Explosion-Proof Motors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438638 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Explosion-Proof Motors Market Size

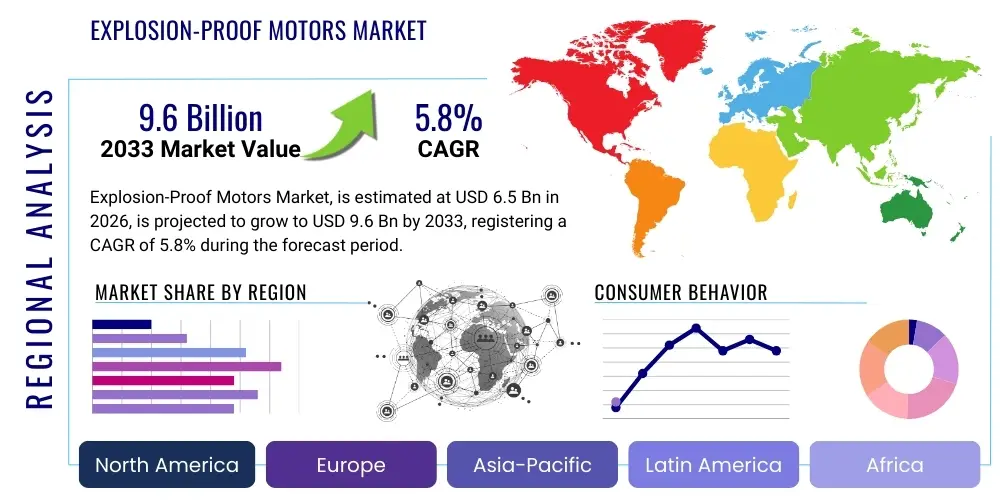

The Explosion-Proof Motors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 6.5 Billion in 2026 and is projected to reach USD 9.6 Billion by the end of the forecast period in 2033.

Explosion-Proof Motors Market introduction

The Explosion-Proof Motors Market encompasses electric motors specifically engineered and certified to operate safely in environments where flammable gases, vapors, dusts, or fibers are present, preventing the motor from acting as an ignition source. These motors are crucial safety components, adhering to stringent international standards such as ATEX (European Union) and IECEx (International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres). Their core design philosophy centers on containing potential internal explosions and ensuring the surface temperature remains below the auto-ignition point of the surrounding hazardous material.

Major applications of these highly specialized motors span critical infrastructure sectors, including upstream and downstream oil and gas operations, chemical processing plants, pharmaceutical manufacturing, mining, and grain handling facilities. They are deployed in pumps, compressors, fans, mixers, and other rotating equipment necessary for operational efficiency in hazardous locations (often classified as Zone 0, Zone 1, or Zone 2). The primary benefit derived from their use is the mandatory regulatory compliance required to ensure personnel safety and asset protection, mitigating catastrophic risks associated with fire and explosion in volatile industrial settings.

The market is primarily driven by escalating global energy demand necessitating increased exploration and production activities in challenging, hazardous zones, coupled with the rigorous enforcement of industrial safety regulations across developed and emerging economies. Furthermore, the persistent focus on modernizing aging industrial infrastructure, particularly in sectors like petrochemicals and specialty chemicals, requires the replacement of older, less compliant equipment with modern, high-efficiency explosion-proof motor variants that integrate advanced features like improved thermal management and compatibility with Variable Frequency Drives (VFDs).

Explosion-Proof Motors Market Executive Summary

The Explosion-Proof Motors Market demonstrates robust growth driven primarily by structural safety mandates and sustained capital expenditure within the oil, gas, and chemical industries. Business trends indicate a strong shift towards motors designed for higher efficiency (IE3/IE4 ratings) and smart integration capabilities, enabling predictive maintenance and remote monitoring within hazardous locations. Key manufacturers are focusing heavily on expanding their certified product portfolios, particularly flameproof (Ex d) and increased safety (Ex e) types, catering to varying hazard classifications and ensuring global regulatory reciprocity (ATEX, IECEx, UL, CSA) to facilitate international trade and deployment across diverse operational sites.

Regionally, the Asia Pacific (APAC) market is witnessing the fastest expansion, fueled by massive infrastructure projects in emerging industrial economies like China and India, especially within chemical processing and LNG (Liquefied Natural Gas) terminals. North America remains a dominant revenue generator, largely due to sustained activity in the shale oil and gas sector and the demanding safety standards enforced by bodies like OSHA. European growth is steady, emphasizing technological innovation and adherence to strict ATEX directives, promoting the adoption of advanced motor designs optimized for energy conservation.

Segment-wise, the low voltage (LV) motors segment holds the largest market share, driven by their pervasive use in standard industrial pumps and machinery. However, the medium and high voltage (MV/HV) segments are growing steadily, catering to large-scale applications such as main line compressors and massive liquid natural gas pumps, essential for scaling up global energy distribution. The material handling and refining application segments are projected to exhibit significant growth trajectories due to heightened activity in port operations and the ongoing modernization of crude processing facilities globally, mandating the highest levels of certified safety equipment.

AI Impact Analysis on Explosion-Proof Motors Market

User inquiries regarding AI's influence in the Explosion-Proof Motors Market center predominantly on themes of operational reliability, remote diagnostic capabilities in inaccessible or dangerous zones, and the optimization of maintenance schedules to minimize downtime. Users seek to understand how AI can enhance the inherent safety features of these critical components, moving beyond basic failure detection to sophisticated failure prediction. A major concern is the secure transmission and analysis of data from explosive environments without compromising intrinsic safety standards, requiring certified hardware and advanced edge computing solutions compatible with hazardous area classifications. The key expectations revolve around leveraging AI for highly accurate predictive maintenance, optimizing motor performance under volatile load conditions, and achieving substantial operational expenditure savings through condition-based monitoring programs.

- AI integration facilitates predictive maintenance schedules, drastically reducing the risk of unexpected motor failures in hazardous environments.

- Machine learning algorithms analyze vibration, temperature, and current signatures to detect subtle anomalies indicating potential component breakdown, enhancing asset longevity.

- AI-powered diagnostic systems enable remote monitoring and fault identification, minimizing the need for human intervention in highly dangerous Zone 0 and Zone 1 locations.

- Optimization of Variable Frequency Drives (VFD) controls via AI ensures motors operate at peak efficiency under fluctuating operational loads, conserving energy and reducing heat generation (a potential ignition source).

- Enhanced inventory management for spare parts by accurately forecasting maintenance needs based on real-time operational wear analyzed by AI platforms.

DRO & Impact Forces Of Explosion-Proof Motors Market

The Explosion-Proof Motors Market is fundamentally shaped by a crucial balance between stringent regulatory imperatives (Drivers), the substantial initial capital investment and complexity associated with certification (Restraints), and the emerging necessity for high-efficiency, smart industrial safety solutions (Opportunities). The overarching impact force is the non-negotiable requirement for operational safety within hazardous locations, which mandates the use of certified explosion-proof equipment regardless of economic cycles or market volatility, providing a stable foundation for demand. This core need for safety compliance dictates market dynamics, ensuring continuous adoption and replacement cycles.

Key drivers include the global expansion of chemical and petrochemical industries, particularly in emerging markets undergoing rapid industrialization, which generates consistent demand for certified equipment. Furthermore, the persistent push by regulatory bodies like the EU (ATEX) and international harmonization efforts (IECEx) ensure that manufacturers continuously upgrade product specifications, driving innovation in safer and more reliable motor designs. The increasing adoption of advanced process technologies, requiring integration with VFDs and specialized motor control systems, also fuels demand for compliant, high-performance explosion-proof variants.

However, the market faces significant restraints, notably the high cost associated with the design, testing, and certification process for explosion-proof equipment, which can deter smaller manufacturers and increase the final product price for end-users. Technical complexity, including the need for specialized installation and maintenance procedures carried out by certified personnel, adds to the operational expenditure. Opportunities lie in the growing demand for energy-efficient IE4/IE5 motors, the expansion of the market into hydrogen production and storage facilities (new hazardous zones), and the increasing adoption of digital transformation initiatives, enabling condition monitoring and remote diagnostics in hazardous areas through intrinsically safe wireless technologies.

Segmentation Analysis

The Explosion-Proof Motors Market is meticulously segmented based on several critical parameters, including the type of protection mechanism employed, the motor efficiency rating, the voltage class, and the specific application industry. These segmentations are vital as they reflect the diverse operational requirements and safety classifications found across various industrial settings globally. The choice of motor type, such as flameproof or increased safety, is entirely dependent on the specific hazardous zone classification (e.g., Zone 1 or Zone 2) defined by regulatory standards, ensuring the highest level of safety is maintained for that particular environment.

Voltage segmentation is crucial for differentiating between standard industrial machinery (Low Voltage) and heavy-duty, large-scale equipment like pipeline compressors or deep-mine ventilation systems (Medium and High Voltage). Meanwhile, segmentation by efficiency rating (e.g., IE3, IE4) highlights the industry's shift towards sustainable and cost-effective operations, where minimizing energy consumption is increasingly prioritized alongside safety. The major end-user segmentation clearly identifies the primary consumption hubs, with Oil and Gas remaining the largest segment due to the inherent volatility of its operational environment.

- By Protection Type:

- Flameproof/Explosion-Proof Enclosure (Ex d)

- Increased Safety (Ex e)

- Intrinsic Safety (Ex i)

- Pressurized Enclosure (Ex p)

- Non-Sparking (Ex n)

- By Voltage:

- Low Voltage (Up to 1,000 V)

- Medium Voltage (1,000 V to 6,900 V)

- High Voltage (Above 6,900 V)

- By Efficiency Rating:

- IE2 (High Efficiency)

- IE3 (Premium Efficiency)

- IE4 (Super Premium Efficiency)

- By Application/End-User:

- Oil and Gas (Upstream, Midstream, Downstream)

- Chemical, Petrochemical, and Pharmaceutical

- Mining and Metallurgy

- Food and Beverage Processing

- Power Generation (Fuel Handling Areas)

- Water and Wastewater Management

Value Chain Analysis For Explosion-Proof Motors Market

The value chain for the Explosion-Proof Motors Market begins with the upstream raw material suppliers, predominantly providing specialized copper, high-grade steel, and composite insulation materials required for robust and temperature-resistant construction. These raw materials must meet strict metallurgical standards to ensure flame containment integrity and thermal stability necessary for hazardous area certification. The manufacturing stage is highly specialized, involving precision casting, winding processes utilizing reinforced components, and rigorous in-house testing regimes to comply with global standards like UL, ATEX, and IECEx. Manufacturers must maintain highly complex quality assurance protocols due to the safety-critical nature of the final product, necessitating heavy investment in R&D and specialized testing facilities.

The downstream segment involves complex distribution channels primarily reliant on certified system integrators and specialized industrial distributors who possess the technical expertise required to advise clients on proper hazardous zone classification and motor selection. Due to the high-stakes nature of the application, direct sales models are often employed for large capital projects, involving close collaboration between the manufacturer and the EPC (Engineering, Procurement, and Construction) firm. Indirect channels utilize authorized distributors who must maintain specific training and certification to handle, install, and service these specialized motors, ensuring product integrity is maintained until final deployment.

Installation, commissioning, and after-sales service form the final critical link in the value chain. This phase often requires the manufacturer or their certified partners to provide highly specialized technical support, including scheduled preventative maintenance (PM) and emergency repair services, which must also adhere to strict hazardous area maintenance guidelines. The profitability in the value chain is often concentrated at the manufacturing level (due to certification barriers) and the specialized service/integration level (due to the technical knowledge required for implementation in complex industrial plants).

Explosion-Proof Motors Market Potential Customers

Potential customers for explosion-proof motors are primarily large industrial entities operating facilities classified as hazardous locations (Zones 0, 1, 2, or Division 1, 2) where combustible substances are handled, processed, or stored. The major end-users are those sectors where ignition risks are inherent and continuous operational safety is paramount, forming a reliable, albeit technically demanding, customer base. These buyers prioritize product certification, long-term reliability, and compatibility with their existing control systems (e.g., integration with VFDs and SCADA systems) over sheer purchasing cost.

The most significant segment comprises integrated oil and gas companies (IOCs and NOCs) involved in drilling, hydraulic fracturing, transportation (pipeline and marine), refining, and petrochemical manufacturing. These operations utilize explosion-proof motors across thousands of pumps, compressors, and agitators. Secondary, yet vital, customer segments include specialty chemical manufacturers that handle volatile solvents and reactants, pharmaceutical companies producing sterile ingredients in solvent-heavy environments, and the mining sector, which requires certified equipment for underground ventilation and material conveyance where methane or coal dust is prevalent.

Furthermore, new growth opportunities arise from the increasing construction of large-scale LNG liquefaction and regasification terminals and hydrogen production facilities, all of which represent highly volatile and regulated environments. These customers typically procure motors through complex, multi-year supply contracts managed by major EPC firms, demanding proof of compliance with both global (IECEx) and regional (ATEX, NEC/CEC) safety certifications to ensure seamless project execution and regulatory approval upon commissioning.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 6.5 Billion |

| Market Forecast in 2033 | USD 9.6 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., Siemens AG, WEG S.A., Nidec Corporation, TECO Electric & Machinery Co., Ltd., Regal Rexnord Corporation, Wolong Electric Group Co., Ltd., Havells India Ltd., Brook Crompton, Marathon Electric, Danaher Corporation, Hyosung Heavy Industries, Leeson Electric, Toshiba International Corporation, Rockwell Automation, General Electric, Schneider Electric, ATB Group, Lenze SE, CG Power and Industrial Solutions Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Explosion-Proof Motors Market Key Technology Landscape

The technological landscape of explosion-proof motors is dominated by advancements in enclosure design, material science, and digital integration capabilities, all aimed at improving reliability and enhancing safety margins. The primary technical differentiation lies in the certification techniques: Flameproof Enclosures (Ex d) rely on robust casings to contain an internal explosion and cool escaping gases, while Increased Safety Motors (Ex e) focus on preventing sparks and hot surfaces altogether, typically through tighter tolerances and enhanced insulation. Modern innovations concentrate on reducing motor surface temperatures, thereby widening the scope for deployment in areas with low auto-ignition temperature substances (e.g., T4 temperature class certification).

A significant technological shift involves the development of explosion-proof motors optimized specifically for operation with Variable Frequency Drives (VFDs). VFD operation introduces harmonic distortions and voltage spikes that can stress insulation systems and increase motor temperatures, posing a challenge in hazardous areas. Manufacturers are responding by incorporating advanced insulation materials (such as optimized varnish and winding configurations) and specialized bearing protection to ensure that the motor maintains its certified temperature classification and isolation properties even under the demanding transient conditions imposed by VFD control at low speeds.

Furthermore, the integration of certified intrinsically safe sensors for condition monitoring is a leading technological trend. These sensors measure critical parameters such as vibration, bearing temperature, and winding temperature without introducing enough energy to ignite the hazardous atmosphere. The data collected by these sensors is transmitted via approved wireless protocols to external diagnostic systems, enabling true condition-based monitoring and remote asset management, transitioning the industry toward Industry 4.0 standards while maintaining absolute safety integrity.

Regional Highlights

The global demand for Explosion-Proof Motors is regionally diverse, reflecting varied levels of industrial maturity, regulatory strictness, and sector activity, particularly within the oil and gas value chain. North America, driven by the substantial exploration and production activities in the U.S. shale plays and the mature industrial base in Canada, represents a leading market in terms of both revenue generation and the early adoption of advanced motor technologies. The region adheres strictly to the National Electrical Code (NEC) and Canadian Electrical Code (CEC), which define hazardous locations using the Division system (Division 1 and 2), creating a specific demand profile for UL and CSA certified products.

Asia Pacific (APAC) is currently the fastest-growing market, propelled by rapid industrialization, massive chemical complex investments in China, India, and Southeast Asia, and escalating energy infrastructure development, particularly LNG terminals and refinery expansions. The adherence to IECEx standards is prevalent across most APAC nations, simplifying the supply chain but intensifying competition among global manufacturers. Increased regional focus on environmental, social, and governance (ESG) factors is also accelerating the demand for high-efficiency IE4 certified explosion-proof motors.

Europe maintains a mature market characterized by extremely strict adherence to the ATEX directive, which governs equipment used in explosive atmospheres across all EU member states. European demand is stable, driven primarily by replacement cycles, ongoing maintenance in the heavily regulated chemical and pharmaceutical sectors, and governmental pushes for energy efficiency, reinforcing the transition away from IE2 and towards IE3 and IE4 motors as standard requirements in new installations.

- North America: Dominant market share due to mature petrochemical infrastructure and continuous capital investment in shale oil and gas operations; strong demand for UL and CSA certified motors.

- Asia Pacific (APAC): Highest growth rate fueled by rapid industrial expansion in chemicals, pharmaceuticals, and manufacturing across China and India; standardized use of IECEx certification.

- Europe: Stable growth driven by strict ATEX compliance, high safety standards, and a mandated focus on adopting Premium Efficiency (IE3/IE4) motors for energy savings.

- Middle East and Africa (MEA): Significant demand linked to massive state-owned oil and gas extraction and processing projects, requiring high-power, medium-voltage explosion-proof motors for critical applications.

- Latin America: Emerging growth market tied to renewed investments in deep-sea drilling and refinery modernization projects in countries like Brazil and Mexico, heavily influenced by IECEx standards.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Explosion-Proof Motors Market.- ABB Ltd.

- Siemens AG

- WEG S.A.

- Nidec Corporation

- TECO Electric & Machinery Co., Ltd.

- Regal Rexnord Corporation

- Wolong Electric Group Co., Ltd.

- Havells India Ltd.

- Brook Crompton

- Marathon Electric

- Danaher Corporation

- Hyosung Heavy Industries

- Leeson Electric

- Toshiba International Corporation

- Rockwell Automation

- General Electric

- Schneider Electric

- ATB Group

- Lenze SE

- CG Power and Industrial Solutions Ltd.

Frequently Asked Questions

Analyze common user questions about the Explosion-Proof Motors market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary drivers accelerating the demand for explosion-proof motors?

The primary drivers include increasingly stringent global safety regulations (like ATEX and IECEx), heightened investment in oil, gas, and chemical production infrastructure, and the necessity to replace older, less efficient motors with modern, certified, high-efficiency (IE3/IE4) models to ensure operational compliance and reduce energy consumption in hazardous zones.

How do the major certification standards, ATEX and IECEx, differ?

ATEX is a mandatory European directive (EU law) focused on equipment and protective systems intended for use in potentially explosive atmospheres within the EU. IECEx is an international certification system facilitating global trade by providing a globally accepted standard for confirming equipment conforms to IEC requirements, offering a unified path for regulatory acceptance across many non-EU countries.

What is the most common technology type used in explosion-proof motor protection?

The most widely deployed technology is the Flameproof or Explosion-Proof Enclosure (Ex d). This method involves designing the motor housing to be sufficiently robust to contain any internal explosion and cool the resulting hot gases before they can ignite the external hazardous atmosphere, making it suitable for Zone 1 and Division 1 environments.

Which end-user industry accounts for the largest share of the explosion-proof motors market?

The Oil and Gas industry, encompassing upstream extraction, midstream transportation, and downstream refining and petrochemical operations, consistently accounts for the largest market share. This dominance is due to the inherent presence of flammable hydrocarbons and volatile gases requiring mandatory use of certified safety equipment.

What role does the push for energy efficiency play in the explosion-proof motor market?

The global push for energy efficiency mandates the increasing adoption of Premium Efficiency (IE3) and Super Premium Efficiency (IE4) explosion-proof motors. Manufacturers are focusing on designing these highly efficient motors that not only minimize energy loss but also generate less heat, which is critical for maintaining safety standards (T-class ratings) in explosive atmospheres.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager