Explosive Emulsifier Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439884 | Date : Jan, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Explosive Emulsifier Market Size

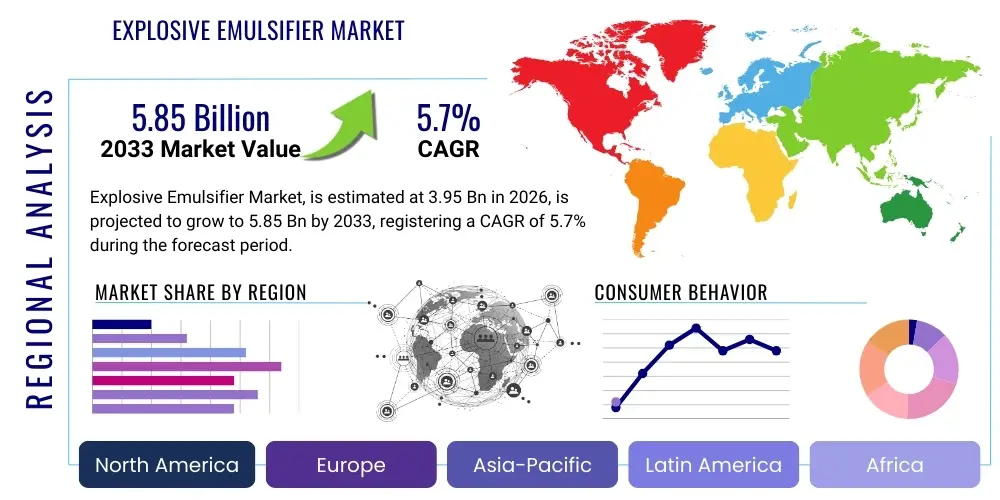

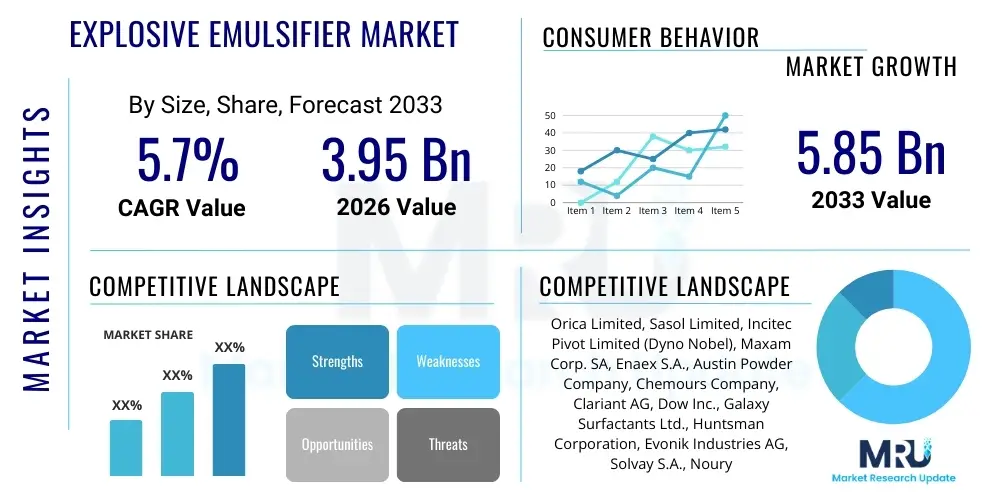

The Explosive Emulsifier Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.7% between 2026 and 2033. The market is estimated at USD 3.95 Billion in 2026 and is projected to reach USD 5.85 Billion by the end of the forecast period in 2033.

Explosive Emulsifier Market introduction

Explosive emulsifiers are critical chemical compounds that facilitate the stable mixing of immiscible liquids, typically water and oil phases, to form an emulsion matrix. This matrix is then combined with oxidizers like ammonium nitrate to produce emulsion explosives, which are widely utilized across various heavy industries. These specialized emulsifiers ensure the homogeneity and stability of the explosive formulation, preventing phase separation over time and maintaining consistent performance characteristics. The stability imparted by these emulsifiers is crucial for the safety, reliability, and efficiency of blasting operations, impacting everything from storage life to detonation velocity.

The primary applications of explosive emulsifiers span across diverse sectors including mining, construction, quarrying, and demolition activities. In mining, they are essential for extracting vast quantities of minerals and ores, enabling the efficient breakage of rock formations. For large-scale construction projects like road building, tunnel excavation, and dam construction, emulsion explosives formulated with these emulsifiers provide controlled and powerful blasting solutions. The inherent benefits of these modern explosives, such as enhanced safety due to reduced sensitivity, improved water resistance in wet environments, and greater energy yield compared to traditional alternatives, are directly attributable to the efficacy of the emulsifier component.

The market for explosive emulsifiers is primarily driven by the continuous global demand for raw materials, necessitating extensive mining operations, and significant investments in infrastructure development, particularly in emerging economies. Rapid urbanization and industrialization further fuel construction activities, creating a sustained need for efficient and safe blasting technologies. Moreover, technological advancements focusing on developing more environmentally friendly and high-performance emulsifiers, coupled with stringent safety regulations encouraging the adoption of safer explosive types, also serve as significant growth catalysts for this specialized market segment.

Explosive Emulsifier Market Executive Summary

The Explosive Emulsifier Market is experiencing robust growth, propelled by the relentless expansion of global mining activities and large-scale infrastructure projects worldwide. Key business trends indicate a strong focus on research and development to create more stable, safer, and environmentally benign emulsifier formulations, aiming to meet evolving regulatory landscapes and increasing demands for operational efficiency. Strategic collaborations between chemical manufacturers and explosive producers are becoming more prevalent, fostering innovation and optimizing supply chains to deliver tailored solutions to end-users. Consolidation within the market is also observable, with larger players acquiring specialized smaller firms to enhance their technological portfolios and market reach, thereby streamlining production and distribution channels globally.

Regionally, the Asia Pacific (APAC) stands out as the fastest-growing market segment, driven by burgeoning economies like China, India, and Southeast Asian nations that are undertaking massive infrastructure development projects and intensifying mineral extraction. North America and Europe, while mature, continue to represent significant market shares, characterized by stringent safety regulations that favor the adoption of advanced emulsion explosives and a constant demand for technological upgrades in their established mining and construction sectors. Latin America also presents considerable opportunities due to its rich mineral resources and ongoing mining investments, whereas the Middle East and Africa are witnessing gradual growth spurred by urbanization and burgeoning resource exploration activities.

Segmentation trends reveal a sustained dominance of water-in-oil emulsion emulsifiers due to their superior stability, water resistance, and widespread adoption in bulk applications. However, there is a growing interest and investment in advanced emulsifier chemistries that offer improved performance in extreme temperatures and specialized applications, alongside a push for bio-based or greener alternatives to address environmental concerns. The demand for emulsion explosives continues to outpace traditional ANFO (Ammonium Nitrate Fuel Oil) explosives in many regions due to enhanced safety profiles and superior performance characteristics, directly impacting the demand for sophisticated emulsifier solutions. This shift necessitates continuous innovation from emulsifier manufacturers to support the evolving needs of the explosive industry.

AI Impact Analysis on Explosive Emulsifier Market

User inquiries regarding AI's impact on the Explosive Emulsifier Market frequently center on how artificial intelligence can enhance safety protocols, optimize manufacturing processes, improve supply chain predictability, and contribute to the development of novel, more effective emulsifier chemistries. Users are keenly interested in the potential for AI-driven predictive analytics to forecast demand for raw materials, thereby mitigating supply chain disruptions and optimizing inventory management. There is also significant curiosity about AI's role in real-time monitoring of explosive stability and performance, ensuring greater operational safety and efficiency in blasting operations. The overarching expectation is that AI will introduce unprecedented levels of precision, safety, and operational intelligence into a market traditionally reliant on empirical methods.

- AI-driven predictive maintenance for manufacturing equipment, reducing downtime and optimizing production cycles.

- Enhanced quality control through AI-powered image processing and sensor data analysis, ensuring consistent emulsifier properties.

- Supply chain optimization using AI algorithms to forecast demand, manage inventory, and identify potential sourcing risks for raw materials.

- Development of novel emulsifier formulations through AI-accelerated material science simulations and molecular modeling.

- Improved safety protocols in explosive handling and storage by AI monitoring of environmental conditions and predictive risk assessment.

- Real-time performance monitoring of emulsion explosives in the field using AI-analyzed sensor data for optimal detonation.

- Automated data analysis from blasting operations to feedback into emulsifier design for continuous improvement.

- AI-enhanced logistics for transport and distribution of emulsifiers and explosives, optimizing routes and reducing carbon footprint.

- Predictive analytics for market trends, enabling manufacturers to align production with future demand for specific emulsifier types.

- Robotics and AI in dangerous or repetitive manufacturing tasks, improving worker safety and production consistency.

DRO & Impact Forces Of Explosive Emulsifier Market

The Explosive Emulsifier Market is significantly influenced by a complex interplay of Drivers, Restraints, and Opportunities, collectively shaped by various impact forces. Key drivers include the escalating global demand for minerals and metals, which directly fuels the mining sector's need for advanced blasting agents, along with extensive infrastructure development projects across both developed and developing economies requiring efficient rock excavation. Additionally, the inherent benefits of emulsion explosives such as superior safety, water resistance, and controlled energy release, compared to traditional explosives, are driving their increased adoption, thereby boosting demand for specialized emulsifiers. Technological advancements focused on high-performance and environmentally safer formulations further propel market growth, addressing industry needs for improved efficiency and sustainability.

However, the market faces notable restraints including stringent regulatory frameworks governing the production, storage, transport, and use of explosives and their components. These regulations often impose high compliance costs and limit market entry for new players. Environmental concerns regarding the chemical footprint of emulsifiers and the residues from blasting operations also present significant challenges, prompting a shift towards greener alternatives which may be more expensive to develop and produce. The capital-intensive nature of research and development for novel emulsifier chemistries, coupled with the cyclical nature of the mining and construction industries, can create market volatility and uncertainty, impacting investment decisions and long-term planning for market participants.

Despite these challenges, substantial opportunities exist within the market. The growing focus on sustainable mining practices and green building initiatives creates a demand for bio-degradable or less toxic emulsifier solutions. Furthermore, advancements in remote detonation technologies and smart blasting systems offer avenues for integrating advanced emulsifiers that can perform optimally under diverse and challenging conditions, enhancing safety and precision. Emerging markets, particularly in Asia Pacific and Latin America, present untapped potential for growth due to their rich mineral reserves and ongoing urbanization, offering new geographical expansion prospects. Strategic partnerships for developing customized solutions for specific geological conditions also represent a significant opportunity for innovation and market differentiation. The continuous quest for safer and more efficient blasting methods globally remains a paramount driver for market innovation and adoption.

Segmentation Analysis

The Explosive Emulsifier Market is segmented to provide a granular understanding of its diverse components, helping stakeholders identify specific trends and opportunities. These segmentations typically categorize the market based on the type of emulsifier, the primary application area, and the chemical composition of the raw materials utilized in their production. Analyzing these segments provides crucial insights into market dynamics, competitive landscapes, and future growth trajectories, enabling businesses to tailor their strategies and product offerings more effectively to meet the varied demands of the global explosive industry.

- By Type:

- Water-in-Oil Emulsifiers

- Oil-in-Water Emulsifiers

- Hybrid Emulsifiers

- By Application:

- Mining (Coal Mining, Metal Mining, Industrial Mineral Mining)

- Construction (Road & Rail Construction, Tunneling, Dam Construction)

- Quarrying

- Demolition

- Oil & Gas Exploration

- Others (e.g., Seismic Exploration)

- By Raw Material:

- Ammonium Nitrate

- Fuel Oil (Diesel, Kerosene)

- Surfactants (Non-ionic, Anionic, Cationic)

- Thickeners

- Gelling Agents

- Other Additives

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, UK, France, Italy, Spain, Rest of Europe)

- Asia Pacific (China, India, Japan, South Korea, Australia, Rest of APAC)

- Latin America (Brazil, Argentina, Rest of Latin America)

- Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Value Chain Analysis For Explosive Emulsifier Market

The value chain for the Explosive Emulsifier Market commences with the upstream segment, encompassing the sourcing and production of critical raw materials. This stage involves suppliers of ammonium nitrate, which serves as the primary oxidizer, various types of fuel oils such as diesel and kerosene, and a diverse range of surfactants (e.g., sorbitan esters, ethoxylated alcohols) that are vital for creating and stabilizing the emulsion. Additionally, other chemical additives like thickeners, gelling agents, and pH modifiers are procured from specialized chemical manufacturers. The quality and availability of these raw materials directly impact the cost-effectiveness and performance characteristics of the final emulsifier product, making strong supplier relationships crucial for manufacturers.

Moving downstream, the value chain progresses to the manufacturing of explosive emulsifiers, where these raw materials are processed and blended according to proprietary formulations to produce stable emulsion bases. These emulsifiers are then sold to explosive manufacturers, who combine them with other components like sensitizers and gassing agents to formulate the final emulsion explosives. Further downstream, these emulsion explosives are distributed to end-users such as large-scale mining companies, construction firms undertaking major infrastructure projects, and quarrying operations. The performance of the emulsifier at this stage directly impacts the efficiency and safety of blasting operations, influencing productivity and operational costs for the end-users.

Distribution channels within the Explosive Emulsifier Market typically involve a combination of direct and indirect sales approaches. For major industrial clients like large mining conglomerates or national construction agencies, direct sales through dedicated sales forces and long-term contracts are common, facilitating technical support and customized solutions. Indirect channels involve a network of specialized distributors and agents who cater to smaller clients or geographically dispersed markets, ensuring broader market penetration and efficient logistics. These distributors often maintain regional warehouses and provide local support, playing a critical role in bridging the gap between manufacturers and diverse end-users, while also managing regulatory compliance for local transportation and storage of hazardous materials.

Explosive Emulsifier Market Potential Customers

The primary potential customers and end-users of explosive emulsifiers are diverse industrial entities heavily involved in large-scale material extraction, earthmoving, and demolition activities. These include global and regional mining companies operating in sectors such as coal, metal ores (e.g., copper, gold, iron), and industrial minerals (e.g., limestone, aggregates). These companies rely extensively on emulsion explosives for efficient overburden removal and ore body fragmentation, making them central to the demand for high-performance emulsifiers that ensure consistent blasting results and operational safety in challenging geological conditions.

Another significant segment of potential customers comprises construction companies engaged in major infrastructure development projects. This includes firms specializing in road and railway construction, tunneling for transportation and utilities, dam building for water management, and large-scale site preparation for industrial and commercial facilities. The need for precise and powerful blasting to clear land, create foundations, and excavate rock formations drives their demand for stable and reliable emulsion explosives, consequently creating a steady market for emulsifier manufacturers. Their preference often leans towards emulsifiers that offer enhanced safety features and adaptability to varying construction environments.

Furthermore, quarrying operations extracting aggregates for the construction industry, specialized demolition contractors involved in controlled implosions or structural dismantling, and companies engaged in oil and gas exploration (particularly for seismic surveying and well perforation) also represent key end-users. These diverse applications underscore the broad utility of emulsion explosives and, by extension, the critical role of high-quality emulsifiers. The demand from these sectors is often influenced by economic cycles, government spending on infrastructure, and commodity prices, which in turn dictate the operational scale and procurement needs for explosive emulsifiers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.95 Billion |

| Market Forecast in 2033 | USD 5.85 Billion |

| Growth Rate | 5.7% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Orica Limited, Sasol Limited, Incitec Pivot Limited (Dyno Nobel), Maxam Corp. SA, Enaex S.A., Austin Powder Company, Chemours Company, Clariant AG, Dow Inc., Galaxy Surfactants Ltd., Huntsman Corporation, Evonik Industries AG, Solvay S.A., Nouryon, Croda International Plc, Stepan Company, Akzo Nobel N.V., KLK Emmerich GmbH, Sinopec Corporation, Mitsubishi Chemical Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Explosive Emulsifier Market Key Technology Landscape

The technological landscape of the Explosive Emulsifier Market is characterized by continuous innovation aimed at enhancing stability, performance, safety, and environmental sustainability of emulsion explosives. A significant area of focus is on advanced emulsification techniques that allow for greater control over droplet size and distribution, thereby optimizing detonation velocity and energy transfer. This includes the development of multi-layered or complex emulsions and inverse emulsions, which offer improved stability under extreme temperature conditions and enhanced resistance to water ingress in challenging blasting environments. Research into novel surfactant chemistries, including gemini surfactants and polymeric surfactants, is crucial for developing more efficient and robust emulsifying agents that can perform optimally with diverse raw material inputs.

Another pivotal aspect of the technology landscape involves the incorporation of specialized additives and sensitizers that can modify the properties of the emulsion. This includes developing micro-balloons or chemical gassing agents that create uniform void spaces within the emulsion matrix, increasing its sensitivity and ensuring consistent detonation. There is also a strong emphasis on smart additive packages that can impart specific functionalities, such as improved rheology for easier pumping into boreholes, enhanced shelf-life, or better compatibility with various types of blasting caps and initiators. These advancements are essential for tailoring emulsion explosives to specific mining conditions and optimizing overall blasting efficiency.

Furthermore, the market is witnessing technological shifts towards greener and safer formulations. This involves the exploration of bio-based or biodegradable emulsifiers derived from renewable resources, aiming to reduce the environmental footprint of explosive manufacturing and use. Alongside this, significant R&D is directed towards reducing the hazardous nature of raw materials and intermediate products, improving worker safety during production and handling. Digitalization and automation are also playing an increasing role, with technologies like AI and IoT being integrated into manufacturing processes for real-time quality control, predictive maintenance, and optimized batch production, thereby driving consistency, efficiency, and safety across the entire value chain of explosive emulsifiers.

Regional Highlights

- North America: A mature market characterized by stringent safety regulations and a strong emphasis on technological advancements in the mining and construction sectors. The U.S. and Canada, with their extensive mineral resources and infrastructure development, represent significant demand, favoring high-performance and safe emulsion explosives.

- Europe: Driven by strict environmental compliance and safety standards, the European market for explosive emulsifiers is focused on sustainable and efficient blasting solutions. Countries like Germany, France, and the UK contribute to a stable demand, particularly for quarrying and civil engineering projects, while investing in greener chemistries.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, urbanization, and massive infrastructure projects in China, India, and Southeast Asian countries. The burgeoning mining sector and large-scale construction activities are creating immense demand for explosive emulsifiers, driving both volume growth and innovation.

- Latin America: Rich in mineral resources, countries like Brazil, Chile, and Peru exhibit substantial demand for explosive emulsifiers, primarily driven by extensive metal and industrial mineral mining operations. Economic stability and foreign investments in resource extraction directly influence market growth in this region.

- Middle East and Africa (MEA): This region is experiencing steady growth, propelled by increasing investments in infrastructure, urban development, and resource exploration, particularly in the construction and quarrying sectors. South Africa, with its significant mining industry, remains a key market, alongside emerging opportunities in the UAE and Saudi Arabia.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Explosive Emulsifier Market.- Orica Limited

- Sasol Limited

- Incitec Pivot Limited (Dyno Nobel)

- Maxam Corp. SA

- Enaex S.A.

- Austin Powder Company

- Chemours Company

- Clariant AG

- Dow Inc.

- Galaxy Surfactants Ltd.

- Huntsman Corporation

- Evonik Industries AG

- Solvay S.A.

- Nouryon

- Croda International Plc

- Stepan Company

- Akzo Nobel N.V.

- KLK Emmerich GmbH

- Sinopec Corporation

- Mitsubishi Chemical Corporation

Frequently Asked Questions

Analyze common user questions about the Explosive Emulsifier market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are explosive emulsifiers and their primary function?

Explosive emulsifiers are chemical agents that stabilize mixtures of immiscible liquids, typically fuel oils and an aqueous oxidizer solution, to form an emulsion matrix. Their primary function is to ensure the homogeneity, stability, and consistent performance of emulsion explosives used in blasting operations.

Which industries are the major consumers of explosive emulsifiers?

The primary consumers are industries requiring large-scale rock excavation and demolition. This includes the mining sector (coal, metal, industrial minerals), construction (roads, tunnels, dams), quarrying, and specialized demolition services.

How do regulations impact the explosive emulsifier market?

Stringent regulations govern the manufacturing, storage, transportation, and use of explosive materials and their components, including emulsifiers. These regulations enforce safety standards, environmental compliance, and quality control, significantly influencing product development, market entry, and operational costs for manufacturers.

What are the key drivers for growth in the explosive emulsifier market?

Key growth drivers include the increasing global demand for minerals and raw materials, extensive infrastructure development projects, the superior safety and performance characteristics of emulsion explosives compared to traditional alternatives, and ongoing technological advancements in emulsifier chemistry.

What role does sustainability play in the development of new emulsifiers?

Sustainability is an increasingly important factor, driving research and development towards bio-based, biodegradable, and less toxic emulsifier formulations. This focus aims to reduce the environmental footprint of explosive production and use, aligning with global green initiatives and evolving regulatory pressures.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager