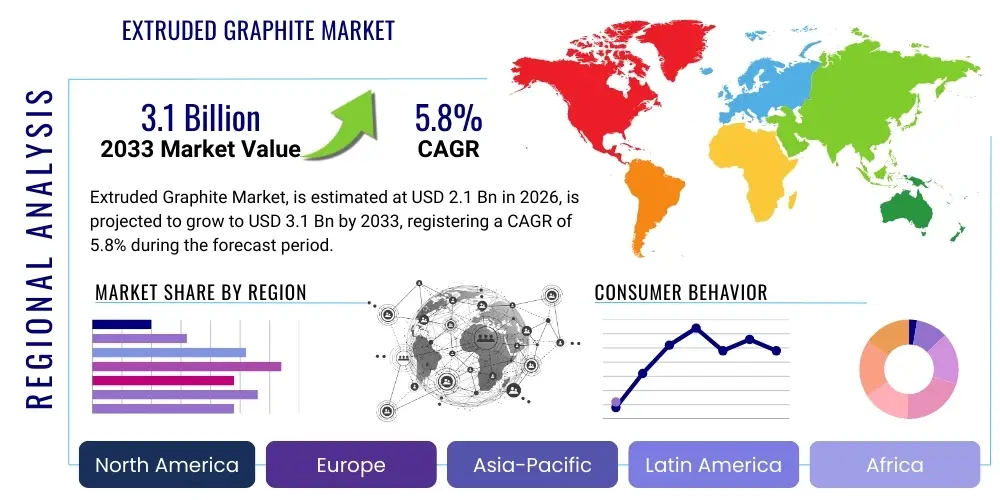

Extruded Graphite Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438569 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Extruded Graphite Market Size

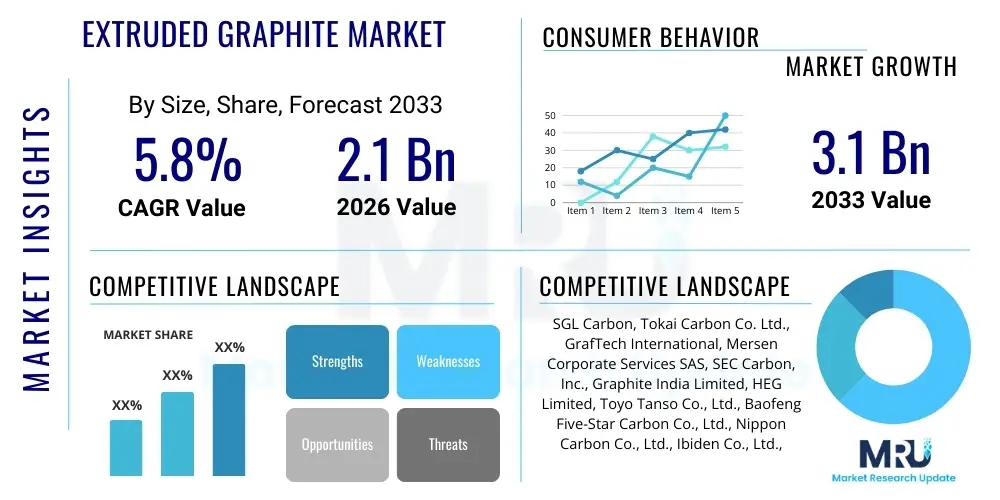

The Extruded Graphite Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 2.1 Billion in 2026 and is projected to reach USD 3.1 Billion by the end of the forecast period in 2033.

Extruded Graphite Market introduction

Extruded graphite constitutes a highly specialized category of carbon material manufactured through the process of mixing fine graphite powder with a pitch binder, heating the mixture, and then forcing it through a die to create specific shapes, typically rods, blocks, or tubes. This process imparts superior mechanical strength and thermal properties compared to molded graphite, making it indispensable in demanding industrial applications. Extruded graphite is characterized by its excellent thermal conductivity, high resistance to thermal shock, low coefficient of thermal expansion, and exceptional chemical inertness, particularly at elevated temperatures. These attributes position it as a critical material in sectors requiring high performance under extreme conditions.

The major applications driving the demand for extruded graphite include the production of electrodes for electrical discharge machining (EDM), crucibles and susceptors used in high-temperature metallurgy and semiconductor manufacturing, and specialized components in nuclear reactors and aerospace thermal management systems. The material’s ability to maintain structural integrity and purity in corrosive environments makes it superior to traditional materials in many processes. Furthermore, its lightweight nature relative to metals contributes to its adoption in mobility and transport technologies.

Key driving factors for market expansion include the surging global demand for electric vehicles (EVs), which utilizes graphite in battery production and in thermal management systems, and the ongoing expansion of the semiconductor industry, which requires high-purity graphite components for crystal growth and processing. The technological advancements in material science, focusing on producing finer grain structures and enhancing density, further extend the utility and performance characteristics of extruded graphite, solidifying its essential role across advanced manufacturing sectors globally.

Extruded Graphite Market Executive Summary

The Extruded Graphite Market is characterized by robust growth, primarily driven by accelerated industrialization in Asia Pacific, particularly China and India, and significant technological shifts in the automotive and electronics sectors globally. Business trends indicate a focus on vertical integration among major manufacturers to secure raw material supply (petroleum coke and coal tar pitch) and maintain quality control over the complex graphitization process. Strategic alliances and capacity expansions targeting high-purity and fine-grain graphite are prominent, reflecting the stringent requirements of end-user industries such as solar energy and advanced weaponry. Pricing stability remains a critical competitive factor, influenced heavily by global energy costs necessary for the high-temperature graphitization phase, which constitutes a major operational expenditure.

Segmental trends highlight the superior growth of fine-grain extruded graphite, favored for precision applications like EDM electrodes and semiconductor components, demanding higher density and isotropic properties. Although traditionally used, coarse-grain graphite maintains steady demand in large-scale metallurgical processes, such as aluminum reduction and steel arc furnaces. Application segmentation shows a distinct shift towards new energy applications (batteries and fuel cells) and aerospace, moving beyond conventional metallurgical uses. Innovations in composite graphite materials, integrating ceramics or carbon fibers, are emerging to further enhance thermal and mechanical performance, addressing highly niche market demands and paving the way for premium product offerings.

Regionally, Asia Pacific dominates the market, acting as both the largest producer and consumer, fueled by massive infrastructure projects, burgeoning EV manufacturing hubs, and concentrated semiconductor fabrication facilities. North America and Europe demonstrate mature market characteristics, focusing on advanced R&D and high-value, high-specification products, especially for nuclear and defense applications, emphasizing material traceability and quality compliance. The implementation of stringent environmental regulations regarding carbon emissions influences manufacturing practices globally, prompting investments in cleaner graphitization technologies and circular economy principles within the graphite production lifecycle.

AI Impact Analysis on Extruded Graphite Market

User queries regarding the impact of Artificial Intelligence (AI) on the Extruded Graphite Market predominantly center on optimization of complex manufacturing processes, predictive maintenance for high-value graphitization furnaces, and enhancement of material quality control. Users express concerns about the potential for AI-driven material discovery to introduce substitutes, but more commonly anticipate AI's role in improving yield rates, reducing energy consumption during the highly energy-intensive heat treatment phase, and optimizing the design of graphite components for specific thermal or mechanical stress applications. The consensus points towards AI being a significant enabler for operational efficiency and predictive quality management rather than a direct disruptor of material demand, ensuring highly customized and reliable products meet stringent industry specifications, especially in advanced electronics manufacturing.

- AI optimizes the pitch coking and graphitization cycles, leading to significant energy savings and reduced processing time, thus lowering operational costs.

- Predictive maintenance models, powered by AI, monitor the condition of critical extrusion and baking equipment, minimizing unscheduled downtime and improving capital asset utilization.

- Machine learning algorithms enhance quality control by analyzing microscopic material characteristics and porosity distribution, ensuring consistent, high-ppurity final products required for semiconductor fabrication.

- AI-driven simulation tools optimize the design of complex graphite molds and tooling, reducing material wastage during the initial design and testing phases.

- Improved supply chain visibility and risk management through AI analytics, particularly tracking the sourcing and quality variability of raw materials like needle coke.

DRO & Impact Forces Of Extruded Graphite Market

The market trajectory for extruded graphite is fundamentally shaped by robust demand from burgeoning high-technology sectors, coupled with inherent supply chain vulnerabilities and technological opportunities. Major drivers include the rapid expansion of the electric vehicle market, necessitating large volumes of high-performance graphite for battery thermal management and conductive components. Simultaneously, the persistent global build-out of semiconductor fabrication plants and the need for precision EDM electrodes fuels demand for ultra-fine grain graphite. Restraints primarily involve the volatile pricing and limited global supply of key raw materials, specifically high-quality needle coke, which requires intensive, capital-heavy processing. Furthermore, the substantial energy requirements for graphitization pose environmental challenges and expose manufacturers to fluctuating energy costs, necessitating continuous investment in efficiency.

Opportunities reside in the development of novel composite graphite materials, incorporating ceramics or carbon nanotubes to achieve superior strength-to-weight ratios and enhanced oxidation resistance, opening new avenues in aerospace and defense. The implementation of advanced manufacturing techniques, such as hot isostatic pressing (HIP), offers paths to produce graphite with near-perfect isotropic properties, highly valued in nuclear and precision engineering. The strategic importance of extruded graphite in critical sectors like nuclear energy and aerospace places it under continuous scrutiny, driving innovations in purity and traceability. These factors combine to create a dynamic market environment where technological differentiation and supply chain security are paramount competitive advantages.

Impact forces acting upon the market are complex and multifaceted. Economic forces, such as global GDP growth and industrial output, directly correlate with the consumption of extruded graphite in metallurgical and manufacturing processes. Regulatory forces, particularly environmental standards related to carbon emissions and waste disposal, necessitate significant capital expenditures for compliance and R&D into cleaner production methods. Technological forces, including advancements in EV battery technology (e.g., solid-state batteries potentially reducing traditional graphite anode demand) and improvements in EDM machining speed, constantly redefine product requirements. The balance between maintaining high purity, achieving low porosity, and managing energy-intensive production defines the success parameters for market participants navigating these diverse and powerful influencing factors.

Drivers

The foremost driver accelerating the extruded graphite market is the rapid globalization of high-technology manufacturing, specifically in electronics and electromobility. Extruded graphite’s superior thermal management capabilities are crucial for modern electronic devices and EV battery packs, where maintaining optimal operating temperatures is essential for longevity and performance. The material's unique combination of high thermal conductivity and low thermal expansion ensures stability in these demanding applications. Furthermore, the move toward miniaturization in semiconductor manufacturing requires incredibly fine and precise tools, making the high purity and fine-grain structure of advanced extruded graphite indispensable for complex etching and tooling processes.

Another significant driver is the increasing investment in nuclear power infrastructure globally, driven by the need for stable, low-carbon energy sources. Extruded graphite is critical in nuclear applications, serving as a moderator or reflector in certain reactor designs due to its excellent neutron-slowing properties and radiation stability. The sustained maintenance and expansion of existing industrial sectors, such as aluminum and steel production, also continue to generate steady demand for large, coarse-grain graphite electrodes, underpinning the foundational market volume. The material’s chemical inertness to molten metals ensures minimal contamination and extended life in high-temperature smelting and refining processes.

- Exponential growth in Electric Vehicle (EV) production driving demand for high-quality battery thermal management components.

- Expansion of the global semiconductor industry requiring ultra-high purity graphite for crystal growth and tooling.

- Increased global investment in nuclear energy and aerospace applications demanding highly reliable and radiation-resistant materials.

- Superior performance characteristics (thermal shock resistance, chemical inertness) compared to alternative materials in high-temperature industrial furnaces.

Restraints

A primary restraint challenging market growth is the volatility and scarcity of premium raw materials, particularly needle coke. High-quality needle coke, derived from petroleum or coal tar pitch, is essential for producing fine-grain, high-performance extruded graphite. Its limited global supply, controlled by a few key refiners, leads to significant price fluctuations and supply chain bottlenecks, directly impacting the operational stability and profitability of graphite producers. The stringent quality specifications demanded by aerospace and nuclear industries further restrict the availability of suitable raw material grades, raising entry barriers.

Furthermore, the production of extruded graphite, especially the graphitization phase, is intensely energy-intensive, requiring sustained high temperatures (up to 3,000°C) for several weeks. This dependency on reliable and affordable electricity sources exposes manufacturers to high variable costs and regulatory scrutiny related to energy consumption and carbon footprint. Although extruded graphite is superior in performance, the total cost of ownership, including complex machining and component replacement schedules, can sometimes lead smaller industries to explore less optimal but cheaper carbon-based alternatives or ceramic compounds, particularly for non-critical applications.

- High volatility and limited global supply of critical raw materials, primarily high-grade needle coke.

- Intense energy consumption and associated high operational costs during the graphitization process.

- Stringent regulatory requirements and high capital investment necessary for compliant production facilities.

- Potential material substitution pressure from advanced ceramic composites and alternative carbon materials in non-critical applications.

Opportunities

Significant opportunities exist in the development and commercialization of specialized, isotropic extruded graphite grades. Isotropic properties (uniform physical characteristics in all directions) are crucial for highly sensitive applications such as plasma etching equipment in semiconductor manufacturing and components within fusion reactors. Investing in advanced post-processing techniques, such as purification and impregnation processes, allows manufacturers to meet these ultra-demanding specifications and command premium pricing, establishing strong competitive moats.

Another key opportunity lies in expanding the use of extruded graphite into emerging renewable energy technologies. Beyond traditional solar panel manufacturing, the demand for graphite components in hydrogen fuel cells, where it serves as bipolar plates, is rapidly accelerating. Innovation in sustainable sourcing and production, including utilizing recycled or bio-based carbon precursors, offers a pathway to mitigate environmental concerns and reduce dependence on conventional petroleum coke. Companies focusing on these green graphite solutions can access emerging eco-conscious markets and gain a significant advantage in regions with strict environmental procurement policies.

- Growing demand for high-performance isotropic graphite for cutting-edge semiconductor and nuclear fusion applications.

- Expansion into the rapidly developing hydrogen fuel cell market, specifically for high-purity bipolar plates.

- Technological advancements in composite graphite materials, enhancing mechanical strength and oxidation resistance for aerospace use.

- Opportunities in sustainable manufacturing practices, including utilizing recycled carbon materials and developing low-emission graphitization techniques.

Segmentation Analysis

The Extruded Graphite Market is comprehensively segmented based on grain size, which fundamentally dictates performance and application suitability; raw material source, influencing purity and cost; and end-use application, which defines the primary demand drivers. Analyzing these segments provides a nuanced understanding of market dynamics, revealing that fine-grain extruded graphite consistently exhibits the highest growth rate due to its critical role in precision manufacturing and high-tech sectors. The segmentation by application clearly demonstrates a strategic shift in demand from traditional metallurgical uses towards high-growth areas like electronics, electric vehicles, and nuclear technology, which require materials with exacting specifications.

Segmentation by grade—fine-grain, medium-grain, and coarse-grain—is critical. Fine-grain graphite (typically < 20 micrometers) offers superior density and mechanical strength, making it ideal for EDM electrodes and high-precision molds. Coarse-grain graphite (up to 800 micrometers) is primarily utilized in large-scale applications like furnace linings and large electrodes, valuing bulk conductivity and low cost. The raw material segmentation underscores the preference for needle coke, particularly in applications demanding high isotropy and low impurity levels, whereas pitch coke often serves as a more cost-effective alternative for less critical structural components.

The end-use application segment confirms the market's dependence on industrial output, with metallurgy and manufacturing traditionally dominating volume. However, the future growth narrative is overwhelmingly tied to the expansion of niche, high-value segments, including aerospace components requiring exceptional thermal shock resistance and photovoltaic manufacturing, utilizing graphite crucibles for silicon crystal growth. Understanding the demand elasticity and technological maturity within each segment allows stakeholders to prioritize R&D investments and capacity expansion for maximum strategic return.

- By Grain Size: Fine-Grain Extruded Graphite, Medium-Grain Extruded Graphite, Coarse-Grain Extruded Graphite

- By Application: EDM Electrodes, Continuous Casting Dies, Crucibles and Boats, Nuclear Components, Furnace Parts and Linings, Semiconductor and LED Manufacturing, Aerospace and Defense

- By End-Use Industry: Metallurgy (Steel, Aluminum), Aerospace and Defense, Electronics and Semiconductors, Nuclear Energy, Chemical Processing, New Energy (EV Batteries, Solar)

- By Raw Material: Petroleum Coke Based, Pitch Coke Based

Value Chain Analysis For Extruded Graphite Market

The value chain for extruded graphite is characterized by intensive upstream processing and high capital expenditure throughout the manufacturing cycle. Upstream analysis focuses on the sourcing and preparation of specialized carbon precursors, primarily high-purity needle coke derived from either petroleum residues or coal tar pitch, along with the binding agents like coal tar pitch. The quality and stable supply of these raw materials are paramount, as they determine the purity, density, and isotropy of the final extruded product. Suppliers of needle coke hold significant bargaining power due to the specialized nature of their product and the limited global production capacity, making long-term contractual agreements essential for graphite manufacturers.

The midstream phase encompasses the core manufacturing processes: mixing, kneading, extrusion through specialized dies, baking (carbonization), and the final, highly energy-intensive graphitization phase (heating up to 3000°C). This stage requires specialized, custom-designed furnaces and precise control to achieve the desired material properties. Due to the high cost of entry and the technical complexity, this segment of the value chain is dominated by a few large, integrated players who possess the necessary proprietary technology and scale to operate efficiently.

Downstream analysis involves distribution channels and direct/indirect sales to end-users. Direct distribution is common for high-specification products (e.g., nuclear and aerospace components) where technical support and material traceability are critical. Indirect channels, involving specialized industrial distributors and machining houses, cater to broader markets like EDM electrode consumption and general metallurgical components. The final customers often require further machining of the extruded graphite blocks into precise shapes, making the relationship with technical machining service providers a vital link in delivering the final component solution.

Extruded Graphite Market Potential Customers

The primary customers for extruded graphite are concentrated within industries that rely on high-temperature processing, chemical inertness, and superior thermal management capabilities. The largest segment of potential buyers includes major steel and aluminum producers, particularly those utilizing electric arc furnaces, who purchase large volumes of coarse-grain electrodes. Beyond traditional heavy industry, the semiconductor fabrication sector represents a high-value customer base, seeking ultra-high purity, fine-grain graphite for crucibles, susceptors, and various tooling used in crystal growing and wafer processing, where material contamination is intolerable.

The growing electric vehicle and renewable energy sectors represent future high-growth customer bases, specifically requiring extruded graphite for battery components (thermal plates, molds) and solar panel manufacturing (polysilicon crystal growth). Furthermore, governmental agencies and defense contractors involved in aerospace and nuclear power generation are highly sensitive buyers, demanding compliance with strict material specifications (e.g., radiation stability, low porosity) and complete material traceability. These end-users typically engage in direct, long-term procurement relationships with certified graphite manufacturers to ensure supply security and quality assurance for mission-critical applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.1 Billion |

| Market Forecast in 2033 | USD 3.1 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SGL Carbon, Tokai Carbon Co. Ltd., GrafTech International, Mersen Corporate Services SAS, SEC Carbon, Inc., Graphite India Limited, HEG Limited, Toyo Tanso Co., Ltd., Baofeng Five-Star Carbon Co., Ltd., Nippon Carbon Co., Ltd., Ibiden Co., Ltd., Lier Chemical Co., Ltd., Guanghan Shida Carbon Co., Ltd., Jiangsu Ningdong Carbon Technology Co., Ltd., Chengdu Carbon Co., Ltd., Morgan Advanced Materials, Schunk Carbon Technology, Beijing North Xinyuan Electrical Carbon, Rescar, Entegris, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Extruded Graphite Market Key Technology Landscape

The technological landscape of the extruded graphite market is defined by continuous innovation aimed at enhancing material purity, reducing porosity, and achieving superior mechanical and thermal performance, particularly for ultra-high-performance applications. A core technology is the optimization of the mixing and extrusion process, utilizing advanced pressure control and temperature profiles to ensure uniform distribution of the binder and carbon filler, directly impacting the final grain structure and density. Furthermore, the selection and preparation of high-grade isotropic needle coke are crucial, often involving proprietary pre-treatment methods to stabilize the precursor material before coking, ensuring that the resulting graphite minimizes thermal anisotropy.

The critical technological differentiation occurs during the graphitization stage. Modern furnaces employ advanced heating elements and insulation techniques to achieve higher temperatures (up to 3000°C) more efficiently, reducing energy consumption and achieving higher levels of purity through volatilization of impurities. Post-processing technologies, such as chemical purification treatments (e.g., halogen treatment) and the use of carbon vapor deposition (CVD) or pitch impregnation, are key to enhancing the material’s oxidation resistance, density, and mechanical integrity, thereby expanding its utility in corrosive environments like chemical processing and advanced metallurgy. These advancements are essential for meeting the non-negotiable purity standards set by the semiconductor and nuclear industries.

In addition to manufacturing refinement, R&D is heavily focused on novel graphite composites. This involves integrating secondary materials, such as carbon fibers, ceramics, or even nano-scale structures like graphene, into the extruded matrix to overcome graphite's inherent limitations, such as moderate strength and susceptibility to oxidation at high temperatures in air. For instance, the development of carbon-carbon composites and metal-impregnated graphite represents a significant technological leap, offering bespoke properties tailored for highly specific, extreme conditions in aerospace thermal shielding and braking systems. The adoption of simulation tools and AI in process modeling further accelerates the optimization cycles for these complex material formulations.

Regional Highlights

- Asia Pacific (APAC): APAC is the unequivocally dominant region in the extruded graphite market, accounting for the largest share in both production capacity and consumption volume. This dominance is intrinsically linked to the concentration of global manufacturing activities, particularly in China, South Korea, and Taiwan. China, in particular, drives massive demand through its expansive steel and aluminum production sectors, while also fueling high-growth applications via its leading role in EV battery manufacturing and domestic semiconductor expansion. The availability of relatively lower-cost labor and governmental support for industrial material production further solidifies the region's competitive edge, although environmental compliance requirements are steadily increasing, impacting smaller, non-compliant producers.

- North America: The North American market is characterized by high demand for specialty, high-specification extruded graphite, predominantly driven by the aerospace, nuclear, and defense sectors. While the volume is lower than in APAC, the value generated per unit is significantly higher due to stringent quality control, traceability requirements, and the necessity for certified materials. The resurgence of investment in domestic semiconductor fabrication (driven by legislative incentives) and the growing emphasis on advanced manufacturing for electric vehicle R&D are key factors stimulating demand for ultra-fine-grain and isotropic graphite grades. Innovation focuses heavily on material science and achieving maximum purity levels.

- Europe: Europe represents a mature market focusing on high-end industrial applications and robust R&D, particularly in renewable energy (solar, wind turbine components) and sophisticated metallurgy. Germany, France, and the UK are major consumption hubs, prioritizing quality, sustainability, and compliance with strict EU environmental regulations. The European automotive industry's rapid transition towards electrification drives considerable demand for thermal management solutions using high-conductivity extruded graphite. Manufacturers here emphasize energy-efficient production processes and the development of specialized, certified materials for critical infrastructure components.

- Latin America: The market in Latin America is primarily driven by the mining and raw materials sector, with sustained demand for large graphite electrodes in copper and steel production, particularly in countries like Brazil and Chile. Market growth is stable but generally slower compared to the tech-driven markets of APAC and North America. Investment in regional manufacturing capabilities is limited, making the region heavily reliant on imports of finished or semi-finished extruded graphite products from established global suppliers, leading to competitive pricing sensitivity.

- Middle East and Africa (MEA): The MEA region exhibits specialized demand tied predominantly to the petrochemical, oil and gas, and primary metals industries. High-performance graphite components are required for severe service environments, including corrosive chemical processing and high-temperature furnace lining applications in regional smelting operations. The growing investment in diversified energy sectors and industrial capacity across the Gulf Cooperation Council (GCC) countries presents emerging opportunities, although supply chain logistics and localized technical expertise remain crucial factors influencing market penetration.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Extruded Graphite Market.- SGL Carbon

- Tokai Carbon Co. Ltd.

- GrafTech International

- Mersen Corporate Services SAS

- SEC Carbon, Inc.

- Graphite India Limited

- HEG Limited

- Toyo Tanso Co., Ltd.

- Baofeng Five-Star Carbon Co., Ltd.

- Nippon Carbon Co., Ltd.

- Ibiden Co., Ltd.

- Lier Chemical Co., Ltd.

- Guanghan Shida Carbon Co., Ltd.

- Jiangsu Ningdong Carbon Technology Co., Ltd.

- Chengdu Carbon Co., Ltd.

- Morgan Advanced Materials

- Schunk Carbon Technology

- Beijing North Xinyuan Electrical Carbon

- Rescar

- Entegris, Inc.

Frequently Asked Questions

Analyze common user questions about the Extruded Graphite market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary differences between extruded graphite and molded graphite?

Extruded graphite is produced by forcing the carbon mixture through a die, resulting in a material with higher density, superior mechanical strength, and directional (anisotropic) properties along the axis of extrusion. Molded graphite is pressed in a mold, typically offering more uniform (isotropic) properties, but often with lower strength and density compared to extruded grades.

Which end-use industries drive the highest demand for high-purity extruded graphite?

The highest demand for ultra-high-purity extruded graphite comes from the semiconductor and nuclear energy industries. Semiconductors require materials free of contaminants for crystal growing and etching processes, while nuclear applications demand certified, radiation-stable graphite components for reactor moderators and reflectors.

How does the volatile supply of needle coke impact the extruded graphite market?

Needle coke is a critical, high-cost raw material used to produce fine-grain extruded graphite. Volatility in its supply and pricing directly affects the operational costs, profit margins, and production stability of graphite manufacturers, particularly those targeting high-performance applications like EDM and aerospace components.

What role does extruded graphite play in the electric vehicle (EV) sector?

In the EV sector, extruded graphite is essential for sophisticated thermal management systems, bipolar plates in fuel cells, and specialized tooling and molds used during the manufacturing of lithium-ion battery components, capitalizing on its high thermal conductivity and chemical resistance.

What key technological trends are shaping the future of extruded graphite manufacturing?

Key technological trends include the integration of AI for process optimization and quality control, the development of advanced purification techniques (like chemical or gas treatments) to meet ultra-high purity demands, and the innovation of graphite composites utilizing carbon fibers or nano-structures to improve structural integrity and oxidation resistance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Special And Extruded Graphite Market Size Report By Type (Detail Graphite, Medium Coarse Graphite (Grain Size 0.8mm), Electrode Graphite (Grain Size 2-4mm)), By Application (Electric Motor Brushes, Photovoltaic Industry, Semiconductor & LED Industries, High Temperature Furnaces, Metal Industry, Glass and Refractory Industries), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Extruded Graphite Market Statistics 2025 Analysis By Application (Heat Treating Field, Foundry & HY Metallurgy Field, Chemical Processing Field), By Type (Pitch Impregnated Type, Un-impregnated Type, Round Type, Square Type), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager