Failure Mode and Effects Analysis (FMEA) Software Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439289 | Date : Jan, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Failure Mode and Effects Analysis (FMEA) Software Market Size

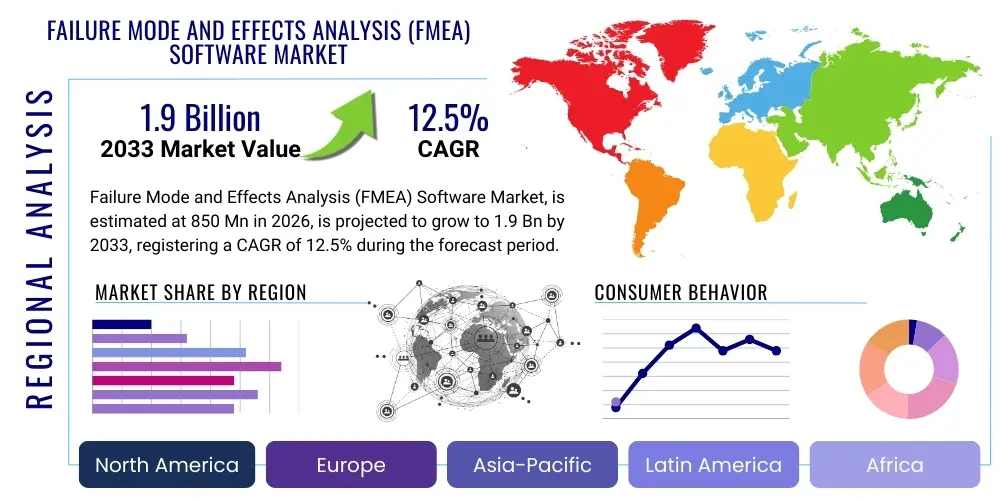

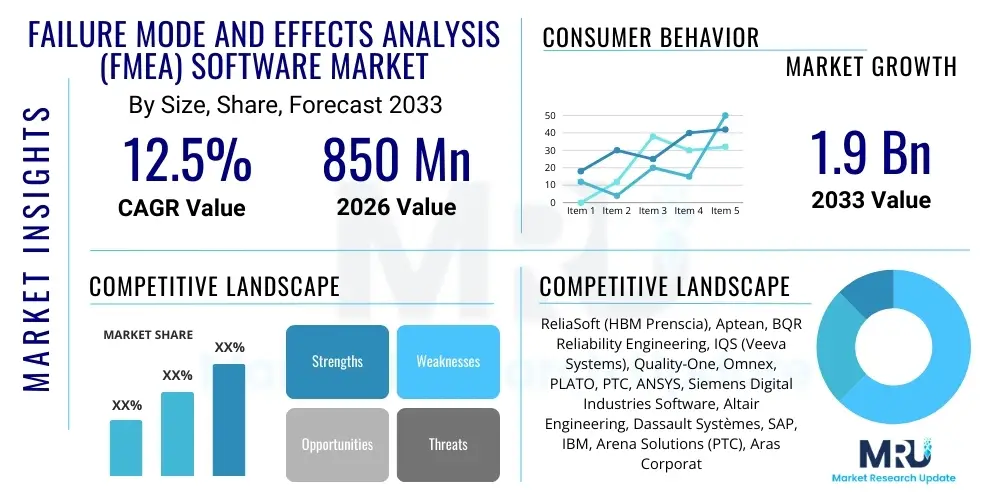

The Failure Mode and Effects Analysis (FMEA) Software Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.5% between 2026 and 2033. The market is estimated at USD 850 million in 2026 and is projected to reach USD 1.9 billion by the end of the forecast period in 2033. This robust growth trajectory is primarily driven by an increasing emphasis on product quality, operational efficiency, and stringent regulatory compliance across diverse industrial sectors. The escalating complexity of modern engineering systems and the imperative for proactive risk management strategies further underscore the criticality and growing adoption of FMEA software solutions, positioning the market for sustained expansion over the coming years.

Failure Mode and Effects Analysis (FMEA) Software Market introduction

The Failure Mode and Effects Analysis (FMEA) Software Market encompasses specialized digital tools designed to facilitate the systematic identification, evaluation, and mitigation of potential failure modes within products, processes, or systems. These sophisticated applications enable organizations to proactively analyze the causes and effects of potential failures, prioritize risks based on severity, occurrence, and detection, and implement corrective actions before issues manifest. The primary objective is to enhance reliability, ensure safety, reduce warranty costs, and comply with industry-specific quality standards. FMEA software provides a structured framework for teams to collaborate, document analyses, and track the effectiveness of implemented risk reduction measures, thereby fostering a culture of continuous improvement.

Major applications of FMEA software span a wide array of industries, including automotive, aerospace and defense, manufacturing, electronics, medical devices, energy, and process industries. In these sectors, the software is instrumental in product design (DFMEA), process design (PFMEA), and system design (SFMEA), helping engineers and quality professionals to pinpoint weaknesses during the early stages of development. The benefits derived from deploying FMEA software are multi-faceted, ranging from significant improvements in product quality and reliability to substantial reductions in operational costs associated with rework, recalls, and warranty claims. It also plays a crucial role in accelerating time-to-market for new products by streamlining development cycles and ensuring compliance with stringent regulatory frameworks.

The market's expansion is significantly propelled by several key driving factors. Regulatory pressures, particularly in highly scrutinized sectors such as automotive (ISO/TS 16949, now IATF 16949) and medical devices (ISO 13485, FDA), mandate the use of robust risk assessment tools, making FMEA software an indispensable asset. Furthermore, the increasing complexity of modern products and manufacturing processes necessitates automated and integrated solutions for managing potential failure points effectively. The global push for enhanced operational efficiency, reduced waste, and a commitment to customer satisfaction also acts as a powerful catalyst for the widespread adoption of these advanced analytical tools, transforming how organizations approach risk and quality management.

Failure Mode and Effects Analysis (FMEA) Software Market Executive Summary

The FMEA Software Market is experiencing dynamic growth, characterized by significant business trends that underscore its evolution. A prominent trend is the accelerating pace of digital transformation across industries, compelling enterprises to integrate FMEA capabilities into broader product lifecycle management (PLM) and enterprise resource planning (ERP) systems. Cloud-based FMEA solutions are gaining substantial traction, offering scalability, enhanced accessibility, and reduced infrastructure overheads, which are particularly appealing to small and medium-sized enterprises (SMEs) seeking cost-effective risk management tools. Moreover, the shift towards predictive quality management, driven by data analytics and artificial intelligence, is transforming how FMEA is conducted, moving from reactive analysis to proactive failure prevention.

Regionally, the market exhibits varied maturity levels and growth rates. North America and Europe currently represent the largest market shares, primarily due to the presence of well-established manufacturing industries, stringent regulatory environments, and high adoption rates of advanced quality management practices. These regions are characterized by a strong emphasis on product innovation and reliability, leading to sustained demand for sophisticated FMEA software. Conversely, the Asia Pacific region is projected to demonstrate the highest growth potential, fueled by rapid industrialization, burgeoning manufacturing sectors in countries like China and India, increasing foreign direct investment, and a growing awareness of international quality standards. Latin America, the Middle East, and Africa are emerging markets, showing gradual but steady adoption as industrial bases expand and regulatory frameworks mature.

Segmentation trends reveal a granular evolution within the FMEA software landscape. Cloud-based deployment models are rapidly outperforming on-premise solutions due to their flexibility and lower upfront costs, becoming a preferred choice for new adopters. Large enterprises continue to invest in comprehensive, integrated FMEA platforms, while SMEs are increasingly opting for subscription-based, user-friendly solutions. By application, FMEA software demand remains strong across design FMEA (DFMEA), process FMEA (PFMEA), and system FMEA (SFMEA), with a growing emphasis on integrating these analyses for a holistic risk perspective. End-user industries such as automotive, aerospace, and medical devices continue to be dominant contributors, but emerging sectors like renewable energy and smart manufacturing are also increasing their adoption, indicating a broader diversification of the market's customer base.

AI Impact Analysis on Failure Mode and Effects Analysis (FMEA) Software Market

Common user questions regarding AI's impact on the FMEA software market frequently revolve around its potential to automate manual processes, enhance the accuracy of risk assessments, and provide predictive insights. Users are keen to understand how AI can move FMEA beyond a static, human-intensive exercise to a dynamic, data-driven process. Key themes emerging from these inquiries include the feasibility of AI-driven failure prediction, the role of machine learning in identifying subtle failure patterns from vast datasets, and the extent to which AI can streamline the FMEA methodology, from data collection and analysis to the recommendation of mitigation strategies. There's also a significant interest in AI's capacity to integrate disparate data sources, such as sensor data, maintenance logs, and historical incident reports, to provide a more holistic and accurate risk profile. Concerns often focus on data quality requirements, the explainability of AI recommendations, and the necessary skill sets for implementing and managing AI-augmented FMEA systems.

The integration of AI and machine learning (ML) capabilities into FMEA software is poised to revolutionize traditional risk assessment methodologies. AI algorithms can analyze extensive historical data, including past failures, maintenance records, and warranty claims, to identify recurring patterns and causal relationships that might be imperceptible to human analysts. This enables a more precise and data-backed calculation of occurrence and detection probabilities, moving FMEA from a qualitative estimation to a more quantitative and predictive science. AI-powered FMEA tools can also significantly reduce the time and effort involved in initial risk assessments by automating data extraction, categorization, and preliminary analysis, allowing FMEA teams to focus on critical thinking and strategic problem-solving rather than tedious data processing.

Furthermore, AI facilitates predictive analytics within FMEA, enabling organizations to anticipate potential failure modes before they occur based on operational data from IoT sensors, digital twins, and real-time performance monitoring. This shift towards proactive risk management allows for the implementation of preventive measures, such as design modifications or predictive maintenance schedules, thereby enhancing product reliability and safety while simultaneously minimizing costly downtime and warranty expenses. The ability of AI to learn and adapt from new data continuously ensures that FMEA analyses remain relevant and accurate over time, reflecting changes in operational conditions, material properties, and environmental factors. This continuous learning cycle provides an unprecedented level of agility and responsiveness in managing complex system risks.

- Automated Data Analysis: AI algorithms can rapidly process vast amounts of unstructured and structured data from various sources, identifying failure patterns and correlations far beyond human capabilities.

- Predictive Failure Identification: Machine learning models can forecast potential failure modes and their likelihood based on historical data, sensor readings, and operational parameters, enabling proactive intervention.

- Enhanced Risk Scoring Accuracy: AI can provide more precise and objective evaluations of failure occurrence and detection rates, leading to more accurate Risk Priority Number (RPN) calculations.

- Intelligent Recommendation Systems: AI can suggest optimal mitigation strategies and corrective actions based on contextual data and best practices, improving decision-making processes.

- Integration with IoT and Digital Twins: AI-powered FMEA software can seamlessly integrate with real-time operational data from IoT devices and digital twin models, offering dynamic risk assessment.

- Streamlined FMEA Process: Automation of data collection, initial analysis, and report generation significantly reduces the manual effort and time required to conduct FMEA studies.

- Continuous Learning and Improvement: AI systems can continuously learn from new data and feedback, adapting their models to improve the accuracy and relevance of FMEA analyses over time.

DRO & Impact Forces Of Failure Mode and Effects Analysis (FMEA) Software Market

The Failure Mode and Effects Analysis (FMEA) Software Market is profoundly influenced by a complex interplay of drivers, restraints, and opportunities, collectively shaped by various impact forces. A primary driver is the escalating demand for product quality and reliability across virtually all industrial sectors. As consumers and regulators become increasingly discerning, companies are compelled to adopt advanced FMEA software to identify and mitigate potential failures early in the product lifecycle, thereby reducing recalls, warranty claims, and reputational damage. Additionally, stringent regulatory frameworks and compliance requirements, particularly in industries such as automotive, aerospace, and medical devices, mandate the use of systematic risk assessment tools, creating a non-negotiable demand for FMEA software. The increasing complexity of modern engineering systems and the global competitive landscape further necessitate efficient and standardized risk management, propelling market growth as businesses seek to streamline operations and ensure robust product performance.

Despite these significant drivers, the market faces several notable restraints that could temper its expansion. High initial investment costs associated with acquiring FMEA software licenses, coupled with the expenses for implementation, customization, and user training, can be a barrier for some organizations, especially small and medium-sized enterprises (SMEs) with limited budgets. Furthermore, the successful adoption and effective utilization of FMEA software require a skilled workforce capable of understanding complex analytical methodologies and interpreting the software's outputs. A shortage of such qualified personnel can hinder widespread implementation. Resistance to change within organizations, particularly from employees accustomed to traditional, manual FMEA processes, also poses a challenge. Integrating FMEA software with existing legacy systems, such as CAD, PLM, or ERP platforms, can present technical complexities and data compatibility issues, slowing down deployment and reducing perceived value.

However, substantial opportunities exist for market players to overcome these restraints and capitalize on emerging trends. The advent of Industry 4.0 and the proliferation of IoT devices offer immense potential for FMEA software to leverage real-time operational data for predictive failure analysis and dynamic risk assessment. The growing adoption of cloud-based FMEA solutions presents an opportunity to lower upfront costs, enhance accessibility, and cater to a broader range of businesses, including SMEs, through flexible subscription models. Furthermore, the integration of advanced technologies like Artificial Intelligence (AI) and Machine Learning (ML) is opening new avenues for automated data analysis, intelligent failure prediction, and optimized mitigation strategies, transforming the FMEA process into a more intelligent and efficient undertaking. Expanding into emerging markets, particularly in Asia Pacific, where industrialization is rapid and quality standards are progressively improving, also offers significant growth prospects for FMEA software vendors.

Segmentation Analysis

The Failure Mode and Effects Analysis (FMEA) Software Market is comprehensively segmented to provide a detailed understanding of its diverse components and dynamics. This segmentation helps in identifying key market trends, competitive landscapes, and growth opportunities across various dimensions, including deployment model, enterprise size, component, application, and end-user industry. Each segment represents distinct market characteristics and addresses specific requirements of different user groups, contributing to a granular view of market structure and functionality. Analyzing these segments provides strategic insights for stakeholders to tailor their product offerings and market approaches effectively.

- By Deployment Model:

- On-premise: Traditional software installed and run on local servers and computers within an organization's infrastructure. Favored by large enterprises with strict data security requirements.

- Cloud-based (SaaS): Software hosted on remote servers and accessed via the internet, typically on a subscription basis. Offers scalability, flexibility, reduced IT overhead, and remote accessibility, increasingly popular with SMEs and enterprises seeking agile solutions.

- By Enterprise Size:

- Large Enterprises: Companies with substantial revenues and workforce, often requiring comprehensive, integrated, and highly customizable FMEA solutions.

- Small and Medium-sized Enterprises (SMEs): Businesses with fewer resources, typically opting for cost-effective, easy-to-implement cloud-based or standardized FMEA software.

- By Component:

- Software: The core FMEA application that provides analytical tools, templates, reporting features, and integration capabilities.

- Services: Includes implementation, customization, training, consulting, and maintenance support provided by vendors or third-party integrators to ensure optimal software utilization and ongoing operational efficiency.

- By Application:

- Design FMEA (DFMEA): Focuses on identifying and mitigating potential failures in product design before prototyping and manufacturing.

- Process FMEA (PFMEA): Aims to analyze and prevent failures in manufacturing or assembly processes.

- System FMEA (SFMEA): Evaluates potential failure modes at a higher system level, considering interfaces and interactions between subsystems.

- Service FMEA (SFMEA): Applied to identify potential failures in service delivery processes.

- By End-User Industry:

- Automotive: Critical for ensuring vehicle safety, reliability, and compliance with stringent industry standards (e.g., IATF 16949).

- Aerospace and Defense: Essential for managing risks in highly complex and safety-critical aircraft and defense systems.

- Manufacturing (General): Used across various discrete and process manufacturing sectors for quality control and operational efficiency.

- Electronics and Semiconductors: Vital for high-volume, precision manufacturing processes and product reliability.

- Medical Devices: Mandated for ensuring patient safety and regulatory compliance (e.g., FDA, ISO 13485).

- Energy and Utilities: Applied in power generation, transmission, and distribution for risk management and operational continuity.

- Others (e.g., Food & Beverage, Construction, Chemical): Growing adoption in sectors prioritizing quality, safety, and process optimization.

Value Chain Analysis For Failure Mode and Effects Analysis (FMEA) Software Market

The value chain for the Failure Mode and Effects Analysis (FMEA) Software Market begins with the upstream activities involving research and development, software architecture design, and the development of core FMEA functionalities. This initial stage encompasses the creation of algorithms for risk assessment, templates for various FMEA types, reporting modules, and integration capabilities with other enterprise systems like PLM, ERP, and CAD. Key upstream players include specialized software developers, data analytics providers, and, increasingly, AI/ML platform developers who supply the foundational technologies and components that power modern FMEA solutions. The quality and innovation at this stage directly influence the efficacy and competitiveness of the final FMEA software product, dictating its ability to handle complex data and provide accurate insights.

Moving downstream, the value chain progresses through software development, testing, and ultimately, the distribution and implementation of the FMEA software. This phase involves extensive quality assurance to ensure the software's robustness, user-friendliness, and compliance with industry standards. Distribution channels play a crucial role in reaching potential customers. Direct sales channels, where software vendors market and sell their products directly to end-user enterprises, allow for bespoke solutions and close client relationships. Conversely, indirect channels involve partnerships with value-added resellers (VARs), system integrators, and consulting firms who often bundle FMEA software with their broader service offerings or integrate it into larger IT projects, extending market reach and providing specialized implementation expertise. The choice of channel often depends on the target customer segment, with larger, complex enterprises often preferring direct engagement for tailored solutions, while SMEs may benefit from the standardized offerings and local support provided by indirect partners.

The final stages of the value chain involve post-sales support, maintenance, and ongoing customer engagement. This includes providing technical assistance, software updates, training programs, and consulting services to ensure that customers maximize the value derived from their FMEA software investment. User training and continuous support are critical for successful adoption, especially given the analytical complexity of FMEA methodologies. Furthermore, customer feedback loop is vital for product improvement, driving future R&D and ensuring the software remains aligned with evolving industry needs and technological advancements. The entire value chain is characterized by a strong emphasis on collaboration between technology providers, software developers, integrators, and end-users to deliver comprehensive and effective risk management solutions.

Failure Mode and Effects Analysis (FMEA) Software Market Potential Customers

The potential customers for Failure Mode and Effects Analysis (FMEA) Software are diverse, spanning a wide array of industries and organizational functions, all sharing a common need for proactive risk management and quality improvement. Primarily, end-users are enterprises operating in sectors where product reliability, safety, and process efficiency are paramount. This includes major players in manufacturing, such as automotive original equipment manufacturers (OEMs) and their extensive supply chains, aerospace and defense contractors, medical device manufacturers, and producers of complex electronics and semiconductors. These industries are driven by stringent regulatory requirements, high safety standards, and the prohibitive costs associated with product failures or recalls, making FMEA software an indispensable tool for maintaining competitive advantage and ensuring compliance.

Beyond these traditionally dominant sectors, a burgeoning customer base is emerging in general manufacturing, energy and utilities, and even select service industries. Companies involved in industrial machinery, consumer goods, food and beverage processing, and construction are increasingly recognizing the value of FMEA software in optimizing their production processes, reducing waste, and enhancing overall product quality. In the energy sector, FMEA software aids in assessing risks related to infrastructure, equipment failures, and operational continuity, while in service-oriented businesses, it helps to identify potential breakdowns in service delivery processes. The growing emphasis on operational excellence, lean manufacturing principles, and sustainability initiatives across various industries is broadening the applicability and appeal of FMEA solutions to a wider spectrum of organizations.

Within these organizations, the key buyers and users of FMEA software typically include quality managers, design engineers, manufacturing engineers, process improvement specialists, reliability engineers, and risk analysts. These professionals are directly responsible for ensuring product safety, process robustness, and compliance with internal and external quality standards. Executive management, particularly those in operations, product development, and supply chain roles, also serve as crucial decision-makers, as FMEA software investments directly impact strategic objectives related to cost reduction, market reputation, and innovation cycles. The demand often arises from the need to streamline manual FMEA processes, integrate risk data across departments, and achieve a more systematic and auditable approach to failure prevention.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 million |

| Market Forecast in 2033 | USD 1.9 billion |

| Growth Rate | 12.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ReliaSoft (HBM Prenscia), Aptean, BQR Reliability Engineering, IQS (Veeva Systems), Quality-One, Omnex, PLATO, PTC, ANSYS, Siemens Digital Industries Software, Altair Engineering, Dassault Systèmes, SAP, IBM, Arena Solutions (PTC), Aras Corporation, Oracle, Ideagen, Greenlight Guru, Sparta Systems (Honeywell) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Failure Mode and Effects Analysis (FMEA) Software Market Key Technology Landscape

The Failure Mode and Effects Analysis (FMEA) Software Market is continuously evolving, driven by advancements in several key technology areas that enhance its capabilities and integration potential. Cloud computing, particularly Software-as-a-Service (SaaS) models, represents a foundational technology, enabling scalable, accessible, and cost-effective deployment of FMEA solutions. This allows organizations to leverage powerful analytical tools without significant upfront infrastructure investment, facilitating collaboration across distributed teams and enabling real-time data access. The inherent flexibility of cloud platforms supports rapid updates and seamless integration with other cloud-based enterprise applications, making FMEA software more agile and responsive to changing business needs and technological shifts.

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is profoundly reshaping the FMEA landscape. AI algorithms are increasingly being used for predictive analytics, capable of identifying potential failure modes based on vast historical data, sensor readings, and operational parameters. ML models can learn from past FMEA analyses and real-world failure data to improve the accuracy of risk assessments, automating parts of the FMEA process and reducing human error. This intelligence also extends to recommending optimal mitigation strategies and corrective actions, transforming FMEA from a reactive documentation exercise into a proactive, intelligent decision-support system. These technologies are crucial for processing the ever-increasing volume and complexity of data generated by modern industrial systems.

Furthermore, the FMEA software market is heavily reliant on robust data analytics and visualization tools, which enable users to interpret complex risk data effectively and communicate findings clearly. Integration capabilities with Product Lifecycle Management (PLM), Enterprise Resource Planning (ERP), Computer-Aided Design (CAD), and Manufacturing Execution Systems (MES) are also paramount, ensuring a holistic view of products and processes from design to end-of-life. The emergence of the Internet of Things (IoT) and Digital Twin technology further enriches FMEA by providing real-time operational data, allowing for dynamic FMEA updates and condition-based risk assessments. These synergistic technologies collectively empower FMEA software to deliver more comprehensive, accurate, and actionable insights, solidifying its role as a critical component of modern quality and risk management ecosystems.

Regional Highlights

- North America: This region holds a significant share of the FMEA software market, primarily driven by the strong presence of highly regulated industries such as automotive, aerospace, defense, and medical devices. Early adoption of advanced quality management practices, coupled with a robust technological infrastructure and substantial investments in research and development, contribute to its market leadership. The demand for sophisticated, integrated FMEA solutions is high, reflecting the region's emphasis on innovation, product reliability, and stringent compliance standards. The region also benefits from a mature ecosystem of software vendors and consulting services.

- Europe: Europe represents another major market for FMEA software, characterized by a strong manufacturing base, particularly in Germany's automotive and machinery sectors, and France's aerospace industry. Strict regulatory environments, including ISO standards and industry-specific certifications, mandate comprehensive risk assessment, fostering widespread adoption of FMEA tools. The region is witnessing a trend towards cloud-based solutions and the integration of FMEA with Industry 4.0 initiatives, aiming to enhance manufacturing efficiency and quality across the continent. Emphasis on product safety and environmental regulations further propels market growth.

- Asia Pacific (APAC): The APAC region is projected to be the fastest-growing market for FMEA software, fueled by rapid industrialization, burgeoning manufacturing sectors in China, India, Japan, and South Korea, and increasing foreign direct investment. As companies in this region strive to meet international quality standards and enhance their global competitiveness, the adoption of FMEA software is accelerating. Growing awareness of product liability, coupled with government initiatives promoting quality and operational excellence, provides significant growth opportunities for market players. The expansion of the electronics and automotive industries is a particular driver.

- Latin America: This region demonstrates steady growth in the FMEA software market, driven by the expanding manufacturing and automotive sectors in countries like Brazil and Mexico. Increasing industrialization and a rising focus on quality control and compliance are encouraging businesses to invest in FMEA solutions. While adoption rates may be lower compared to more developed regions, there is a clear upward trend as local industries integrate into global supply chains and seek to enhance their product and process reliability. The market here is still developing, offering long-term potential for growth.

- Middle East and Africa (MEA): The MEA market for FMEA software is an emerging landscape, characterized by gradual adoption. Growth is primarily observed in industries such as oil and gas, utilities, and nascent manufacturing sectors. As these economies diversify and industrial infrastructure expands, the need for robust risk management and quality assurance tools becomes more pronounced. Investment in large-scale industrial projects and a growing awareness of international safety and quality standards are key factors contributing to the slow but consistent market expansion in this region. Opportunities exist for vendors offering tailored, scalable solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Failure Mode and Effects Analysis (FMEA) Software Market.- ReliaSoft (HBM Prenscia)

- Aptean

- BQR Reliability Engineering

- IQS (Veeva Systems)

- Quality-One

- Omnex

- PLATO

- PTC

- ANSYS

- Siemens Digital Industries Software

- Altair Engineering

- Dassault Systèmes

- SAP

- IBM

- Arena Solutions (PTC)

- Aras Corporation

- Oracle

- Ideagen

- Greenlight Guru

- Sparta Systems (Honeywell)

Frequently Asked Questions

Analyze common user questions about the Failure Mode and Effects Analysis (FMEA) Software market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is FMEA software and why is it essential for modern industries?

FMEA (Failure Mode and Effects Analysis) software is a specialized digital tool designed to systematically identify, evaluate, and mitigate potential failure modes within products, processes, or systems. It is essential for modern industries because it enables proactive risk management, allowing organizations to pinpoint potential weaknesses and their root causes early in the development cycle, before they lead to costly failures, recalls, or safety incidents. This systematic approach enhances product quality, improves reliability, reduces warranty costs, ensures compliance with stringent industry regulations (e.g., ISO, IATF), and ultimately strengthens brand reputation. In today's complex manufacturing and operational environments, where product complexity and regulatory pressures are constantly increasing, FMEA software provides a structured, collaborative, and auditable framework for maintaining high standards of quality and operational efficiency, making it a critical component for competitive advantage and sustainable business operations. It transforms manual, error-prone processes into streamlined, data-driven analytical workflows.

How does FMEA software integrate with other enterprise systems like PLM or ERP?

FMEA software integrates with other enterprise systems like Product Lifecycle Management (PLM) and Enterprise Resource Planning (ERP) to create a seamless, interconnected data ecosystem, enhancing visibility and data consistency across an organization. Integration with PLM systems allows FMEA analyses to be directly linked to product designs, specifications, and engineering changes, ensuring that risk assessments evolve concurrently with product development. This prevents siloed information and ensures that design revisions are immediately reflected in FMEA documentation, streamlining compliance and reducing redundancy. Data from FMEA software, such as identified risks and recommended actions, can feed into the PLM system to inform design improvements or validation processes. Conversely, PLM provides FMEA with critical design data. Integration with ERP systems often focuses on linking FMEA outcomes to production planning, resource allocation, and quality control processes. For instance, critical failure modes identified in PFMEA (Process FMEA) can trigger specific quality checks or maintenance schedules within the ERP system, influencing procurement, inventory, and manufacturing workflows. This connectivity ensures that risk mitigation strategies are not only documented but also actively implemented and monitored throughout the operational lifecycle, optimizing resource utilization and improving overall process efficiency. These integrations are often achieved through APIs (Application Programming Interfaces) or specialized connectors, enabling automated data exchange and real-time updates across platforms.

What are the key benefits of adopting cloud-based (SaaS) FMEA software?

Adopting cloud-based (SaaS) FMEA software offers a multitude of benefits, making it an increasingly popular choice for organizations of all sizes. Firstly, it significantly reduces initial investment costs, as there is no need to purchase expensive hardware or manage complex on-premise infrastructure. Instead, users pay a subscription fee, converting a capital expenditure into a more manageable operational expense. Secondly, cloud solutions provide unparalleled scalability and flexibility, allowing organizations to easily scale up or down their FMEA capabilities based on project demands or business growth without requiring IT intervention. This agility is crucial for adapting to dynamic market conditions. Thirdly, cloud-based FMEA software offers enhanced accessibility, enabling users to access the platform from any location with an internet connection, fostering collaboration among geographically dispersed teams and facilitating remote work. Data security is often a top concern, and reputable SaaS providers typically offer robust security measures, data encryption, and regular backups, often surpassing what many individual organizations can implement on their own. Lastly, automatic updates and maintenance are handled by the vendor, ensuring users always have access to the latest features, bug fixes, and security patches without any downtime or manual effort, thereby reducing IT burden and ensuring continuous operational efficiency. This combination of cost-effectiveness, flexibility, accessibility, and streamlined management positions cloud-based FMEA as a highly attractive solution for modern risk management.

How do AI and Machine Learning enhance the effectiveness of FMEA software?

AI and Machine Learning (ML) significantly enhance the effectiveness of FMEA software by transforming it into a more predictive, data-driven, and automated tool. Traditionally, FMEA has been a manual, subjective, and time-consuming process heavily reliant on expert knowledge and historical data. AI and ML introduce capabilities such as predictive failure identification, where algorithms can analyze vast datasets from past failures, sensor data, and operational logs to anticipate potential failure modes and their likelihood before they occur. This moves FMEA from a reactive assessment to a proactive prevention strategy, allowing for timely intervention and design modifications. Furthermore, AI-powered FMEA tools can automate the laborious task of data collection, categorization, and preliminary risk scoring, significantly reducing human effort and improving consistency. Machine learning models can continuously learn from new data, improving the accuracy of occurrence and detection ratings, leading to more precise Risk Priority Number (RPN) calculations. They can also identify complex, subtle patterns and correlations in data that human analysts might miss, leading to a more comprehensive understanding of risks. Moreover, AI can provide intelligent recommendations for mitigation strategies based on best practices and historical success rates, optimizing decision-making processes. By integrating with IoT devices and digital twins, AI-enabled FMEA software can also offer real-time risk assessment, providing dynamic insights into system health and potential vulnerabilities. This transformative impact elevates FMEA from a static document to a living, intelligent risk management system, driving superior product reliability and operational safety.

Which industries are the primary adopters of FMEA software and why?

The primary adopters of FMEA software are industries where product reliability, safety, and adherence to stringent quality standards are paramount, and the costs of failure are exceptionally high. The automotive industry is a leading adopter, driven by consumer safety expectations, complex vehicle systems, and strict regulatory frameworks like IATF 16949. FMEA software is crucial for managing risks in design, manufacturing processes, and supply chains, preventing recalls and ensuring vehicle performance. Similarly, the aerospace and defense sector heavily relies on FMEA software due to the extreme safety requirements and the catastrophic potential of component failures in aircraft and defense systems. Compliance with FAA regulations and military standards necessitates rigorous risk assessment throughout the product lifecycle. The medical devices industry is another significant adopter, where FMEA is mandated by regulatory bodies like the FDA and ISO 13485 to ensure patient safety and product efficacy. Any malfunction in a medical device can have severe consequences, making proactive failure analysis indispensable. Furthermore, the electronics and semiconductor industry utilizes FMEA software to manage the complexity of microelectronics manufacturing, high-volume production, and the intricate design of integrated circuits, where even minute defects can lead to widespread product failures. These industries all share common characteristics: highly engineered products, complex manufacturing processes, significant R&D investment, and a critical need to minimize risks and maximize reliability, making FMEA software an essential strategic tool for maintaining competitive advantage and regulatory compliance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager