Ferrite Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434771 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Ferrite Market Size

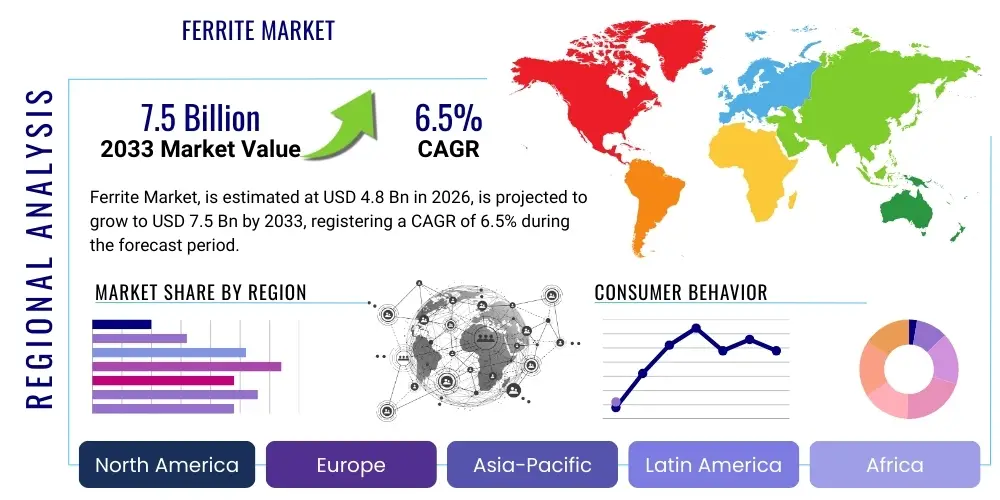

The Ferrite Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 4.8 Billion in 2026 and is projected to reach USD 7.5 Billion by the end of the forecast period in 2033.

Ferrite Market introduction

The Ferrite Market encompasses the production and distribution of ceramic materials composed primarily of iron oxide (Fe₂O₃) combined with one or more metallic elements such as manganese, zinc, nickel, or barium. These materials are characterized by their strong magnetic properties, high electrical resistivity, and low eddy current losses, making them indispensable components in modern electronic and electrical systems. Ferrites are broadly classified into soft ferrites (low coercivity, easily magnetized and demagnetized) and hard ferrites (high coercivity, used for permanent magnets). Key product types include Manganese-Zinc (MnZn) ferrites, Nickel-Zinc (NiZn) ferrites, and Strontium/Barium ferrites.

Major applications of ferrites span across several critical sectors, including consumer electronics, automotive manufacturing, telecommunications infrastructure, and power generation. Soft ferrites are extensively utilized in inductors, transformers, electromagnetic interference (EMI) filters, and recording heads, crucial for high-frequency circuit operation and noise suppression. Hard ferrites, conversely, find their primary use in permanent magnet motors, speakers, and magnetic separators due to their cost-effectiveness and robust magnetic field generation capability. The inherent benefits of ferrites, such as stability at high frequencies, superior temperature coefficients, and excellent dielectric properties, drive their adoption across increasingly complex electronic designs.

The market growth is fundamentally driven by the escalating demand for advanced electronic devices, the rapid expansion of the electric vehicle (EV) sector, and the proliferation of 5G networks globally. Ferrites are essential for efficiently managing power conversion and ensuring signal integrity in these high-speed, high-power density applications. Furthermore, stringent regulations concerning electromagnetic compatibility (EMC) necessitate the increased deployment of ferrite cores and shields, securing the market's trajectory through the forecast period. The material's unique combination of magnetic and electrical characteristics solidifies its role as a foundational component in technological progress.

Ferrite Market Executive Summary

The global Ferrite Market is currently experiencing robust expansion, fundamentally propelled by critical shifts in business trends, including the widespread adoption of advanced driver-assistance systems (ADAS) in the automotive industry and the massive investment in data center infrastructure worldwide. Business trends indicate a strong focus on developing high-performance, low-loss ferrite materials, particularly those suited for high-frequency operations above 1 MHz, crucial for modern power electronics and wireless charging applications. Mergers and acquisitions focused on securing specialized intellectual property in powder metallurgy and material synthesis techniques are defining the competitive landscape. Furthermore, manufacturers are increasingly integrating vertical operations to control the supply chain of raw materials like iron oxide and zinc, mitigating volatility risks and ensuring product consistency in high-volume production cycles.

Segment trends reveal that the Soft Ferrite segment, particularly MnZn and NiZn formulations, maintains the largest market share, predominantly driven by demand from transformer and inductor manufacturing for switch-mode power supplies (SMPS) and renewable energy systems. However, the Hard Ferrite segment, fueled by the permanent magnets required for small, efficient motors in robotics and consumer appliances, is projected to exhibit the fastest growth rate. The application landscape is witnessing a significant shift toward specialized components for Electric Vehicle (EV) power train systems, including charging infrastructure and on-board filtering components, demanding ferrites with enhanced thermal stability and saturation flux density.

Regionally, Asia Pacific (APAC) stands as the dominant market, attributable to its status as the global manufacturing hub for electronics, automotive components, and telecommunication equipment, led by high consumption rates in China, Japan, and South Korea. North America and Europe demonstrate mature market growth, primarily driven by the upgrade of existing infrastructure, the push towards 5G implementation, and stringent EMC standards enforcement, necessitating high-quality ferrite absorbers and beads. The market's overall trajectory points toward innovation focused on miniaturization, higher energy efficiency, and materials capable of withstanding extreme operational environments, ensuring the continued relevance of ferrite technology in next-generation electronics.

AI Impact Analysis on Ferrite Market

User queries regarding the impact of Artificial Intelligence (AI) on the Ferrite Market often center on two primary themes: first, how AI-driven design optimization influences the properties and development of new ferrite materials, and second, the direct correlation between the growth of AI hardware (data centers, edge computing, high-performance computing) and the resultant demand for specialized ferrite components. Users frequently ask if AI algorithms can predict optimal doping elements or sintering processes to achieve desired magnetic permeability or saturation flux density, bypassing traditional trial-and-error methods. Concerns also emerge regarding whether the increased integration of highly sophisticated silicon chips, enabled by AI applications, will necessitate miniaturized, high-frequency ferrite components that push the current manufacturing limits. The core expectation is that AI will accelerate the discovery of novel ferrite compositions and drive massive, sustained demand for advanced power management and EMI filtering components within AI infrastructure.

AI is set to revolutionize the research and development pipeline for ferrite materials. Machine learning models are being deployed to analyze vast datasets relating material microstructure, composition, processing parameters, and resulting magnetic properties. This capability allows researchers to rapidly identify synthesis pathways for ferrites optimized for specific high-frequency or high-power applications, significantly reducing the time-to-market for specialized components required in 5G base stations, autonomous vehicle sensors, and industrial automation systems. The precision afforded by AI in controlling variables during the manufacturing process—such as calcination temperature, sintering duration, and atmosphere control—will enhance batch consistency and overall product quality, crucial for mission-critical applications.

Furthermore, the massive computational load associated with training and running AI models (especially large language models and deep neural networks) requires extensive data center infrastructure characterized by high power consumption and density. Every server, power supply unit, and cooling system in these data centers relies heavily on high-efficiency inductors and transformers, which predominantly utilize high-grade soft ferrites (e.g., high-permeability MnZn ferrites). The increasing deployment of Edge AI devices also necessitates smaller, lighter, and more efficient power components, driving demand for miniaturized ferrite chips and cores for noise suppression and power filtering, thus directly linking AI adoption to sustained market volume for advanced ferrite products.

- AI-driven material discovery accelerates the development of novel ferrite compositions with superior performance (e.g., lower core loss at 10 MHz).

- Predictive modeling using machine learning optimizes manufacturing processes, improving consistency and reducing defects in mass-produced ferrite cores.

- Increased investment in AI data centers drives massive demand for high-efficiency soft ferrites used in server power supplies (SMPS).

- The rise of Edge AI and IoT necessitates smaller, high-frequency ferrite beads and chips for power filtering and electromagnetic compatibility (EMC) compliance.

- AI contributes to supply chain optimization, predicting demand fluctuations for key raw materials (iron oxide, zinc, nickel) used in ferrite production.

DRO & Impact Forces Of Ferrite Market

The dynamics of the Ferrite Market are governed by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively constitute the impact forces shaping its trajectory. The primary driver is the pervasive digitization across industries, notably the rapid expansion of the automotive electronics sector, propelled by electric vehicle mandates and increased embedded computing for ADAS. Concurrently, the global rollout of 5G technology demands high volumes of ferrites for efficient radio frequency (RF) components and noise suppression in dense communication arrays. These drivers exert substantial upward pressure on production capacity, particularly for specialized, high-performance soft ferrites capable of handling increased switching frequencies and thermal loads.

However, the market faces significant restraints. The dependence on key raw materials, specifically iron oxide, zinc, nickel, and manganese, exposes the industry to supply chain volatility and price fluctuations, particularly amplified by geopolitical tensions affecting global mining and refining operations. Furthermore, the inherent brittleness of ceramic ferrite materials poses challenges in processing and handling, sometimes limiting their application in environments requiring high mechanical stress tolerance or ultra-small form factors where polymer composites might be preferred. Regulatory pressures related to environmental impact also necessitate capital expenditure in cleaner processing technologies, adding to operational costs.

Opportunities for growth are vast, centered mainly on technological substitution and emerging application areas. The transition from Nickel-Zinc to higher-performance Manganese-Zinc ferrites in high-current applications, coupled with the development of composite ferrite materials, presents avenues for market differentiation. The burgeoning field of wireless charging technology, both in consumer electronics and EVs, requires highly efficient, specialized ferrite sheets and tiles for magnetic flux guidance and heat management, offering a high-growth niche. The stringent enforcement of electromagnetic interference (EMI) regulations across all industrial and consumer goods further ensures a continuous demand floor for ferrite-based filtering components, confirming the long-term strategic relevance of this market.

Segmentation Analysis

The Ferrite Market segmentation provides a crucial framework for understanding the diverse applications, materials, and technological needs that define the industry. The market is primarily segmented based on material type (Soft Ferrite and Hard Ferrite), application (Electronics, Automotive, Telecommunications, Power Generation), and end-use sectors. Soft ferrites dominate in terms of volume due to their indispensable role in power conditioning and signal processing, particularly MnZn ferrites for low-frequency power applications and NiZn ferrites for high-frequency filtering. Hard ferrites, while smaller in volume, are critical for permanent magnet solutions, essential in electric motors and loudspeakers, driving significant revenue.

Segmentation by application clearly illustrates the market's reliance on the electronic and automotive sectors. The rapid integration of electronic control units (ECUs), sensors, and communication systems in vehicles has made automotive a high-growth segment, demanding ferrites capable of operating reliably under extreme temperatures and vibration. Similarly, the consumer electronics segment, driven by the miniaturization of smartphones, laptops, and wearables, demands specialized ferrite beads and cores for EMI suppression, ensuring compliance with global regulatory standards while maintaining device performance and portability.

Further granularity exists within the material types, distinguishing between key chemical compositions. For soft ferrites, the ratio of manganese, zinc, and iron oxide is carefully controlled to tailor permeability and saturation characteristics, essential for optimizing transformer efficiency. For hard ferrites, the differentiation between Barium Ferrite and Strontium Ferrite impacts magnetic strength, with Strontium Ferrite often preferred due to its superior performance characteristics, particularly its higher coercivity, making segmentation analysis vital for targeted product development and market penetration strategies across different industrial verticals.

- By Material Type:

- Soft Ferrite

- Manganese-Zinc (MnZn) Ferrite

- Nickel-Zinc (NiZn) Ferrite

- Hard Ferrite

- Strontium Ferrite

- Barium Ferrite

- Soft Ferrite

- By Form:

- Cores and Rods

- Beads and Chips

- Plates and Sheets

- Magnets

- By Application:

- Transformers and Inductors

- Electromagnetic Interference (EMI) Filters and Absorbers

- Recording Heads

- Permanent Magnets (Motors, Actuators)

- By End-User Industry:

- Automotive (EVs, ADAS, Infotainment)

- Consumer Electronics (Smartphones, PCs, Home Appliances)

- Telecommunications (5G Infrastructure, Base Stations)

- Power Generation and Distribution (SMPS, Renewable Energy Inverters)

- Aerospace and Defense

- Industrial Automation and Robotics

Value Chain Analysis For Ferrite Market

The Value Chain for the Ferrite Market begins with the rigorous Upstream Analysis, which focuses on the sourcing and refinement of foundational raw materials: high-purity iron oxide (hematite), manganese, zinc, nickel compounds, and strontium/barium carbonates. This stage is capital-intensive and critical, as the purity and particle size distribution of the initial powders directly dictate the final magnetic and electrical properties of the ferrite component. Key activities include mineral extraction, chemical precipitation, and calcination of precursor materials. Maintaining stable supply contracts for these metals is a strategic priority for manufacturers to manage cost and ensure consistent quality required for high-frequency applications. The complexity of material synthesis, involving precise stoichiometric control, necessitates specialized knowledge and proprietary processing techniques at the initial production phase.

The Midstream component involves the core manufacturing processes: mixing, milling (to achieve the desired particle size), calcining (pre-sintering), pressing (shaping into cores, beads, or magnets), and the final high-temperature sintering. Sintering is the most crucial step, determining the material's density, microstructure, and magnetic performance. Quality control measures, including magnetic property testing (permeability, coercivity, core loss) and dimensional precision checks, are integrated throughout. This stage requires significant investment in advanced sintering furnaces, tooling, and magnetic testing equipment. Manufacturers often specialize in either soft or hard ferrites due to the divergent processing requirements and material handling needs.

The Downstream analysis focuses on Distribution Channels and end-user integration. Products move through direct sales channels to large Original Equipment Manufacturers (OEMs) in the automotive and power electronics sectors, or through indirect channels involving global distributors, specialized electronic component resellers, and local agents catering to smaller enterprises and maintenance, repair, and overhaul (MRO) markets. The effectiveness of the distribution network relies on logistics efficiency, inventory management (especially for custom-sized cores), and the provision of technical support to guide customers in component selection for specific applications like EMI suppression or high-frequency power conversion. The technical nature of the product mandates that indirect distribution partners possess strong application engineering expertise.

Ferrite Market Potential Customers

The potential customer base for the Ferrite Market is exceptionally broad, spanning multiple high-technology and heavy industrial sectors, driven by the universal need for efficient power conversion and electromagnetic compatibility (EMC). Primary end-users are large-scale Electronics Manufacturing Services (EMS) providers and Original Equipment Manufacturers (OEMs) specializing in telecommunications equipment, such as companies building 5G base stations, fiber optic network hardware, and microwave communication systems, which rely heavily on high-permeability soft ferrites for impedance matching and signal filtering. The sustained demand from consumer electronics giants for miniaturized components in smartphones, laptops, and charging pads also constitutes a massive recurring customer segment, where ferrite beads and chips are essential for noise reduction and regulatory compliance.

A rapidly expanding segment of critical customers resides within the Automotive Industry, particularly manufacturers of Electric Vehicles (EVs) and their Tier 1 suppliers. These customers purchase high-grade ferrites for inductors and transformers in onboard chargers, DC-DC converters, motor control systems, and complex ADAS sensor arrays. The need for robust, thermally stable ferrites capable of handling high currents in demanding vehicular environments makes this a premium customer segment. Furthermore, the Industrial Automation and Robotics sectors represent growing buyers, utilizing hard ferrites for permanent magnets in small, high-torque, brushless DC motors, and soft ferrites for power supplies in control systems and robotic actuators.

The power and energy sector, including utility companies and renewable energy system integrators, forms another vital customer group. These users deploy ferrites extensively in high-power Switch-Mode Power Supplies (SMPS), solar inverters, and wind turbine systems to achieve high efficiency and reduce energy losses during conversion. Given the stringent requirements for reliability and longevity in power infrastructure, these customers demand ferrites with certified quality and predictable performance over extended operational periods. Therefore, potential customers range from mass-market consumer device assemblers requiring billions of small components to specialized industrial partners requiring custom, high-power cores.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.8 Billion |

| Market Forecast in 2033 | USD 7.5 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | TDK Corporation, VACUUMSCHMELZE GmbH & Co. KG, Murata Manufacturing Co., Ltd., Magnetics, Inc., Hitachi Metals, Ltd. (now part of Resonac), Ningbo Yunsheng Co., Ltd., JFE Ferrite Corporation, DMEGC Magnetic Co., Ltd., Acme Magnets, Fair-Rite Products Corp., Kemet Corporation, Nanjing New Conda Magnetic Co., Ltd., Steward Advanced Materials LLC, CE+T Power, Philips (Ferroxcube). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ferrite Market Key Technology Landscape

The technological landscape of the Ferrite Market is characterized by continuous refinement of material science and manufacturing processes aimed at achieving superior magnetic properties under demanding operational conditions, particularly high temperature and high frequency. A core technology involves advanced powder preparation techniques, such as co-precipitation and spray pyrolysis, which ensure nano-scale particle uniformity, leading to lower core losses and higher saturation flux density in the final sintered component. For soft ferrites, the technology focuses heavily on optimizing grain boundary resistance and reducing eddy currents, utilizing specialized doping agents (e.g., calcium, silicon) to control grain growth during sintering. This precision engineering is vital for the performance of high-frequency transformers in modern power supplies, where efficiency is paramount.

Another crucial technological advancement is the development of ultra-thin, high-density ferrite sheets and tiles, essential for magnetic shielding and flux guidance in wireless power transfer (WPT) systems. These materials require excellent mechanical flexibility alongside high permeability, pushing manufacturers towards composite formulations combining ferrite powders with polymer binders. Furthermore, the push towards miniaturization, driven by consumer electronics and IoT devices, requires sophisticated photolithography and thin-film deposition techniques for producing microscopic ferrite chip components (beads and inductors) with sub-millimeter dimensions, integrating seamlessly onto printed circuit boards (PCBs) while maintaining effective EMI filtering capabilities.

In the domain of hard ferrites, technological innovation revolves around maximizing energy product (BHmax) through oriented crystal structures, achieved via complex magnetic field alignment during the pressing and sintering stages. Strontium ferrite, often replacing traditional barium ferrite due to its superior performance, is being refined through advanced sintering profiles that minimize porosity and enhance coercivity, leading to stronger, more stable permanent magnets. Additionally, the industry is exploring hybrid materials, such as combining ferrites with metal powders (e.g., iron-silicon-aluminum alloys), to create composite cores that balance the benefits of high saturation magnetization (from metals) with the high resistivity (from ferrites) for specialized power inductors, showcasing the industry's commitment to pushing material boundaries.

Regional Highlights

- Asia Pacific (APAC): Dominates the global market share, serving as the central manufacturing hub for electronics, automotive components, and large-scale renewable energy infrastructure. High consumption is driven by countries like China (leading in EV and 5G deployment), Japan, and South Korea, focusing heavily on MnZn and NiZn soft ferrites for export-oriented electronics production and domestic industrial automation.

- North America: Exhibits strong growth, primarily fueled by defense spending, advanced telecommunications infrastructure upgrades (5G/6G research), and significant regulatory emphasis on electromagnetic compatibility (EMC) in the high-tech sector. Demand is concentrated on high-quality, customized ferrite cores and chips for aerospace and medical electronics.

- Europe: Characterized by mature automotive manufacturing and stringent environmental regulations, driving intense demand for high-performance soft ferrites in electric vehicle power electronics and industrial motor control systems. Germany, the UK, and Italy are key contributors, focusing on R&D for low-loss materials and sophisticated magnetic solutions.

- Latin America (LATAM): Represents an emerging market with gradual industrialization and increasing investment in consumer electronics assembly and infrastructure projects. Market growth is stable, driven by basic electrical components and entry-level magnetic systems, though adoption rates for high-end specialized ferrites remain moderate.

- Middle East and Africa (MEA): Shows steady potential, linked to expanding power distribution networks, burgeoning telecommunications projects, and localized manufacturing initiatives. Demand is primarily focused on standard hard ferrites for motors and basic soft ferrites for power filtering in telecommunications equipment and infrastructure development.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ferrite Market.- TDK Corporation

- VACUUMSCHMELZE GmbH & Co. KG

- Murata Manufacturing Co., Ltd.

- Magnetics, Inc.

- Hitachi Metals, Ltd. (now part of Resonac)

- Ningbo Yunsheng Co., Ltd.

- JFE Ferrite Corporation

- DMEGC Magnetic Co., Ltd.

- Acme Magnets

- Fair-Rite Products Corp.

- Kemet Corporation

- Nanjing New Conda Magnetic Co., Ltd.

- Steward Advanced Materials LLC

- CE+T Power

- Philips (Ferroxcube)

- TOKIN Corporation

- JPM Co., Ltd.

- Sumida Corporation

- Jiangsu Feixing Electronics Co., Ltd.

- Suzhou Taizhu Technology Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Ferrite market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between MnZn and NiZn ferrites, and where are they used?

MnZn (Manganese-Zinc) ferrites are characterized by high permeability and low resistivity, making them ideal for lower frequency applications (below 1 MHz) such as power transformers and inductors in Switch-Mode Power Supplies (SMPS) and broadband chokes. NiZn (Nickel-Zinc) ferrites exhibit lower permeability but significantly higher resistivity, suitable for high-frequency operations (above 1 MHz), predominantly used in radio frequency (RF) circuits, EMI suppression beads, and high-frequency noise filters.

How does the growth of Electric Vehicles (EVs) specifically influence the demand for ferrites?

EV adoption drives substantial demand for high-performance ferrites, particularly in power electronics systems. Ferrites are essential components in high-current inductors and transformers found in onboard chargers, DC-DC converters, and motor inverters. These applications require soft ferrites with enhanced thermal stability and minimal core loss to ensure maximum energy efficiency and system reliability within the vehicle's high-temperature operational environment.

What major challenges constrain the expansion of the Ferrite Market?

Key constraints include the volatility of raw material prices, particularly zinc, nickel, and manganese, which impacts manufacturing costs. Furthermore, ferrites are brittle ceramic materials, posing mechanical limitations in certain high-stress applications. The increasing complexity of electronic devices also demands continuous investment in R&D to develop ultra-low loss materials that meet demanding miniaturization and high-frequency performance requirements.

Which geographical region holds the largest market share for ferrite consumption?

The Asia Pacific (APAC) region currently dominates the global Ferrite Market, primarily due to its concentration of global manufacturing capabilities in consumer electronics, automotive components, and telecommunication infrastructure. Countries such as China, Japan, and South Korea are the major consumers, driving high demand for both soft ferrites used in mass-produced electronics and hard ferrites for permanent magnets.

What role do ferrites play in 5G network deployment and infrastructure?

Ferrites are indispensable in 5G infrastructure for ensuring signal integrity and suppressing electromagnetic interference (EMI). They are used extensively in base station filters, antenna systems, and power amplifiers as high-frequency noise absorbers and electromagnetic shielding components. NiZn ferrites, specifically, are critical for high-frequency RF signal processing and maximizing data transmission efficiency in dense 5G communication arrays.

What technological advancements are driving soft ferrite performance improvements?

Technological focus is centered on reducing power losses at high frequencies. Advancements include precise control over powder preparation (e.g., nano-scale particle synthesis) and advanced doping techniques using trace elements like calcium or silicon. These methods optimize the grain structure of the ferrite material during sintering, consequently lowering hysteresis and eddy current losses, making the materials suitable for highly efficient, high-density power converters operating at several megahertz.

How are hard ferrites being utilized in the robotics and industrial automation sector?

Hard ferrites, specifically Strontium Ferrite magnets, are widely used in brushless DC (BLDC) motors and stepper motors that power robotic arms, conveyors, and automated handling systems. Their cost-effectiveness, high coercivity (resistance to demagnetization), and reliable performance in motors make them a preferred choice for achieving the precise motion control and high torque required in modern industrial automation and advanced robotics applications.

What is the significance of the Value Chain’s upstream analysis for ferrite manufacturers?

The upstream analysis is crucial as the quality and cost of the final ferrite product are heavily dependent on the purity and consistency of the raw materials (iron oxide, zinc, nickel). Manufacturers must secure stable, high-purity sources and control the initial powder preparation (e.g., milling and calcination) with extreme precision, as variations in particle size directly impact the material's fundamental magnetic properties after the final sintering process.

Are composite ferrite materials expected to replace traditional monolithic ferrites?

Composite ferrite materials, often combining ferrite powder with polymer matrices or conductive metals, are not expected to entirely replace monolithic ferrites but will increasingly complement them in niche applications. Composites are valued for their mechanical flexibility, light weight, and tailor-made electromagnetic properties, especially in applications like wireless charging pads and complex EMI shielding components where traditional ceramics may be too brittle or dimensionally limited.

What regulatory factors significantly impact the demand for ferrite products globally?

Stringent global regulations concerning Electromagnetic Compatibility (EMC), such as the European Union’s CE mark requirements and the U.S. FCC standards, significantly drive the demand for ferrites. Since ferrites are highly effective at suppressing unwanted electromagnetic noise (EMI), manufacturers of virtually all electronic devices must incorporate ferrite beads, chokes, and cores to comply with these mandatory standards, ensuring device safety and interoperability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Soft Ferrite Core Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Ferrite Magnets Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Soft Ferrite Material Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- NFC Ferrite Sheet Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Soft Ferrite Core Market Size Report By Type (Nickel-Zinc Ferrite Core, MnZn Ferrite Core, Other), By Application (Consumer Electronics, Household appliances, Communication, Automotive, LED, Other), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager