Excimer Laser Mirror Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435805 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Excimer Laser Mirror Market Size

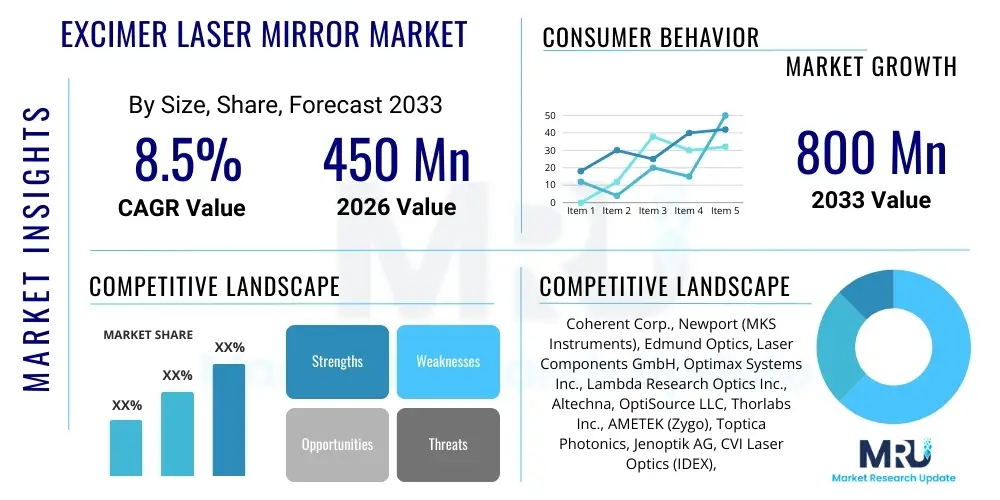

The Excimer Laser Mirror Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 800 Million by the end of the forecast period in 2033.

Excimer Laser Mirror Market introduction

The Excimer Laser Mirror Market encompasses specialized optical components designed to withstand the high energy density and harsh ultraviolet (UV) radiation emitted by excimer lasers. Excimer lasers, known for their short wavelength output (typically ArF at 193 nm, KrF at 248 nm, or XeCl at 308 nm), are critical tools in advanced manufacturing, particularly in microlithography for semiconductor fabrication and precision material processing. The mirrors used in these systems are essential for beam steering, beam conditioning, and resonator cavity design, requiring exceptional flatness, surface quality, and damage threshold to maintain beam integrity and system longevity.

Excimer laser mirrors are manufactured using high-purity fused silica or crystal substrates, layered with highly reflective dielectric coatings deposited using advanced techniques like ion-beam sputtering (IBS). These mirrors must exhibit minimal absorption at the specific excimer wavelength to prevent thermal distortion and catastrophic optical damage, which is a major challenge given the inherent energy of UV light. The stringent performance requirements mean that the market is dominated by highly specialized manufacturers capable of achieving angstrom-level precision and rigorous quality control protocols necessary for applications like deep ultraviolet (DUV) lithography, where even minor imperfections can translate into yield losses in semiconductor production.

Major applications driving market expansion include the increasing demand for advanced chips requiring smaller feature sizes, medical procedures such as refractive eye surgery (LASIK/PRK), and emerging uses in photovoltaic manufacturing and flexible display production. Key benefits derived from these components include enhanced laser efficiency, prolonged laser lifespan, precise beam delivery, and stability in high-repetition-rate environments. These factors, coupled with continuous innovation in coating materials and deposition technology, position the excimer laser mirror market as a vital and growing segment within the broader photonics industry.

Excimer Laser Mirror Market Executive Summary

The Excimer Laser Mirror Market is characterized by robust growth, primarily fueled by the accelerating pace of technological advancement in the semiconductor sector. Business trends indicate a shift towards mirrors optimized for 193 nm ArF immersion lithography, necessitating ultra-low loss coatings and complex curvature designs. Strategic partnerships between mirror manufacturers and leading semiconductor equipment providers (OEMs) are crucial for co-development and market penetration, emphasizing the oligopolistic nature of the high-end segment. Furthermore, increasing investment in advanced R&D across Asia Pacific, specifically in China and South Korea, is reshaping the competitive landscape, pushing established players to innovate continuously regarding damage threshold and cost efficiency.

Regionally, Asia Pacific maintains its dominance, driven by the massive concentration of semiconductor fabrication facilities (fabs) and the region’s commitment to expanding domestic chip production capabilities. North America and Europe, while slower in new fab construction, remain critical markets due to their strong presence in excimer laser system manufacturing and advanced medical device production. Emerging regional trends include the localization of supply chains, prompted by geopolitical trade tensions, encouraging regional manufacturing hubs for essential optical components and reducing reliance on single-source suppliers for critical technology inputs.

Segmentation trends highlight the increasing importance of the 193 nm segment, reflecting the current roadmap of microchip manufacturing where resolution enhancement techniques demand the highest quality optics. While the 248 nm segment (KrF) maintains relevance in certain industrial applications like wire stripping and marking, the most lucrative opportunities lie in specialized high-fluence optics required for DUV lithography. By coating material, dielectric mirrors are overwhelmingly preferred over metallic options due to their superior reflectivity and damage resilience, further segmenting the market based on advanced deposition techniques such as plasma-enhanced chemical vapor deposition (PECVD) and reactive sputtering, which offer highly uniform and dense thin films.

AI Impact Analysis on Excimer Laser Mirror Market

User questions regarding AI's impact on the Excimer Laser Mirror Market frequently revolve around three main themes: how AI can optimize the manufacturing process, its role in predictive maintenance and quality control, and whether AI-driven applications will necessitate new types of excimer laser systems. Based on this, the key insight is that AI is not directly replacing excimer lasers or mirrors, but rather acting as an essential enabler for enhanced efficiency and yield improvement throughout the entire semiconductor manufacturing value chain. AI algorithms are increasingly being integrated into optical inspection and quality assurance systems to detect microscopic defects in mirror coatings that are invisible to traditional methods, thus significantly boosting the yield rates of these ultra-precision components. Furthermore, AI is critical for optimizing the complex multi-layer deposition processes, allowing manufacturers to achieve tighter specifications and superior optical performance consistency required for next-generation lithography tools.

- AI-Enhanced Quality Control: Utilizing machine learning for automated inspection of mirror surface defects and coating uniformity, ensuring compliance with stringent lithography standards.

- Process Optimization: Deployment of AI to model and fine-tune thin-film deposition parameters (e.g., vacuum level, temperature, gas flow) to maximize coating density and damage threshold.

- Predictive Maintenance: AI tools analyze real-time operational data from excimer laser systems (e.g., mirror degradation, fluence loss) to predict mirror lifetime and scheduling replacement, minimizing costly downtime in fabs.

- Design Acceleration: AI models assist in the rapid simulation and optimization of complex multi-layer dielectric stack designs to achieve specific reflectivity curves across the UV spectrum.

- Supply Chain Management: Using AI to forecast demand variability for specialized mirrors based on semiconductor industry cycles, ensuring efficient inventory and supply chain resilience.

DRO & Impact Forces Of Excimer Laser Mirror Market

The Excimer Laser Mirror Market dynamics are shaped by a delicate balance of technological necessity and economic constraints. The primary driver is the relentless pursuit of Moore's Law, compelling chipmakers to adopt DUV lithography tools that fundamentally require state-of-the-art excimer optics for feature resolution below 20 nm. Coupled with the expansion of high-growth sectors like automotive electronics and 5G infrastructure, the consistent high volume demand for advanced chips directly translates into robust demand for associated optical components. However, this growth is significantly restrained by the extremely high cost and long lead times associated with manufacturing these mirrors, which require cleanroom environments, specialized infrastructure, and highly skilled labor. Furthermore, the inherent susceptibility of UV optics to damage and degradation necessitates frequent replacement, creating a structural demand while simultaneously imposing a high operational expenditure on end-users.

Opportunities for market players emerge from the shift towards Extreme Ultraviolet (EUV) systems, which, while not directly using excimer lasers, require highly specialized vacuum optics and complementary technologies developed for the DUV segment. Moreover, the expanding application of excimer lasers in medical devices, particularly in advanced ophthalmology, represents a stable and high-margin market segment less sensitive to the cyclical nature of the semiconductor industry. Innovations focusing on enhanced damage thresholds through novel coating materials and deposition techniques, such as amorphous fluorides, present significant competitive advantages and market expansion avenues. Strategic efforts to lower manufacturing costs through automation and yield improvement will be crucial for capturing broader market segments beyond premium lithography.

Impact forces in this market are overwhelmingly driven by technological obsolescence risk and the oligopolistic structure of the supply chain. The threat of substitutes, while currently low in the DUV space, must be monitored, particularly with the gradual adoption of EUV technology for the most critical layers of logic chips. The bargaining power of buyers, primarily large semiconductor OEMs and leading fabs, is high due to the small pool of qualified suppliers, forcing manufacturers to compete fiercely on performance and reliability metrics. Conversely, the bargaining power of suppliers of raw materials (high-purity fused silica) remains moderate but is subject to stringent quality requirements, making sourcing a critical factor for maintaining consistency and cost control in production.

Segmentation Analysis

The segmentation of the Excimer Laser Mirror Market provides a granular view of demand across various wavelengths, applications, and end-use industries, highlighting distinct technological requirements and market dynamics within each category. The market is fundamentally segmented by laser type, which directly dictates the required optical properties, wavelength (193 nm being the most critical), and expected fluence resistance. Application-wise, the market is overwhelmingly concentrated in the high-precision realms of microlithography and medical surgery, sectors demanding zero-tolerance for component failure and exceptional optical fidelity. Understanding these segments is vital for manufacturers to allocate R&D resources and tailor production capabilities to meet specialized client needs, ensuring compliance with stringent industry standards like SEMI (for semiconductors) and ISO (for medical devices).

Further segmentation by substrate material reveals a preference for high-purity fused silica due to its exceptional UV transparency and low thermal expansion, although calcium fluoride (CaF2) and magnesium fluoride (MgF2) are sometimes used for specialized windows and beam splitters that complement the mirror technology. The type of mirror, such as high reflectors (HR), output couplers (OC), and beam steering mirrors, dictates the specific coating architecture required. For instance, HR mirrors demand maximum reflectance (typically >99.9%) at the operating wavelength, requiring complex periodic multi-layer stacks, while output couplers balance reflectivity and transmission for optimal laser power extraction. This comprehensive segmentation reflects the technical complexity and high specialization characteristic of the excimer laser optics ecosystem.

- By Wavelength:

- 193 nm (ArF Excimer Laser)

- 248 nm (KrF Excimer Laser)

- 308 nm (XeCl Excimer Laser)

- Other Wavelengths (e.g., 157 nm, 351 nm)

- By Application:

- Microlithography (Semiconductor Manufacturing)

- Medical (Ophthalmology, Dermatology)

- Industrial Material Processing (Marking, Drilling, Annealing)

- Research and Scientific

- By Mirror Type:

- High Reflectors (HR Mirrors)

- Output Couplers (OC Mirrors)

- Beam Steering Mirrors

- Cavity Mirrors

- By End-Use Industry:

- Semiconductor

- Healthcare

- Industrial

- Aerospace and Defense

Value Chain Analysis For Excimer Laser Mirror Market

The value chain for Excimer Laser Mirrors is characterized by several highly specialized and interlinked stages, beginning with upstream material suppliers who provide ultra-high purity fused silica and crystal blanks. The quality of these raw materials is paramount, as imperfections directly impact the mirror's ability to withstand high UV fluence without damage. The second stage involves substrate preparation, including grinding, polishing, and super-polishing to achieve sub-nanometer surface roughness, a process executed by specialized precision optics firms. This highly technical upstream phase sets the foundation for the mirror's ultimate performance characteristics.

The midstream phase focuses on advanced thin-film coating deposition, the core technological differentiator in the market. Manufacturers utilize sophisticated vacuum coating systems, typically employing Ion-Beam Sputtering (IBS) or Plasma-Assisted Deposition (PAD), to deposit multi-layer dielectric stacks with angstrom-level control. This is followed by rigorous testing, including spectral measurement and high-fluence laser damage threshold (LIDT) certification. The distribution channel is often direct, particularly for the high-volume semiconductor segment, where mirror manufacturers supply directly to Excimer Laser OEMs (e.g., Coherent, Cymer/ASML) or large Tier 1 semiconductor fabricators for replacement optics, emphasizing the critical nature of technical support and certification throughout the direct channel.

Downstream analysis reveals that the primary market consumption is concentrated in highly centralized industrial sectors. End-users in semiconductor lithography require customized mirrors as part of massive capital equipment investments, demanding long-term supply agreements and stringent quality control audits. Indirect distribution is minimal, typically reserved for smaller research institutions or niche industrial applications utilizing third-party integrators. The tight coupling between manufacturers and end-users underscores the high cost of failure and the need for seamless technical integration, making the value chain relatively insulated and focused on high-performance metrics rather than low-cost alternatives.

Excimer Laser Mirror Market Potential Customers

Potential customers for Excimer Laser Mirrors are predominantly institutions and corporations operating specialized, high-capital equipment where precision and material interaction are critical. The largest and most demanding customer base resides in the semiconductor industry, specifically memory and logic chip manufacturers (e.g., TSMC, Samsung, Intel) and the major equipment suppliers (e.g., ASML) who integrate these mirrors into DUV lithography scanners. These customers require mirrors operating at 193 nm with unmatched durability and stability to ensure high throughput and acceptable yield in multi-billion dollar fabrication facilities. Their purchasing decisions are driven purely by performance specifications, reliability, and long-term supply assurance, often negotiating complex, multi-year contracts.

The second major cohort comprises medical device manufacturers and specialized ophthalmic clinics utilizing excimer lasers for refractive surgeries (LASIK/PRK). These customers prioritize stability, repeatability, and safety, often favoring 193 nm or 308 nm mirrors that are biocompatible or certified for clinical use. Though the volume is lower than in semiconductors, the price sensitivity is reduced due to the high-value nature of the medical procedures, maintaining a strong demand for premium, certified optics. Other potential customers include academic and government research laboratories, advanced industrial processing centers focusing on micro-machining or display panel fabrication, and companies involved in the production of high-performance photonic devices and sensors that rely on UV laser processing capabilities.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 800 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Coherent Corp., Newport (MKS Instruments), Edmund Optics, Laser Components GmbH, Optimax Systems Inc., Lambda Research Optics Inc., Altechna, OptiSource LLC, Thorlabs Inc., AMETEK (Zygo), Toptica Photonics, Jenoptik AG, CVI Laser Optics (IDEX), Synoptics (EO), Advanced Optics Inc., V-Technology, Ophir Optics (Newport), II-VI Incorporated (now Coherent). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Excimer Laser Mirror Market Key Technology Landscape

The technological landscape of the Excimer Laser Mirror Market is dominated by advancements in thin-film deposition and substrate preparation necessary to achieve ultra-high damage thresholds (LIDT) and broadband reflectivity required for complex excimer systems. Ion Beam Sputtering (IBS) stands out as the predominant technology for producing the multi-layer dielectric stacks. IBS offers superior film density, minimal scattering, and extremely low absorption losses compared to traditional methods like electron beam evaporation. This precise control over film thickness and structure is mandatory for 193 nm mirrors used in immersion lithography, where environmental factors like moisture and temperature stability are critical, and only highly dense, defect-free coatings can ensure longevity and stable performance under aggressive operating conditions.

A second critical technology involves the preparation and super-polishing of the fused silica substrates. Achieving root mean square (RMS) roughness below 0.3 nm is essential to minimize scatter and potential initiation sites for laser damage. Advancements in Magneto-Rheological Finishing (MRF) and Chemical Mechanical Polishing (CMP) are key enablers in achieving these stringent surface quality standards economically. Furthermore, the industry is increasingly leveraging advanced metrology, including highly sensitive Atomic Force Microscopy (AFM) and phase-shifting interferometry, to verify the flatness and surface quality across large mirror aperture sizes, ensuring that the component meets the demanding specifications required for maintaining wavefront fidelity in complex optical trains.

Future technological shifts are focused on developing novel coating materials that offer even higher LIDT, moving beyond traditional oxide and fluoride mixtures. Research is underway into amorphous and nanocomposite materials that demonstrate improved UV stability and thermal management properties. Additionally, manufacturers are exploring advanced inspection techniques, potentially utilizing AI-driven image processing, to rapidly identify and classify sub-surface defects within the optical substrate and coating layers that might compromise long-term performance. This continuous technological race is essential to keep pace with the semiconductor roadmap, which consistently pushes the limits of optical endurance and precision.

Regional Highlights

The geographical distribution of the Excimer Laser Mirror Market is heavily correlated with the global footprint of high-tech manufacturing, particularly semiconductor fabrication plants (fabs). Asia Pacific (APAC) dominates the global market both in terms of consumption volume and future growth potential. This dominance is attributed to countries like China, South Korea, Taiwan, and Japan, which host the majority of the world's leading semiconductor foundries (e.g., TSMC, Samsung, SK Hynix). These regions are making massive capital investments in expanding their DUV and advanced chip manufacturing capacity, ensuring continuous high demand for specialized excimer optics, particularly 193 nm mirrors for advanced nodes.

North America and Europe constitute mature but highly strategic markets. North America, driven by the presence of major excimer laser system manufacturers (OEMs) and leading research institutions, holds a significant share in the high-value segment, focusing on R&D, specialized defense applications, and high-precision medical optics. Europe benefits from strong photonics clusters, especially in Germany and the Netherlands (home to ASML), focusing both on component manufacturing excellence and end-user applications in sophisticated industrial processing and medical technology. While the sheer volume of consumption is lower than in APAC, these regions drive innovation in coating and materials science.

Latin America, the Middle East, and Africa (MEA) currently represent smaller markets, primarily served by imported laser systems and replacement parts, with demand concentrated in academic research, specific medical applications, and nascent industrial laser processing centers. Growth in these regions is expected to be modest but steady, linked to industrial diversification efforts and increased investment in localized healthcare infrastructure. The geopolitical landscape and trade policies are increasingly influencing regional supply chains, prompting some end-users to seek regional sourcing options, which could spur localized manufacturing capacity outside the traditional APAC and North American strongholds over the long term.

- Asia Pacific (APAC): The largest and fastest-growing market, powered by massive semiconductor industry expansion in Taiwan, South Korea, and Mainland China; critical hub for 193 nm lithography optics.

- North America: Key center for excimer laser OEM manufacturing, high-value medical applications (LASIK), and advanced R&D in high-fluence damage resistance; strong demand for premium, custom optics.

- Europe: Important market driven by robust industrial manufacturing sectors and significant presence in DUV equipment manufacturing; focus on industrial processing and advanced photonics research.

- Rest of the World (MEA & Latin America): Emerging market driven by medical infrastructure growth and increasing adoption of excimer lasers in industrial micromachining; reliance on imported technology.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Excimer Laser Mirror Market.- Coherent Corp. (formerly II-VI Incorporated)

- Newport (MKS Instruments, including Spectra-Physics)

- ASML Holding N.V. (through Cymer optics division)

- Edmund Optics

- Laser Components GmbH

- Optimax Systems Inc.

- Lambda Research Optics Inc.

- Altechna

- OptiSource LLC

- Thorlabs Inc.

- AMETEK (Zygo Corporation)

- Jenoptik AG

- CVI Laser Optics (IDEX Corporation)

- Synoptics (Electro-Optics)

- Advanced Optics Inc.

- Materion Corporation

- Shanghai Optics Inc.

- OPTEC Inc.

- Fujifilm (focusing on lithography components)

Frequently Asked Questions

Analyze common user questions about the Excimer Laser Mirror market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the demand for 193 nm Excimer Laser Mirrors?

The primary factor driving demand is the aggressive expansion of deep ultraviolet (DUV) lithography in semiconductor manufacturing. 193 nm mirrors are essential components in ArF immersion scanners used to produce advanced logic and memory chips below the 20 nm node, requiring optics with extreme stability and the highest laser damage threshold (LIDT).

How does the high-fluence environment of excimer lasers affect mirror lifespan?

Excimer laser mirrors operate under intense ultraviolet (UV) radiation, causing gradual photochemical damage and coating degradation, often termed "color center formation." This high-fluence environment significantly limits the mirror's operational lifespan, necessitating frequent replacement and making high laser damage threshold (LIDT) coatings a crucial performance metric for end-users.

Which coating technology provides the best performance for UV Excimer Mirrors?

Ion Beam Sputtering (IBS) is widely recognized as the superior coating technology for UV Excimer Mirrors, particularly at 193 nm. IBS produces highly dense, non-porous multi-layer dielectric films with minimal absorption and scatter, translating directly into a higher laser damage threshold and better environmental stability compared to other deposition methods.

What is the market segmentation based on application?

The market is primarily segmented into Microlithography (dominant consumer for semiconductor manufacturing), Medical (high-value applications like LASIK eye surgery), and Industrial Material Processing (drilling, annealing, and marking). Microlithography represents the highest volume and most stringent technical requirement segment.

How is the adoption of Extreme Ultraviolet (EUV) lithography impacting the Excimer Laser Mirror Market?

While EUV lithography uses a different light source and reflective masks, its increasing adoption for the most advanced chip layers does not eliminate the need for DUV (Excimer) systems, which remain critical for manufacturing less critical layers and older node devices. The impact is a slight moderation in the explosive growth of the 193 nm segment, while expertise developed in DUV optics remains relevant for EUV’s specialized vacuum optical components.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager