Fiber Reinforced Polymer (FRP) Rebars Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438229 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Fiber Reinforced Polymer (FRP) Rebars Market Size

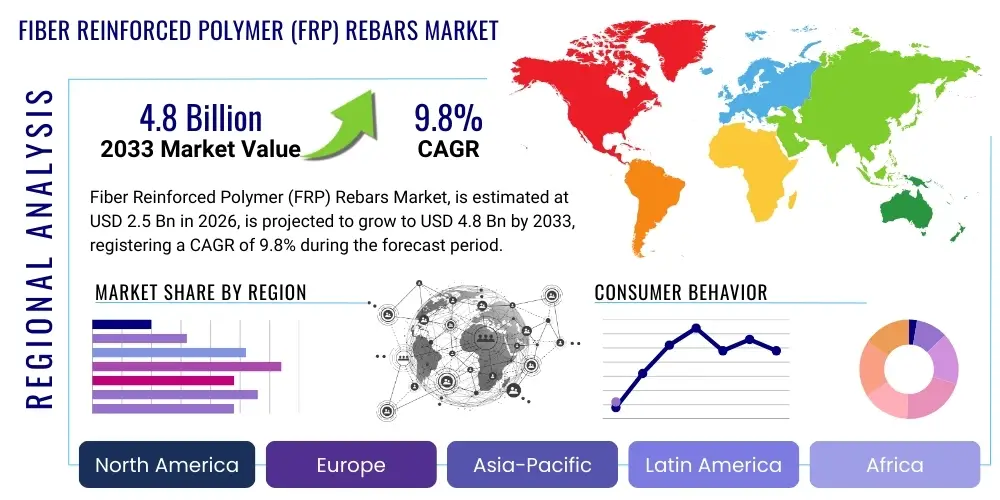

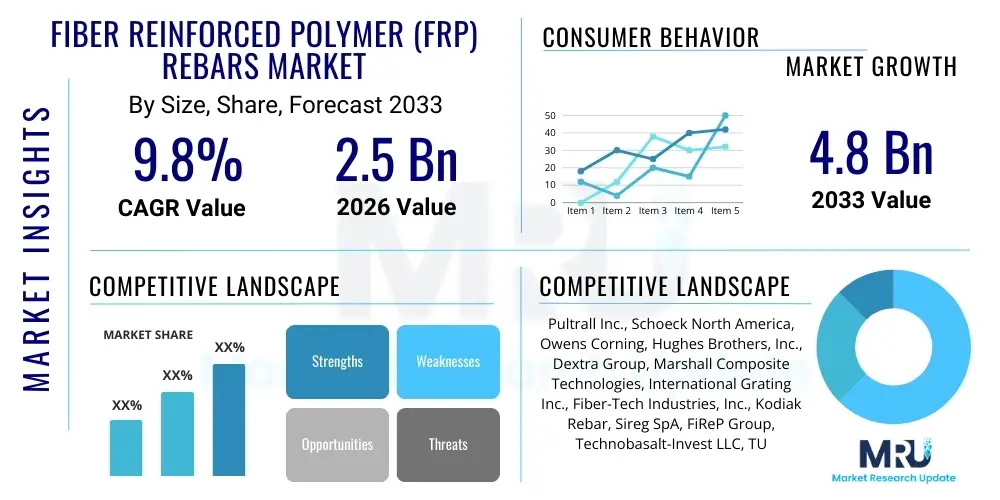

The Fiber Reinforced Polymer (FRP) Rebars Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.8% between 2026 and 2033. The market is estimated at USD 2.5 Billion in 2026 and is projected to reach USD 4.8 Billion by the end of the forecast period in 2033.

Fiber Reinforced Polymer (FRP) Rebars Market introduction

The Fiber Reinforced Polymer (FRP) Rebars Market encompasses advanced composite materials designed to replace traditional steel reinforcement bars in concrete structures. FRP rebars are typically composed of high-strength fibers—such as glass (GFRP), carbon (CFRP), basalt (BFRP), or aramid (AFRP)—embedded in a thermosetting resin matrix, primarily vinyl ester, epoxy, or polyester. This innovative construction material offers superior resistance to corrosion, high tensile strength, and lightweight properties, making it an increasingly favored alternative in harsh environments where traditional steel reinforcement is susceptible to degradation from chlorides, moisture, and chemical exposure. The primary product description centers on its non-corrosive, non-conductive, and structurally robust characteristics, positioning it as critical for long-term infrastructure durability.

Major applications of FRP rebars span critical infrastructure sectors, including bridge decks, highway pavement, marine structures (docks, seawalls), water treatment facilities, and highly corrosive industrial environments, such as chemical plants and processing facilities. A significant and growing application area is in Magnetic Resonance Imaging (MRI) rooms and electrical substations where non-magnetic reinforcement is mandatory. The core benefits driving adoption include significantly reduced maintenance costs over the lifecycle of the structure due to the elimination of rust-induced cracking (spalling), extended service life, and ease of handling and installation due to their lighter weight compared to steel.

Key driving factors propelling the market growth are the global focus on infrastructure renewal, particularly in developed economies facing aging concrete assets, and stringent regulatory standards demanding more durable and sustainable construction practices. Furthermore, the increasing recognition of life cycle assessment (LCA) benefits, where the initial higher material cost is offset by decades of maintenance savings, strengthens the business case for FRP adoption. The sustained expansion in civil engineering projects, combined with ongoing research into reducing production costs and enhancing standardization, solidifies the market's positive trajectory.

Fiber Reinforced Polymer (FRP) Rebars Market Executive Summary

The FRP Rebars Market is experiencing robust acceleration, fundamentally driven by the escalating demand for infrastructure resilience against corrosion and seismic activity. Key business trends indicate a significant shift in manufacturing focus towards Basalt Fiber Reinforced Polymer (BFRP) due to its cost-effectiveness relative to Carbon FRP and better performance metrics compared to standard Glass FRP (GFRP). Strategic partnerships between composite manufacturers and large-scale engineering and construction firms are becoming prevalent, aimed at integrating FRP solutions early into major public works projects. Moreover, innovation is centered on developing hybrid FRP rebars and optimizing surface treatments to enhance bond strength with various concrete mixtures, addressing historical adoption barriers related to standardization and construction familiarity.

Regional trends highlight the dominance of North America and Europe, fueled by governmental investment programs targeting the repair and replacement of structurally deficient bridges and marine facilities. In North America, state-level mandates and demonstration projects showcasing the longevity of GFRP in bridge decks are instrumental in expanding usage. Asia Pacific, particularly China and India, represents the fastest-growing region, driven by massive new urbanization projects and the need for durable infrastructure in coastal and chemically aggressive industrial zones. The Middle East is also emerging as a significant market due to large-scale desalination and water treatment plant construction, where corrosion resistance is paramount.

Segment trends reveal that the Application segment dominated by the Bridge and Road construction category, which requires high fatigue resistance and minimal deflection. However, the Water Treatment and Marine Structures segments are showing the highest CAGR, reflecting focused investment in highly corrosive environments. In terms of Fiber Type segmentation, GFRP remains the volume leader due to its affordability and proven track record, while CFRP continues to command the highest revenue share in specialized, high-performance applications like high-rise buildings and military installations. The Vinyl Ester Resin segment is preferred over Epoxy in applications requiring superior chemical resistance, such as chemical processing plants and containment structures.

AI Impact Analysis on Fiber Reinforced Polymer (FRP) Rebars Market

Common user questions regarding AI's impact on the FRP Rebars Market typically revolve around optimizing material composition, enhancing quality assurance (QA) during manufacturing, and predicting structural performance and longevity. Users frequently inquire how AI can reduce the variability inherent in composite manufacturing processes, ensure consistent fiber-to-resin ratios, and minimize waste. Concerns also focus on using AI-driven structural health monitoring (SHM) systems to accurately assess the remaining useful life (RUL) of FRP-reinforced structures, translating complex sensor data into actionable maintenance schedules. The overarching expectation is that AI will streamline the highly complex design and manufacturing workflows associated with composite materials, thereby lowering production costs and improving end-product reliability, which is crucial for achieving broader market acceptance against conventional steel.

- AI optimizes the pultrusion manufacturing process parameters, including temperature, pulling speed, and resin bath consistency, minimizing defects and ensuring uniform mechanical properties across batches.

- Machine learning algorithms analyze non-destructive testing (NDT) data (ultrasonics, thermal imaging) to automate quality control checks, instantly identifying micro-cracks or voids that could compromise structural integrity.

- Predictive modeling using historical performance data and environmental variables (temperature, humidity, chemical exposure) allows civil engineers to accurately forecast the long-term durability and fatigue life of FRP-reinforced structures.

- Generative design tools, powered by AI, assist in customizing FRP rebar shapes, densities, and fiber orientations for specific high-stress applications (e.g., seismic zones), optimizing load bearing while minimizing material usage.

- AI-driven supply chain management systems enhance the forecasting of raw material needs (fiber roving, resin), mitigating price volatility and ensuring timely delivery for complex infrastructure projects.

- Advanced image recognition deployed in construction sites assists in verifying the correct placement and spacing of FRP rebars before concrete pouring, reducing human error and improving compliance with engineering specifications.

DRO & Impact Forces Of Fiber Reinforced Polymer (FRP) Rebars Market

The market dynamics for Fiber Reinforced Polymer (FRP) Rebars are fundamentally shaped by the strong drivers related to infrastructure longevity and the powerful restraint concerning initial material cost and regulatory inertia. Key drivers include the overwhelming superiority of FRP in corrosion resistance, which offers significant life-cycle cost advantages, particularly in marine, coastal, and de-icing salt-affected regions. Opportunities are primarily centered around exploiting the non-conductive and non-magnetic properties of FRP for specialized high-value applications, such as power generation facilities, medical infrastructure, and emerging green building mandates focused on durability. Conversely, the high initial capital expenditure required for FRP compared to readily available commodity steel remains the most significant restraint, alongside the inherent necessity for extensive material and installation knowledge specific to composites.

Impact forces acting on the market are multifaceted, combining economic, technological, and regulatory influences. Economically, the volatility in raw material prices, particularly petrochemical-derived resins and specialized carbon/basalt fibers, poses a challenge to maintaining competitive pricing. Technologically, ongoing advancements in pultrusion efficiency, coupled with the development of cost-effective basalt and hybrid fibers, are actively reducing production costs, thereby lessening the impact of the cost restraint. Furthermore, regulatory bodies in North America and Europe are gradually incorporating FRP standards (e.g., ACI, CSA standards) into mainstream building codes, which is transitioning FRP from a niche material to an accepted mainstream alternative, acting as a powerful positive force.

The primary opportunities lie in the vast, untapped market for concrete rehabilitation and repair globally, where traditional steel replacement is frequently mandated but provides only a temporary fix in aggressive environments. FRP offers a permanent solution in these scenarios. Additionally, the increasing global emphasis on sustainable construction and reduced carbon footprints favors FRP, which, despite its resin content, offers significant environmental benefits over the lifetime of the structure compared to steel, requiring fewer interventions and material replacements. Overcoming the initial investment hurdle through performance-based design and life-cycle costing education is the key strategic imperative for market players.

Segmentation Analysis

The FRP Rebars market segmentation provides a granular view of material preference and end-use demand across diverse application environments. Segmentation is fundamentally structured around Fiber Type, which dictates performance characteristics and cost (Glass, Carbon, Basalt being the main types); Resin Type, which influences chemical resistance and thermal properties (Epoxy, Vinyl Ester, Polyester); and Application, which defines the end-user requirements and volumes (Infrastructure, Marine, Water Treatment, etc.). The analysis highlights that while GFRP dominates in volume due to affordability in general construction and bridge work, the high-performance segments are increasingly reliant on CFRP and BFRP, particularly where high tensile strength and chemical inertness are prerequisites.

- By Fiber Type

- Glass Fiber Reinforced Polymer (GFRP)

- Carbon Fiber Reinforced Polymer (CFRP)

- Basalt Fiber Reinforced Polymer (BFRP)

- Aramid Fiber Reinforced Polymer (AFRP)

- By Resin Type

- Vinyl Ester

- Epoxy

- Polyester

- By Application

- Bridge & Road Construction (Decks, Barriers, Foundations)

- Marine Structures (Docks, Seawalls, Piers)

- Water Treatment Plants (Tanks, Channels, Filtering Systems)

- Industrial Applications (Chemical Processing, Mining)

- General Buildings and Infrastructure (Parking Garages, Tunnels)

- By Region

- North America (U.S., Canada, Mexico)

- Europe (Germany, U.K., France, Italy, Spain)

- Asia Pacific (China, Japan, India, South Korea)

- Latin America (Brazil, Argentina)

- Middle East and Africa (UAE, Saudi Arabia, South Africa)

Value Chain Analysis For Fiber Reinforced Polymer (FRP) Rebars Market

The Value Chain for the FRP Rebars Market begins with the upstream procurement of essential raw materials, primarily synthetic fibers (glass, carbon, basalt) and high-performance thermosetting resins (vinyl ester, epoxy). This upstream segment is characterized by specialized chemical and composite raw material suppliers, where cost control and quality consistency of precursors significantly influence the final rebar price and performance. Fiber manufacturing, particularly for carbon and basalt, requires high capital expenditure and specialized processes, creating concentrated supply points. Resin suppliers focus heavily on customizing formulations to meet specific pultrusion process requirements, ensuring rapid curing and optimal mechanical properties.

The midstream stage involves the core manufacturing process, mainly pultrusion, where the fibers are saturated with resin and pulled through a heated die to form the composite rebar shape. Manufacturers in this stage invest heavily in automated pultrusion lines and quality control systems to produce rebars of varying diameters and profiles, ensuring adherence to stringent international standards (e.g., ACI 440.1R-15). Direct distribution channels are often favored for large-scale infrastructure projects, involving direct negotiation and supply contracts between the manufacturer and the construction main contractor or government body. This direct approach ensures technical support and streamlined logistics for customized orders.

Downstream analysis focuses on distribution and end-user application. Indirect distribution utilizes local construction material suppliers, specialized composite distributors, and wholesalers, primarily serving smaller commercial and residential projects. Effective market penetration relies heavily on educating structural engineers and contractors on handling, cutting, and tying FRP rebars, which differ from traditional steel. The final value realization occurs at the construction site, where the installation efficiency and the long-term performance benefits solidify the product's value proposition. Successful companies often integrate technical consulting services into their downstream offerings to ensure proper installation and maximize project success.

Fiber Reinforced Polymer (FRP) Rebars Market Potential Customers

Potential customers for Fiber Reinforced Polymer (FRP) Rebars are diverse, spanning multiple sectors that prioritize long-term durability and resistance to corrosive environments over low initial material cost. The primary end-users or buyers are large governmental infrastructure agencies (Department of Transport, Public Works), major civil engineering contractors specializing in bridge and road construction, and maritime infrastructure developers responsible for coastal and offshore structures. These customers require materials that drastically reduce life-cycle maintenance costs and extend the service life of assets subjected to constant exposure to salt, freeze-thaw cycles, and heavy traffic loading.

A second crucial segment of potential customers includes operators of wastewater treatment facilities, desalination plants, and chemical processing complexes. In these environments, exposure to aggressive chemicals, including sulfates, acids, and high concentrations of chlorides, necessitates reinforcement materials that are chemically inert. FRP rebars are non-reactive, making them ideal for the concrete containment structures, tanks, and channels in these plants, where steel rebar failure is a frequent and costly problem. Furthermore, the specialized construction sector, including builders of electrical substations and medical facilities (MRI rooms), constitutes a high-value, albeit smaller, customer segment due to the mandatory requirement for non-magnetic and non-conductive reinforcement to prevent electromagnetic interference.

In essence, the core customer profile is shifting from price-sensitive general construction to value-driven, specialized infrastructure projects where failure costs are exceptionally high. Key decision-makers in these customer groups focus not only on material specifications but also on the supplier's capacity for certification, adherence to engineering standards, and ability to provide comprehensive installation support and performance guarantees. Long-term structural integrity and minimal operational disruption are the ultimate purchasing criteria for these specialized buyers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.5 Billion |

| Market Forecast in 2033 | USD 4.8 Billion |

| Growth Rate | 9.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Pultrall Inc., Schoeck North America, Owens Corning, Hughes Brothers, Inc., Dextra Group, Marshall Composite Technologies, International Grating Inc., Fiber-Tech Industries, Inc., Kodiak Rebar, Sireg SpA, FiReP Group, Technobasalt-Invest LLC, TUF-BAR, FRP Systems, BASF SE (Raw Material Supplier), Nippon Electric Glass Co., Ltd. (Raw Material Supplier), Creative Pultrusions, Inc., Aslan FRP, Capstone Composites, Fibertrusion Systems. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fiber Reinforced Polymer (FRP) Rebars Market Key Technology Landscape

The technological landscape of the FRP Rebars market is predominantly defined by the pultrusion manufacturing process, which is the foundational method for producing continuous, consistent composite profiles. Pultrusion involves pulling saturated fibers through a heated die, optimizing the orientation of the fibers to maximize tensile strength and stiffness. Recent technological advancements focus on enhancing the speed and efficiency of pultrusion while ensuring zero-defect products. Innovations include specialized resin injection systems that minimize fiber damage and void formation, and the utilization of automated laser-based quality monitoring during the pull process to instantly detect and correct inconsistencies in resin content or fiber alignment, thereby improving the overall cost-effectiveness of high-volume production.

Beyond the core manufacturing technique, significant technological effort is directed towards raw material optimization and surface engineering. The development of advanced thermosetting resins, specifically those featuring enhanced chemical resistance (e.g., highly cross-linked vinyl ester systems) and reduced cure times, contributes to faster production cycles. Furthermore, research into fiber composites is expanding the use of Basalt Fiber Reinforced Polymer (BFRP) due to its superior high-temperature and chemical resistance compared to Glass FRP (GFRP), offering a mid-tier performance option between GFRP and high-cost Carbon FRP (CFRP). These material innovations directly address demanding application requirements in industrial and high-heat environments.

A critical area of technological focus is the improvement of the interface between the FRP rebar and the concrete matrix. Unlike steel, FRP lacks natural ductility and its bond strength relies heavily on its surface profile. Manufacturers are employing advanced surface profiling technologies, such as winding continuous helical glass fibers around the core or using sand coating techniques, to maximize mechanical interlock with concrete. Additionally, integrating smart sensor technology (e.g., embedded fiber optic sensors) directly within the rebar during pultrusion represents a nascent but high-potential technological trend, enabling real-time structural health monitoring and predictive maintenance strategies for major infrastructure projects, thereby increasing the intrinsic value proposition of FRP reinforcement.

Regional Highlights

- North America: This region is characterized by substantial governmental funding directed toward aging infrastructure renewal (e.g., federal infrastructure bills in the U.S.). The adoption is highest in coastal regions and states employing large amounts of de-icing salts, where corrosion is the primary cause of structural failure. The U.S. and Canada lead the market, driven by progressive transportation departments standardizing GFRP use in bridge decks and barrier walls.

- Europe: Europe is a mature market focusing on high-performance applications and sustainable construction. Countries like Germany and the UK show high adoption in specialized fields such as tunneling, magnetic environments, and chemical industry facilities. The region benefits from stringent EU regulations promoting durable construction materials and standardized composite design guidelines, facilitating broader engineering acceptance.

- Asia Pacific (APAC): APAC is the fastest-growing region, driven by rapid urbanization, massive infrastructure expansion in coastal mega-cities, and significant investment in new industrial and energy infrastructure (e.g., nuclear power plants and LNG terminals). China, Japan, and India are the primary growth engines, although standardization and initial cost constraints remain a challenge compared to steel.

- Latin America: This region exhibits burgeoning demand, specifically in coastal areas of Brazil and Mexico, due to high humidity and chloride exposure affecting existing concrete structures. Market growth is sensitive to local economic stability and government investment cycles, with potential focused on marine infrastructure and water utility upgrades.

- Middle East and Africa (MEA): The MEA region represents a high-potential niche market due to extreme temperatures, high salinity exposure, and extensive water management projects (desalination and sewage treatment). The UAE and Saudi Arabia are investing heavily in long-life infrastructure that demands non-corrosive reinforcement materials.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fiber Reinforced Polymer (FRP) Rebars Market.- Pultrall Inc.

- Schoeck North America

- Owens Corning

- Hughes Brothers, Inc.

- Dextra Group

- Marshall Composite Technologies

- International Grating Inc.

- Fiber-Tech Industries, Inc.

- Kodiak Rebar

- Sireg SpA

- FiReP Group

- Technobasalt-Invest LLC

- TUF-BAR

- FRP Systems

- BASF SE (Raw Material Supplier)

- Nippon Electric Glass Co., Ltd. (Raw Material Supplier)

- Creative Pultrusions, Inc.

- Aslan FRP

- Capstone Composites

- Fibertrusion Systems

Frequently Asked Questions

Analyze common user questions about the Fiber Reinforced Polymer (FRP) Rebars market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of using FRP rebars instead of traditional steel rebars?

FRP rebars offer superior corrosion resistance, eliminating rust-induced cracking and spalling, leading to structural service lives often exceeding 100 years. They are also significantly lighter (about one-quarter the weight of steel) and non-magnetic/non-conductive, making them essential for marine structures, bridge decks exposed to de-icing salts, and specialized facilities like MRI rooms.

Which type of fiber (GFRP, CFRP, BFRP) dominates the market and why?

Glass Fiber Reinforced Polymer (GFRP) dominates the market by volume because it offers the best balance of corrosion resistance, structural performance, and low cost, making it the most economical replacement for standard steel in general infrastructure applications like bridge decks and highways. Carbon Fiber Reinforced Polymer (CFRP) is reserved for specialized, high-stress, high-value projects due to its significantly higher cost and strength.

What is the main restraint preventing wider adoption of FRP rebars?

The most significant restraint is the high initial material cost compared to standard commodity steel rebars. Although the life-cycle cost is lower due to reduced maintenance, the initial capital expenditure hurdle, coupled with a lack of universal awareness and established building codes in all regions, slows widespread adoption in non-critical construction.

How do installation practices differ between FRP and steel rebars?

FRP rebars require specific handling because they cannot be bent on-site; all bends must be pre-manufactured. They are typically cut using specialized abrasive tools to avoid damaging the fibers, and plastic or cable ties are used for connecting the grid, rather than standard steel tie wire, to prevent damage to the composite material coating.

Where are FRP rebars most critically needed based on application?

FRP rebars are most critically needed in highly corrosive environments, primarily bridge decks, highway pavements, marine structures (piers, jetties, sea walls), and chemical containment or water treatment facilities. These environments cause rapid deterioration of steel, making FRP's corrosion immunity a crucial factor for longevity and safety.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager