Extrusion Gear Pumps Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440193 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Extrusion Gear Pumps Market Size

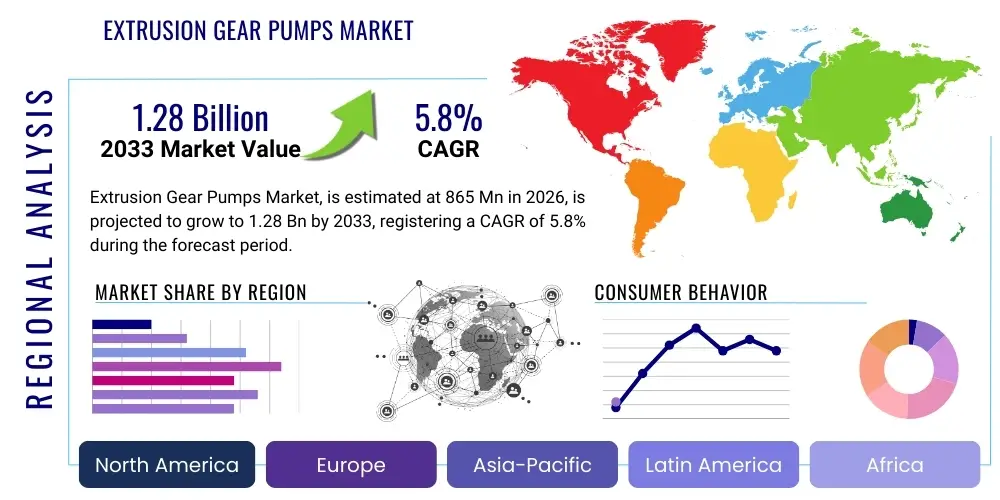

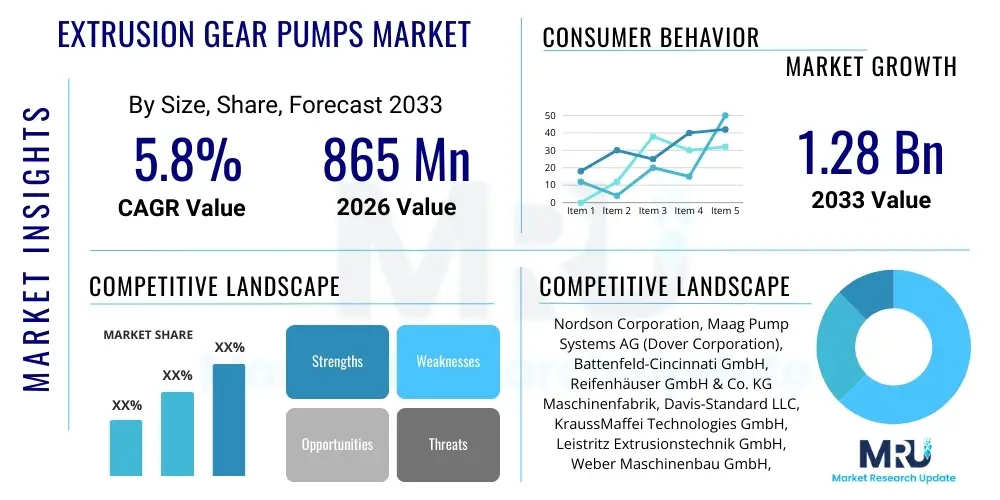

The Extrusion Gear Pumps Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 865 Million in 2026 and is projected to reach USD 1.28 Billion by the end of the forecast period in 2033.

Extrusion Gear Pumps Market introduction

Extrusion gear pumps are highly specialized positive displacement pumps designed to deliver a precise and pulsation-free melt stream from an extruder to a die. Primarily utilized in the plastics and rubber processing industries, these pumps play a crucial role in enhancing the quality, consistency, and throughput of extruded products. They are engineered to handle high viscosity polymer melts and maintain stable pressure and flow rates even under varying extruder conditions, which is essential for producing high-quality films, sheets, profiles, pipes, and compounded materials.

The core function of an extrusion gear pump involves taking the molten polymer from the extruder, building up the necessary pressure, and uniformly delivering it to the die. This process significantly improves the dimensional accuracy and surface finish of the final product by eliminating variations caused by extruder surges or fluctuations. Major applications span across diverse sectors including packaging, automotive, building and construction, medical, and consumer goods, where precision and material integrity are paramount.

The key benefits of integrating extrusion gear pumps into processing lines include improved product quality, reduced material waste due to fewer rejects, increased production efficiency through higher throughput, and enhanced control over the extrusion process. These advantages are driving market growth, alongside the increasing demand for high-performance plastics, the proliferation of complex multi-layer products, and the continuous push for automation and energy efficiency within manufacturing environments globally.

Extrusion Gear Pumps Market Executive Summary

The Extrusion Gear Pumps Market is characterized by robust growth driven by the expanding global plastics and rubber processing industries, coupled with an increasing demand for high-quality, precision-engineered extruded products. Key business trends include a heightened focus on automation and Industry 4.0 integration, allowing for more sophisticated control systems and real-time monitoring of extrusion processes. Manufacturers are also innovating in material science for pump components, enhancing durability and performance when handling abrasive or corrosive polymers, and developing energy-efficient models to align with sustainability goals and reduce operational costs.

Regionally, Asia Pacific continues to be the dominant force in the market, primarily due to the rapid industrialization, burgeoning manufacturing sector, and significant investment in new production capacities, particularly in countries like China and India. North America and Europe, while mature markets, demonstrate steady growth driven by technological advancements, the adoption of specialized high-performance polymers, and the replacement of older equipment with more efficient and precise gear pumps. Latin America, the Middle East, and Africa represent emerging markets with considerable untapped potential, fueled by developing infrastructure projects and increasing industrial output.

From a segmentation perspective, melt gear pumps continue to hold the largest share due to their widespread application in various extrusion processes, while dosing gear pumps are gaining traction in niche applications requiring extremely accurate metering. Applications in film and sheet extrusion, as well as compounding and pelletizing, remain primary revenue generators. The market is also seeing trends towards customization, where pumps are tailored for specific polymer types or unique production requirements, underscoring the shift towards specialized solutions in a competitive industrial landscape.

AI Impact Analysis on Extrusion Gear Pumps Market

The integration of Artificial intelligence (AI) is set to significantly transform the Extrusion Gear Pumps market, addressing user concerns around operational efficiency, predictive maintenance, and quality consistency. Users are seeking solutions that can minimize downtime, optimize process parameters autonomously, and ensure consistent product quality across long production runs. AI-driven analytics will enable a shift from reactive maintenance to proactive interventions, predicting potential pump failures based on sensor data and historical performance, thereby reducing costly unscheduled stoppages. Furthermore, AI algorithms can analyze real-time extrusion data to fine-tune pump speeds, pressures, and temperatures, leading to optimized energy consumption and enhanced material utilization. This predictive and adaptive capability is expected to significantly elevate the performance and reliability of extrusion lines, meeting the industry's demand for higher precision and lower operational costs.

- AI-powered predictive maintenance: Monitors pump health and predicts failures, minimizing downtime.

- Real-time process optimization: Adjusts pump parameters based on AI analysis of melt flow and pressure.

- Enhanced quality control: AI identifies deviations in extruded product quality, linking them to pump performance.

- Automated fault diagnosis: AI algorithms rapidly pinpoint issues within the pump or extrusion line.

- Improved energy efficiency: AI optimizes pump operation to reduce power consumption.

- Digital twin simulation: AI enables virtual testing and optimization of pump designs and operational scenarios.

- Advanced material processing: AI assists in fine-tuning pumps for challenging or novel polymer formulations.

DRO & Impact Forces Of Extrusion Gear Pumps Market

The Extrusion Gear Pumps market is propelled by several robust drivers, primarily the burgeoning global demand for plastics and rubber products across various industries, including packaging, automotive, and construction. The increasing need for high-quality, defect-free extruded products with tight dimensional tolerances is forcing manufacturers to adopt precision equipment like gear pumps. Furthermore, the relentless pursuit of increased production efficiency, reduced material waste, and lower operational costs encourages the integration of advanced gear pump systems that offer stable melt delivery and improved process control. The growing trend towards automation and Industry 4.0 in manufacturing facilities also acts as a significant driver, as modern gear pumps are designed to integrate seamlessly with sophisticated control systems.

Despite these growth factors, the market faces certain restraints. The relatively high initial capital investment required for extrusion gear pumps can be a barrier for small and medium-sized enterprises (SMEs), particularly in developing regions. Maintenance requirements, although critical for ensuring longevity and performance, can also add to operational expenses if not managed efficiently. Moreover, the cyclical nature of the plastics and rubber industries, which are often influenced by global economic conditions, can lead to fluctuations in demand. Competition from alternative pumping technologies or even continued reliance on conventional extruder-only systems in less demanding applications also presents a constraint for market expansion.

Opportunities for market growth are abundant, particularly with the increasing adoption of high-performance and specialty polymers that demand precise processing capabilities. The ongoing development of smart manufacturing and AI integration offers significant potential for enhancing pump performance, predictive maintenance, and overall line efficiency. Emerging economies, with their rapidly expanding industrial bases and increasing consumer demand, present new geographical markets for extrusion gear pump manufacturers. Furthermore, the industry's focus on sustainable manufacturing practices and the processing of recycled or bio-based polymers open avenues for gear pumps specifically designed to handle these materials effectively. Technological advancements in pump materials, designs, and control systems will continue to create new opportunities for specialized and high-value solutions.

Segmentation Analysis

The Extrusion Gear Pumps market is comprehensively segmented to address the diverse needs and applications within the plastics and rubber processing industries. These segments provide a clear understanding of the market landscape, allowing stakeholders to identify key areas of demand, technological development, and competitive intensity. The primary segmentation criteria revolve around pump type, specific application areas, the end-use industries served, and the types of materials processed, reflecting the specialized nature of these industrial components.

- By Type

- Melt Gear Pumps

- Dosing Gear Pumps

- Metering Gear Pumps

- By Application

- Film & Sheet Extrusion

- Profile & Pipe Extrusion

- Compounding & Pelletizing

- Fiber Extrusion

- Cable & Wire Extrusion

- Blown Film Extrusion

- Recycling Applications

- By End-Use Industry

- Packaging

- Automotive

- Building & Construction

- Medical

- Electronics

- Consumer Goods

- Textile

- Agriculture

- By Material Processed

- Thermoplastics (e.g., PE, PP, PVC, PET, PA, PC)

- Elastomers & Rubber

- Adhesives & Sealants

- Specialty Polymers & Composites

- Bio-based Polymers

Value Chain Analysis For Extrusion Gear Pumps Market

The value chain for the Extrusion Gear Pumps Market begins with a critical upstream segment involving the sourcing of specialized raw materials and precision components. This includes high-grade steels for gears and housings, advanced ceramics for bearings, and specialized alloys for seals and shafts, all requiring superior wear resistance, temperature stability, and corrosion resistance. Key suppliers in this stage include material manufacturers, foundries, and precision machining companies that provide the foundational elements meeting stringent specifications. The quality and availability of these materials directly impact the performance, longevity, and cost-effectiveness of the final gear pump product. Relationships with reliable and innovative upstream suppliers are crucial for maintaining competitive advantages in product development and manufacturing efficiency.

Moving through the value chain, the core manufacturing stage involves the intricate design, engineering, and assembly of the gear pumps. Manufacturers invest heavily in R&D to develop innovative pump designs, optimize gear profiles, enhance sealing mechanisms, and integrate advanced control features. Precision manufacturing processes, including CNC machining, heat treatment, and specialized surface coatings, are employed to achieve the tight tolerances and robust construction required for high-performance operation. Quality control and testing are paramount at this stage to ensure each pump meets rigorous performance standards for flow accuracy, pressure stability, and operational reliability. This stage is dominated by specialized engineering companies with deep expertise in fluid dynamics and polymer processing.

The downstream segment of the value chain focuses on distribution, sales, and aftermarket services. Distribution channels can be direct, where pump manufacturers sell directly to large-scale extrusion line integrators and end-users, or indirect, involving a network of specialized distributors, agents, and system integrators. These indirect channels often provide localized technical support, installation assistance, and maintenance services, which are critical for customer satisfaction. Aftermarket services, including spare parts supply, routine maintenance, troubleshooting, and repair, represent a significant part of the value proposition, ensuring the sustained operation and efficiency of the pumps throughout their lifecycle. Effective distribution and robust service networks are vital for market penetration and customer retention.

Extrusion Gear Pumps Market Potential Customers

The primary potential customers for extrusion gear pumps are companies operating within the plastics, rubber, and chemical processing industries that utilize extrusion technology for manufacturing a wide array of products. This includes plastic film and sheet manufacturers who require precise melt delivery to produce uniform, high-quality films for packaging, agricultural, and industrial applications. These customers are highly sensitive to product quality and consistency, making extrusion gear pumps an indispensable component in their production lines for achieving tight thickness tolerances and superior surface finishes, which directly impacts their market competitiveness and material yield.

Another significant segment of potential customers comprises compounding and pelletizing companies. These firms specialize in blending various polymers with additives, fillers, and colorants to create customized plastic compounds or masterbatches. Extrusion gear pumps are critical in this sector for ensuring consistent mixing and uniform pellet formation, which directly influences the quality and performance of the final compounded material. The ability of gear pumps to handle high-viscosity melts and maintain stable pressure is paramount for these processes, where material homogeneity and throughput are key operational metrics.

Furthermore, manufacturers of profiles, pipes, and tubing, particularly for the automotive, construction, and medical industries, represent substantial potential customers. These applications demand high dimensional accuracy, smooth surfaces, and robust mechanical properties, all of which are significantly enhanced by the use of extrusion gear pumps. Companies producing specialized products like medical tubing, automotive weather seals, or construction profiles rely on the precision and stability offered by these pumps to meet stringent industry standards and customer specifications. The growing complexity of multi-layer products across these sectors further solidifies the need for advanced melt delivery systems.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 865 Million |

| Market Forecast in 2033 | USD 1.28 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Nordson Corporation, Maag Pump Systems AG (Dover Corporation), Battenfeld-Cincinnati GmbH, Reifenhäuser GmbH & Co. KG Maschinenfabrik, Davis-Standard LLC, KraussMaffei Technologies GmbH, Leistritz Extrusionstechnik GmbH, Weber Maschinenbau GmbH, Entex Rust & Mitschke GmbH, Zenith Pumps (Parker Hannifin Corp.), Dynisco LLC, Pexco LLC, Coperion GmbH, Gneuss Kunststofftechnik GmbH, Graham Engineering Corporation, Guill Tool & Engineering Co., Inc., Delta Extrusion, Luwa AG, Mitsubishi Heavy Industries Plastic Technology Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Extrusion Gear Pumps Market Key Technology Landscape

The technological landscape of the Extrusion Gear Pumps market is continuously evolving, driven by the demand for higher precision, efficiency, and reliability in polymer processing. A significant area of focus is on advanced materials for pump components, particularly for gears, bearings, and seals. Manufacturers are increasingly utilizing specialized tool steels, high-performance ceramics, and sophisticated surface coatings (such as nitriding, PVD/CVD coatings) that offer superior wear resistance, corrosion protection, and enhanced thermal stability. These material advancements are crucial for extending pump lifespan, reducing maintenance intervals, and enabling the processing of more abrasive, corrosive, or high-temperature polymers without compromising performance.

Another pivotal technological development lies in the precision engineering and manufacturing techniques employed for pump construction. Ultra-precise machining processes, including CNC milling and grinding, are essential for achieving the tight tolerances required for efficient gear meshing, minimal backflow, and pulsation-free melt delivery. This precision is directly linked to the pump's ability to provide stable pressure and volumetric flow, which are critical for the dimensional accuracy and consistency of extruded products. Innovations in gear tooth profiles and sealing mechanisms are also contributing to improved volumetric efficiency and reduced shear heating, leading to better product quality and energy savings.

Furthermore, the integration of smart technologies and advanced control systems is transforming the operational capabilities of extrusion gear pumps. Modern pumps are equipped with sophisticated sensors for real-time monitoring of melt pressure, temperature, and rotational speed. These sensors feed data into advanced Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCS), often incorporating AI and machine learning algorithms. This allows for predictive maintenance, automatic process optimization, and seamless integration into broader Industry 4.0 manufacturing environments. Such intelligent control systems not only enhance operational efficiency and product quality but also enable remote monitoring and diagnostics, significantly reducing potential downtime and optimizing overall production line performance.

Regional Highlights

- North America: A mature market characterized by early adoption of advanced extrusion technologies and a strong focus on high-performance polymers. Growth is driven by innovation, stringent quality requirements in automotive and medical sectors, and the upgrading of existing infrastructure. The region benefits from significant R&D investments and a demand for automation and energy-efficient solutions.

- Europe: Similar to North America, Europe is a technologically advanced market with a strong emphasis on sustainability, circular economy principles, and high-value-added products. Countries like Germany and Italy are major manufacturing hubs for extrusion machinery and components. Strict environmental regulations and the shift towards recycled and bio-based polymers are driving demand for specialized gear pumps.

- Asia Pacific (APAC): The largest and fastest-growing market, propelled by rapid industrialization, expanding manufacturing bases in China, India, and Southeast Asian countries, and increasing domestic consumption of plastic products. Significant investments in new production capacities, coupled with a strong emphasis on cost-effective yet efficient solutions, are key drivers. This region is a major global production center for packaging, consumer goods, and construction materials.

- Latin America: An emerging market experiencing steady growth, supported by investments in infrastructure, automotive manufacturing, and packaging industries. Economic stabilization and increasing foreign direct investment are contributing to the adoption of modern extrusion technologies. Brazil and Mexico are leading countries in this region for market expansion.

- Middle East and Africa (MEA): This region presents significant growth potential, driven by ongoing industrialization, diversification efforts away from oil dependence, and increasing demand for plastic products in construction, packaging, and agriculture. Saudi Arabia, UAE, and South Africa are key markets, with a growing focus on developing robust local manufacturing capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Extrusion Gear Pumps Market.- Nordson Corporation

- Maag Pump Systems AG (Dover Corporation)

- Battenfeld-Cincinnati GmbH

- Reifenhäuser GmbH & Co. KG Maschinenfabrik

- Davis-Standard LLC

- KraussMaffei Technologies GmbH

- Leistritz Extrusionstechnik GmbH

- Weber Maschinenbau GmbH

- Entex Rust & Mitschke GmbH

- Zenith Pumps (Parker Hannifin Corp.)

- Dynisco LLC

- Pexco LLC

- Coperion GmbH

- Gneuss Kunststofftechnik GmbH

- Graham Engineering Corporation

- Guill Tool & Engineering Co., Inc.

- Delta Extrusion

- Luwa AG

- Mitsubishi Heavy Industries Plastic Technology Co., Ltd.

- Colmec SRL

Frequently Asked Questions

What is an extrusion gear pump and why is it used?

An extrusion gear pump is a positive displacement pump that provides a precise, pulsation-free melt stream from an extruder to a die. It's used to enhance product quality, ensure consistent dimensions, and improve throughput by stabilizing melt pressure and flow, particularly in plastics and rubber processing, overcoming the inherent pulsations of a screw extruder.

How do extrusion gear pumps improve product quality and efficiency?

Extrusion gear pumps improve product quality by delivering a highly consistent, homogeneous melt stream to the die, which minimizes variations in product thickness and surface finish. Efficiency is boosted through reduced material waste due to fewer rejects, increased line speed, and precise control over the extrusion process, leading to higher throughput and lower operational costs.

What are the primary applications of extrusion gear pumps?

The primary applications include film and sheet extrusion, profile and pipe extrusion, compounding and pelletizing, fiber extrusion, and cable and wire coating. These pumps are critical in industries such as packaging, automotive, building and construction, and medical, where precision and material integrity are paramount for the final product.

What key factors are driving the growth of the Extrusion Gear Pumps Market?

The market's growth is primarily driven by the increasing global demand for high-quality plastics and rubber products, the continuous push for automation and Industry 4.0 integration in manufacturing, and the need for improved production efficiency and reduced waste. Innovations in material science and energy-efficient designs also contribute significantly to market expansion.

How is AI impacting the future of extrusion gear pumps?

AI is transforming extrusion gear pumps by enabling predictive maintenance to minimize downtime, real-time process optimization for enhanced efficiency and quality, and automated fault diagnosis. AI-driven analytics help fine-tune pump parameters, leading to improved energy efficiency and the ability to process complex materials more effectively, thus ushering in an era of smarter, more autonomous extrusion lines.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager