Explosion Proof Inverter Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434345 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Explosion Proof Inverter Market Size

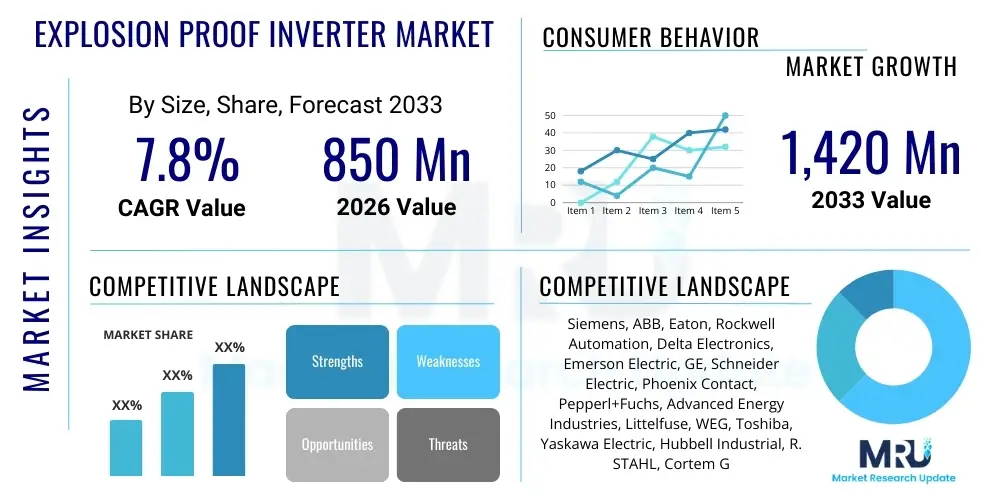

The Explosion Proof Inverter Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 850 million in 2026 and is projected to reach USD 1,420 million by the end of the forecast period in 2033.

Explosion Proof Inverter Market introduction

Explosion proof inverters are highly specialized power conversion systems designed and certified to operate safely in hazardous environments, classified by the presence of flammable gases, vapors, mists, or combustible dusts. These critical devices convert DC power, often sourced from battery banks or renewable sources, into reliable AC power while preventing internal sparks or excessive surface temperatures that could ignite the surrounding atmosphere. Key applications span across the energy sector, particularly in offshore oil rigs, natural gas processing facilities, chemical synthesis plants, and mining operations where strict regulatory compliance (such as ATEX, IECEx, and UL standards) is mandatory for operational safety and risk mitigation. The primary benefit is ensuring personnel and asset safety by maintaining power reliability in highly volatile zones, simultaneously adhering to stringent environmental and worker protection legislation. Market growth is fundamentally driven by the escalating demand for power management systems in expanding petrochemical and refining industries, coupled with the increasing adoption of renewable energy sources in remote and hazardous locations.

Explosion Proof Inverter Market Executive Summary

The Explosion Proof Inverter Market is experiencing significant buoyancy driven by heightened global focus on industrial safety standards and the ongoing expansion of upstream and midstream oil and gas infrastructure, particularly in developing economies. Business trends highlight a strong shift toward digitalization and integration of ruggedized IoT capabilities within inverter units for enhanced predictive maintenance and remote monitoring, crucial for optimizing uptime in inaccessible hazardous locations. Regional trends indicate that Asia Pacific is emerging as the fastest-growing market, propelled by rapid industrialization, large-scale chemical manufacturing investment, and the rigorous adoption of international safety protocols. Meanwhile, North America and Europe maintain leading positions due to established regulatory frameworks and high investment in advanced, certified equipment. Segment trends show that the Flameproof Enclosure protection type dominates the revenue share due to its robust nature and suitability for Zone 1 applications, while the Oil & Gas sector remains the largest end-user segment, although mining and pharmaceuticals are showing accelerated adoption rates requiring custom solutions for dust and solvent vapor hazards, respectively. Overall, the market remains highly competitive, focusing on certifications, power density, and modularity to address diverse operational requirements.

AI Impact Analysis on Explosion Proof Inverter Market

User inquiries regarding AI's influence in the Explosion Proof Inverter Market commonly center on improving predictive maintenance reliability, enhancing real-time safety diagnostics, and optimizing power consumption under volatile operational conditions. Users are concerned about how AI algorithms can integrate seamlessly with intrinsically safe components without compromising explosion protection integrity, seeking assurances that advanced software does not introduce unintended fault paths. Key expectations include utilizing machine learning to analyze historical operational data (temperature, voltage fluctuation, load profiles) to forecast potential component failure—particularly in remote, inaccessible hazardous areas—thereby minimizing unplanned shutdowns and reducing the high costs associated with manual inspections and reactive repairs in dangerous zones. Furthermore, there is significant interest in AI-driven load management systems that can dynamically adjust inverter output to optimize efficiency and minimize thermal stress, a critical factor in maintaining compliance with surface temperature limits in classified hazardous zones.

The implementation of AI/ML models is expected to revolutionize how these mission-critical assets are managed throughout their lifecycle. AI is enabling the development of advanced digital twins of inverter systems, allowing operators to simulate the effects of extreme operational stress or environmental changes, ensuring compliance and reliability before physical deployment. This predictive capability moves maintenance from time-based scheduling to condition-based intervention, offering substantial operational savings. However, the adoption requires overcoming technical challenges related to cybersecurity for networked hazardous area devices and ensuring that the certified hardware (often requiring non-standard processors) can handle complex computational models efficiently, maintaining compliance with safety integrity levels (SIL) required for explosion protection.

- Enhanced Predictive Maintenance: AI algorithms analyze sensor data (vibration, heat, current harmonics) to forecast component degradation, scheduling maintenance precisely before failure, thereby maximizing uptime in hazardous areas.

- Real-Time Anomaly Detection: Machine learning models continuously monitor operational parameters against baseline performance, instantly identifying subtle deviations indicative of potential faults or compromised explosion integrity.

- Optimized Thermal Management: AI systems dynamically adjust cooling and power throttling strategies to ensure inverter surface temperatures remain strictly below the auto-ignition temperatures of surrounding flammable substances.

- Remote Diagnostics and Troubleshooting: AI assists technicians in diagnosing complex system failures remotely, reducing the need for personnel entry into highly dangerous Zone 0 or Zone 1 environments.

- Improved Energy Efficiency: Load-optimization models powered by AI minimize wasted energy and associated heat generation, contributing to both sustainability goals and explosion safety compliance.

DRO & Impact Forces Of Explosion Proof Inverter Market

The market is primarily driven by stringent global regulations mandating certified electrical equipment in hazardous locations (Drivers), while facing significant limitations due to the high initial capital expenditure associated with certified components and the complexity of integration with legacy systems (Restraints). Opportunities arise from the global energy transition, particularly the deployment of solar and wind power in remote industrial sites and the burgeoning pharmaceutical and food processing sectors requiring specialized explosion protection against dust and solvent vapors. Impact Forces are characterized by high barriers to entry due to demanding certification requirements (low threat of new entrants), moderate rivalry among established global players offering comprehensive safety portfolios (moderate competitive intensity), strong bargaining power of specialized component suppliers (supplier power), and low customer price sensitivity given the life-critical nature of the product (buyer power). Technological substitution poses a low threat as alternative power conversion methods do not currently meet the required safety integrity levels.

Segmentation Analysis

The Explosion Proof Inverter Market is comprehensively segmented based on the critical parameters of explosion protection method, power output rating, the voltage class handled, and the specific industry application, allowing for targeted product development and market penetration strategies. The protection type segmentation is paramount, differentiating between solutions suitable for varying degrees of hazard risk, influencing design complexity and manufacturing costs. Application segmentation highlights the dominance of the extractive industries but also underscores the rapid expansion into niche sectors like wastewater treatment and specialty chemical manufacturing, which demand customized protection against unique hazardous substances. Power output segmentation determines the scale of the operation the inverter can support, ranging from low-power monitoring systems to high-power grid tie-ins in remote industrial parks. Understanding these segments provides manufacturers with crucial insights into the evolving regulatory landscape and end-user needs for robustness, redundancy, and certified compliance.

- Protection Type:

- Flameproof Enclosure (Ex d)

- Intrinsic Safety (Ex i)

- Pressurized Enclosure (Ex p)

- Oil Immersion (Ex o)

- Sand Filling (Ex q)

- Encapsulation (Ex m)

- Power Output:

- Low Power (Up to 10 kW)

- Medium Power (10 kW to 100 kW)

- High Power (Above 100 kW)

- Voltage Class:

- Low Voltage (Up to 1,000 V)

- Medium Voltage (1,000 V to 35 kV)

- Application:

- Oil & Gas (Upstream, Midstream, Downstream)

- Chemical & Petrochemical

- Mining

- Pharmaceuticals

- Food & Beverage Processing

- Wastewater Treatment

- Power Generation (Renewable Energy Integration in Hazardous Areas)

Value Chain Analysis For Explosion Proof Inverter Market

The value chain for explosion proof inverters begins with upstream activities dominated by highly specialized component manufacturers providing certified semiconductors, ruggedized capacitors, complex filtering systems, and specialized intrinsically safe microcontrollers. These suppliers operate in a highly regulated environment, demanding strict quality control and traceability. Midstream activities involve the core manufacturing and assembly processes, where certified enclosure design, thermal management integration, and crucial certification testing (such as ATEX, UL, and IECEx conformity assessment) add the most significant value and complexity, necessitating expertise in hazardous area classification standards. Downstream, the distribution channel is highly specialized, relying on system integrators and value-added resellers who possess the technical knowledge required to install, commission, and maintain these safety-critical systems within industrial settings, often working directly with EPC contractors to ensure end-to-end regulatory compliance. Direct sales typically occur for large-scale, complex projects requiring extensive customization, while indirect channels leverage regional distributors specialized in safety equipment and industrial controls, ensuring wide market reach and localized support in disparate geographies.

Explosion Proof Inverter Market Potential Customers

Potential customers for explosion proof inverters are primarily large-scale industrial entities operating within highly regulated and hazardous environments where reliable power conversion is essential for core operations and mandated safety. The principal buyers include major international oil companies (IOCs) and national oil companies (NOCs) engaged in exploration, drilling, refining, and pipeline operations, where continuous, safe power supply is vital for control systems and emergency shutdown infrastructure. Chemical and petrochemical manufacturers, particularly those dealing with flammable solvents, gases, and high-temperature reactions, represent another significant customer base, demanding certified inverters for process control and instrumentation. Furthermore, mining operations, facing hazards from methane gas and combustible dusts, require ruggedized inverters for underground ventilation and machinery control. The emerging pharmaceutical sector, handling volatile organic compounds (VOCs) during drug synthesis, and municipal utilities managing explosive gases in wastewater treatment plants also constitute growing segments of potential end-users, seeking solutions tailored to their specific Zone classification and material handling requirements.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 million |

| Market Forecast in 2033 | USD 1,420 million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens, ABB, Eaton, Rockwell Automation, Delta Electronics, Emerson Electric, GE, Schneider Electric, Phoenix Contact, Pepperl+Fuchs, Advanced Energy Industries, Littelfuse, WEG, Toshiba, Yaskawa Electric, Hubbell Industrial, R. STAHL, Cortem Group, Extronics, BARTEC. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Explosion Proof Inverter Market Key Technology Landscape

The technology landscape of the explosion proof inverter market is fundamentally defined by strict adherence to international safety standards, necessitating innovative approaches in thermal management and enclosure design to prevent ignition. Core technologies revolve around robust, certified enclosure techniques such as Flameproof (Ex d) systems, which are designed to withstand an internal explosion and prevent the propagation of the flame to the outside atmosphere, and Intrinsically Safe (Ex i) circuitry, which limits the electrical and thermal energy to below the ignition point of the hazardous material. A critical technological focus is on high-efficiency power electronics, utilizing wide-bandgap semiconductors like Silicon Carbide (SiC) and Gallium Nitride (GaN). These advanced materials enable smaller, lighter, and more efficient inverter designs, reducing heat generation—a major safety concern in hazardous areas—and allowing for higher power density within certified enclosures. Furthermore, advanced monitoring and fault detection technologies, including non-invasive sensors and embedded diagnostics, are being incorporated to provide real-time status updates without compromising the integrity of the protective enclosure, enhancing both safety and operational longevity.

Regional Highlights

- North America: Dominated by stringent regulatory environments (OSHA, NEC) and high expenditure in the oil and gas sector (Permian Basin, offshore Gulf of Mexico), focusing heavily on reliable, certified high-power inverters. The region demands robust digitalization and sophisticated remote monitoring capabilities integrated into explosion protection systems.

- Europe: Driven by ATEX and IECEx directives, Europe maintains a technological lead in intrinsic safety solutions, particularly for process control and automation in the chemical and pharmaceutical industries. Emphasis is placed on energy efficiency, sustainability, and modular inverter designs suitable for older, retrofitted industrial plants.

- Asia Pacific (APAC): The fastest-growing market, characterized by rapid expansion in refining capacity, massive infrastructure projects in China and India, and increasing safety adoption in rapidly industrializing economies. Growth is volume-driven, with strong demand across mining, power generation, and specialized chemical sectors.

- Middle East and Africa (MEA): Significant market growth tied directly to massive capital investments in oil, gas, and petrochemical expansion projects (e.g., Saudi Arabia, UAE, Qatar). Demand is concentrated on high-power, heavy-duty inverters capable of withstanding extreme ambient temperatures while meeting rigorous safety standards.

- Latin America: Moderate growth fueled by recovering mining activities in countries like Chile and Peru and ongoing investment in Brazilian offshore oil production. Market adoption is sensitive to commodity price fluctuations and relies heavily on international safety standards adoption.

North America holds a substantial share of the global Explosion Proof Inverter Market, largely attributed to the mature and highly regulated oil and gas industry, particularly in the United States and Canada. The region benefits from early and comprehensive implementation of safety standards mandated by federal agencies such as the Occupational Safety and Health Administration (OSHA) and adhered to via the National Electrical Code (NEC). Investment trends show a pivot towards integrating explosion-proof power solutions with smart grid initiatives and decentralized energy generation, especially in remote exploration and production sites. Furthermore, the robust pharmaceutical and aerospace manufacturing sectors contribute to steady demand for intrinsically safe and encapsulated systems suitable for areas dealing with specific volatile organic compounds (VOCs). The market here is characterized by demands for high reliability, long operational lifespans, and readily available certified service and maintenance support, often requiring UL and CSA certifications alongside international standards.

Europe represents a technologically sophisticated market, heavily influenced by the ATEX (Atmosphères Explosibles) Directive and the transition toward renewable energy sources. European manufacturers are leaders in developing compact, highly efficient inverter designs utilizing advanced materials and integrated diagnostic features. The market structure emphasizes intrinsic safety (Ex i) and pressurized enclosures (Ex p) for complex process automation systems found throughout the continent's established chemical, refining, and specialized manufacturing sectors. Regulatory compliance is paramount, often driving demand for equipment with dual certifications (ATEX/IECEx) to facilitate international trade. The push for industrial decarbonization also sees increasing deployment of explosion proof inverters in biogas plants and hydrogen production facilities, indicating a shift towards supporting new energy infrastructures within hazardous classifications.

The Asia Pacific (APAC) region is projected to exhibit the highest growth rate during the forecast period due to large-scale infrastructure investment, rapid industrialization, and increasing awareness and enforcement of global safety standards. Countries like China, India, and Southeast Asian nations are rapidly expanding their domestic refining, chemical processing, and mining capacities, driving massive procurement volumes of explosion proof equipment. While price sensitivity can be a factor, the pressure from multinational companies operating within APAC to maintain consistent global safety standards accelerates the adoption of internationally certified inverters. Challenges in this region often involve navigating varied local standards alongside international requirements, necessitating flexible manufacturing and supply chain strategies to meet diverse and rapidly evolving market needs across this expansive geography.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Explosion Proof Inverter Market.- Siemens AG

- ABB Ltd.

- Eaton Corporation plc

- Rockwell Automation, Inc.

- Delta Electronics, Inc.

- Emerson Electric Co.

- General Electric (GE)

- Schneider Electric SE

- Phoenix Contact

- Pepperl+Fuchs SE

- Advanced Energy Industries, Inc.

- Littelfuse, Inc.

- WEG S.A.

- Toshiba Corporation

- Yaskawa Electric Corporation

- Hubbell Industrial Controls

- R. STAHL AG

- Cortem Group

- Extronics Ltd.

- BARTEC Group

Frequently Asked Questions

Analyze common user questions about the Explosion Proof Inverter market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the key safety standards governing Explosion Proof Inverters?

The primary global standards include the European ATEX directives (covering equipment for potentially explosive atmospheres) and the international IECEx system, which facilitates global trade. In North America, UL (Underwriters Laboratories) and CSA (Canadian Standards Association) certifications based on the National Electrical Code (NEC) are crucial for market access and operational compliance.

How do Flameproof Enclosures (Ex d) differ from Intrinsic Safety (Ex i) in inverter protection?

Flameproof Enclosures (Ex d) contain the explosion within a robust housing, preventing flame propagation to the external hazardous atmosphere, and are suitable for higher power applications. Intrinsic Safety (Ex i) limits the electrical energy and thermal energy of the circuitry to levels incapable of igniting the hazardous mixture, primarily used for low-power instrumentation and signaling.

Which industry segment is the largest end-user for Explosion Proof Inverters?

The Oil & Gas industry is currently the dominant end-user segment globally. This sector requires high-power, certified inverters for critical applications in upstream drilling, midstream transportation (pipelines), and downstream refining, where flammable hydrocarbons are consistently present, necessitating the highest level of protection.

What major technological advancement is influencing the efficiency and size of these inverters?

The transition to Wide-Bandgap (WBG) semiconductors, particularly Silicon Carbide (SiC) and Gallium Nitride (GaN), is significantly influencing the market. These materials allow for higher switching frequencies, increased power density, reduced heat generation, and improved overall system efficiency, which is vital for maintaining compliance with surface temperature restrictions in explosion-proof designs.

What is the primary constraint limiting the rapid adoption of explosion proof inverters?

The major constraint is the significantly high capital expenditure (CAPEX) required for certified explosion-proof equipment compared to standard industrial inverters. The rigorous design, specialized materials, extensive testing, and complex certification processes inherent to the technology drive up the manufacturing and final purchase costs considerably.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager