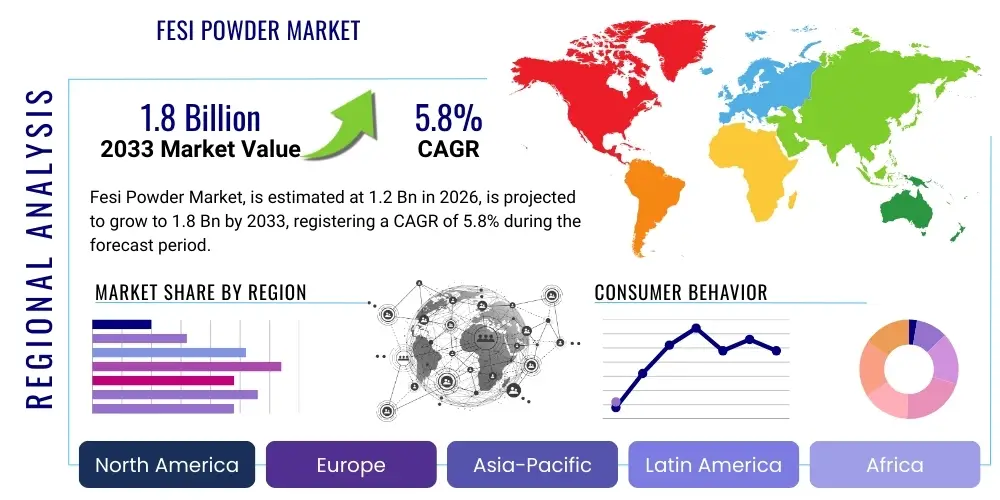

Fesi Powder Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439752 | Date : Jan, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Fesi Powder Market Size

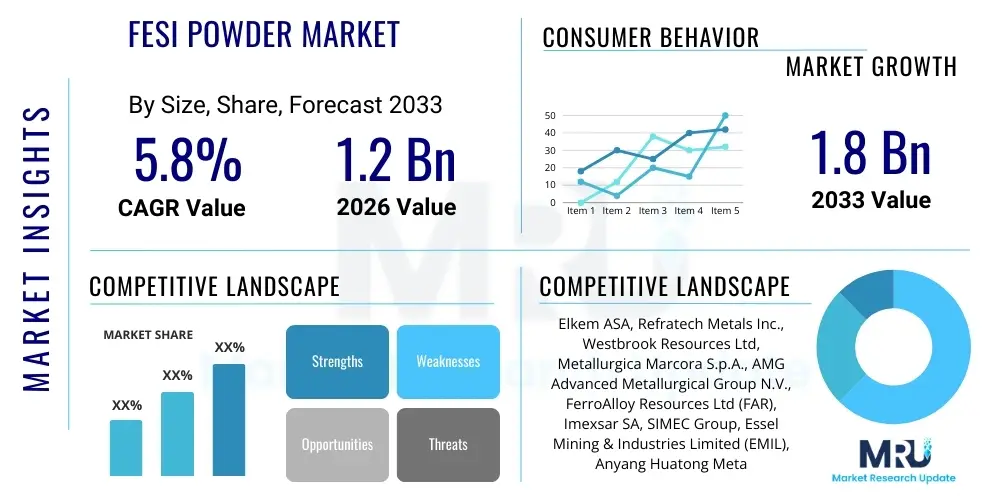

The Fesi Powder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.2 billion in 2026 and is projected to reach USD 1.8 billion by the end of the forecast period in 2033.

Fesi Powder Market introduction

The Fesi Powder Market is characterized by its fundamental role across diverse industrial applications, primarily serving as a critical alloying agent and deoxidizer within metallurgical processes. This versatile product, derived from ferrosilicon, undergoes meticulous processing into a fine powder, which enhances its reactivity and allows for precise incorporation in various manufacturing stages, thereby optimizing material properties and overall production efficiency. Its extensive utility spans the steel manufacturing, foundry and casting, and welding industries, delivering significant benefits such as improved metal strength, enhanced corrosion resistance, and specific magnetic properties, with market growth driven substantially by global industrial expansion, large-scale infrastructure development, and the burgeoning automotive sector's increasing demand for high-performance materials.

Fesi Powder Market Executive Summary

The Fesi Powder Market's executive summary reveals key business trends indicating a strong emphasis on supply chain optimization, technological advancements in powder metallurgy, and an increasing focus on sustainable production practices among key players. Regionally, the market exhibits robust growth in Asia Pacific, particularly driven by industrialization in China and India, while mature markets in Europe and North America demonstrate stability with a focus on specialized applications and high-quality product formulations. Segment-wise, the steel manufacturing and foundry industries continue to dominate demand for Fesi powder, with emerging opportunities observed in advanced materials and niche chemical applications, underscoring a dynamic market landscape poised for sustained expansion and innovation in metallurgical processes globally.

AI Impact Analysis on Fesi Powder Market

The integration of Artificial Intelligence (AI) in the Fesi Powder Market is a topic of significant interest for stakeholders, with common user questions revolving around AI's capacity to optimize production efficiency, enhance product quality control, and streamline supply chain management. Users are particularly keen on understanding how AI can facilitate predictive maintenance for manufacturing equipment, leading to reduced downtime and operational costs, and how it can be leveraged for advanced material design and discovery to develop new Fesi powder formulations with superior properties. Additionally, there are inquiries into AI's role in analyzing market demand fluctuations, enabling more accurate forecasting, and contributing to more sustainable and environmentally conscious production methodologies by minimizing waste and energy consumption across the Fesi powder value chain.

- AI-driven process optimization: Enhancing milling and atomization parameters for consistent particle size and purity, leading to improved product quality and reduced waste.

- Predictive analytics for equipment maintenance: Minimizing operational downtime and extending the lifespan of machinery used in Fesi powder production through data-driven fault detection and preventive scheduling.

- Supply chain efficiency and demand forecasting: Utilizing AI algorithms to analyze market trends, raw material availability, and logistics, thereby optimizing inventory levels and ensuring timely delivery to end-users.

- Advanced material design and formulation: Accelerating the development of new Fesi powder variants with tailored properties for specific applications through AI-powered simulation and combinatorial testing.

- Quality control and defect detection: Implementing AI-vision systems for real-time inspection of powder characteristics, identifying impurities or inconsistencies with high precision, far surpassing manual inspection capabilities.

DRO & Impact Forces Of Fesi Powder Market

The Fesi Powder Market is significantly influenced by a confluence of drivers, restraints, and opportunities, alongside various impact forces that shape its trajectory. Key drivers include the robust demand from the global steel industry, which relies heavily on Fesi powder for deoxidation and alloying, as well as the continuous growth in the automotive, construction, and infrastructure sectors demanding high-strength, lightweight materials. Conversely, the market faces restraints such as the inherent volatility in raw material prices, particularly iron ore and silicon, coupled with increasingly stringent environmental regulations concerning emissions and energy consumption in metallurgical processes, which can escalate operational costs. Opportunities emerge from the rapid industrialization in developing economies, the advent of advanced alloy development requiring specialized Fesi powder grades, and the increasing adoption of sustainable manufacturing practices, all of which are further amplified by impactful forces such as global economic cycles influencing industrial output, ongoing technological advancements in powder production, and geopolitical stability affecting trade and supply chain resilience.

Segmentation Analysis

The Fesi Powder Market exhibits a diverse range of segmentation crucial for understanding its intricate dynamics and identifying specific growth avenues. These segments categorize the market based on various parameters including application areas, particle size distribution, product grade, and end-use industries, providing a detailed framework for market analysis. Each segment is driven by unique demand characteristics and technological requirements, influencing production methods and market strategies for key players. The comprehensive segmentation analysis allows for a deeper insight into consumer preferences, regional consumption patterns, and the competitive landscape, facilitating targeted marketing and product development initiatives across the Fesi powder value chain.

- By Application

- Steel Manufacturing

- Carbon Steel Production

- Stainless Steel Production

- Alloy Steel Production

- High-Strength Low-Alloy (HSLA) Steel Production

- Electrical Steel Production

- Foundry and Casting

- Gray Iron Castings

- Ductile Iron Castings

- Malleable Iron Castings

- Steel Castings

- Specialty Alloy Castings (e.g., wear-resistant alloys)

- Welding and Brazing

- Welding Electrodes and Fluxes

- Brazing Alloys and Pastes

- Cored Wires for Welding

- Chemical and Pharmaceutical Industries

- Reducing Agents and Catalysts

- Pyrotechnics and Explosives

- Pharmaceutical Intermediates

- Other Applications

- Powder Metallurgy (e.g., sintered parts)

- Heavy Media Separation

- Magnetic Materials

- Surface Coatings and Thermal Spraying

- Steel Manufacturing

- By Product Grade

- Standard Grade Fesi Powder (e.g., 75% Si, 65% Si)

- Low Aluminum (Al) Grade Fesi Powder

- Low Carbon (C) Grade Fesi Powder

- High Purity Grade Fesi Powder

- Customized Alloys and Particle Sizes

- By Particle Size

- Coarse Fesi Powder (e.g., >100 mesh)

- Medium Fesi Powder (e.g., 100-325 mesh)

- Fine Fesi Powder (e.g., <325 mesh)

- Ultra-Fine Fesi Powder (e.g., microns, nanoparticles)

- By End-Use Industry

- Automotive Industry

- Construction and Infrastructure

- Aerospace and Defense

- Heavy Machinery and Equipment

- Consumer Goods

- Oil and Gas

- Electrical and Electronics

Value Chain Analysis For Fesi Powder Market

The Fesi Powder Market's value chain commences with the upstream analysis, primarily focusing on the sourcing and processing of essential raw materials, namely high-quality iron ore and silicon, along with other minor alloying elements, which are then fused to produce ferrosilicon alloys. This intermediate product undergoes further processing, including crushing, milling, and atomization, to achieve the desired particle size and purity for Fesi powder. Downstream analysis involves the distribution and ultimate consumption of Fesi powder by various end-use industries, predominantly steel mills, foundries, and welding electrode manufacturers, where it serves critical functions as a deoxidizer, inoculant, and alloying agent to enhance material properties. Distribution channels in this market are typically a mix of direct sales from large producers to major industrial clients, supplemented by an extensive network of distributors, agents, and traders who facilitate access for smaller enterprises and specialized applications, ensuring broad market reach and efficient delivery of this vital industrial input across global markets.

Fesi Powder Market Potential Customers

The Fesi Powder Market's potential customers encompass a broad spectrum of industrial end-users, fundamentally rooted in sectors that require advanced metallurgical inputs for material enhancement and process optimization. Primary buyers include major steel manufacturers, who utilize Fesi powder extensively for deoxidation, desulfurization, and as an alloying element to produce various grades of carbon, stainless, and alloy steels with specific strength, hardness, and corrosion resistance properties. Foundries represent another significant customer segment, relying on Fesi powder as an inoculant and chill reducer in the production of gray and ductile iron castings, thereby improving mechanical properties and microstructure. Furthermore, manufacturers of welding electrodes and fluxes are key consumers, incorporating Fesi powder to enhance weld metal quality, arc stability, and reduce spatter, solidifying its role as an indispensable component across heavy industries and advanced manufacturing.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 1.8 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Elkem ASA, Refratech Metals Inc., Westbrook Resources Ltd, Metallurgica Marcora S.p.A., AMG Advanced Metallurgical Group N.V., FerroAlloy Resources Ltd (FAR), Imexsar SA, SIMEC Group, Essel Mining & Industries Limited (EMIL), Anyang Huatong Metallurgy Refractory Co., Ltd., FESIL AS, Sinoferro Inc., Wuxi Xinbo Carbon Products Co., Ltd., Henan Star Metallurgy Material Co., Ltd., Shanghai Jinte Corporation, Shyam Ferro Alloys Limited, Danube Ferroalloys, OMCO Alloys, M & M Alloys, Ferroglobe PLC |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fesi Powder Market Key Technology Landscape

The Fesi Powder Market's key technology landscape is continuously evolving, driven by the imperative to enhance product purity, optimize particle size distribution, and improve overall production efficiency. Advanced manufacturing processes such as gas atomization, water atomization, and mechanical grinding and milling techniques are pivotal, offering superior control over powder morphology and metallurgical properties essential for specialized applications like additive manufacturing and high-performance alloys. Innovations in quality control, including sophisticated analytical techniques for chemical composition analysis, particle size analysis (e.g., laser diffraction), and surface characterization, ensure that Fesi powder meets the rigorous standards required by demanding industries. Furthermore, technologies focused on energy efficiency, waste heat recovery, and the utilization of cleaner production methods are gaining prominence, reflecting a growing industry commitment towards sustainable manufacturing practices and reducing the environmental footprint of Fesi powder production processes.

Regional Highlights

- Asia Pacific (APAC): Dominates the Fesi Powder Market due to its robust industrial growth, particularly in steel manufacturing and foundry industries in China, India, and Southeast Asian countries. Massive infrastructure development projects and a burgeoning automotive sector fuel significant demand.

- North America: Characterized by a stable market with a focus on high-quality, specialized Fesi powder grades for advanced steel production, aerospace, and defense applications. Technological innovation and stringent quality standards drive product development.

- Europe: A mature market that emphasizes sustainable production methods, environmental compliance, and high-performance alloys. Countries like Germany and Italy are key consumers for specialized casting and steel applications, including electric vehicle components.

- Latin America: Exhibits moderate growth, influenced by its developing steel and automotive industries, particularly in Brazil and Mexico. Economic stability and foreign investment in manufacturing sectors are critical growth drivers.

- Middle East and Africa (MEA): An emerging market with increasing investments in steel production capacities and infrastructure projects, notably in Saudi Arabia and South Africa. Demand is poised for growth as industrialization progresses, albeit from a smaller base.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fesi Powder Market.- Elkem ASA

- Refratech Metals Inc.

- Westbrook Resources Ltd

- Metallurgica Marcora S.p.A.

- AMG Advanced Metallurgical Group N.V.

- FerroAlloy Resources Ltd (FAR)

- Imexsar SA

- SIMEC Group

- Essel Mining & Industries Limited (EMIL)

- Anyang Huatong Metallurgy Refractory Co., Ltd.

- FESIL AS

- Sinoferro Inc.

- Wuxi Xinbo Carbon Products Co., Ltd.

- Henan Star Metallurgy Material Co., Ltd.

- Shanghai Jinte Corporation

- Shyam Ferro Alloys Limited

- Danube Ferroalloys

- OMCO Alloys

- M & M Alloys

- Ferroglobe PLC

Frequently Asked Questions

What is Fesi Powder and its primary use?

Fesi Powder, or Ferrosilicon Powder, is an alloy of iron and silicon in powdered form, predominantly used as a deoxidizer and alloying agent in steelmaking and as an inoculant in the production of cast iron, enhancing material strength and other properties.

Which industries are the major consumers of Fesi Powder?

The primary consumers of Fesi Powder are the steel manufacturing industry, foundries and casting operations, and the welding and brazing sectors, where it plays a critical role in metallurgical processes.

What are the key drivers for the Fesi Powder Market growth?

Key drivers include the surging demand from the global steel industry, growth in automotive and construction sectors requiring high-performance materials, and rapid industrialization in emerging economies.

What challenges does the Fesi Powder Market face?

The market faces challenges such as the volatility of raw material prices (iron ore, silicon), stringent environmental regulations impacting production costs, and the need for energy-efficient manufacturing processes.

How does Fesi Powder contribute to sustainable manufacturing?

Fesi Powder contributes to sustainability by enabling the production of more durable and lightweight materials, which can reduce energy consumption in end-use applications and promote resource efficiency in metallurgical processes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Fesi Powder Market Statistics 2025 Analysis By Application (Metallurgy (Mineral), Machinery), By Type (0-1mm, 1-3mm, 3-8mm), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Fesi Powder Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (3-8mm, 1-3mm, 0-1mm, Others), By Application (Machinery Industry, Metallurgy, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager