Zirconia Beads Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441911 | Date : Feb, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Zirconia Beads Market Size

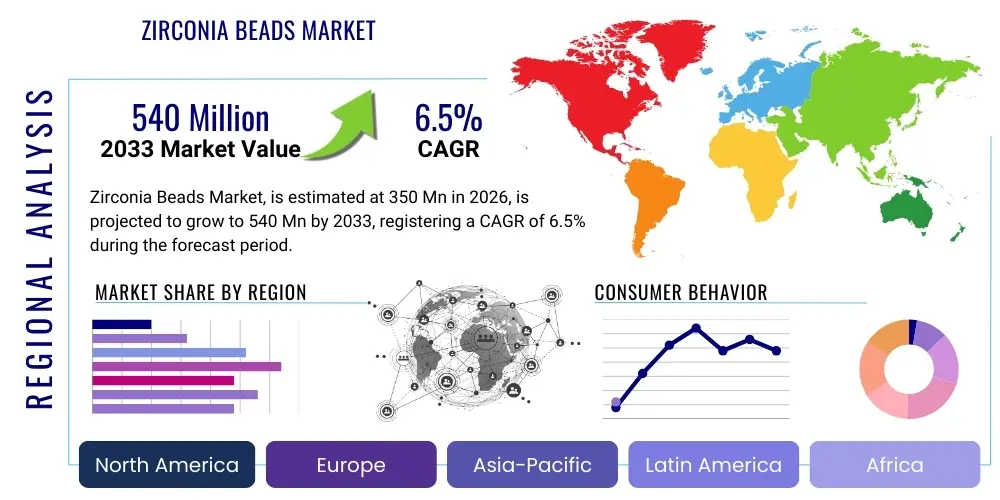

The Zirconia Beads Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 350 Million in 2026 and is projected to reach USD 540 Million by the end of the forecast period in 2033. This significant expansion is primarily attributed to the escalating demand for ultra-fine grinding and dispersion media across highly specialized industries such as advanced ceramics, pharmaceuticals, and next-generation electronics manufacturing. The superior performance characteristics of zirconia beads, including exceptional hardness, high density, and minimal contamination risk, position them as indispensable components in achieving particle size reduction below the sub-micron level, a critical requirement in modern material processing.

The valuation trajectory reflects a paradigm shift in industrial processing where efficiency and material purity are paramount. Global efforts toward miniaturization in electronic components and the stringent quality standards in pharmaceutical formulations necessitate milling media that can withstand intense mechanical stress while preventing abrasive wear and material loss. Geographically, the market expansion is heavily correlated with industrialization trends in the Asia Pacific region, particularly China and India, where manufacturing capacities for paints, coatings, and specialized technical ceramics are rapidly increasing. Furthermore, sustained investment in lithium-ion battery technology, requiring high-purity cathode and anode material preparation, serves as a powerful underlying growth vector for high-quality zirconia bead consumption through 2033.

Zirconia Beads Market introduction

The Zirconia Beads Market encompasses the production, distribution, and consumption of spherical grinding and milling media predominantly composed of Zirconium Dioxide (ZrO2). These advanced ceramic beads are characterized by their remarkable chemical inertness, high fracture toughness, and superior abrasion resistance, making them ideal for high-energy milling processes where conventional steel or glass media fail. They are specifically engineered to efficiently disperse and grind challenging materials, including high-viscosity pastes, mineral ores, highly saturated pigments, and complex chemical compounds, ensuring homogeneous mixtures and ultra-fine particle size distribution. The market offers various types of zirconia beads, differentiated primarily by their stabilizing agents, such as Yttria-Stabilized Zirconia (Y-TZP) and Ceria-Stabilized Zirconia (Ce-TZP), which tailor their mechanical properties for specific application environments.

Major applications of zirconia beads span numerous industrial verticals, fundamentally driving enhanced product quality and manufacturing throughput. In the paints and coatings industry, they facilitate the efficient dispersion of pigments and fillers, resulting in brighter colors and improved consistency. The electronics sector relies on them for grinding specialized ceramic materials used in components like multilayer ceramic capacitors (MLCCs). Additionally, in the burgeoning life sciences segment, particularly pharmaceuticals and biotechnology, zirconia beads are essential for cell disruption and the ultra-fine milling of active pharmaceutical ingredients (APIs) to enhance bioavailability. These applications underscore the product's value proposition: providing mechanical energy transfer with minimal media wear and zero metallic contamination, thus protecting the integrity and purity of the end-product.

The driving factors underpinning market growth are intrinsically linked to technological advancements requiring increasingly fine materials. The global shift toward nanotechnology, where particle size control is critical for material performance, elevates the demand for high-performance milling media. Benefits realized by end-users include reduced milling time, lower energy consumption due to high density, and extended lifespan of milling equipment components. Furthermore, stringent regulatory requirements in sectors like food and pharmaceuticals regarding product purity further accelerate the adoption of contamination-free zirconia beads over metallic alternatives. The ongoing research and development focusing on developing smaller diameter beads (below 0.1 mm) also expand their applicability in highly specialized niche areas, propelling market expansion.

Zirconia Beads Market Executive Summary

The Zirconia Beads Market is poised for substantial growth, driven by key macro-economic and industrial trends focused on high-efficiency processing and material purity. Business trends indicate a movement toward vertical integration among key manufacturers, aimed at securing raw material supplies (zircon sand) and maintaining stringent quality control over the complex manufacturing processes, such as sintering and spheronization. Strategic mergers and acquisitions are observed as companies seek to consolidate technological expertise, particularly in advanced stabilization techniques and small-diameter bead manufacturing. Furthermore, significant capital expenditure is being directed toward expanding production capacity in high-growth regions, catering to the burgeoning demand from electric vehicle battery component suppliers and advanced material researchers, thereby shaping the competitive landscape toward innovation and scalability.

Regional trends highlight the Asia Pacific (APAC) region’s undisputed dominance, fueled by its robust manufacturing base for electronics, automotive components, and industrial coatings. Rapid urbanization, coupled with governmental support for advanced manufacturing initiatives in countries like China, South Korea, and Japan, positions APAC as the primary revenue generator and growth engine. North America and Europe, while mature markets, continue to offer stable demand, largely driven by specialized applications in high-end aerospace coatings and pharmaceutical production, emphasizing premium, high-cost, customized zirconia media. Emerging markets in Latin America and the Middle East show potential, linked to infrastructure projects and expanding mineral processing operations, though their cumulative market share remains comparatively smaller, requiring targeted distribution strategies.

Segment trends reveal that the Yttria-Stabilized Zirconia (Y-TZP) segment maintains the largest market share due to its superior mechanical strength, fracture toughness, and universal applicability across demanding milling scenarios. However, specialized segments like Ceria-Stabilized Zirconia (Ce-TZP) are gaining traction in specific applications requiring exceptionally high density for ultra-high-energy milling of challenging materials. Application-wise, the paints, inks, and coatings segment remains the largest consumer, but the fastest growth trajectory is observed within the electronics and battery materials segment, reflecting the massive global pivot towards electrification and digitalization. Manufacturers are therefore prioritizing R&D efforts aimed at optimizing bead geometry and surface chemistry to meet the increasingly narrow tolerance requirements of these high-growth sectors, ensuring high throughput and minimal material wastage.

AI Impact Analysis on Zirconia Beads Market

Common user inquiries regarding the impact of Artificial Intelligence (AI) on the Zirconia Beads Market frequently center on themes of manufacturing efficiency, material optimization, and quality assurance. Users are keen to understand how AI-driven predictive maintenance can reduce costly downtime associated with ball mills and dispersion equipment, often inquiring about AI’s role in forecasting media wear rates based on operational parameters like speed, temperature, and slurry viscosity. Another critical concern revolves around AI's ability to accelerate R&D for novel zirconia formulations, particularly how machine learning algorithms can analyze complex material synthesis data to predict optimal stabilizing agent ratios or sintering profiles, thereby minimizing empirical trial-and-error and speeding up time-to-market for specialized beads.

Furthermore, significant user interest focuses on AI’s deployment in automated quality control. Traditional inspection methods for zirconia beads rely on visual checks or limited statistical sampling for size and sphericity. Users expect AI vision systems and deep learning models to perform 100% inspection, identifying surface defects, irregularities, and dimensional inconsistencies with greater accuracy and speed than human operators. This implementation promises to drastically elevate the average quality standard of marketed beads, crucial for sensitive applications like biomedical milling, where even minor defects can lead to contamination or inefficient grinding. The integration of AI tools is moving beyond simple data logging toward prescriptive analytics, offering manufacturers actionable insights to refine the complex ceramic processing steps.

The overarching expectation is that AI integration will fundamentally transform the operational expenditure model of zirconia bead manufacturing. By optimizing energy consumption in high-temperature sintering furnaces through real-time process control and reducing material waste by minimizing defect rates, AI provides a pathway to cost competitiveness. Ultimately, the technology acts as an enabler for mass customization, allowing manufacturers to rapidly adjust production parameters to meet bespoke customer requirements related to density, diameter tolerance, and surface roughness, effectively improving supply chain responsiveness and customer satisfaction across the highly demanding end-user industries.

- AI-driven predictive maintenance optimizes milling equipment performance, reducing unplanned downtime and enhancing operational lifespan.

- Machine learning accelerates the discovery and optimization of new zirconia formulations, particularly stabilizing agents and sintering parameters.

- Automated quality control systems using AI vision inspect bead sphericity, size distribution, and surface defects with high precision, minimizing manufacturing inconsistencies.

- AI optimizes energy usage in high-temperature sintering processes, contributing to lower production costs and improved sustainability metrics.

- Supply chain risk modeling using AI enhances resilience against raw material volatility (zircon sand) and logistical disruptions.

DRO & Impact Forces Of Zirconia Beads Market

The market for Zirconia Beads is significantly influenced by a powerful combination of drivers, restraints, and strategic opportunities that collectively dictate its growth trajectory and competitive dynamics. The primary driver is the accelerating global adoption of nanotechnology and advanced materials, which necessitates precision grinding to achieve particle sizes in the nanometer range, achievable only with the high density and minimal attrition characteristics of zirconia beads. Simultaneously, the massive global push toward electric vehicles (EVs) drives intense demand from the lithium-ion battery sector, where zirconia media is essential for preparing high-purity, uniform electrode slurries. These technological pull factors create a sustained high-demand environment, compelling manufacturers to increase capacity and focus on quality control.

However, the market faces notable restraints, chiefly the relatively high initial capital expenditure required for sophisticated milling equipment designed to utilize high-density ceramic media, making adoption challenging for smaller enterprises. Furthermore, the volatility in the pricing and supply chain of key raw materials, primarily high-grade zircon sand, presents a persistent challenge that can impact production costs and lead times. The manufacturing process itself is energy-intensive, particularly the high-temperature sintering stage, which introduces operational costs and environmental regulatory pressures. Comparatively cheaper alternatives, such as glass or lesser-grade ceramic beads, although less efficient, still serve as a competitive restraint in price-sensitive application areas, requiring manufacturers to continuously emphasize the superior total cost of ownership (TCO) associated with zirconia.

The major opportunities in the market lie in advanced material innovation and geographical expansion. Research into developing ultra-small diameter beads (e.g., below 50 microns) opens new avenues in fields like quantum dots and specialized drug delivery systems. The growing focus on sustainability presents an opportunity for developing closed-loop manufacturing processes and exploring the viability of recycling spent zirconia media, reducing reliance on virgin raw materials. The immense, untapped potential in emerging economies for infrastructural and industrial development provides fertile ground for market penetration, requiring localized manufacturing and distribution partnerships. The combined influence of these factors—high-tech drivers, inherent cost restraints, and innovation-led opportunities—shapes the market's dynamic impact forces.

Segmentation Analysis

The Zirconia Beads Market is systematically segmented based on composition (stabilizer type), bead size, and application, allowing for targeted product development and focused marketing strategies. Compositional segmentation is crucial as it determines the physical and mechanical properties of the media, directly influencing suitability for high-stress or high-purity grinding tasks. Bead size segmentation, ranging from macro to nano dimensions, reflects the required fineness of the finished product, with ultra-fine beads dominating the high-value segments like electronics and advanced pharmaceuticals. Application segmentation demonstrates the market's wide industrial footprint, showcasing the reliance of industries such as coatings, agrochemicals, and metallurgy on these specialized milling tools, thereby guiding investment in capacity tailored to regional industrial profiles.

- By Type/Composition:

- Yttria Stabilized Zirconia (Y-TZP) Beads

- Ceria Stabilized Zirconia (Ce-TZP) Beads

- Zirconium Silicate Beads

- Magnesia Stabilized Zirconia (Mg-PSZ) Beads

- By Size:

- Small Diameter (0.05 mm – 0.8 mm)

- Medium Diameter (0.8 mm – 2.0 mm)

- Large Diameter (2.0 mm and above)

- By Application:

- Paints, Inks, and Coatings

- Electronics and Battery Materials

- Agrochemicals and Fertilizers

- Pharmaceuticals and Life Sciences

- Mining and Mineral Processing

- Specialty Ceramics and Advanced Materials

Value Chain Analysis For Zirconia Beads Market

The value chain for Zirconia Beads begins with the upstream procurement of high-purity raw materials, predominantly zircon sand, which must undergo rigorous processing to extract zirconium dioxide. This critical initial stage dictates the purity and eventual cost structure of the end product. Key activities in the upstream segment involve mining, beneficiation, and chemical processing to achieve the required fineness and purity levels necessary for ceramic synthesis. Manufacturers must establish stable, long-term relationships with zircon suppliers, often located in geographically concentrated areas, to mitigate supply chain risks. The quality of these precursor materials directly influences the performance characteristics (e.g., density, hardness) of the final bead product, necessitating strict inbound quality checks and sophisticated inventory management.

The midstream involves the highly technical manufacturing process, including particle preparation (often through sol-gel or chemical co-precipitation), spheronization, and high-temperature sintering, typically involving temperatures exceeding 1,400°C. This phase is capital-intensive and requires specialized expertise in ceramic engineering to control parameters like particle size distribution and stabilizing agent concentration to ensure uniformity and desired mechanical properties. Advanced quality assurance checks, utilizing technologies like image analysis and density meters, are integral to maintaining product specifications. Downstream activities involve distribution channels, which are specialized given the industrial nature of the product. Direct sales channels are common for large volume, customized orders to major end-users (e.g., large coating manufacturers or battery producers), allowing for technical consultation and tailored logistics.

Indirect distribution, involving specialized chemical distributors or industrial suppliers, caters to smaller customers or niche markets. Effective downstream logistics require robust packaging to prevent chipping and damage during transit, ensuring the precision spherical geometry is maintained until delivery. Potential customers, including contract manufacturers and formulation specialists, often rely heavily on distributor expertise regarding media selection and optimal milling parameters. The value chain is constantly under pressure to enhance efficiency through technological adoption, particularly in sintering, and to streamline logistics to ensure rapid delivery, especially in sectors with just-in-time manufacturing models like automotive coatings and electronics component fabrication.

Zirconia Beads Market Potential Customers

Potential customers for high-performance zirconia beads are concentrated in industries that mandate precise particle size reduction, high material purity, and operational efficiency, making them the primary buyers (end-users) of the product. The largest consumer base resides within the paint, coatings, and ink sector, where manufacturers require highly efficient media to disperse complex organic and inorganic pigments, resulting in high-gloss, stable formulations for automotive, architectural, and industrial applications. These customers prioritize high wear resistance and consistent bead sphericity to maximize mill throughput and minimize contamination risks, viewing zirconia beads as a critical consumable asset that enhances the quality and shelf-life of their final product offerings.

Another rapidly expanding segment of critical potential customers originates from the advanced materials and electronics industry, specifically companies involved in the production of lithium-ion battery components, particularly cathode and anode materials. The preparation of these electrode slurries demands extremely homogeneous mixing and precise particle morphology control to ensure optimal electrochemical performance and energy density. These buyers often require ultra-small diameter (sub-micron) zirconia beads, prioritizing purity (zero metallic contamination) above all else. Similarly, manufacturers of advanced technical ceramics, used in aerospace and medical devices, are high-value customers due to their stringent quality requirements and demand for media capable of grinding extremely hard, non-metallic precursors.

Furthermore, the pharmaceutical and biotechnology sectors represent highly attractive, albeit regulated, customer bases. Companies involved in manufacturing Active Pharmaceutical Ingredients (APIs) often employ wet milling using zirconia beads to achieve nanosized drug particles, enhancing dissolution rates and bioavailability—a process known as nanonization. Agrochemical companies, producing specialized pesticides and herbicides in suspension concentrate (SC) formulations, also rely heavily on zirconia media for stable dispersion. These customers demand consistent lot-to-lot quality and often require documentation proving compliance with health and safety standards, solidifying the market’s reliance on certified, high-quality bead suppliers for mission-critical applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350 Million |

| Market Forecast in 2033 | USD 540 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | TOSOH Corporation, Saint-Gobain, Toray Industries, Kemet, Dantsin Technology, Innovnano, Union Process Inc., Zircoa, Cumi Abrasives and Refractories, Shandong Zibo HITECH New Materials Co., Ltd., Wenzhou Yongsheng Grinding Materials Co., Ltd., Metoxit AG, Industrial Tectonics Inc. (ITI), King’s Ceramics and Chemicals, SpheriTech, Noritake Co. Ltd., Nanjing Tianshi New Material Technologies Co., Ltd., Washington Mills, S.E.A.M. Srl, Magspray. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Zirconia Beads Market Key Technology Landscape

The technological landscape of the Zirconia Beads Market is defined by continuous innovation aimed at improving homogeneity, sphericity, mechanical durability, and reducing particle size variance, all critical factors for high-performance milling. A key area of technological development is in synthesis methods. While traditional methods involve high-temperature fusion and crushing, advanced techniques like the Sol-Gel process and Hydrothermal Synthesis are increasingly utilized. Sol-Gel provides superior control over particle size and morphology at the nano level, resulting in beads with higher purity and greater mechanical strength compared to sintered methods. This precision is essential for producing the highly uniform, defect-free media demanded by the electronics and pharmaceutical industries. Manufacturers are investing heavily in process automation and inert atmosphere processing to minimize impurities and enhance yield, ensuring consistency across large production batches.

Another vital aspect of the technology landscape is the development and optimization of stabilizing agents. Yttria-Stabilized Zirconia (Y-TZP) remains the industry benchmark due to its excellent combination of strength and toughness, preventing the phase transformation from tetragonal to monoclinic structure under stress, which would otherwise lead to failure. However, research is progressing on alternative stabilizing systems, such as Ceria (Ce-TZP) and Magnesia (Mg-PSZ), designed for specialized, extremely high-density or high-temperature applications. These advancements require sophisticated material characterization tools, including X-ray Diffraction (XRD) and Scanning Electron Microscopy (SEM), to rigorously test crystal structure, microhardness, and wear resistance, confirming that the new formulations meet stringent performance requirements under intense milling conditions, thereby justifying their higher cost.

Furthermore, technology focused on post-synthesis processing and quality control is rapidly evolving. Techniques such as proprietary surface treatments are being deployed to enhance the smoothness and chemical inertness of the beads, minimizing adhesion of milled material and improving cleanability, which is crucial in regulated industries. The integration of advanced computational modeling, including Finite Element Analysis (FEA), is utilized to simulate stress distribution within the mill, optimizing the bead size and material choice for specific mill geometries and processing environments. This combination of advanced synthesis, stabilization R&D, and rigorous quality assurance technologies forms the backbone of the modern zirconia bead manufacturing sector, enabling the creation of media capable of grinding materials to previously unattainable levels of fineness efficiently and reliably.

Regional Highlights

- Asia Pacific (APAC): Dominance and High Growth: APAC commands the largest market share globally and is anticipated to exhibit the fastest growth rate throughout the forecast period. This is primarily driven by the region's immense manufacturing base, especially in China, South Korea, and Japan, which dominate the production of lithium-ion batteries, consumer electronics, and automotive coatings. Significant governmental support for advanced manufacturing and rapid industrialization in emerging nations further cement APAC’s position as the core consumer and exporter of milled materials, requiring substantial quantities of high-quality zirconia media.

- North America: Technological Sophistication and Niche Demand: The North American market is characterized by high demand for specialized, high-performance zirconia beads, particularly in pharmaceutical nanonization, advanced aerospace coatings, and high-tech defense applications. While the market volume is lower than APAC, the focus is on premium, custom-engineered products and cutting-edge R&D applications. Stringent regulatory environments necessitate high-purity media, driving demand for top-tier Y-TZP products and supporting innovation in bead technology.

- Europe: Mature Market with Environmental Focus: Europe is a mature market, exhibiting steady demand driven by the established automotive industry, high-end printing inks, and specialty chemicals sector. European consumers place a strong emphasis on sustainability and energy efficiency, leading to increased adoption of zirconia beads to optimize milling processes and reduce energy consumption. Strict REACH regulations influence material sourcing and manufacturing, encouraging local producers to prioritize eco-friendly and compliant production methods.

- Latin America (LATAM): Growth Potential in Mineral Processing: The LATAM market, while currently small, presents substantial growth potential linked to expansion in mineral processing, mining, and paints and coatings industries, particularly in Brazil and Mexico. The adoption of high-performance media is gradually increasing as local industries modernize their grinding and dispersion techniques, moving away from conventional, lower-efficiency media to enhance productivity and final product quality.

- Middle East and Africa (MEA): Emerging Industrial Demand: The MEA region’s demand is primarily driven by infrastructure development, petroleum-based coatings, and emerging local manufacturing hubs. The reliance on imported goods is high, but ongoing economic diversification efforts are expected to boost the consumption of zirconia beads, particularly in industrial coatings and specialized chemicals necessary for construction and oil & gas applications, requiring robust, wear-resistant media.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Zirconia Beads Market.- TOSOH Corporation

- Saint-Gobain

- Toray Industries

- Kemet International Ltd.

- Dantsin Technology Co., Ltd.

- Innovnano - Advanced Materials, S.A.

- Union Process Inc.

- Zircoa Inc.

- Cumi Abrasives and Refractories Ltd.

- Shandong Zibo HITECH New Materials Co., Ltd.

- Wenzhou Yongsheng Grinding Materials Co., Ltd.

- Metoxit AG

- Industrial Tectonics Inc. (ITI)

- King’s Ceramics and Chemicals

- SpheriTech Private Limited

- Noritake Co. Ltd.

- Nanjing Tianshi New Material Technologies Co., Ltd.

- Washington Mills Electro Minerals Corp.

- S.E.A.M. Srl

- Magspray Technology Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Zirconia Beads market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for Zirconia Beads in the current market?

The primary factor driving demand is the global need for ultra-fine particle size reduction, particularly within the electronics (e.g., MLCCs, battery materials) and pharmaceutical sectors. Zirconia beads' superior density and high wear resistance enable efficient nanonization and pure material processing, crucial for high-performance end-products.

How do Yttria-Stabilized Zirconia (Y-TZP) beads differ from other types?

Y-TZP beads are stabilized with Yttria, providing exceptional mechanical strength, fracture toughness, and resistance to phase transformation under mechanical stress. This makes them highly suitable for high-energy, continuous grinding operations where longevity and minimal media wear are paramount, differentiating them from less tough types like Zirconium Silicate.

Which geographical region holds the largest market share for Zirconia Beads and why?

The Asia Pacific (APAC) region holds the largest market share. This dominance is due to the massive scale of manufacturing in key industries such as automotive coatings, consumer electronics, and especially lithium-ion battery production concentrated in countries like China, South Korea, and Japan, fueling high consumption volume.

What are the main drawbacks or restraints affecting the Zirconia Beads Market?

The main restraints include the high initial cost of zirconia beads compared to conventional media, and the significant capital expenditure required for specialized, high-energy milling equipment. Additionally, volatility in the supply and pricing of the raw material, high-purity zircon sand, poses a persistent challenge to stable production costs.

What role does Artificial Intelligence (AI) play in the manufacturing of Zirconia Beads?

AI is increasingly used to optimize manufacturing efficiency by controlling complex sintering processes, reducing energy consumption, and implementing advanced predictive maintenance for milling equipment. Furthermore, AI vision systems enhance quality control by performing rapid, precise inspection of bead sphericity and defect detection.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager