Exam Gloves Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438790 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Exam Gloves Market Size

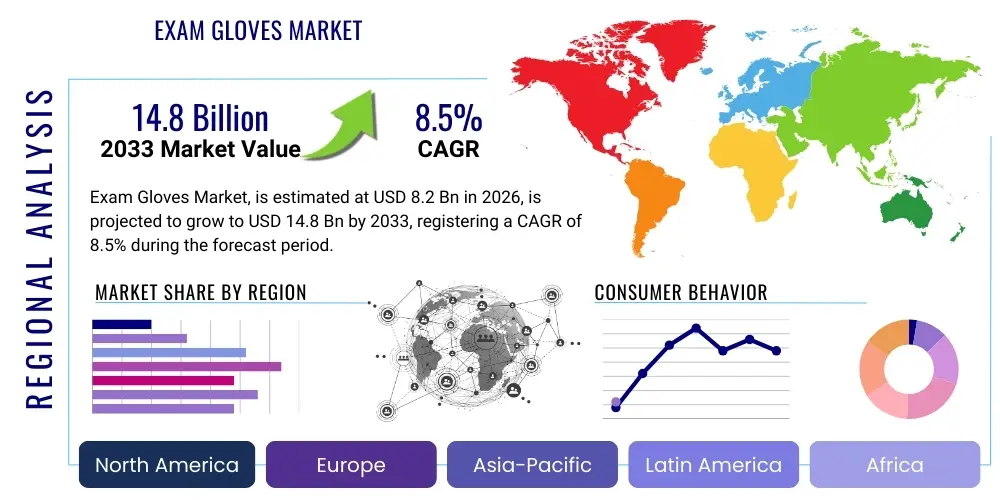

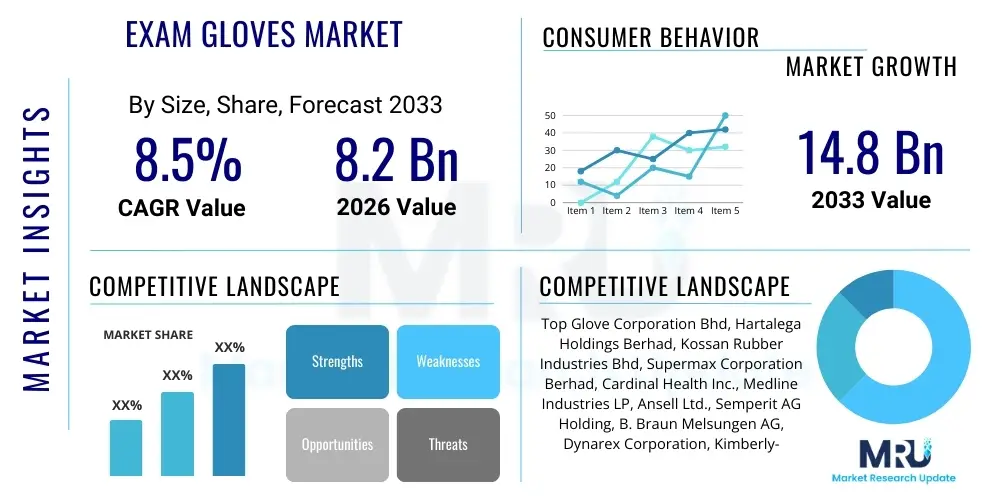

The Exam Gloves Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 8.2 Billion in 2026 and is projected to reach USD 14.8 Billion by the end of the forecast period in 2033. This robust growth trajectory is primarily driven by the consistent expansion of the global healthcare infrastructure, heightened awareness regarding infection control protocols, and the rapid shift towards safer, synthetic glove materials, particularly nitrile. The market’s resilience is rooted in the non-discretionary nature of its product, which is essential across numerous medical and non-medical settings, ensuring sustained demand irrespective of economic cycles.

Exam Gloves Market introduction

The Exam Gloves Market encompasses disposable protective barriers designed for single use during medical examinations and procedures to prevent cross-contamination between caregivers and patients. These essential medical devices are categorized primarily by material—Latex, Nitrile, and Vinyl—each offering distinct advantages in terms of barrier protection, tactile sensitivity, and resistance to chemical permeation. Nitrile gloves, known for their superior puncture resistance and hypoallergenic properties, have rapidly dominated the market, largely replacing traditional latex variants in many clinical environments due to increasing latex allergy prevalence among healthcare professionals and patients. The fundamental purpose of these gloves is two-fold: ensuring occupational safety for medical personnel and maintaining sterile or clean conditions for patient care, thereby upholding stringent public health standards.

Major applications of exam gloves span the entire spectrum of the healthcare ecosystem, including hospitals, ambulatory surgical centers (ASCs), diagnostic laboratories, dental clinics, and long-term care facilities. Beyond clinical settings, they are increasingly utilized in pharmaceutical manufacturing, food processing, and cleaning industries, highlighting their versatility as a general-purpose contamination barrier. The inherent benefits derived from the widespread use of exam gloves include a significant reduction in Hospital-Acquired Infections (HAIs), improved adherence to global hygiene guidelines, and enhanced protection against exposure to biological fluids and hazardous chemicals. This indispensable role cements their status as a critical consumable product within the medical supply chain, driving continuous demand growth globally.

Driving factors propelling the Exam Gloves Market include the escalating global geriatric population, which necessitates increased frequency of medical intervention and care; the rising incidence of infectious diseases, demanding strict barrier controls; and stringent governmental regulations and guidelines concerning personal protective equipment (PPE) usage, particularly in response to recent global pandemics. Furthermore, technological advancements leading to improved glove characteristics, such as enhanced dexterity, grip texture, and biodegradable options, contribute to market expansion and user acceptance. The sustained investment in healthcare infrastructure development, especially in emerging economies, further reinforces the market’s positive outlook, ensuring a stable environment for manufacturers and distributors alike.

Exam Gloves Market Executive Summary

The global Exam Gloves Market is defined by intense competition, rapid material innovation, and significant supply chain volatility observed over the recent past. Business trends indicate a strategic shift by leading manufacturers toward vertical integration, ensuring better control over raw material procurement—specifically butadiene and acrylonitrile for nitrile production—and mitigating risks associated with external geopolitical or logistics disruptions. Sustainability is emerging as a critical trend, with increasing research and development focused on biodegradable and recyclable glove alternatives to address the massive waste generated by single-use PPE. Furthermore, market players are actively investing in advanced manufacturing automation to increase production capacity and improve quality consistency while managing rising labor costs, particularly in major manufacturing hubs across Asia Pacific.

Regional trends clearly demarcate North America as the most dominant market in terms of revenue, driven by high per capita healthcare spending, widespread adoption of rigorous infection prevention protocols, and the mandatory use of high-quality synthetic gloves in clinical settings. Conversely, the Asia Pacific region is anticipated to exhibit the highest Compound Annual Growth Rate (CAGR), fueled by expanding public and private healthcare investments, population growth, and the concentration of the world’s largest manufacturing base (e.g., Malaysia, Thailand, China). European markets prioritize regulatory compliance and high-performance standards, exhibiting strong demand for premium, powder-free nitrile gloves, while Latin America and MEA represent burgeoning opportunities, primarily driven by governmental initiatives aimed at improving primary healthcare access and reducing communicable disease transmission.

Segmentation trends highlight the overwhelming preference for the Nitrile segment, which commands the largest market share and is expected to grow the fastest, attributed to its superior protection profile and mitigation of Type I hypersensitivity reactions linked to natural rubber latex. The powder-free segment is now the industry standard across developed economies, driven by safety concerns associated with the aerosolization of cornstarch powder and its potential to transfer allergens. Hospitals and Surgical Centers remain the primary end-user segment, although the non-healthcare sector, particularly food service and industrial safety, is exhibiting accelerated growth, creating diverse revenue streams for market participants. Strategic partnerships between large distributors and Group Purchasing Organizations (GPOs) are defining the commercial landscape, optimizing procurement efficiency and stabilizing pricing for high-volume customers.

AI Impact Analysis on Exam Gloves Market

User queries regarding the integration of Artificial Intelligence (AI) in the Exam Gloves Market typically revolve around operational efficiency, quality assurance, and predictive supply chain management, rather than the product itself being enhanced by AI. Key concerns center on how manufacturers can utilize AI-driven analytics to better forecast demand spikes (especially post-pandemic), optimize production scheduling to handle varying nitrile feedstock prices, and ensure automated quality control checks to meet stringent regulatory standards without human bias or error. Users also frequently inquire about AI’s role in automating inventory management within large hospital systems and GPOs, seeking to minimize stockouts while reducing overall warehousing costs. The consensus expectation is that AI will not fundamentally change the glove material or function, but it will revolutionize the manufacturing process, logistics, and distribution efficiency, making the supply chain more robust and responsive to global health crises.

The implementation of AI and Machine Learning (ML) algorithms is set to significantly transform the manufacturing core of the exam gloves industry. Predictive maintenance models, fueled by sensor data from dipping lines, are being deployed to anticipate equipment failure, minimizing costly downtime and improving overall yield. Furthermore, sophisticated image recognition AI is used for automated quality inspection, instantaneously identifying micro-holes, tears, or inconsistencies in glove thickness at high speeds, ensuring only flawless products enter the packaging phase. This level of automated precision surpasses traditional manual inspection methods, leading to higher consistency and reduced liability risks for manufacturers. AI’s ability to analyze massive datasets related to raw material costs, energy consumption, and logistical routes provides manufacturers with crucial insights for operational optimization and competitive pricing strategies, ultimately fostering a more efficient and less wasteful production ecosystem.

Beyond the factory floor, AI is instrumental in streamlining the complex global supply chain associated with exam gloves, which often involves cross-continental shipping and intricate regulatory compliance. AI-powered demand forecasting tools analyze historical consumption data, seasonal health trends, and even real-time news related to infectious disease outbreaks to generate highly accurate demand predictions. This capability allows distributors and healthcare providers to maintain optimal inventory levels, effectively preventing the devastating shortages experienced during the early stages of recent pandemics. Moreover, AI aids in simulating optimal warehouse locations and distribution routes, minimizing transportation costs and reducing the carbon footprint associated with global distribution, thereby addressing sustainability goals increasingly prioritized by major purchasers, including governmental health agencies.

- AI-driven predictive demand forecasting enhances supply chain resilience against unforeseen global health events.

- Machine learning optimizes dipping line parameters, reducing material waste and improving manufacturing yield.

- Computer vision systems automate quality control, identifying defects (pinholes, thickness variation) instantly and accurately.

- AI algorithms assist in optimizing inventory levels for hospitals and distributors, preventing stockouts and excess inventory costs.

- Advanced analytics provide real-time insights into raw material price fluctuations (e.g., nitrile input costs) for strategic purchasing.

- Automation and robotics guided by AI reduce human interaction in sterile packaging, further minimizing contamination risks.

DRO & Impact Forces Of Exam Gloves Market

The Exam Gloves Market dynamics are powerfully influenced by a combination of inherent drivers, structural restraints, and emerging opportunities, collectively shaping the direction and pace of market evolution. The primary drivers include the universally growing need for personal protection in clinical and non-clinical environments, spurred by heightened awareness of infection prevention protocols and mandatory regulatory mandates across developed nations. The continuous global threat of viral outbreaks, coupled with the expansion of the aging population requiring frequent medical care, ensures a persistently high baseline demand for disposable barriers. These factors create strong inertial forces, making exam gloves an inelastic commodity within the healthcare sector, sustaining growth even during economic downturns, solidifying the market's stability and future potential.

Conversely, the market faces significant restraints, most notably the high volatility and upward trend in raw material prices, particularly for synthetic rubber components like acrylonitrile and butadiene used in nitrile glove manufacturing. This dependency on petrochemical derivatives exposes manufacturers to fluctuating energy and crude oil costs, compressing profit margins and necessitating complex hedging strategies. Furthermore, the immense environmental impact of billions of non-biodegradable, single-use gloves poses a substantial long-term challenge and restraint, urging regulators and consumers toward sustainable alternatives that are currently more expensive or less performance-optimized. This creates a difficult trade-off between cost-efficiency, performance, and environmental responsibility that market players must navigate carefully.

Opportunities for market growth are prominently found in geographical expansion into underserved markets, especially in emerging economies in Asia, Latin America, and Africa, where healthcare infrastructure investment is accelerating, leading to improved access to professional medical services and resulting institutional adoption of proper barrier protocols. Technological opportunities exist in the development of next-generation materials, such as hybrid thermoplastic elastomers (TPEs) or advanced biodegradable polymers, which could maintain the performance characteristics of nitrile while addressing environmental concerns. Furthermore, strategic market segmentation focusing on highly specialized applications—such as chemotherapy-rated gloves or fentanyl-resistant gloves—allows manufacturers to capture premium pricing segments and diversify beyond general-purpose examination use. The combined effect of these forces suggests a dynamic market that is growing robustly but requires constant adaptation to supply chain challenges and evolving environmental standards.

Segmentation Analysis

The Exam Gloves Market is comprehensively segmented based on material type, powder status, end-use vertical, and distribution channel, providing a granular view of demand patterns and strategic market positioning. The material segmentation remains the most pivotal, determining performance, cost structure, and target end-user suitability. Nitrile continues to lead this segmentation due to its superior chemical resistance, puncture strength, and non-allergenic profile, increasingly mandated in clinical environments. The segmentation by end-use confirms hospitals and surgical centers as the primary consumers, although the rapid growth in ambulatory care centers and home healthcare services is diversifying the consumption landscape and necessitating new distribution models optimized for smaller, decentralized ordering patterns.

Segmentation by powder status, distinguishing between powdered and powder-free gloves, has seen the powder-free segment become dominant globally, driven by clinical safety requirements and regulatory bans imposed in major markets like the US, intended to mitigate the risks associated with powder residue causing respiratory issues and potential latex sensitization. Analyzing distribution channels highlights the crucial role played by Group Purchasing Organizations (GPOs) and large regional distributors in bulk procurement for institutional buyers, while online retail channels are increasingly important for small businesses, dental practices, and individual consumers, especially post-pandemic. Understanding these distinct segments is essential for manufacturers to tailor product formulations, pricing strategies, and supply chain logistics effectively to specific customer needs and regulatory environments across different geographic regions.

- By Material Type:

- Nitrile

- Latex (Natural Rubber)

- Vinyl (PVC)

- Polyisoprene

- By Powder Status:

- Powdered

- Powder-Free

- By End-Use Vertical:

- Hospitals and Clinics

- Ambulatory Surgical Centers (ASCs)

- Diagnostic and Clinical Laboratories

- Dental Clinics

- Long-Term Care Facilities (LTCF)

- Non-Healthcare (Food Service, Industrial, Cleanroom)

- By Distribution Channel:

- Direct Sales

- Distributors and Wholesalers

- E-commerce and Online Channels

- Group Purchasing Organizations (GPOs)

Value Chain Analysis For Exam Gloves Market

The value chain for the Exam Gloves Market begins with the highly complex upstream analysis, focusing on the procurement of primary raw materials. For nitrile gloves, this involves securing consistent, high-quality supplies of petrochemical derivatives, namely butadiene and acrylonitrile, which are synthesized into Nitrile Butadiene Rubber (NBR) latex. Price stability in these upstream chemical markets is a major determinant of profitability for midstream manufacturers. Suppliers of NBR latex, predominantly concentrated in Asia, exert significant bargaining power. For natural rubber latex gloves, the upstream depends on global rubber plantations, making this segment susceptible to agricultural yields, climate change impacts, and commodity price fluctuations. Effective upstream management requires long-term supply contracts and strategic risk mitigation against raw material cost volatility, which necessitates significant capital investment in inventory management systems.

The midstream phase involves the sophisticated manufacturing and conversion process, where NBR or natural rubber latex is converted into finished gloves through dipping, leaching, curing, chlorination (for powder-free), and packaging. This stage is capital-intensive, requiring specialized, high-volume production lines and adherence to rigorous quality standards (e.g., AQL levels defined by regulatory bodies). Manufacturers focus on optimizing process efficiency, reducing pinhole defects, and standardizing chlorination techniques to ensure the final product meets international performance criteria, including tensile strength and barrier integrity. Direct and indirect distribution channels then move the product downstream. Direct channels involve manufacturers supplying large hospital groups or government entities through tender processes. Indirect channels heavily rely on specialized medical distributors, wholesalers, and crucially, Group Purchasing Organizations (GPOs), which aggregate demand from various healthcare providers to negotiate favorable long-term contracts and manage inventory logistics for their members efficiently.

Downstream analysis centers on reaching the diverse end-users, ensuring timely delivery, and managing the high volume of disposable inventory required daily in clinical settings. GPOs play a dominant role in North America and Europe, streamlining procurement for hospitals and integrated delivery networks (IDNs). Traditional medical distributors provide localized warehousing and just-in-time delivery services for smaller clinics and dental offices. E-commerce platforms are increasingly facilitating the purchase of gloves for non-healthcare uses (e.g., aesthetics, cleaning, tattoo parlors) and for smaller, independent practices, offering greater accessibility and competitive pricing. The efficiency of the downstream logistics, including customs clearance for globally sourced products and maintaining sterile warehousing conditions, is paramount to sustaining supply security and responsiveness across the entire value chain.

Exam Gloves Market Potential Customers

The primary customer base for the Exam Gloves Market is extensive and highly diversified, spanning all institutional settings requiring stringent infection control and barrier protection. The largest end-users are unequivocally within the professional healthcare sector, encompassing hospitals (both public and private), which utilize the highest volumes of specialty and general-purpose gloves for everything from surgical preparation to routine patient examinations. Ambulatory Surgical Centers (ASCs) and dedicated outpatient clinics represent a rapidly growing customer segment, reflecting the general shift of minor procedures and diagnostics away from inpatient hospital settings. These clinical buyers prioritize high-quality, high-dexterity powder-free nitrile gloves that meet specific clinical performance and allergy prevention criteria.

Beyond traditional acute care, crucial potential customers include long-term care facilities (LTCFs) and nursing homes, where continuous daily use is necessary for hygiene and elderly patient care, demanding durable, cost-effective options. Diagnostic and clinical laboratories constitute another significant segment, requiring specific resistance to various chemical reagents and cytotoxic materials, often necessitating chemotherapy-rated gloves. Furthermore, the burgeoning dental industry, driven by rising awareness of oral hygiene and preventative care, provides a stable, high-frequency customer base, predominantly consuming nitrile gloves tailored for enhanced tactile sensitivity needed for precise dental procedures.

In addition to the core healthcare segments, a growing group of potential customers originates from the non-healthcare sector, representing a major diversification opportunity. This includes the food processing and handling industry, regulated by stringent food safety standards; the pharmaceutical and biotechnology sector, requiring cleanroom-compatible gloves; and various industrial applications, such as manufacturing, automotive repair, and cleaning services, where chemical or biological barrier protection is necessary. The expansion of these non-medical uses—often driven by occupational safety regulations—ensures that market demand is broadened beyond purely medical expenditure, making the customer base robust against fluctuations in healthcare spending alone and guaranteeing continuous product uptake.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 8.2 Billion |

| Market Forecast in 2033 | USD 14.8 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Top Glove Corporation Bhd, Hartalega Holdings Berhad, Kossan Rubber Industries Bhd, Supermax Corporation Berhad, Cardinal Health Inc., Medline Industries LP, Ansell Ltd., Semperit AG Holding, B. Braun Melsungen AG, Dynarex Corporation, Kimberly-Clark Corporation, Unigloves, Molnlycke Health Care AB, Rubberex Corporation, SHIELD Scientific, Adventa Berhad, YTY Group, WRP Asia Pacific Sdn Bhd, Halyard Health (now part of Owens & Minor), Innova Latex. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Exam Gloves Market Key Technology Landscape

The core technology landscape in the Exam Gloves Market centers on optimizing the dipping, leaching, and chlorination processes to enhance product attributes and reduce manufacturing costs. A significant technological focus is placed on the precise control of the dipping process, utilizing advanced automation and robotics to ensure consistent film thickness across the glove, which directly correlates to barrier protection and tactile sensitivity. Innovations in former design and material composition are aimed at reducing the amount of raw material needed per glove without compromising the acceptable quality level (AQL) standards. Furthermore, manufacturers are increasingly implementing sophisticated online quality monitoring systems, utilizing non-destructive testing methods like high-speed air leak detection and AI-powered visual inspection to minimize defects and achieve low AQL rates, which is crucial for gaining large institutional contracts.

The shift towards nitrile necessitates continuous R&D in polymerization technology to create next-generation NBR compounds. Key technological advancements include developing low-modulus nitrile formulations that offer elasticity and comfort comparable to natural rubber latex while retaining superior puncture and chemical resistance. This is achieved through proprietary cross-linking agents and optimized compounding techniques. Another critical area is surface treatment technology: advanced chlorination and polymer coating processes are continually refined to achieve superior donning properties, reduced tackiness, and the complete elimination of residual chemicals, making the powder-free gloves highly comfortable and safe for extended use by healthcare professionals who may be prone to dermatitis. These innovations are vital for differentiating premium products in a highly commoditized market.

Looking ahead, the technological landscape is being shaped by sustainability demands. Significant investment is directed toward biodegradable polymer technology that can decompose more rapidly in industrial composting environments or landfills. While challenging due to the need for performance parity with nitrile, manufacturers are exploring bio-based synthetic components and incorporating specialized additives to accelerate decomposition rates without impacting the gloves' functional life or barrier integrity. Additionally, advancements in smart manufacturing—integrating IoT sensors across the entire production line to collect real-time data—are critical for implementing AI analysis, improving overall equipment effectiveness (OEE), and rapidly scaling production capacity in response to global events, thereby enhancing the technological maturity and responsiveness of the entire industry.

Regional Highlights

The analysis of the Exam Gloves Market across major geographies reveals distinct consumption patterns, regulatory environments, and manufacturing capabilities, crucial for strategic market penetration.

- North America (Dominant Market): This region, led by the United States, commands the largest share of the global exam gloves market revenue. The dominance is driven by high per capita healthcare expenditures, the mandatory implementation of stringent FDA and OSHA regulations requiring the use of high-quality synthetic gloves (especially powder-free nitrile) across nearly all clinical settings, and a high rate of adoption of advanced medical technologies and infection control protocols. The presence of major Group Purchasing Organizations (GPOs) facilitates high-volume, standardized procurement, emphasizing product consistency and contractual stability.

- Asia Pacific (Fastest Growing Market and Manufacturing Hub): APAC is characterized by being the epicenter of global glove manufacturing, with countries like Malaysia, Thailand, and China accounting for the vast majority of the world's supply capacity. Market growth within APAC itself is accelerating due to massive government investment in expanding public healthcare infrastructure, rising awareness about infectious disease management, and rapidly increasing patient volumes. While manufacturing efficiency keeps costs low, domestic consumption is shifting towards higher quality, imported or premium domestically produced synthetic gloves as regulatory standards rise.

- Europe (Strict Quality Standards and Sustainability Focus): European markets exhibit robust demand, characterized by a preference for certified, high-performance nitrile and non-latex alternatives, driven by EU regulations (MDR compliance) and strong worker safety standards. Countries like Germany and the UK maintain high procurement standards, often emphasizing sustainability credentials, leading to a strong demand for innovative, environmentally conscious glove solutions, even at a premium price point.

- Latin America (Emerging Market Potential): This region is exhibiting steady growth, fueled by efforts to modernize healthcare systems and increase access to primary care in countries like Brazil and Mexico. Demand is highly price-sensitive, leading to a mix of lower-cost vinyl and latex gloves, though regulatory pressure is gradually pushing institutions toward higher-performance synthetic materials, presenting significant long-term growth potential for nitrile manufacturers focusing on cost-effective scalability.

- Middle East and Africa (MEA) (Infrastructure Development): Growth in MEA is highly concentrated in the GCC nations, driven by substantial investment in state-of-the-art medical cities and stringent hygiene mandates. The rapid establishment of high-standard hospitals and clinics fuels demand for imported, high-quality exam gloves, while African nations represent a massive volume opportunity linked to humanitarian aid initiatives and improvements in public health access and disaster response capabilities, though logistics remain challenging.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Exam Gloves Market.- Top Glove Corporation Bhd

- Hartalega Holdings Berhad

- Kossan Rubber Industries Bhd

- Supermax Corporation Berhad

- Cardinal Health Inc.

- Medline Industries LP

- Ansell Ltd.

- Semperit AG Holding

- B. Braun Melsungen AG

- Dynarex Corporation

- Kimberly-Clark Corporation

- Unigloves

- Molnlycke Health Care AB

- Rubberex Corporation

- SHIELD Scientific

- Adventa Berhad

- YTY Group

- WRP Asia Pacific Sdn Bhd

- Halyard Health (now part of Owens & Minor)

- Innova Latex

Frequently Asked Questions

Analyze common user questions about the Exam Gloves market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is driving the shift from Latex to Nitrile gloves?

The primary driver is the increased awareness and incidence of Type I (immediate) hypersensitivity reactions associated with natural rubber latex proteins among healthcare workers and patients. Nitrile gloves offer a comparable fit and tactile sensitivity without the allergy risk, coupled with superior puncture resistance and chemical barrier protection, making them the standard choice for professional clinical environments globally.

How do global supply chain issues affect the pricing of Exam Gloves?

Global supply chain volatility significantly impacts pricing because the core raw material for nitrile gloves, Nitrile Butadiene Rubber (NBR) latex, is synthesized from petroleum derivatives (butadiene and acrylonitrile). Disruptions in petrochemical production, logistics bottlenecks (shipping costs), and geopolitical events directly influence feedstock prices, leading to fluctuations in manufacturing costs and final product pricing for distributors and end-users.

What role does the environment play in the future of the Exam Gloves Market?

Environmental concerns are a critical factor, driving innovation towards sustainability. Traditional single-use gloves contribute substantially to plastic waste in landfills. Future market growth relies heavily on the technological success and mass production of biodegradable, compostable, or recyclable glove alternatives that meet rigorous performance standards required for medical use, driven by increasing regulatory and consumer pressure for greener PPE solutions.

Which regulatory standards are most important for Exam Gloves in key markets?

In North America, the FDA (Food and Drug Administration) regulates medical gloves, requiring adherence to established standards for barrier integrity (AQL) and labeling. In Europe, the Medical Device Regulation (MDR) is paramount, necessitating comprehensive technical documentation and CE marking. These standards ensure product safety, performance, and legal compliance, heavily influencing product design and manufacturing quality control across global supply chains.

What are the fastest-growing end-use sectors for Exam Gloves?

While hospitals remain the largest consumer, the fastest-growing sectors include Ambulatory Surgical Centers (ASCs), diagnostic and specialized clinical laboratories (due to increased testing volume), and the long-term care facilities market. Additionally, the non-healthcare sector, specifically the food service, cleanroom, and industrial safety segments, is expanding rapidly as occupational health and safety standards become stricter worldwide.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager