FBIC Conductive Bag Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435181 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

FBIC Conductive Bag Market Size

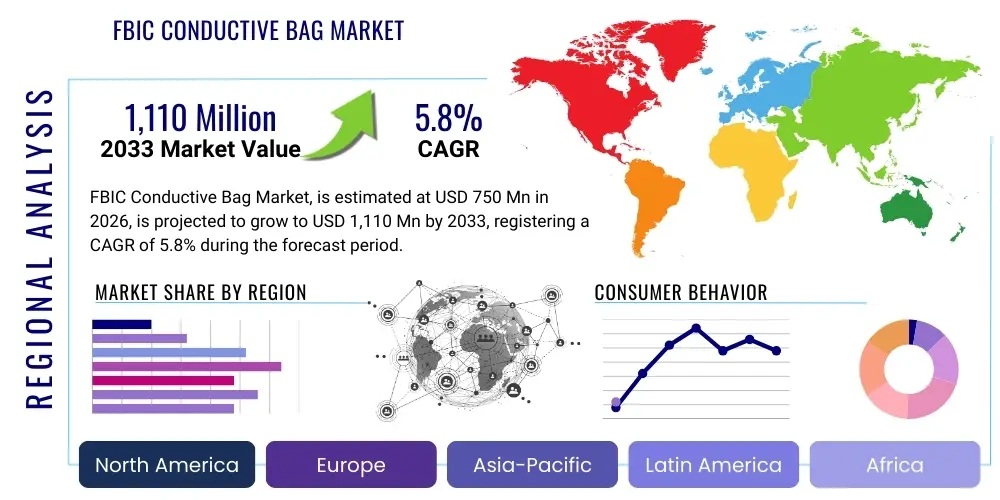

The FBIC Conductive Bag Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $750 Million USD in 2026 and is projected to reach $1,110 Million USD by the end of the forecast period in 2033.

FBIC Conductive Bag Market introduction

The Flexible Intermediate Bulk Container (FIBC) Conductive Bag Market centers on specialized industrial packaging designed to safely handle, store, and transport materials that are combustible or sensitive to electrostatic discharge (ESD). These bags, primarily classified as Type C (groundable) and Type D (dissipative, non-groundable), are crucial for industries dealing with fine powders, chemicals, and pharmaceuticals where static electricity buildup presents a severe risk of ignition or explosion. The bags are manufactured using complex weaving techniques involving conductive threads or specific coating additives, ensuring that any generated static charge is safely dissipated or channeled away, thus meeting stringent international safety standards such as IEC 61340-4-4 and NFPA 77.

The primary function of these conductive FIBCs is mitigating the hazard of electrostatic discharge during rapid filling and emptying processes, which are standard in bulk material handling. Major applications span the chemical sector (including pigments, resins, and hazardous intermediates), the pharmaceutical industry (for APIs and excipients), and the food processing sector (for fine grain powders like starch or sugar, which pose dust explosion risks). The increasing regulatory focus on workplace safety and environmental protection globally is accelerating the adoption of these specialized bags over traditional non-conductive alternatives (Type A and Type B), driving sustained market demand across developed and emerging economies.

Key benefits associated with using FBIC Conductive Bags include enhanced operational safety, reduced risk of material loss due to fire or explosion, and compliance with strict regulatory regimes governing explosive atmospheres (ATEX directives). Driving factors for market expansion include the continuous expansion of the global chemical manufacturing base, particularly in Asia Pacific, coupled with technological advancements in material science that improve the conductivity and durability of Type D bags, which offer inherent anti-static properties without the need for grounding.

FBIC Conductive Bag Market Executive Summary

The FBIC Conductive Bag Market exhibits robust growth, primarily propelled by the rigorous enforcement of industrial safety standards across chemicals, pharmaceuticals, and specialized food ingredients sectors. Business trends show a distinct shift toward Type D FIBCs, favored for their superior operational flexibility and reduced risk of human error associated with improper grounding, although Type C remains essential for high-hazard environments requiring guaranteed earth connectivity. Manufacturers are increasingly focused on integrating smart packaging elements, such as RFID tags, into these specialized bags to improve traceability and supply chain efficiency, particularly for high-value or highly hazardous materials.

Regionally, Asia Pacific (APAC) stands out as the fastest-growing market, driven by rapid industrialization, large-scale chemical production expansion in countries like China and India, and a growing emphasis on adopting international safety protocols to support export-oriented manufacturing. North America and Europe, while mature, maintain significant market shares due to established regulatory frameworks (e.g., OSHA, ATEX) and persistent demand from established chemical and pharmaceutical giants. Latin America and MEA are emerging markets, showing accelerated growth potential driven by infrastructure investments in oil and gas derivatives and increasing domestic manufacturing capabilities.

Segment trends highlight the dominance of the chemical industry as the largest end-user segment, utilizing bags for the transport of flammable powders and solvents. In terms of material, virgin polypropylene remains the primary constituent, but innovation in conductive composite materials is gaining traction. Capacity-wise, bags designed for 1,000 kg to 1,500 kg capacities are the most popular, reflecting standard bulk handling requirements. Overall, the market remains highly competitive, necessitating continuous innovation in material conductivity and structural integrity to maintain compliance and attract sophisticated industrial buyers.

AI Impact Analysis on FBIC Conductive Bag Market

User queries regarding the impact of Artificial Intelligence (AI) on the FBIC Conductive Bag Market primarily revolve around operational efficiency, quality control, and predictive supply chain management. Common concerns center on how AI can enhance the critical safety function of these bags—specifically, whether AI monitoring systems can offer real-time assurance of bag integrity and static dissipation performance, mitigating the risks associated with manual inspection protocols. Users are keen to understand the application of machine learning (ML) in predicting material degradation or potential failure points in the complex conductive fabric structure, a significant concern given the high-stakes nature of the materials being handled.

AI’s most immediate impact is expected within the manufacturing and logistics segments. In manufacturing, AI-powered computer vision systems can analyze the intricate weaving patterns and the proper integration of conductive filaments (carbon or stainless steel) during production, ensuring zero-defect rates for critical safety features—a capability that far surpasses traditional human quality checks. Furthermore, in logistics, ML algorithms optimize inventory levels and forecast demand for specific bag types (C vs. D) based on seasonal chemical production cycles and regulatory changes, reducing carrying costs and ensuring timely supply to high-risk industrial sites.

Looking forward, AI is set to integrate FBIC usage data—such as temperature exposure, handling stresses captured via smart sensors, and usage frequency—to provide predictive maintenance alerts for customers regarding the useful lifespan of reusable bags, moving beyond generic discard schedules. This integration transforms the bag from a passive containment unit into an active data point in the material handling ecosystem, fundamentally improving safety compliance and streamlining audit processes across regulated industries. The synthesis of sensor data and AI analytics will minimize operational downtime caused by catastrophic packaging failures.

- AI-driven Computer Vision Systems: Automated, real-time defect detection in conductive thread weaving and coating application, ensuring compliance with strict resistivity standards.

- Predictive Maintenance: ML algorithms analyze sensor data (temperature, pressure) embedded in bags to predict material stress and potential failure, optimizing bag reuse cycles.

- Supply Chain Optimization: AI forecasting models refine production schedules and inventory distribution for high-demand Type C and Type D FIBCs based on end-user industry output.

- Enhanced Traceability: Integration of AI with RFID/IoT tracking provides granular visibility into the handling history and environmental exposure of high-value or sensitive materials contained within the bags.

- Process Automation: AI optimizes bulk filling and discharge procedures by analyzing material flow dynamics and adjusting grounding processes dynamically to minimize static charge generation.

DRO & Impact Forces Of FBIC Conductive Bag Market

The FBIC Conductive Bag Market is primarily driven by stringent global regulations mandating safe handling protocols for combustible powders, pharmaceuticals, and chemicals in environments designated as potentially explosive (Ex zones). These regulations, such as the European ATEX directive, the US OSHA standards, and various international harmonized standards (e.g., IEC), compel manufacturers and processors to utilize specialized conductive or static-dissipative packaging like Type C and Type D FIBCs. The increasing volume of hazardous materials transported internationally further amplifies the need for certified, high-quality packaging solutions that minimize risk during cross-border logistics. This regulatory environment creates a continuous and non-negotiable baseline demand, serving as the most significant market driver.

However, the market faces significant restraints, notably the relatively high cost associated with manufacturing and mandatory independent testing of Type C and Type D bags compared to standard Type A and Type B FIBCs. The complexity arises from incorporating specialized conductive materials (carbon black, metallic fibers) and the intensive quality assurance processes required to guarantee a specific resistance level throughout the bag's structure. Furthermore, the risk of improper use, particularly failure to correctly ground Type C bags, introduces liability and operational risks for end-users, sometimes leading smaller operations to seek less efficient, albeit compliant, alternatives or heavily rely on internal grounding procedures rather than specialized packaging.

Opportunities for growth are concentrated in the rapid expansion of the global specialty chemical and Active Pharmaceutical Ingredient (API) manufacturing sectors, particularly in emerging economies where industrial standards are quickly being elevated to match Western benchmarks. The shift towards higher-value, lower-volume hazardous products necessitates safer, more reliable packaging. A key emerging opportunity lies in developing hybrid FIBC solutions that combine the best aspects of Type C and Type D bags, offering enhanced dissipation properties with integrated, user-friendly grounding verification mechanisms, potentially addressing the restraint associated with improper grounding and high liability risks. The increasing complexity of materials handled across sectors provides continuous impetus for innovation.

Segmentation Analysis

The FBIC Conductive Bag market is primarily segmented based on the type of conductivity mechanism employed (Type C or Type D), the capacity of the bag, the material used in manufacturing, and the end-user industry. Type C bags, which require grounding, dominate historically due to their assured connectivity to earth, while Type D bags are gaining market share rapidly due to their ability to safely dissipate charges without physical connection, offering superior flexibility in operational settings. Understanding these segments is crucial for manufacturers to tailor product offerings to specific safety protocols required by chemical and pharmaceutical clients.

- By Type

- Type C (Groundable)

- Type D (Static Dissipative)

- By Capacity

- Less than 500 kg

- 500 kg to 1,000 kg

- 1,000 kg to 1,500 kg

- Above 1,500 kg

- By Material

- Polypropylene (PP)

- Other Polymers (e.g., specialized composites)

- By End-Use Industry

- Chemicals and Petrochemicals

- Pharmaceuticals and Healthcare

- Food and Beverage (Combustible Powders)

- Mining and Minerals

- Others (e.g., Pigments, Plastics)

Value Chain Analysis For FBIC Conductive Bag Market

The value chain for FBIC Conductive Bags begins upstream with the procurement of specialized raw materials. This includes high-grade virgin polypropylene resins and essential conductive additives, such as carbon black masterbatches, conductive coatings, or specialized conductive threads (often stainless steel fibers or conductive carbon-coated filaments). Given the regulatory importance of conductivity, relationships with certified raw material suppliers who can ensure material consistency and purity are paramount. The upstream phase also includes the manufacturing of technical textiles, where polymer tapes are extruded, slit, and woven into the fabric panels that will form the main body of the FIBC. Quality control at this stage is critical, as the density and placement of conductive elements directly determine the final bag’s compliance rating.

The core manufacturing and processing stage involves weaving the fabric, cutting panels, specialized coating (lamination to add moisture resistance), printing, and critically, sewing the final bag. For Type C bags, ensuring the consistent electrical connection across all panels and the grounding tab is essential. For Type D bags, the proprietary static dissipative coating must be uniformly applied and tested. Distribution channels typically involve specialized industrial packaging distributors who possess expertise in handling and stocking hazardous goods packaging. Direct sales models are common for major chemical and pharmaceutical end-users who require highly customized specifications, allowing manufacturers to maintain tight control over quality assurance and technical support.

Downstream, the product moves into end-user operations, including filling, transportation, storage, and discharge. End-users require robust operational guidelines and training to ensure bags are handled according to safety specifications, especially the proper grounding of Type C bags. Indirect distribution, leveraging third-party logistics (3PL) providers specialized in industrial packaging, serves smaller enterprises. The value chain is characterized by stringent quality checkpoints, driven by the need for compliance, making testing laboratories and certification bodies key external influencers that validate product integrity before market entry.

FBIC Conductive Bag Market Potential Customers

Potential customers for FBIC Conductive Bags are predominantly large-scale industrial entities operating within hazardous environments where the handling of finely divided powders or flammable substances generates significant static electricity risks. The primary segment comprises chemical manufacturers dealing with organic compounds, pigments, resins, and hazardous intermediates. These companies use conductive FIBCs extensively for inter-plant transfer and global shipment of bulk materials, requiring compliance with regional standards like ATEX or NEC (National Electrical Code) to safeguard personnel and assets from catastrophic dust explosions or flash fires.

A second crucial segment includes pharmaceutical and biotechnology companies, particularly those involved in manufacturing Active Pharmaceutical Ingredients (APIs) and specialized excipients. API manufacturing often involves handling fine, easily dispersible powders that are both high-value and pose significant dust explosion risks. For these customers, certified Type C and Type D bags are non-negotiable components of their Good Manufacturing Practices (GMP) and safety protocols, ensuring product purity is maintained alongside electrostatic safety. The high cost of product recall or facility shutdown mandates investment in the highest quality conductive packaging.

Furthermore, the food and beverage industry, specifically processors dealing with fine powders such as flour, starch derivatives, sugar, and certain instant beverage mixes, represents a growing customer base. Although often overlooked, many food-grade powders possess low minimum ignition energy (MIE), making static charge a serious ignition source. Mining operations, particularly those handling pulverized metal ores or specific mineral powders, also constitute a significant, albeit niche, customer group requiring robust, high-capacity conductive solutions capable of withstanding harsh handling environments. These diverse end-users prioritize safety compliance, material integrity, and operational efficiency when selecting conductive FIBC suppliers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $750 Million USD |

| Market Forecast in 2033 | $1,110 Million USD |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Greif Inc., Bulk-Pack Inc., Conitex Sonoco, Berry Global Group, Taihua Group, LC Packaging International B.V., Intertape Polymer Group (IPG), Jumbo Bag Corporation, HALO FIBC, MiniBulk, Enviosack, FIBC-Silvassa, K.P. Woven, Sackmaker J&HM Dickson Ltd., Plastipak Packaging, Inc., RDA Bulk Packaging, Starlinger & Co. GmbH, United Bags, Coastal Bag Company, Inc., Tex-Trude S.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

FBIC Conductive Bag Market Key Technology Landscape

The technology landscape for FBIC Conductive Bags is highly specialized, revolving around achieving consistent electrical conductivity and structural integrity under demanding industrial conditions. The core technology involves the incorporation of conductive elements—either filaments woven directly into the fabric (typically Type C bags utilizing carbon-coated or stainless steel threads) or specialized chemical additives and coatings applied to the polymer base (common in Type D bags). Precision weaving technology ensures that the resistance pathway across the bag surface remains below the maximum permissible threshold (typically 10 Ohms to earth for Type C), which is essential for compliance and safety. Manufacturers heavily invest in advanced extrusion and weaving equipment capable of handling high-modulus, fine-denier conductive yarns without compromising the material’s mechanical strength.

A critical technological advancement is in the development of proprietary static dissipative coatings for Type D FIBCs. These coatings utilize specialized polymer matrixes doped with conductive materials to provide passive dissipation of static charge without requiring physical grounding. The effectiveness of Type D technology relies on maintaining surface resistance within the prescribed safety range (usually 10 to 10 Ohms) even under varying humidity conditions. Testing and validation technologies, such as advanced resistance and breakdown voltage testers compliant with IEC 61340-4-4, are integral to the production line, ensuring that every batch meets the required safety performance before shipment, establishing a high technical barrier to entry for new players.

Furthermore, technology is increasingly focused on enhancing traceability and user assurance. The integration of high-frequency RFID tags or QR codes directly into the conductive material matrix allows for enhanced supply chain management and automated usage logging, addressing concerns about bag reuse and lifecycle management in highly regulated sectors. Innovations in material science are exploring more sustainable conductive polymers and methods to incorporate recycled content without sacrificing the critical electrostatic properties, positioning technological development squarely at the intersection of safety compliance, operational efficiency, and environmental responsibility, thereby driving future market competitive advantage.

Regional Highlights

- Asia Pacific (APAC): Dominates market growth due to rapidly expanding chemical and pharmaceutical manufacturing bases, particularly in China, India, and Southeast Asia. Increasing adoption of global safety standards driven by export demands fuels high investment in compliant packaging solutions.

- North America: A mature market characterized by stringent federal regulations (OSHA, FDA) and high adoption rates of premium Type D FIBCs. Demand is stable, driven by established chemical processing giants and specialized food manufacturers in the US and Canada.

- Europe: Highly regulated by ATEX directives concerning explosive atmospheres, driving mandatory use of certified conductive packaging. Strong focus on sustainable production practices and circular economy initiatives prompts demand for durable, reusable, and traceable conductive bags.

- Middle East and Africa (MEA): Emerging market showing significant potential, linked to expanding petrochemical industries and substantial infrastructure investments. Growth is contingent on the adoption of international safety protocols in new industrial zones.

- Latin America: Steady growth fueled by increasing international trade in agricultural chemicals and mining products. Market maturity is varied, with countries like Brazil and Mexico leading the regional adoption of specialized FIBCs to meet export requirements.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the FBIC Conductive Bag Market.- Greif Inc.

- Bulk-Pack Inc.

- Conitex Sonoco

- Berry Global Group

- Taihua Group

- LC Packaging International B.V.

- Intertape Polymer Group (IPG)

- Jumbo Bag Corporation

- HALO FIBC

- MiniBulk

- Enviosack

- FIBC-Silvassa

- K.P. Woven

- Sackmaker J&HM Dickson Ltd.

- Plastipak Packaging, Inc.

- RDA Bulk Packaging

- Starlinger & Co. GmbH

- United Bags

- Coastal Bag Company, Inc.

- Tex-Trude S.A.

Frequently Asked Questions

Analyze common user questions about the FBIC Conductive Bag market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Type C and Type D conductive FIBC bags?

Type C bags are conductive and must be electrically connected (grounded) to an earth point during filling and emptying to dissipate static charge. Type D bags are static dissipative and contain proprietary fabrics that safely dissipate static charges into the atmosphere without needing a physical connection to the ground, offering greater operational flexibility.

Which end-user industry drives the highest demand for FBIC Conductive Bags?

The chemical and petrochemical industry is the largest end-user segment, primarily due to the frequent handling of highly flammable powders and solvents that necessitate strict compliance with international explosion safety standards like ATEX and NFPA.

What regulatory standards govern the manufacturing and use of conductive FIBCs?

The core international standard is IEC 61340-4-4, which defines testing methods for bulk bags used in potentially explosive atmospheres. Regional compliance also requires adherence to directives such as the European ATEX directive and various national occupational safety and health administrations (OSHA) guidelines.

How does the high cost of conductive bags impact market adoption?

The higher cost, resulting from specialized materials (conductive threads, coatings) and mandatory third-party testing, acts as a restraint, particularly for smaller businesses. However, the cost of non-compliance and potential liability from catastrophic incidents typically outweighs the price difference, maintaining demand among high-risk processors.

What role does technology play in enhancing the safety of conductive bags?

Advanced technology focuses on improved material science for better static dissipation (Type D innovation) and integrating smart features like RFID tags for enhanced traceability and lifecycle management, ensuring bags are not reused beyond their certified safe lifespan.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager