X Ray Ionizers?

The largest consumer sector is Semiconductor Manufacturing, particularly wafer fabrication and advanced packaging. Other major consumers include Flat Panel Display (FPD) manufacturing, high-precision electronics assembly, and specialized medical device production, all requiring stringent ESD control.

How does the performance of Soft X-Ray Ionizers compare to Hard X-Ray Ionizers?

Soft X-Ray Ionizers are generally preferred for localized static neutralization within process tools and confined spaces due to their efficiency over short distances and lower energy requirements. Hard X-Ray Ionizers penetrate deeper and are used for ionizing air across larger volumes or through complex mechanical barriers, though they are less commonly specified.

What is the Compound Annual Growth Rate (CAGR) projected for the X Ray Ionizers Market?

The X Ray Ionizers Market is projected to exhibit a robust Compound Annual Growth Rate (CAGR) of 7.8% between the years 2026 and 2033, driven by ongoing investment in advanced cleanroom infrastructure across Asia Pacific.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager