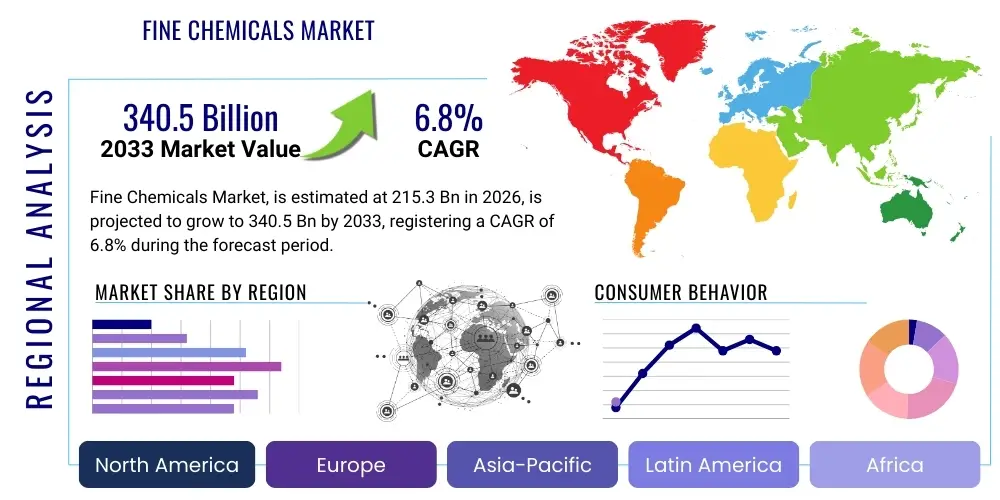

Fine Chemicals Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439195 | Date : Jan, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Fine Chemicals Market Size

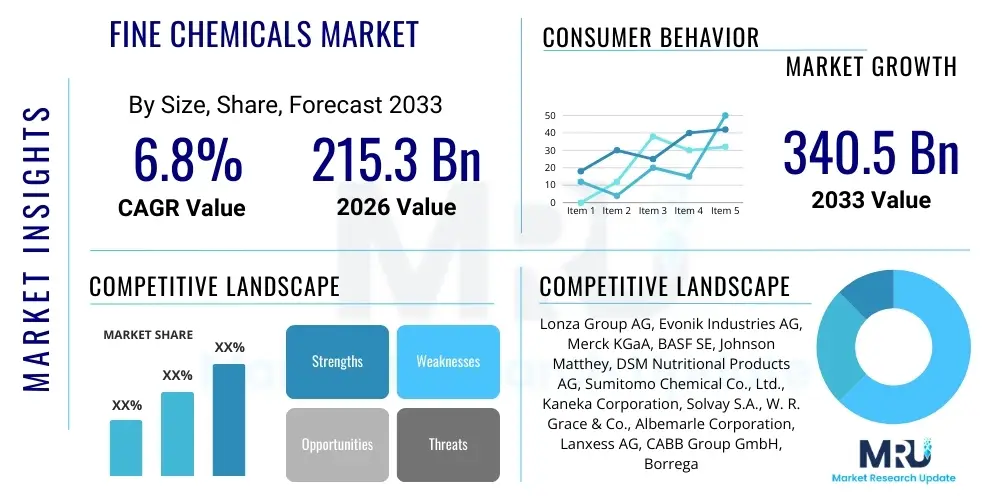

The Fine Chemicals Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 215.3 billion in 2026 and is projected to reach USD 340.5 billion by the end of the forecast period in 2033.

Fine Chemicals Market introduction

The fine chemicals market encompasses a dynamic sector of the chemical industry focused on the production of complex, single, pure chemical substances, typically produced in multi-step batch processes. These chemicals are characterized by their high purity, specific molecular structure, and often specialized applications, serving as crucial building blocks and active ingredients across a multitude of sophisticated industries. Unlike commodity chemicals, fine chemicals are produced in relatively smaller volumes and at higher prices, justifying their intricate manufacturing processes and stringent quality control standards. Their unique properties enable them to impart specific functionalities to end products, making them indispensable components in advanced formulations.

Products within this market range from active pharmaceutical ingredients (APIs), intermediates for agrochemicals, and specialty additives for polymers to electronic chemicals and highly specialized ingredients for cosmetics and personal care. The demand for fine chemicals is intrinsically linked to the innovation cycles and growth trajectories of these end-user industries, driving continuous research and development into novel synthetic routes and product functionalities. Major applications include drug synthesis, crop protection, advanced material development, and the creation of high-performance electronic components. The precise and tailored nature of fine chemicals ensures their critical role in achieving desired product performance, efficacy, and safety across these diverse sectors.

The market's expansion is fundamentally driven by several key factors. These include the escalating demand for innovative pharmaceuticals to address various health challenges, the need for enhanced agricultural productivity through effective crop protection solutions, and the rapid advancements in the electronics industry necessitating high-purity materials. Furthermore, the growing consumer preference for specialized personal care products and nutraceuticals also contributes significantly to market growth. The benefits derived from fine chemicals are manifold, offering superior performance, improved sustainability in some applications, and enabling the creation of advanced products that meet increasingly complex technical and regulatory requirements.

Fine Chemicals Market Executive Summary

The Fine Chemicals Market is characterized by robust growth, driven by an increasing emphasis on R&D, technological advancements in synthesis, and expanding applications across critical end-user industries. Business trends indicate a shift towards customized synthesis services, with a growing number of pharmaceutical, agrochemical, and specialty material companies outsourcing their complex chemical manufacturing requirements to specialized fine chemical producers. This trend is fueled by the need for cost-efficiency, speed-to-market, and access to advanced synthetic capabilities. Furthermore, strategic collaborations and mergers & acquisitions are prevalent, as companies seek to consolidate market share, expand product portfolios, and integrate value chain capabilities, particularly in niche segments requiring specialized expertise and infrastructure. Sustainability initiatives are also shaping business practices, with a rising focus on green chemistry principles and eco-friendly production methods to meet evolving environmental regulations and consumer demands.

Regionally, the market exhibits dynamic growth patterns. Asia Pacific continues to emerge as the dominant and fastest-growing region, primarily due to the rapid industrialization, burgeoning pharmaceutical and agrochemical sectors, and significant investments in manufacturing capabilities within countries like China and India. North America and Europe, while mature markets, maintain substantial shares, propelled by strong innovation ecosystems, advanced research facilities, and the presence of leading global players. These regions are pioneers in developing high-value fine chemicals, particularly for the biotechnology, advanced electronics, and specialized materials industries. Latin America, the Middle East, and Africa are showing promising growth, attributed to increasing foreign investments, expanding healthcare infrastructure, and rising agricultural activities, creating new demand avenues for fine chemical products.

Segment-wise, the market demonstrates diverse growth drivers. The pharmaceutical sector remains a cornerstone, with the increasing prevalence of chronic diseases and the subsequent demand for new drug discoveries and generic API production driving significant fine chemical consumption. The agrochemical segment is also a major contributor, driven by the global need for food security and efficient crop protection. Emerging segments such as electronic chemicals, nutraceuticals, and cosmeceuticals are experiencing accelerated growth, propelled by technological advancements and evolving consumer lifestyles. Within the type segmentation, advanced intermediates and custom synthesis services are particularly dynamic, reflecting the increasing complexity of modern chemical compounds and the specialized manufacturing expertise required for their production. This diverse segmentation underscores the broad utility and strategic importance of fine chemicals across the global industrial landscape.

AI Impact Analysis on Fine Chemicals Market

Users frequently inquire about the transformative potential of Artificial Intelligence (AI) in the fine chemicals market, particularly concerning its ability to revolutionize R&D, optimize production processes, and enhance supply chain efficiency. Key themes often revolve around how AI can accelerate drug discovery, improve the precision of chemical synthesis, reduce manufacturing costs, and ensure product quality and consistency. Concerns sometimes include the significant upfront investment required for AI integration, the need for specialized data scientists and AI experts within chemical companies, and data security challenges associated with proprietary formulations and processes. However, expectations are largely optimistic, anticipating a paradigm shift towards more intelligent, sustainable, and rapid development of complex chemical entities, ultimately leading to faster innovation cycles and a competitive advantage for early adopters in the fine chemicals sector.

The integration of AI is expected to streamline numerous facets of the fine chemicals value chain, from initial molecular design to post-production logistics. This includes leveraging machine learning algorithms to predict optimal reaction conditions, analyze vast datasets of chemical structures for novel compound discovery, and simulate complex chemical processes before physical experimentation. Such capabilities promise to significantly reduce the time and resources traditionally required for R&D, while simultaneously improving success rates. Furthermore, AI-powered predictive maintenance and real-time process monitoring are anticipated to minimize downtime, prevent deviations, and enhance overall operational efficiency within fine chemical manufacturing facilities, leading to a more robust and responsive production environment that can adapt quickly to market demands and material availability fluctuations.

Ultimately, the impact of AI extends beyond mere operational improvements, influencing strategic decision-making and fostering a more data-driven approach to fine chemical production. It enables companies to identify market trends more accurately, optimize inventory management, and even predict potential supply chain disruptions, thereby bolstering resilience. The ability of AI to analyze complex variables and generate actionable insights will empower fine chemical manufacturers to make more informed choices regarding product development, process optimization, and market positioning. This strategic leverage will be crucial for companies seeking to maintain competitiveness and lead innovation in a rapidly evolving global market, ensuring that the fine chemicals industry remains at the forefront of technological advancement and sustainable practices.

- Accelerated Drug Discovery and Development: AI algorithms analyze vast chemical libraries and biological data to identify potential drug candidates, predict their efficacy, toxicity, and synthesis pathways, significantly shortening the lead optimization phase for pharmaceutical fine chemicals.

- Optimized Chemical Synthesis Pathways: Machine learning models predict optimal reaction conditions, catalysts, and solvent systems, leading to higher yields, improved selectivity, reduced by-products, and enhanced process efficiency for complex fine chemical production.

- Predictive Quality Control and Assurance: AI-driven analytical tools monitor production parameters in real-time, detecting deviations and predicting potential quality issues before they occur, ensuring consistent high purity and specification adherence for fine chemical batches.

- Automated Process Optimization and Control: AI-powered systems dynamically adjust process parameters in manufacturing plants, optimizing energy consumption, material usage, and cycle times, leading to reduced operational costs and increased throughput.

- Enhanced Supply Chain Resilience and Demand Forecasting: AI analyzes market trends, geopolitical factors, and historical data to forecast demand more accurately, optimize inventory levels, identify potential supply chain risks, and suggest alternative sourcing strategies for raw materials and intermediates.

- Development of Novel Materials and Catalysts: AI can predict the properties of new chemical structures and design novel catalysts with enhanced activity and selectivity, fostering innovation in specialty additives, electronic chemicals, and advanced intermediates.

- Improved Safety and Environmental Monitoring: AI tools can predict potential hazards in chemical reactions, monitor emissions, and optimize waste treatment processes, contributing to safer operations and more sustainable manufacturing practices in fine chemical production.

DRO & Impact Forces Of Fine Chemicals Market

The Fine Chemicals Market is significantly influenced by a confluence of driving forces, restraining factors, and emerging opportunities. A primary driver is the burgeoning demand from various end-user industries, particularly pharmaceuticals, agrochemicals, and electronics. The increasing global population, coupled with a rising prevalence of chronic diseases, fuels the need for innovative drug therapies and generic active pharmaceutical ingredients (APIs), directly translating into higher demand for pharmaceutical fine chemicals. Similarly, the imperative for global food security, alongside the need for efficient crop protection against pests and diseases, propels the agrochemical sector's reliance on fine chemical intermediates. Furthermore, rapid advancements in consumer electronics, automotive electrification, and high-performance computing necessitate high-purity and specialized fine chemicals for their advanced components and materials, reinforcing market growth across these sectors.

Despite these robust drivers, the market faces notable restraints. Stringent regulatory frameworks imposed by bodies such as the FDA, EMA, and EPA, particularly concerning product safety, environmental impact, and manufacturing standards, present significant hurdles. Compliance with these regulations often entails substantial investments in R&D, process modifications, and documentation, increasing operational costs and market entry barriers for new players. High production costs, primarily due to the complex multi-step synthesis processes, specialized equipment requirements, and the need for highly skilled labor, also act as a restraint. Additionally, the globalized nature of raw material sourcing exposes the fine chemical industry to supply chain vulnerabilities, including geopolitical tensions, trade restrictions, and logistics disruptions, which can impact production schedules and profitability. Environmental concerns related to chemical waste generation and energy consumption during synthesis further add to the regulatory and operational pressures.

Conversely, the market is rife with opportunities that could reshape its future trajectory. The emergence of bio-based fine chemicals and the increasing adoption of green chemistry principles represent a significant avenue for sustainable growth. Innovations in biocatalysis and fermentation technologies are enabling the production of fine chemicals with reduced environmental footprints and improved energy efficiency, aligning with global sustainability goals. Developing economies, particularly in Asia Pacific and Latin America, offer untapped market potential due to their expanding industrial bases, growing disposable incomes, and increasing investments in healthcare and agriculture. Moreover, strategic collaborations, joint ventures, and mergers & acquisitions among fine chemical manufacturers and end-user industries are facilitating knowledge transfer, resource pooling, and market penetration, fostering innovation and creating new product development synergies. Advancements in continuous manufacturing and process intensification technologies further promise to enhance efficiency and reduce costs, opening new pathways for market expansion.

Segmentation Analysis

The Fine Chemicals Market is broadly segmented by type and by application, providing a comprehensive understanding of its diverse landscape and the specific niches within it. This segmentation allows for a detailed analysis of market dynamics, revealing which product categories and end-use sectors are driving growth, influencing pricing strategies, and attracting significant investment. The intricate nature of fine chemicals means that their classification by type often reflects their chemical complexity and functional role, while segmentation by application highlights their critical importance across a vast array of industries that rely on their specialized properties for product performance and innovation. Each segment exhibits unique growth drivers, competitive landscapes, and regulatory considerations, necessitating a granular approach to market assessment.

- By Type:

- Specialty Additives: These include performance-enhancing compounds for polymers, coatings, lubricants, and other materials, such as antioxidants, UV stabilizers, plasticizers, and flame retardants. Their demand is driven by the need for superior material properties and extended product lifespans.

- Advanced Intermediates: Complex chemical compounds that serve as crucial building blocks in the synthesis of APIs, agrochemicals, and specialty polymers. This segment is highly reliant on the R&D pipelines of pharmaceutical and agrochemical industries, requiring stringent purity and precise molecular structures.

- Custom Synthesis: Involves the contract manufacturing of specific chemical compounds according to client specifications, often for proprietary drug candidates or niche applications. This service-oriented segment is driven by outsourcing trends, cost-efficiency, and access to specialized expertise and equipment.

- Catalysts: Substances that increase the rate of chemical reactions without being consumed, playing a vital role in fine chemical synthesis, polymerization, and environmental applications. This includes heterogeneous, homogeneous, organometallic, and biocatalysts, crucial for process efficiency and selectivity.

- Electronic Chemicals: High-purity chemicals specifically designed for the electronics industry, including photoresists, etching agents, high-purity solvents, and specialty gases used in semiconductor manufacturing, display fabrication, and other microelectronic applications.

- Nutraceuticals & Cosmeceuticals Ingredients: Active ingredients used in health supplements, functional foods, and advanced cosmetic formulations. This segment is driven by increasing consumer awareness regarding health, wellness, and anti-aging benefits, including vitamins, amino acids, antioxidants, and emollients.

- By Application:

- Pharmaceuticals: Encompasses active pharmaceutical ingredients (APIs), pharmaceutical intermediates, and excipients used in the manufacturing of drugs for human and animal health. This is a dominant segment due to continuous drug discovery and generic drug production.

- Agrochemicals: Includes intermediates for pesticides, herbicides, fungicides, and plant growth regulators critical for crop protection and enhancing agricultural productivity. Global food security concerns are a key driver for this segment.

- Specialty Polymers & Plastics: Fine chemicals used as monomers, cross-linking agents, or performance additives to enhance the properties of polymers for various high-end applications in automotive, aerospace, and construction.

- Dyes & Pigments: Specialized organic and inorganic fine chemicals that provide color to textiles, paints, coatings, plastics, and printing inks, requiring high colorfastness and specific application properties.

- Paints & Coatings: Fine chemicals serving as binders, dispersants, rheology modifiers, and protective agents to improve the durability, appearance, and functionality of architectural, industrial, and automotive coatings.

- Cosmetics & Personal Care: Active ingredients such as vitamins, anti-aging compounds, UV filters, fragrances, and emollients used in skin care, hair care, and other personal hygiene products, driven by consumer lifestyle trends.

- Food & Feed Additives: Fine chemicals used to enhance flavor, preserve, color, or enrich food and animal feed products, including antioxidants, acidulants, emulsifiers, and amino acids, driven by food safety and quality demands.

- Electronics: High-purity chemicals and specialty materials essential for the manufacturing of semiconductors, printed circuit boards, displays, and other electronic components, critical for device performance and reliability.

- Textiles: Fine chemicals used for dyeing, printing, finishing, and functionalizing textile fibers and fabrics, providing properties like water repellency, flame retardancy, and wrinkle resistance.

- Water Treatment: Specialty chemicals used for purification, disinfection, scale inhibition, and corrosion control in industrial and municipal water treatment processes.

- Flavors & Fragrances: Complex chemical compounds that provide distinctive tastes and aromas for food, beverages, perfumes, and other consumer products, requiring high purity and specific sensory profiles.

- Adhesives & Sealants: Fine chemicals acting as monomers, curing agents, tackifiers, and modifiers to achieve specific bonding strengths, flexibility, and environmental resistance in various adhesive and sealant formulations.

Value Chain Analysis For Fine Chemicals Market

The value chain for the Fine Chemicals Market is a complex and highly specialized network, beginning with the sourcing of raw materials and culminating in the delivery of sophisticated chemical products to diverse end-user industries. Upstream, the chain involves suppliers of basic and intermediate chemicals, which are often commodity chemicals or more refined specialty intermediates. These raw materials can include petrochemical derivatives, agricultural products, or minerals, which undergo initial processing before entering the fine chemical manufacturing stage. The quality, purity, and consistent supply of these upstream inputs are paramount, as they directly impact the final product characteristics and the efficiency of subsequent synthesis steps. Strong relationships with reliable raw material suppliers are critical for fine chemical manufacturers to ensure supply chain stability and maintain cost-effectiveness.

In the midstream segment, fine chemical manufacturers are at the heart of the value chain. This stage involves intricate multi-step batch synthesis processes, purification, and quality control. Manufacturers leverage specialized chemical expertise, advanced reactor technologies, and stringent analytical methods to convert raw materials into high-purity fine chemicals. Key activities include process development, optimization of reaction conditions, separation, and packaging. Custom synthesis, toll manufacturing, and the production of advanced intermediates or active ingredients represent significant value-adding activities here. The intellectual property associated with synthetic routes and process know-how is a crucial competitive advantage. Investment in R&D and pilot plant facilities is essential for innovation and scaling up production from laboratory to commercial volumes, ensuring that products meet exacting customer specifications.

Downstream, the value chain extends to distribution channels and direct engagement with end-user industries. Fine chemicals often require specialized handling, packaging, and regulatory compliance for transport, making efficient distribution networks vital. These can include direct sales teams for large-volume or highly specialized orders, as well as third-party distributors who provide logistics, warehousing, and local market access for a broader customer base. Indirect channels may also involve formulators or compounders who incorporate fine chemicals into their own products before selling to the ultimate end-user. The primary end-users or buyers are pharmaceutical companies, agrochemical producers, electronics manufacturers, cosmetic formulators, and food & beverage companies. The success in the downstream segment depends on effective market penetration, technical support to customers, and a deep understanding of the application-specific requirements and regulatory landscapes of each target industry.

Fine Chemicals Market Potential Customers

The Fine Chemicals Market serves a highly diverse and specialized customer base, spanning a multitude of industries that rely on high-purity, precisely structured chemical compounds for their product development and manufacturing processes. These end-users are typically sophisticated industrial buyers who require chemical products with specific functionalities, stringent quality standards, and often, customized specifications. The critical role of fine chemicals in imparting unique properties or acting as active ingredients makes these customers highly dependent on reliable and innovative fine chemical suppliers. Understanding the distinct needs and regulatory environments of these various customer segments is paramount for fine chemical manufacturers to tailor their offerings and foster long-term partnerships, ensuring relevance and competitiveness in a dynamic market.

One of the most significant customer segments comprises pharmaceutical companies, including both large multinational corporations and smaller biotech firms. These entities purchase fine chemicals primarily as Active Pharmaceutical Ingredients (APIs) for drug formulations, as well as crucial intermediates used in multi-step drug synthesis. Their demand is driven by ongoing drug discovery efforts, the need for generic drug production, and the requirement for consistent quality and regulatory compliance (e.g., GMP standards). Similarly, agrochemical companies are major buyers, utilizing fine chemicals as intermediates for synthesizing pesticides, herbicides, fungicides, and plant growth regulators. Their purchasing decisions are influenced by agricultural trends, crop protection needs, and the development of more effective and environmentally friendly agrochemical products.

Beyond pharmaceuticals and agrochemicals, the electronics industry represents a rapidly growing customer base, demanding ultra-high purity fine chemicals such as photoresists, etching agents, and specialized gases for semiconductor manufacturing, printed circuit board fabrication, and display technologies. The performance and reliability of electronic devices are directly linked to the quality of these fine chemicals. Other significant end-user industries include cosmetics and personal care, where fine chemicals serve as active ingredients (e.g., vitamins, anti-aging compounds), emollients, and fragrances; the food and beverage sector, utilizing fine chemicals as flavors, preservatives, and nutritional additives; and the specialty polymers and coatings industries, which require specific monomers, cross-linkers, and performance additives to achieve desired material properties and functionalities. Each of these customer groups places unique demands on fine chemical suppliers, from purity levels and regulatory documentation to bespoke synthesis capabilities and supply chain reliability.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 215.3 billion |

| Market Forecast in 2033 | USD 340.5 billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Lonza Group AG, Evonik Industries AG, Merck KGaA, BASF SE, Johnson Matthey, DSM Nutritional Products AG, Sumitomo Chemical Co., Ltd., Kaneka Corporation, Solvay S.A., W. R. Grace & Co., Albemarle Corporation, Lanxess AG, CABB Group GmbH, Borregaard, Daicel Corporation, Nippon Kayaku Co., Ltd., Chemcon Speciality Chemicals Ltd., Ajinomoto Co., Inc., Tate & Lyle PLC, Croda International Plc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fine Chemicals Market Key Technology Landscape

The Fine Chemicals Market is a hotbed of technological innovation, constantly evolving to meet the demands for higher purity, greater efficiency, and enhanced sustainability in chemical synthesis. One of the most impactful advancements is the increasing adoption of flow chemistry, which transitions traditional batch processes into continuous manufacturing. This technology offers numerous advantages, including superior reaction control, enhanced safety by reducing hazardous intermediates, improved heat and mass transfer, and potentially higher yields with greater selectivity. Flow reactors, particularly microreactors, allow for precise control over reaction parameters, enabling the synthesis of complex fine chemicals with improved reproducibility and reduced environmental footprint, making them highly attractive for high-value-added products and specialized applications where precise control is paramount for product quality.

Another transformative technology gaining significant traction is biocatalysis, which utilizes enzymes or whole cells as catalysts for chemical transformations. This approach offers unparalleled selectivity (chemo-, regio-, and stereoselectivity) under mild reaction conditions, leading to fewer by-products, reduced energy consumption, and often eliminates the need for harsh reagents or solvents. Biocatalytic processes are inherently greener, aligning with growing industry and regulatory pressure for sustainable manufacturing practices. The ability to perform complex transformations with high precision makes biocatalysis particularly valuable in the synthesis of chiral fine chemicals, such as those found in pharmaceuticals and agrochemicals, where stereospecificity is critical for biological activity. Continued advancements in enzyme engineering and directed evolution are further expanding the scope and efficiency of biocatalytic applications in the fine chemicals sector.

Furthermore, the digital revolution, driven by Artificial Intelligence (AI), Machine Learning (ML), and Industry 4.0 principles, is profoundly impacting the fine chemical landscape. AI and ML are being deployed for predictive modeling in drug discovery, optimizing reaction pathways, and accelerating materials design by simulating molecular interactions and predicting properties. This data-driven approach significantly reduces experimental trial-and-error, shortening R&D cycles. Industry 4.0 concepts, including IoT sensors, advanced automation, and real-time data analytics, are enabling smart manufacturing facilities that can monitor, control, and optimize production processes autonomously. This leads to improved operational efficiency, predictive maintenance, enhanced quality control, and better supply chain management, ensuring agile and responsive production that can quickly adapt to market demands and unforeseen disruptions, thereby securing a competitive edge for fine chemical manufacturers. Other technologies like green chemistry principles, solvent-free reactions, and process intensification further contribute to the market's technological evolution.

Regional Highlights

- North America: This region holds a significant share in the fine chemicals market, driven by a robust pharmaceutical sector, extensive R&D investments, and strong demand from the electronics and specialty materials industries. The presence of major biotechnology and chemical companies, coupled with advanced research infrastructure and stringent regulatory standards, fosters innovation, particularly in high-value fine chemicals for novel drug discovery and advanced manufacturing. The United States is a key contributor, leading in custom synthesis and advanced intermediates.

- Europe: A mature yet highly innovative market, Europe is characterized by a strong focus on sustainable chemistry, green synthesis routes, and high-quality specialty chemicals. Countries like Germany, Switzerland, and the UK are prominent players, boasting a strong presence in pharmaceuticals, agrochemicals, and flavors & fragrances. Strict environmental regulations and a preference for bio-based fine chemicals are shaping market trends, driving continuous investment in eco-friendly technologies and process optimization.

- Asia Pacific (APAC): Positioned as the fastest-growing market, APAC is driven by rapid industrialization, expanding pharmaceutical and agrochemical industries, and significant investments in manufacturing capabilities, especially in China and India. These countries serve as major production hubs for fine chemical intermediates and APIs due to competitive labor costs and a large skilled workforce. Rising disposable incomes and increasing healthcare expenditure further fuel the demand for diverse fine chemical applications across the region.

- Latin America: This region demonstrates promising growth, particularly in the agrochemical and pharmaceutical sectors, influenced by increasing agricultural output and expanding healthcare infrastructure. Countries such as Brazil and Mexico are witnessing growing domestic demand and attracting foreign direct investment in fine chemical manufacturing. The market here is characterized by the need for cost-effective solutions and a rising focus on local production to reduce reliance on imports.

- Middle East and Africa (MEA): The MEA region is an emerging market for fine chemicals, with growth primarily supported by investments in petrochemical industries, expanding pharmaceutical manufacturing capabilities, and agricultural development initiatives. Countries in the Gulf Cooperation Council (GCC) are leveraging their abundant energy resources to develop downstream chemical industries, including specialty and fine chemicals. Infrastructure development and a growing healthcare sector are key drivers for market expansion in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fine Chemicals Market.- Lonza Group AG

- Evonik Industries AG

- Merck KGaA

- BASF SE

- Johnson Matthey

- DSM Nutritional Products AG

- Sumitomo Chemical Co., Ltd.

- Kaneka Corporation

- Solvay S.A.

- W. R. Grace & Co.

- Albemarle Corporation

- Lanxess AG

- CABB Group GmbH

- Borregaard

- Daicel Corporation

- Nippon Kayaku Co., Ltd.

- Chemcon Speciality Chemicals Ltd.

- Ajinomoto Co., Inc.

- Tate & Lyle PLC

- Croda International Plc

Frequently Asked Questions

What are fine chemicals and how do they differ from commodity chemicals?

Fine chemicals are pure, complex chemical substances produced in relatively small volumes, often through multi-step batch processes, and are characterized by their high purity and specific molecular structure. They differ from commodity chemicals, which are high-volume, low-cost, less complex chemicals used as basic building blocks, by their higher value, specialized applications, and more intricate manufacturing requirements, serving as crucial ingredients in high-tech industries.

Which industries are the primary end-users of fine chemicals?

The primary end-users of fine chemicals include the pharmaceutical industry for Active Pharmaceutical Ingredients (APIs) and intermediates, the agrochemical industry for crop protection agents, the electronics industry for high-purity materials, and the cosmetics & personal care sector for active ingredients. Other significant users are the food & beverage, specialty polymers, paints & coatings, and flavors & fragrances industries, all requiring specialized chemical compounds for product performance.

What are the key growth drivers for the Fine Chemicals Market?

The market's growth is primarily driven by the increasing demand from end-user industries such as pharmaceuticals, agrochemicals, and electronics, fueled by global population growth, health awareness, and technological advancements. Rising R&D investments in new molecule synthesis, the shift towards customized chemical solutions, and the growing adoption of bio-based and sustainable fine chemicals further contribute to market expansion.

How is Artificial Intelligence impacting the Fine Chemicals Market?

Artificial Intelligence (AI) is significantly impacting the Fine Chemicals Market by accelerating drug discovery, optimizing complex chemical synthesis pathways, enhancing predictive quality control, and improving supply chain efficiency. AI-driven platforms enable faster material design, reduce experimental trial-and-error, and facilitate automated process optimization, leading to cost reductions and faster time-to-market for innovative fine chemical products.

What are the main challenges faced by the fine chemicals industry?

The fine chemicals industry faces challenges such as stringent regulatory frameworks and environmental compliance, which necessitate substantial investments in R&D and process modification. High production costs due to complex synthesis and specialized equipment, coupled with potential raw material price volatility and supply chain disruptions, also pose significant hurdles. Competition from generic products and the need for continuous innovation further contribute to the market's complexities.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Cyanuric Acid Market Size Report By Type (Particle Cyanuric Acid, Powdered Cyanuric Acid), By Application (Fine Chemicals Industry, Synthetic Resin, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Fine Chemicals Market Statistics 2025 Analysis By Application (Pharmaceuticals, Food and Beverages, Agriculture, Industrial Additives, Other), By Type (Pharmaceuticals, Vitamins, Other), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Fine Chemicals Market Statistics 2025 Analysis By Application (Pharmaceutical, Food & Beverage, Agriculture, Industrial Additive), By Type (Drug, Vitamin, Pesticide), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Sodium Permanganate Market Statistics 2025 Analysis By Application (Water Treatment, Electronics, Fine Chemicals & Pharmaceuticals), By Type (Sodium Permanganate 40%, Sodium Permanganate 20%, Other), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Petrochemical Wastewater Treatment Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Biological Treatment, Ion exchange treatment, Membrane Treatment, Physico chemical treatment), By Application (Energy, Upstream oil and gas, Refining and petrochemicals Chemicals, Pharmaceutical, cosmetics, fine chemicals Metals and mining, Food and beverage Microelectronics, Healthcare providers), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager