Ferromagnetic Fluid Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431633 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Ferromagnetic Fluid Market Size

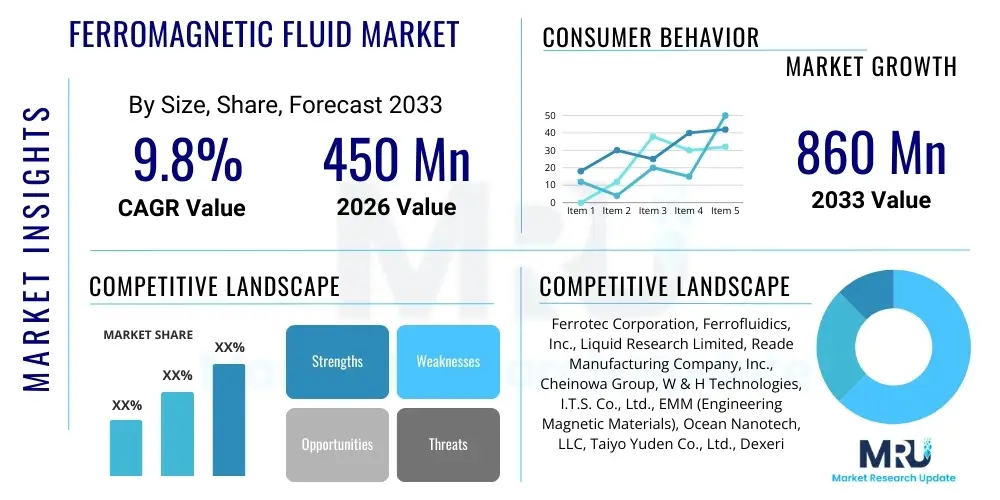

The Ferromagnetic Fluid Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 860 Million by the end of the forecast period in 2033.

Ferromagnetic Fluid Market introduction

The Ferromagnetic Fluid Market, often referred to as ferrofluid, involves stable colloidal suspensions of magnetic nanoparticles (typically magnetite or hematite) dispersed in a carrier liquid, such as oil, water, or organic solvents. These fluids possess the unique characteristic of becoming strongly magnetized in the presence of a magnetic field, while retaining the flow properties of a liquid when the field is removed. This dual nature allows ferrofluids to be utilized in highly specialized industrial, medical, and consumer electronics applications where traditional fluids or solids are inadequate.

Key applications of ferrofluids span across rotary seals in high-vacuum environments, damping systems to reduce vibration, sophisticated heat transfer mechanisms in electronic cooling, and advanced medical diagnostics. The product description hinges on the stability and particle size distribution, which are critical for maintaining fluidity and magnetic responsiveness. The magnetic nanoparticles are typically coated with a surfactant layer to prevent agglomeration, ensuring the colloidal stability necessary for long-term performance in demanding conditions.

The primary driving factor for market growth is the increasing demand for high-performance sealing solutions in the semiconductor manufacturing and aerospace industries, coupled with the rapid adoption of effective thermal management solutions in high-power electronics. Furthermore, continuous advancements in nanotechnology and surface chemistry are enabling the creation of new ferrofluid compositions with tailored properties, expanding their potential use in biomedical fields, particularly for targeted drug delivery and magnetic resonance imaging (MRI) contrast agents.

Ferromagnetic Fluid Market Executive Summary

The Ferromagnetic Fluid Market is characterized by robust technological innovation, driven largely by demand from high-precision engineering sectors. Current business trends indicate a strong shift towards developing customized water-based and biocompatible ferrofluids, facilitating greater penetration into the biomedical and environmental remediation segments. Key market players are focusing on vertical integration and strategic partnerships to secure raw material supply chains (specifically high-purity magnetic nanoparticles) and accelerate product development tailored for specific OEM requirements in data centers and electric vehicle manufacturing. The commercialization of advanced synthesis techniques, such as co-precipitation and thermal decomposition, is improving production efficiency and material quality, thereby reducing overall costs and stimulating broader adoption.

Regional trends reveal Asia Pacific (APAC) as the fastest-growing market, primarily fueled by the massive electronics manufacturing base in countries like China, South Korea, and Taiwan, which utilize ferrofluids extensively in spindle motor bearings and high-speed seals. North America and Europe maintain technological leadership, focusing on high-value applications in aerospace, defense, and specialized laboratory equipment. Segmentation trends highlight the dominance of oil-based ferrofluids in traditional sealing applications due to their stability and low vapor pressure, while water-based variants are gaining momentum due to their environmentally friendly profiles and compatibility with biological systems.

The overall market trajectory suggests that while sealing applications remain the core revenue generator, the highest growth potential lies within emerging applications, particularly in microfluidics, energy harvesting (ferrofluid-based mechanical rectifiers), and advanced thermal management solutions for next-generation computing infrastructure. Successful navigation of stringent regulatory standards, especially for biocompatible fluids, will be crucial for sustained growth in the healthcare domain, positioning niche segments for significant future expansion and market consolidation opportunities.

AI Impact Analysis on Ferromagnetic Fluid Market

Common user questions regarding AI's impact on the Ferromagnetic Fluid Market often center around optimizing nanoparticle synthesis, predicting fluid stability under extreme conditions, and accelerating the design of novel ferrofluid compositions for specific magnetic and thermal properties. Users are keen to understand how AI-driven simulations can replace traditional, time-consuming laboratory experimentation in characterizing factors like viscosity, saturation magnetization, and long-term sedimentation rates. Furthermore, interest exists in leveraging machine learning to enhance quality control during high-volume manufacturing and to identify new application niches that exploit the complex interaction between fluid dynamics and magnetic fields, especially in intricate microfluidic chip designs or high-efficiency acoustic devices.

AI is poised to revolutionize the R&D and manufacturing processes of ferrofluids by introducing predictive modeling and autonomous optimization loops. Specifically, machine learning algorithms can analyze vast datasets concerning precursor concentrations, reaction temperatures, and surfactant structures, rapidly identifying optimal synthesis protocols that yield nanoparticles with precise size uniformity and superior colloidal stability. This capability significantly reduces the time-to-market for specialized fluids required by advanced industries such as aerospace and advanced semiconductor lithography. Moreover, the integration of AI in computational fluid dynamics (CFD) modeling allows engineers to simulate ferrofluid behavior in complex geometries, such as thermal conduits or dynamic sealing mechanisms, ensuring peak performance and reliability under operational stress far exceeding human simulation capacity.

In application deployment, AI-powered sensor networks can monitor the health and performance of ferrofluid-based components (e.g., rotary seals in vacuum chambers or dampers in specialized machinery) in real-time. By analyzing variations in temperature, pressure, and magnetic response signatures, AI systems can predict incipient failures or degradation of the fluid properties, allowing for proactive maintenance and extending the service life of expensive equipment. This predictive maintenance capability, facilitated by AI's pattern recognition prowess, not only minimizes operational downtime but also cements ferrofluids as a preferred solution for mission-critical, high-reliability systems across various industrial verticals.

- AI optimizes nanoparticle synthesis parameters (e.g., reaction temperature, precursor ratio) to achieve precise particle size distribution and enhanced magnetic properties.

- Machine learning models predict the long-term colloidal stability and sedimentation rate of new ferrofluid formulations under diverse environmental conditions, accelerating R&D.

- AI-enhanced Computational Fluid Dynamics (CFD) simulates complex magnetic fluid behavior in microchannels and thermal management systems for optimized device design.

- Predictive maintenance algorithms use real-time sensor data from ferrofluid seals and dampers to forecast degradation and scheduled replacements, minimizing operational failures.

- Automated quality control systems utilize image recognition to analyze nanoparticle morphology and aggregation during large-scale manufacturing, ensuring high product consistency.

DRO & Impact Forces Of Ferromagnetic Fluid Market

The Ferromagnetic Fluid Market is fundamentally influenced by a confluence of strong technical drivers relating to specialized performance requirements, balanced by significant restraining factors concerning material costs and regulatory hurdles, while vast opportunities emerge from cross-sectoral technological convergence. The primary driver involves the indispensability of ferrofluids in creating ultra-reliable, contamination-free rotary seals essential for high-vacuum and semiconductor processing equipment, where even trace particulate contamination is unacceptable. Simultaneously, the market is restrained by the relatively high cost of synthesis, particularly for producing high-purity, uniformly sized nanoparticles and the necessary stabilizing surfactants, limiting adoption in high-volume, cost-sensitive consumer applications. The synergistic combination of these forces dictates market pricing, competitive strategies, and the speed of innovation adoption across different industrial segments.

Drivers are substantially amplified by the increasing proliferation of advanced electronic devices requiring highly efficient, passive thermal management solutions, such as ferrofluid-based heat sinks and cooling loops in data center servers and powerful graphic processing units (GPUs). Furthermore, the burgeoning demand for specialized medical technologies, including high-resolution MRI and targeted hyperthermia treatments utilizing magnetic nanoparticles, opens up new high-margin verticals. Opportunities are vast in customizing fluid compositions for specific applications—for instance, developing radiation-resistant ferrofluids for nuclear technology or biocompatible variants for drug delivery—moving the market away from standardized products toward highly specialized, performance-driven offerings.

However, significant restraining forces include the technical challenge of maintaining long-term stability in highly aggressive chemical or thermal environments, which can lead to particle agglomeration and subsequent performance loss. Moreover, the lack of standardized regulatory frameworks specifically addressing the environmental and human health impacts of engineered magnetic nanomaterials poses a barrier to entry, particularly in European and North American consumer-facing markets. The impact forces, therefore, lean towards technological differentiation and regulatory compliance, compelling manufacturers to invest heavily in advanced encapsulation techniques and rigorous stability testing to mitigate these risks and capitalize on high-growth opportunities.

Drivers:

- Increasing demand for non-contact, high-reliability rotary seals in semiconductor manufacturing (wafer processing) and high-speed mechanical systems.

- Growing necessity for effective passive thermal management solutions in high-power electronics, data centers, and advanced computing hardware.

- Expansion of medical applications, including targeted drug delivery, magnetic separation techniques, and enhanced MRI contrast agents.

- Advancements in magnetic bearing technology requiring low-friction, high-precision magnetic fluids.

Restraints:

- High synthesis cost associated with producing nanoparticles of uniform size and high purity, limiting scalability for commodity applications.

- Technical challenges related to the long-term colloidal stability and chemical compatibility of ferrofluids under extreme operating conditions (high temperature, high shear).

- Regulatory hurdles and concerns regarding the long-term environmental and biological safety of engineered nanomaterials.

Opportunities:

- Development of specialized, application-specific ferrofluids (e.g., radiation-resistant, cryogenic, or high-temperature variants).

- Emerging use in renewable energy applications such as magnetocaloric refrigeration and highly efficient solar collectors.

- Integration into advanced acoustic devices (speakers and microphones) for improved damping and heat dissipation.

- Growth potential in microfluidics and lab-on-a-chip technologies for magnetic manipulation of cells and reagents.

Impact Forces:

- Intensity of Rivalry: Moderate, characterized by specialized competition focused on intellectual property related to particle coating and fluid formulation stability.

- Bargaining Power of Buyers: High, especially large OEMs in the semiconductor and aerospace sectors who demand highly customized specifications and competitive pricing.

- Bargaining Power of Suppliers: Moderate to High, driven by the specialized nature of high-purity magnetic nanoparticles and stabilizing surfactants, often sourced from niche chemical suppliers.

- Threat of Substitutes: Low in high-vacuum sealing (where ferrofluids are indispensable), but moderate in standard thermal management or damping applications (where thermal gels or traditional fluids compete).

- Threat of New Entrants: Low, due to high capital requirements for sophisticated synthesis facilities, complex regulatory compliance, and the need for deep technical expertise in nanotechnology and magnetism.

Segmentation Analysis

The Ferromagnetic Fluid Market segmentation provides a granular view of distinct market dynamics based on the carrier liquid used (Type), the specific industrial requirement it addresses (Application), and the geographic consumption patterns (Region). Analyzing these segments is crucial for strategic decision-making, as performance characteristics—such as temperature tolerance, volatility, and biocompatibility—are intrinsically linked to the fluid type. For instance, oil-based fluids dominate high-performance sealing, while water-based fluids are gaining traction in biomedical and environmental contexts where organic compatibility is paramount. The diverse application segments, ranging from sophisticated mechanical seals to cutting-edge medical diagnostic tools, underscore the versatility and broad technological relevance of ferrofluids.

The Type segmentation includes Oil-Based, Water-Based, and Synthetic Ferrofluids. Oil-Based ferrofluids, utilizing hydrocarbons or synthetic esters, offer excellent thermal stability and low vapor pressure, making them the standard for vacuum rotary seals and specific damping mechanisms. Water-Based ferrofluids, preferred for their low toxicity and ease of handling, are expanding rapidly in medical research, targeted therapeutics, and environmental cleanup operations (e.g., magnetic separation of pollutants). Synthetic ferrofluids, often incorporating perfluorinated ethers or specific organic solvents, are engineered for extremely niche applications, such as high-temperature environments or chemical resistance requirements in specific industrial processes, commanding premium prices due to their specialized formulation complexity.

The Application segmentation reveals that the Seals segment (including rotary seals, vacuum feedthroughs, and exclusion seals) currently holds the largest market share due to its indispensable role in the semiconductor and hard disk drive (HDD) industries. However, the Heat Transfer and Medical/Biotechnology segments are projected to exhibit the highest CAGR, driven by the increasing need for efficient, magnet-driven cooling systems in electronics and the continuous breakthroughs in nanomedicine, particularly magnetic hyperthermia and MRI contrast enhancement. Understanding this market structure allows suppliers to focus R&D investment on areas promising the highest returns and competitive advantage.

- By Type:

- Oil-Based Ferrofluids (Hydrocarbons, Esters)

- Water-Based Ferrofluids (Aqueous Solutions)

- Synthetic Ferrofluids (Perfluorinated Ethers, Other Specialized Solvents)

- By Application:

- Seals (Rotary, Vacuum Feedthroughs, Exclusion Seals)

- Dampers and Shock Absorbers

- Sensors and Actuators (Inclinometers, Position Sensors)

- Heat Transfer and Thermal Management (Liquid Cooling Systems, Heat Sinks)

- Medical and Biotechnology (Targeted Drug Delivery, Hyperthermia, MRI Contrast Agents)

- Acoustic Devices (Loudspeakers, Microphones)

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, UK, France, Italy, Rest of Europe)

- Asia Pacific (China, Japan, South Korea, India, Rest of APAC)

- Latin America (Brazil, Argentina, Rest of Latin America)

- Middle East and Africa (UAE, Saudi Arabia, Rest of MEA)

Value Chain Analysis For Ferromagnetic Fluid Market

The value chain of the Ferromagnetic Fluid Market begins with the upstream procurement and synthesis of core raw materials, primarily high-purity iron precursors and specialized stabilizing surfactants. The quality and uniformity of these materials directly impact the final product performance. Upstream activities involve complex chemical synthesis processes, such as co-precipitation or hydrothermal synthesis, used by specialized chemical companies to create magnetic nanoparticles (usually Fe3O4 or γ-Fe2O3) in the nanometer range. This stage is capital-intensive and requires stringent quality control to ensure particle size homogeneity, a crucial determinant of the ferrofluid's long-term stability and magnetic response. Strong relationships with reliable chemical suppliers are vital for maintaining the competitive edge in material sourcing and cost management.

The central stage involves the manufacturing and formulation of the ferrofluid itself, where the magnetic nanoparticles are dispersed in the carrier liquid (oil, water, or synthetic solvent) using sophisticated mixing and sonication techniques, followed by the addition of proprietary surfactants to prevent aggregation. This stage adds significant value through intellectual property related to formulation stability, temperature range optimization, and application-specific tailoring. Distribution channels are highly specialized; due to the technical nature of the product, direct sales from manufacturers to Original Equipment Manufacturers (OEMs) dominate the high-end segments (semiconductors, aerospace). Indirect channels, utilizing specialized distributors, cater primarily to smaller industrial users and research institutions requiring smaller batch sizes or standardized products.

Downstream activities center on the integration of ferrofluids into complex mechanical and electronic systems. End-users require highly technical support and customized solutions for integration into seals, dampers, or cooling systems. The performance of the ferrofluid is often inseparable from the design of the device it serves, meaning close collaboration between the ferrofluid manufacturer and the end-user engineering team is essential. Direct interaction ensures the fluid meets specific operational parameters (e.g., viscosity at operating temperature, magnetic field requirements). The final value derived comes from the enhanced performance, longevity, and reliability provided by the ferrofluid-integrated system, particularly in high-stakes environments where reliability is non-negotiable.

Ferromagnetic Fluid Market Potential Customers

Potential customers for the Ferromagnetic Fluid Market are predominantly specialized industrial and technological entities requiring solutions that leverage magnetic responsiveness combined with fluid dynamic properties. The largest segment of end-users consists of semiconductor fabrication equipment manufacturers and hard disk drive (HDD) producers, who utilize ferrofluidic seals to maintain ultra-clean, high-vacuum environments essential for precise manufacturing processes. The exceptional sealing capabilities of these fluids prevent abrasive particulate matter from entering critical components, ensuring process yield and product quality, positioning them as essential consumables in microelectronics manufacturing.

Another significant customer base includes aerospace and defense contractors, who integrate ferrofluids into specialized damping systems, inertial guidance components, and fluid bearings for satellites and high-speed mechanical assemblies. These applications require fluids that maintain integrity and performance across extreme temperature ranges and high-G force conditions. Furthermore, the burgeoning field of medical technology represents a high-growth customer segment, with researchers and medical device manufacturers exploring ferrofluids for novel drug delivery vectors, non-invasive hyperthermia cancer treatments, and advanced magnetic resonance imaging (MRI) systems where enhanced contrast and targeted manipulation are required, indicating a shift toward biocompatible and sterile formulations.

The market also serves niche but critical customers in consumer electronics (high-end audio equipment manufacturers utilizing ferrofluids in loudspeaker voice coils for cooling and damping) and laboratory/scientific equipment (including specialized magnetometers and high-precision fluid dynamics research apparatus). These customers are primarily interested in the unique thermal dissipation and damping characteristics offered by ferrofluids, justifying the premium price point for enhanced device performance and reliability over standard alternatives, thereby diversifying the market demand beyond core industrial applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 860 Million |

| Growth Rate | 9.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ferrotec Corporation, Ferrofluidics, Inc., Liquid Research Limited, Reade Manufacturing Company, Inc., Cheinowa Group, W & H Technologies, I.T.S. Co., Ltd., EMM (Engineering Magnetic Materials), Ocean Nanotech, LLC, Taiyo Yuden Co., Ltd., Dexerials Corporation, Nanogap Subnm Company, BASF SE, Sigma-Aldrich (Merck KGaA), Advanced Nanotechnologies, Inc., JMC Magnetics, American Elements, SNT Co., Ltd., Micromod Partikeltechnologie GmbH, Strem Chemicals, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ferromagnetic Fluid Market Key Technology Landscape

The technological landscape of the Ferromagnetic Fluid Market is fundamentally driven by advancements in three core areas: nanoparticle synthesis, stabilization chemistry, and application engineering. In synthesis, the transition from traditional chemical precipitation methods to highly controlled techniques like thermal decomposition and solvothermal synthesis allows manufacturers to achieve narrow particle size distributions (typically 3–15 nm), which is paramount for superior colloidal stability and optimal magnetic response. These advanced synthesis methods are critical for producing high-quality ferrofluids suitable for specialized medical and aerospace applications where performance tolerances are extremely tight. Further technological innovation is focused on developing 'smart' magnetic fluids whose properties (viscosity, magnetic moment) can be tuned externally or respond dynamically to environmental cues.

Stabilization chemistry, which involves the selection and grafting of surfactants onto the nanoparticle surface, represents another critical technological frontier. Research focuses on creating multi-layered or polymer-grafted surfactants (steric stabilization) that provide robust protection against particle aggregation across wider temperature and pH ranges, significantly improving the longevity of the fluid, particularly in harsh industrial environments or in complex biological media. Biocompatible surfactants, such as dextran or polyethylene glycol (PEG), are key technological enablers for market penetration into the high-value medical sector, ensuring non-toxicity and immunological compatibility necessary for in vivo applications like targeted drug carriers.

Application engineering breakthroughs primarily concern the design of magnetic circuits and fluid containment structures that maximize the performance benefits of ferrofluids. For instance, in thermal management, microchannel heat sinks are being engineered with specific magnetic field gradients to actively manipulate the ferrofluid flow, enhancing heat transfer efficiency beyond conventional limits. In sealing applications, technological advancements focus on miniaturization and creating hybrid seals that combine ferrofluids with elastomeric materials to handle higher differential pressures and rotational speeds, enabling the use of ferrofluid seals in smaller, more powerful electronic devices and advanced manufacturing robotics, thereby securing the market's long-term competitive advantage over mechanical sealing solutions.

Regional Highlights

- Asia Pacific (APAC): APAC is anticipated to dominate the Ferromagnetic Fluid Market, both in consumption and production capacity, driven primarily by its immense manufacturing base for consumer electronics, hard disk drives, and semiconductors. Countries like China, South Korea, and Taiwan are major users of ferrofluidic seals in their high-precision manufacturing facilities. Furthermore, significant government investment in nanotechnology R&D across regions like India and Japan is accelerating the adoption of ferrofluids in localized medical and environmental applications. The region’s cost-competitive manufacturing environment also drives global supply of standardized ferrofluids.

- North America: North America is characterized by high-value, specialized applications, leading the market in technology adoption, particularly in the aerospace, defense, and advanced medical sectors (biotechnology and hyperthermia research). The U.S. remains a global hub for semiconductor equipment manufacturing, demanding ultra-high-purity ferrofluids for vacuum processing. High R&D spending and the presence of key industry players specializing in niche, custom-formulated ferrofluids ensure steady, albeit highly specialized, market growth in this region.

- Europe: The European market maintains a strong focus on industrial precision engineering, robotics, and automotive components (e.g., specialized vehicle suspension dampers). Germany, known for its advanced machinery manufacturing, is a significant consumer of ferrofluid seals and damping systems. Furthermore, stringent environmental regulations are fueling research into sustainable, water-based ferrofluids for environmental cleanup applications (magnetic separation of microplastics and oil spills), providing a unique regional driver.

- Latin America (LATAM): The LATAM market is currently characterized by moderate growth, primarily driven by industrial maintenance and repair operations (MRO) in the petrochemical and mining sectors, requiring robust sealing solutions. While manufacturing integration is lower compared to APAC, the increasing investment in domestic electronics assembly and localized R&D initiatives, particularly in Brazil and Mexico, suggests future growth in standard industrial ferrofluid consumption.

- Middle East and Africa (MEA): The MEA region's market presence is relatively small but growing, spurred by investment in advanced oil and gas extraction technologies (requiring high-pressure, temperature-resistant seals) and nascent technological hubs in the UAE and Saudi Arabia. Market expansion is closely tied to infrastructure development and diversification efforts away from traditional energy sectors, generating long-term demand for high-reliability components, including specialized ferrofluidic systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ferromagnetic Fluid Market.- Ferrotec Corporation

- Liquid Research Limited

- Ferrofluidics, Inc.

- Reade Manufacturing Company, Inc.

- Cheinowa Group

- W & H Technologies

- I.T.S. Co., Ltd.

- EMM (Engineering Magnetic Materials)

- Ocean Nanotech, LLC

- Taiyo Yuden Co., Ltd.

- Dexerials Corporation

- Nanogap Subnm Company

- BASF SE

- Sigma-Aldrich (Merck KGaA)

- Advanced Nanotechnologies, Inc.

- JMC Magnetics

- American Elements

- SNT Co., Ltd.

- Micromod Partikeltechnologie GmbH

- Strem Chemicals, Inc.

Frequently Asked Questions

Analyze common user questions about the Ferromagnetic Fluid market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of using ferromagnetic fluids in sealing applications compared to traditional mechanical seals?

Ferromagnetic fluids offer non-contact, friction-free sealing, which is crucial for high-speed, contamination-sensitive environments like semiconductor vacuum chambers and hard disk drives. They provide superior hermetic sealing and longevity, eliminating abrasive wear, shaft vibration, and particle generation inherent in conventional mechanical seals, thus ensuring ultra-clean operation and high reliability.

How is the stability of a ferrofluid maintained, and why is this critical for long-term performance?

Ferrofluid stability is maintained through the application of a surfactant layer (either single or double layer) coated onto the magnetic nanoparticles. This surfactant prevents particle agglomeration (clumping) due to van der Waals forces. Stability is critical because aggregation leads to sedimentation, causing performance degradation, increased viscosity, and ultimately, component failure, especially in dynamic applications.

Which carrier fluid type (oil-based vs. water-based) dominates the market and what are their respective use cases?

Oil-based ferrofluids currently dominate the market volume, primarily due to their excellent thermal stability, low volatility, and suitability for industrial sealing and damping applications. However, water-based ferrofluids are experiencing the fastest growth, driven by demand from the biomedical sector, environmental remediation, and any application requiring low toxicity and biocompatibility.

What role does ferrofluid technology play in the evolving field of advanced thermal management?

Ferrofluids are utilized in advanced thermal management by leveraging their magnetic properties to enhance heat transfer efficiency. By applying external magnetic fields, the fluid flow can be actively manipulated (magnetically pumped or directed) within cooling loops, increasing convection and improving the dissipation of heat from high-power electronic components such as CPUs, GPUs, and high-intensity lasers, leading to better passive cooling solutions.

What major challenges restrict the widespread adoption of ferrofluids in consumer applications?

The primary restriction is the high manufacturing cost associated with producing stable, high-purity magnetic nanoparticles, coupled with the specialized hardware (magnetic circuits) required for integration. While used in high-end acoustic devices, their cost-effectiveness relative to conventional fluids remains a barrier for mass-market consumer electronics, limiting adoption primarily to specialized and high-value industrial sectors.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager