Fabric Dyeing Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440147 | Date : Jan, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Fabric Dyeing Machine Market Size

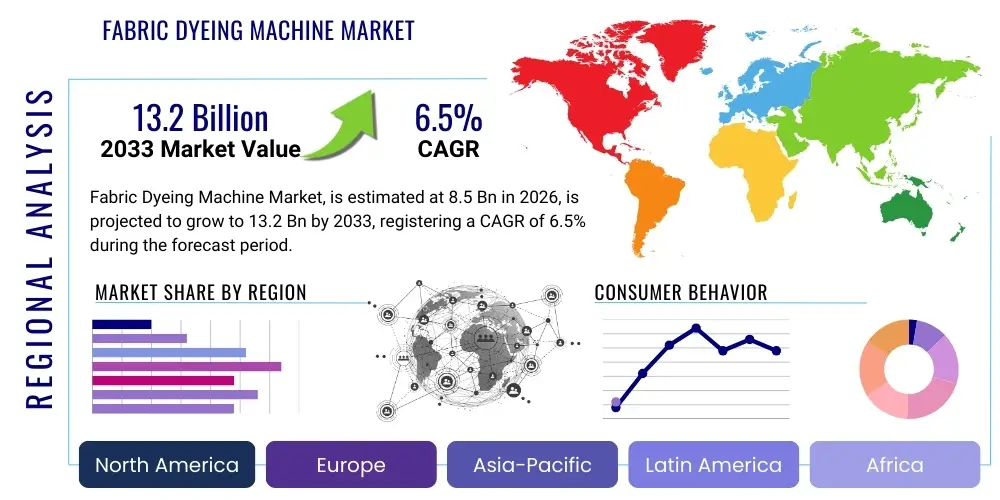

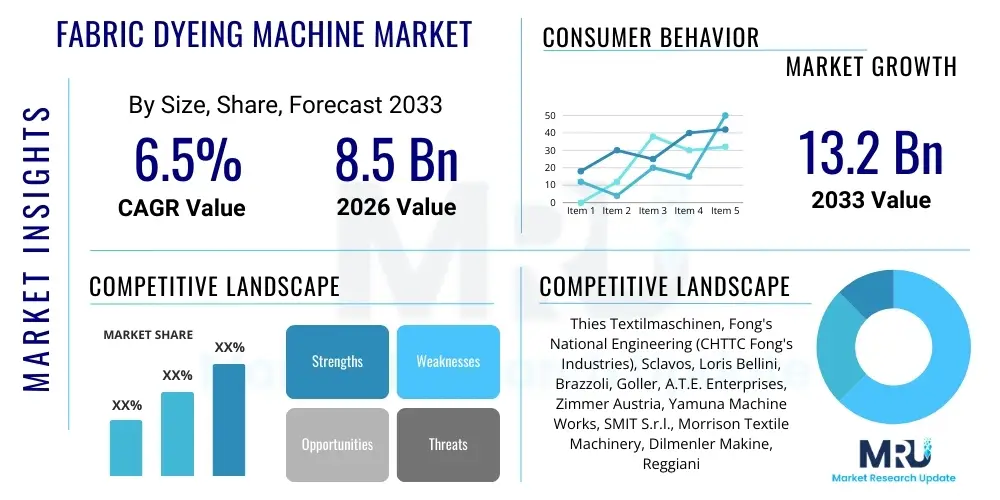

The Fabric Dyeing Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 8.5 billion in 2026 and is projected to reach USD 13.2 billion by the end of the forecast period in 2033. This robust growth is primarily driven by the escalating demand for vibrant and diverse textile products across various industries, coupled with continuous advancements in dyeing technologies aimed at enhancing efficiency, reducing environmental impact, and improving product quality.

Fabric Dyeing Machine Market introduction

The Fabric Dyeing Machine Market encompasses the global industry involved in the manufacturing, distribution, and utilization of machinery designed to impart color to fabrics. These machines are integral to the textile processing industry, playing a crucial role in transforming raw fabrics into aesthetically pleasing and commercially viable products. From batch dyeing systems for specialized orders to continuous dyeing lines for high-volume production, the product portfolio is diverse, catering to a wide spectrum of textile types and operational scales.

Major applications of fabric dyeing machines span across the apparel industry, where they color garments for fashion and sportswear; the home furnishing sector, for textiles like curtains, upholstery, and bedding; and the rapidly expanding technical textiles segment, including automotive interiors, medical textiles, and protective wear. The benefits offered by modern fabric dyeing machines include superior color consistency, high throughput, reduced water and energy consumption, and enhanced automation, leading to lower operational costs and improved product quality. These machines are designed to handle various fabric compositions, ensuring uniform dye penetration and fastness, which are critical for end-product performance and longevity.

Key driving factors for the market's growth include the ever-increasing global demand for colored and patterned textiles, driven by fashion trends and rising disposable incomes. Furthermore, technological innovations focusing on sustainable dyeing processes, such as low liquor ratio dyeing, supercritical CO2 dyeing, and advanced automation, are significantly contributing to market expansion. The growing emphasis on environmental responsibility and regulatory compliance is also pushing manufacturers to invest in more eco-friendly and resource-efficient dyeing solutions, thereby stimulating demand for advanced machinery.

Fabric Dyeing Machine Market Executive Summary

The Fabric Dyeing Machine Market is experiencing dynamic shifts, characterized by several prevailing business, regional, and segment trends. From a business perspective, there is a pronounced industry-wide move towards automation, digitalization, and the integration of Industry 4.0 principles, aiming to create smarter, more interconnected, and highly efficient dyeing factories. This trend is driven by the need to optimize production processes, reduce labor costs, and enhance precision in dyeing operations. Furthermore, textile manufacturers are increasingly prioritizing sustainability, leading to a surge in demand for machines that offer lower water and energy consumption, waste reduction, and the capability to use eco-friendly dyes, thereby aligning with global environmental objectives and regulatory pressures. Customization and the ability to handle smaller batch sizes efficiently are also gaining prominence, reflecting the fast-changing fashion cycles and personalized consumer demands.

Regionally, the Asia Pacific (APAC) continues to dominate the market, primarily due to its robust textile manufacturing base, particularly in countries like China, India, Bangladesh, and Vietnam, which serve as major global production hubs for apparel and textiles. This region benefits from lower production costs and a large skilled labor pool, driving significant investments in modern dyeing machinery. Europe and North America, while having mature textile industries, are distinguished by their focus on high-technology, specialized, and sustainable dyeing solutions, catering to high-value-added textiles and technical applications. These regions are at the forefront of R&D for advanced dyeing technologies and eco-friendly practices. Emerging markets in Latin America, the Middle East, and Africa are also exhibiting considerable growth potential, fueled by increasing industrialization and local demand for textiles, prompting investments in contemporary dyeing infrastructure.

Segmentation trends indicate a strong preference for automatic and semi-automatic dyeing machines, which offer enhanced control, consistency, and reduced human intervention compared to manual systems. Within machine types, jet dyeing machines remain popular for their versatility and efficiency with various fabric types, while package dyeing machines are favored for yarn and knitted fabrics. There is a growing demand for specialized machines tailored for technical textiles, which require precise and high-performance dyeing processes to meet stringent industry standards. Moreover, the market is witnessing a notable shift towards machines incorporating low liquor ratio technologies and advanced heat recovery systems, reflecting the industry's commitment to resource conservation and operational cost reduction, reinforcing the sustainability narrative across all segments.

AI Impact Analysis on Fabric Dyeing Machine Market

Users frequently inquire about the transformative potential of Artificial Intelligence (AI) in revolutionizing the fabric dyeing machine market, focusing on aspects such as efficiency gains, waste reduction, predictive maintenance capabilities, and the overall enhancement of dyeing precision. There is a strong user expectation that AI will address long-standing challenges like color consistency, resource overconsumption, and operational downtime. The core concerns revolve around how AI can integrate seamlessly with existing machinery, the required investment in AI-driven systems, and the potential for a significant return on investment through optimized processes and reduced environmental footprint. Users are particularly keen on understanding AI's role in creating smart, autonomous dyeing operations capable of real-time adaptation and predictive insights.

Based on these inquiries, the key themes summarizing users' expectations and concerns about AI's influence include its capacity to drive unparalleled operational excellence, foster sustainable manufacturing practices, and enable a new era of intelligent automation in textile dyeing. Users anticipate AI will empower manufacturers to achieve precise color matching across diverse fabric batches, minimize water and chemical usage through optimized process parameters, and pre-emptively identify potential machine malfunctions, thereby significantly reducing unplanned downtime. The overarching expectation is that AI will be a pivotal technology in propelling the fabric dyeing industry towards greater efficiency, sustainability, and competitive advantage, albeit with considerations around integration complexity and initial capital outlay.

- Predictive Maintenance: AI algorithms analyze sensor data from dyeing machines to predict equipment failures before they occur, optimizing maintenance schedules and minimizing costly downtime.

- Real-Time Process Optimization: AI-powered systems monitor dyeing parameters (temperature, pH, dye concentration) in real-time, making autonomous adjustments to ensure optimal color uptake and consistency, reducing human error.

- Advanced Color Matching: Machine learning models accurately predict dye recipes and combinations required to achieve specific colors across different fabric types, significantly reducing trial-and-error and material waste.

- Resource Consumption Optimization: AI optimizes water, energy, and chemical usage by analyzing historical data and current conditions, leading to substantial reductions in operational costs and environmental impact.

- Quality Control Automation: AI-driven vision systems detect color defects, uneven dyeing, or other fabric imperfections with high precision and speed, enhancing product quality and reducing manual inspection needs.

- Smart Supply Chain Integration: AI can forecast demand for specific colors and fabric types, enabling more efficient planning of dyeing processes and raw material procurement, leading to a more responsive supply chain.

- Customization and Small Batch Production: AI facilitates rapid recalibration of dyeing parameters for diverse orders, making short runs and customized production economically viable and highly efficient.

DRO & Impact Forces Of Fabric Dyeing Machine Market

The Fabric Dyeing Machine Market is shaped by a complex interplay of drivers, restraints, opportunities, and broader impact forces that collectively influence its growth trajectory and competitive landscape. Key drivers include the ever-expanding global textile industry, propelled by fashion trends, population growth, and rising disposable incomes that fuel demand for diverse apparel and home textiles. Technological advancements are continually pushing the boundaries of what is possible, with innovations in automation, energy efficiency, and sustainable dyeing processes attracting significant investment. The increasing emphasis on sustainable and eco-friendly manufacturing practices, driven by both consumer demand and stringent environmental regulations, also acts as a powerful driver, compelling textile manufacturers to upgrade to more resource-efficient machinery.

However, the market also faces considerable restraints. The high initial capital investment required for purchasing advanced fabric dyeing machines can be a significant barrier, especially for small and medium-sized enterprises (SMEs). Strict environmental regulations concerning water discharge, chemical usage, and energy consumption often necessitate costly upgrades or operational changes, adding to manufacturers' financial burdens. Furthermore, the textile industry's reliance on skilled labor for complex dyeing processes, coupled with a global shortage of such expertise, poses operational challenges. Fluctuations in raw material prices (dyes, chemicals) and energy costs also contribute to operational uncertainties, impacting profitability and investment decisions within the market.

Opportunities within the market are abundant, particularly in the realm of eco-friendly dyeing technologies such as supercritical CO2 dyeing, ozone treatment, and low liquor ratio machines, which promise significant reductions in water and chemical consumption. The ongoing integration of Industry 4.0 principles, including IoT, AI, and big data analytics, is creating avenues for smart factories, predictive maintenance, and optimized production lines. Emerging markets in Southeast Asia, Africa, and Latin America present vast untapped potential as their textile industries expand and modernize. Moreover, the growing demand for technical textiles across various sectors like automotive, medical, and protective wear, which require specialized dyeing processes, opens up niche market segments for advanced machinery. These dynamics collectively define the competitive environment, where innovation and sustainability are increasingly becoming critical differentiators.

Segmentation Analysis

The Fabric Dyeing Machine Market is comprehensively segmented to reflect the diverse technological capabilities, operational scales, and end-user applications that characterize this essential industry. These segmentations provide a granular view of market dynamics, enabling a more precise understanding of specific growth drivers, competitive landscapes, and emerging trends across different product categories and industrial applications. The primary dimensions for segmentation include the type of machine, the mode of operation, the fabric type processed, and the end-use industry utilizing the dyed textiles. Each segment is influenced by unique technological requirements, production volumes, and regulatory standards, illustrating the market's complexity and specialization.

Segmentation by machine type, for instance, differentiates between batch and continuous dyeing systems, with further classification into jet, jig, overflow, beam, and package dyeing machines, each designed for specific fabric characteristics and production efficiencies. Operation mode distinguishes between manual, semi-automatic, and fully automatic machines, reflecting varying levels of human intervention and automation capabilities. The fabric type segmentation highlights the specialized machinery required for woven, knitted, and non-woven textiles, considering their distinct structural properties and dye absorption characteristics. Finally, the end-use industry segmentation provides insight into the diverse applications of dyed fabrics, ranging from the high-volume apparel sector to specialized technical textiles in automotive, medical, and industrial fields, each with unique performance and aesthetic requirements.

This multi-faceted segmentation allows market participants to identify lucrative niches, understand competitive dynamics, and tailor their product offerings to specific market demands. For instance, the growing emphasis on sustainable practices impacts machine type and operation mode, driving demand for resource-efficient automatic systems. Similarly, the expansion of technical textiles necessitates the development of highly precise and robust dyeing machines capable of handling complex synthetic fibers. Analyzing these segments is crucial for strategic planning, product development, and market entry decisions, offering a holistic perspective on the Fabric Dyeing Machine Market's structure and future growth opportunities.

- By Machine Type:

- Jet Dyeing Machine

- Jig Dyeing Machine

- Overflow Dyeing Machine

- Beam Dyeing Machine

- Package Dyeing Machine

- Others (e.g., Continuous Dyeing Range, Garment Dyeing Machine)

- By Operation Mode:

- Automatic

- Semi-Automatic

- Manual

- By Fabric Type:

- Woven

- Knitted

- Non-woven

- By End-Use Industry:

- Apparel

- Home Furnishing

- Technical Textiles

- Automotive

- Others (e.g., Medical Textiles, Sports & Outdoor Wear)

Value Chain Analysis For Fabric Dyeing Machine Market

The value chain for the Fabric Dyeing Machine Market is a complex network of interconnected activities, beginning with raw material sourcing and extending through manufacturing, distribution, and ultimate application in textile production. This chain encompasses various stages, each adding value to the final product and influencing its cost, quality, and market reach. Upstream analysis involves the procurement of critical components and raw materials such as specialized metals, electrical and electronic components, control systems (PLCs, sensors), pumps, motors, and automation software. Key suppliers in this segment are often highly specialized, providing components that determine the machine's efficiency, reliability, and technological capabilities, thus forming a crucial foundation for machine manufacturing.

Midstream activities primarily involve the design, engineering, and manufacturing of the fabric dyeing machines. This stage includes intensive research and development to incorporate new technologies, enhance energy and water efficiency, and improve dyeing precision. Manufacturers invest heavily in advanced manufacturing processes, quality control, and assembly to produce machines that meet stringent industry standards and customer specifications. This phase also includes integrating advanced features such as automation, AI compatibility, and sustainable dyeing technologies, differentiating products in a competitive market. The brand reputation, technological expertise, and intellectual property of machine manufacturers are paramount at this stage.

Downstream analysis focuses on the distribution channels and the end-users of fabric dyeing machines. Distribution can occur through direct sales teams for large-scale projects and customized solutions, or through a network of distributors, agents, and system integrators who provide local sales, technical support, and after-sales services. These channels are crucial for market penetration and customer relationship management. The primary end-users are textile mills, apparel manufacturers, home furnishing companies, and technical textile producers, who integrate these machines into their production lines. Effective distribution and robust after-sales support are vital for customer satisfaction and repeat business, ensuring the efficient operation and longevity of the dyeing machines throughout their lifecycle.

Fabric Dyeing Machine Market Potential Customers

The potential customers for the Fabric Dyeing Machine Market are diverse, spanning various segments of the textile industry, each with unique operational needs, production scales, and specific requirements for dyeing technology. These end-users are primarily driven by the need for efficient, high-quality, and increasingly sustainable solutions to color fabrics, yarns, and garments for their respective markets. Their purchasing decisions are often influenced by factors such as machine capacity, automation levels, environmental impact, operational costs, and the ability to process specific types of fibers and fabrics. Understanding these customer segments is crucial for manufacturers to tailor their product offerings and marketing strategies effectively.

Large-scale textile mills and integrated manufacturing units represent a significant customer base, often requiring high-capacity, fully automatic, and continuous dyeing ranges to process vast volumes of fabric. These players prioritize high throughput, consistent quality, and advanced automation to maintain competitive advantage in global markets. Apparel manufacturers, particularly those involved in fast fashion or specialized garment production, seek versatile dyeing machines capable of handling different fabric blends and achieving a wide spectrum of colors with quick turnaround times. Their demand is often for flexible solutions that can adapt to rapid changes in fashion trends and production schedules.

Moreover, companies specializing in home furnishings (e.g., bedding, curtains, upholstery) and technical textiles (e.g., automotive interiors, medical textiles, sportswear, geotextiles) are vital potential customers. The home furnishing sector demands machines that ensure color fastness and durability, while technical textiles producers require highly specialized dyeing equipment capable of precise color application and often involving complex chemical processes to imbue fabrics with specific functional properties. Smaller independent dyeing houses and custom textile workshops also constitute a segment, often preferring semi-automatic or smaller-capacity batch dyeing machines that offer flexibility for bespoke orders and niche market requirements, highlighting the broad spectrum of buyers in this dynamic market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 8.5 Billion |

| Market Forecast in 2033 | USD 13.2 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Thies Textilmaschinen, Fong's National Engineering (CHTTC Fong's Industries), Sclavos, Loris Bellini, Brazzoli, Goller, A.T.E. Enterprises, Zimmer Austria, Yamuna Machine Works, SMIT S.r.l., Morrison Textile Machinery, Dilmenler Makine, Reggiani Macchine, Tong Geng Enterprise Co., Ltd., Santex Rimar Group, Then GmbH (part of Fong's), Bruckner Textile Technologies, Monforts Textilmaschinen, Vald Henriksen, Xorella AG. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fabric Dyeing Machine Market Key Technology Landscape

The Fabric Dyeing Machine Market is undergoing a profound technological transformation, driven by the dual imperatives of enhancing operational efficiency and promoting environmental sustainability. At the forefront of this evolution are innovations aimed at significantly reducing resource consumption, particularly water and energy, while maintaining or improving dyeing quality. One critical area is the development of low liquor ratio dyeing machines, which minimize the water-to-fabric ratio, thereby leading to substantial savings in water, chemicals, and energy required for heating and processing. Complementing this, advanced heat recovery systems are being integrated into dyeing lines to capture and reuse thermal energy, further boosting energy efficiency and reducing the carbon footprint of textile production. These technologies are pivotal in helping manufacturers meet stringent environmental regulations and reduce their operational expenditures.

Automation and digitalization are also reshaping the technological landscape, with the widespread adoption of PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition) systems for precise control and monitoring of dyeing parameters. The integration of Industry 4.0 concepts, including the Internet of Things (IoT) and artificial intelligence (AI), is enabling the creation of smart dyeing factories. IoT sensors collect real-time data on machine performance, dye bath conditions, and energy consumption, which AI algorithms then analyze to optimize processes, predict maintenance needs, and ensure consistent color matching. This level of connectivity and data intelligence allows for unprecedented levels of precision, predictive capabilities, and overall operational visibility, moving towards fully autonomous dyeing cycles.

Furthermore, innovations in alternative dyeing processes are gaining traction. Supercritical CO2 dyeing, for instance, eliminates the need for water altogether, using carbon dioxide as the solvent, which can be recycled, offering a truly waterless and highly efficient dyeing solution. While still in nascent stages for broad adoption due to high initial investment, its potential for zero wastewater discharge is immense. Other advancements include plasma treatments for surface modification of fabrics to enhance dye uptake, and ozone technology for desizing and bleaching, reducing reliance on conventional chemical-intensive methods. The ongoing convergence of mechanical engineering with chemical science, data analytics, and environmental engineering is continuously pushing the boundaries of what is possible in fabric dyeing, aiming for faster, cleaner, and more cost-effective solutions.

Regional Highlights

- Asia Pacific (APAC): The largest and fastest-growing market, driven by its dominance as a global textile manufacturing hub. Countries like China, India, Bangladesh, Vietnam, and Pakistan lead in production and export, necessitating continuous investment in advanced dyeing machinery to meet global demand and modernize existing facilities.

- Europe: A mature market characterized by a focus on high-value textiles, technical textiles, and sustainable dyeing solutions. Germany, Italy, Switzerland, and Turkey are key players, emphasizing research and development, automation, and eco-friendly technologies to comply with strict environmental regulations and cater to premium segments.

- North America: This region exhibits a strong demand for specialized, high-performance, and technical textiles, with a growing emphasis on smart manufacturing and automation to enhance efficiency and reduce labor costs. Investment is primarily in advanced, resource-efficient machines capable of handling complex synthetic fibers and meeting niche market demands.

- Latin America: An emerging market with significant growth potential, fueled by increasing local textile production and a rising consumer base. Countries like Brazil, Mexico, and Argentina are investing in modern dyeing machinery to upgrade their textile industries, driven by both domestic consumption and export opportunities.

- Middle East and Africa (MEA): This region is witnessing steady growth in the textile sector, particularly in countries like Turkey, Egypt, and the UAE, which are establishing themselves as textile manufacturing and trading hubs. Increasing investment in industrial infrastructure and a growing awareness of modern dyeing technologies are contributing to market expansion in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fabric Dyeing Machine Market.- Thies Textilmaschinen

- Fong's National Engineering (CHTTC Fong's Industries)

- Sclavos

- Loris Bellini

- Brazzoli

- Goller

- A.T.E. Enterprises

- Zimmer Austria

- Yamuna Machine Works

- SMIT S.r.l.

- Morrison Textile Machinery

- Dilmenler Makine

- Reggiani Macchine

- Tong Geng Enterprise Co., Ltd.

- Santex Rimar Group

- Then GmbH (part of Fong's)

- Bruckner Textile Technologies

- Monforts Textilmaschinen

- Vald Henriksen

- Xorella AG

Frequently Asked Questions

What are the latest technological advancements in fabric dyeing machines?

The latest advancements include low liquor ratio machines for water and chemical savings, integrated heat recovery systems for energy efficiency, and advanced automation with PLC/SCADA controls. Additionally, there is a growing focus on AI and IoT integration for real-time process optimization, predictive maintenance, and precise color matching, as well as the exploration of waterless dyeing technologies like supercritical CO2 dyeing.

How do environmental regulations affect the fabric dyeing machine market?

Environmental regulations significantly influence the market by driving demand for more sustainable and eco-friendly dyeing machines. Manufacturers are compelled to develop machines that reduce water consumption, minimize chemical discharge, lower energy usage, and facilitate the use of biodegradable dyes. This pressure encourages innovation in dyeing processes and machinery design to meet compliance standards and consumer demand for green products.

What role does automation play in modern fabric dyeing?

Automation is crucial in modern fabric dyeing, ensuring consistent quality, reducing labor costs, and increasing production efficiency. Automated systems offer precise control over dyeing parameters (temperature, pH, time), reducing human error and improving reproducibility. They also enable advanced features like automatic dosing, recipe management, and process monitoring, essential for smart factories and Industry 4.0 integration.

Which regions are experiencing significant growth in the fabric dyeing machine market?

The Asia Pacific (APAC) region, particularly countries like China, India, and Bangladesh, is experiencing the most significant growth due to its extensive textile manufacturing base and increasing investments in modernizing production facilities. Emerging markets in Latin America, the Middle East, and Africa are also showing considerable growth potential as their textile industries expand and industrialization progresses.

What are the key sustainability trends influencing fabric dyeing machine development?

Key sustainability trends include the development of machines with ultra-low liquor ratios to conserve water, integrated energy-saving features (e.g., heat recovery), and compatibility with eco-friendly dyes and chemicals. There is also a strong emphasis on reducing overall waste, minimizing effluent discharge through advanced filtration and recycling systems, and extending machine lifespan through predictive maintenance, all contributing to a circular economy approach in textile production.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager