Fine Grinder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431743 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Fine Grinder Market Size

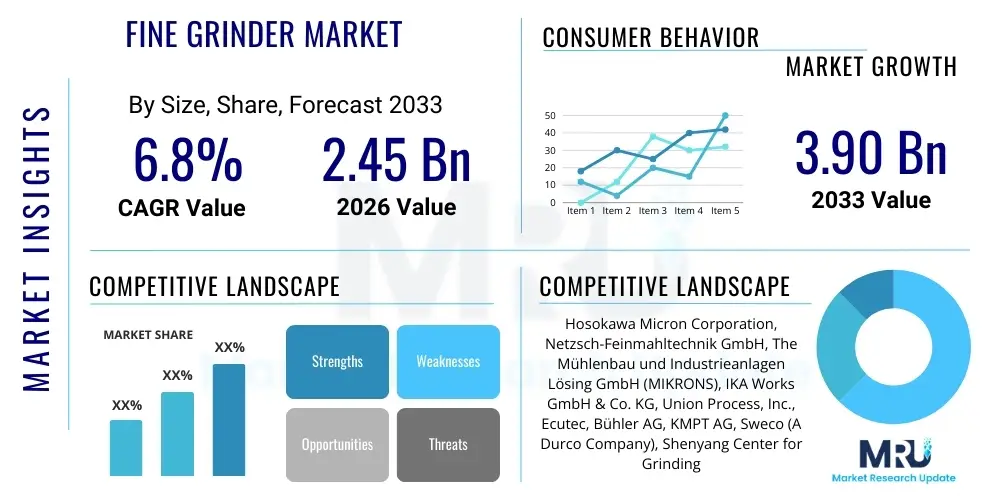

The Fine Grinder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 2.45 Billion in 2026 and is projected to reach USD 3.90 Billion by the end of the forecast period in 2033.

Fine Grinder Market introduction

The Fine Grinder Market encompasses specialized industrial equipment designed for ultrafine particle size reduction, crucial for achieving specific material properties across various high-technology sectors. Fine grinders, including jet mills, ball mills, and stirred media mills, are engineered to process materials down to the micron or even sub-micron range, ensuring high surface area, enhanced reactivity, and precise formulation consistency. These systems are integral in industries where particle morphology dictates final product performance, such as pharmaceuticals requiring high bioavailability, advanced ceramics needing uniform sintering, and chemical manufacturing demanding specific reaction kinetics.

Major applications of fine grinders span critical sectors including pharmaceutical API processing, advanced material synthesis (e.g., battery materials), specialized food ingredients (e.g., cocoa, spices, functional proteins), and mineral processing (e.g., precious metal ore refinement, pigment production). The necessity for precise particle distribution is a primary driver, as inconsistencies in grinding quality can lead to product failure or regulatory non-compliance. Benefits associated with adopting sophisticated fine grinding technology include significant improvements in processing efficiency, reduced energy consumption compared to conventional methods, and the capability to handle extremely hard or temperature-sensitive materials while maintaining strict quality parameters.

The market's driving factors are fundamentally tied to global trends in miniaturization and material optimization. Increasing demand for high-performance additives, coupled with stringent regulatory standards favoring high-purity and consistent formulations in healthcare and food industries, necessitates superior grinding solutions. Furthermore, rapid technological advancements in energy storage materials, particularly the shift towards higher-density battery components, are fueling investment in ultrafine grinding capabilities capable of handling novel chemistries and achieving the necessary homogeneity for optimal device performance.

Fine Grinder Market Executive Summary

The Fine Grinder Market is currently characterized by significant investment in automation and predictive maintenance technologies aimed at optimizing operational efficiency and minimizing downtime, reflecting a major business trend favoring long-term cost reduction over initial capital expenditure. Key business trends also include the consolidation of specialized grinding equipment manufacturers and the increasing adoption of toll processing services, allowing smaller manufacturers to access high-end grinding capabilities without significant infrastructure investment. The shift toward sustainable processing methods is influencing product development, with manufacturers focusing on energy-efficient designs, particularly in stirred media and high-pressure grinding roll (HPGR) technologies, addressing the historically high energy demands of comminution processes.

Regionally, the Asia Pacific (APAC) continues to dominate market growth, driven primarily by the colossal expansion of the chemical processing, electronics, and battery manufacturing sectors in countries like China, India, and South Korea. North America and Europe, while growing at a steadier pace, are leading the adoption of advanced automation and regulatory compliance technologies, particularly in the pharmaceutical and food safety domains where traceability and validation are paramount. The emergence of specialized mineral extraction and processing projects in Latin America and the Middle East & Africa is providing niche opportunities for robust, high-throughput fine grinding equipment suited for handling abrasive and difficult-to-process ores and industrial minerals.

Segment trends reveal that the pharmaceutical and chemical industries remain the largest end-users, demanding ultra-precise jet mills and pharmaceutical-grade ball mills. However, the fastest growth is observed in the energy and electronics segment, largely fueled by the exponential demand for electrode materials for lithium-ion batteries and highly specialized conductive powders, requiring grinding technologies capable of preserving particle morphology and preventing contamination. Equipment type segmentation highlights a growing preference for stirred media mills due to their superior efficiency in wet grinding and achieving nano-scale particle sizes, essential for advanced coatings and slurries.

AI Impact Analysis on Fine Grinder Market

Users frequently inquire about how AI can mitigate the operational complexities associated with fine grinding, specifically asking about predictive maintenance schedules, optimization of milling parameters for varying raw material batches, and real-time contamination detection. Based on these recurring themes, AI's primary influence centers on transforming grinding processes from empirically driven operations to highly adaptive, data-informed systems. This transition is expected to lead to unprecedented levels of energy efficiency, reduction in material waste, and vastly improved final product consistency by autonomously adjusting operational variables like feed rate, rotor speed, and air flow based on immediate feedback from integrated sensors and historical performance data, thereby maximizing uptime and reducing the Total Cost of Ownership (TCO).

- Implementation of Predictive Maintenance (PdM) algorithms based on acoustic and vibration analysis to forecast equipment failure, minimizing unplanned downtime.

- Real-time process optimization through Machine Learning (ML) models that adjust parameters (e.g., mill load, media size, slurry concentration) to maintain targeted particle size distribution (PSD) automatically.

- Enhanced quality control by using Computer Vision (CV) and neural networks to analyze particle images and detect minute morphological deviations or contamination at sub-micron levels.

- Optimization of energy consumption by dynamically balancing throughput against power input, leading to significant reduction in specific energy requirements (kWh/ton).

- Automated anomaly detection in processing materials, allowing for early intervention when unexpected material hardness or flow characteristics are encountered.

- Development of digital twins of grinding circuits, enabling simulation of new material processing conditions and process design without physical trials.

DRO & Impact Forces Of Fine Grinder Market

The Fine Grinder Market is fundamentally propelled by the increasing global demand for high-specification materials across critical industries, particularly the pharmaceutical sector where high bioavailability requires particle sizes below 10 microns, and the advanced materials sector, driven by the need for enhanced surface area in catalysts and battery components. These precision requirements serve as the primary Driver (D). However, the market faces significant Restraints (R), notably the high capital expenditure required for sophisticated, contamination-free grinding systems and the substantial energy consumption associated with achieving ultra-fine particle reduction (Rittinger’s Law), which pressures manufacturers to find more efficient solutions. Opportunities (O) abound in the integration of specialized grinding with nanotechnology applications, particularly in the dispersion and stabilization of nanoparticles, and the growing focus on circular economy initiatives which necessitate efficient processing of recycled and waste materials.

The core Impact Forces influencing the market dynamics stem from technological advancements and rigorous regulatory pressure. The force of technological innovation constantly pushes the limits of particle size reduction, with advancements in jet milling and stirred media technologies continually lowering the minimum achievable particle diameter while improving throughput. Concurrently, strict regulatory environments, especially concerning material safety and purity in the food and medical sectors (e.g., FDA, EMA compliance), exert strong pressure on manufacturers to invest in highly validated, hygienic, and precise grinding equipment, often favoring specialized material construction and inert processing environments.

These forces create a dynamic equilibrium: while high investment costs restrict market entry (Restraint), the undeniable need for superior product performance (Driver) mandates the adoption of advanced, capital-intensive equipment. The market growth trajectory is highly responsive to advancements in material science—as new materials (e.g., composite battery cathodes, specialized APIs) are developed, customized fine grinding solutions become immediately necessary, creating continuous Opportunity. Failure to meet these dual challenges of efficiency and compliance can result in a loss of market share, making the integration of smart, energy-efficient processing solutions a non-negotiable factor for long-term viability.

Segmentation Analysis

The Fine Grinder Market is structurally segmented based on crucial attributes including Equipment Type, Application, and Operating Principle, providing a granular view of specific industry demands and technological preferences. This detailed segmentation allows manufacturers to tailor machine design and capabilities—such as capacity, material contact surfaces, and energy efficiency profiles—to the precise requirements of various end-user sectors, which range from high-volume mineral processing to highly precise, low-volume pharmaceutical manufacturing. Understanding these segmentation nuances is crucial for strategic market positioning and product development, especially as specialized industries increasingly demand customization to handle unique material characteristics like thermal sensitivity, hardness, and electrostatic properties.

Segmentation by Equipment Type is critical as it defines the mechanism of comminution; for instance, air jet mills are preferred for delicate, contamination-sensitive materials due to their reliance on air impingement rather than mechanical contact, whereas stirred media mills are dominant in wet grinding applications requiring nano-scale particle sizes. Application segmentation reflects the ultimate destination and use case of the processed material, influencing regulatory requirements and processing volume. The shift towards battery materials processing, for example, demands dedicated explosion-proof and tightly controlled grinding environments due to the volatile nature of some precursor chemicals and the strict quality control required for electrochemical performance.

The operational segmentation, such as batch versus continuous processing, determines system throughput and integration into larger manufacturing lines. Continuous fine grinding systems are essential for high-volume commodity production (like cement or industrial minerals), maximizing throughput and minimizing energy fluctuations. Conversely, batch systems, typically smaller and highly flexible, are preferred in pharmaceutical research and development or specialty chemical production where material costs are high and precise control over small quantities is mandatory. These interlinked segmentations underscore the market's diversity and the need for highly specialized engineering solutions rather than monolithic equipment platforms.

- By Equipment Type: Jet Mills, Ball Mills (Dry/Wet), Stirred Media Mills, Hammer Mills, Roller Mills, High-Pressure Grinding Rolls (HPGR).

- By Application: Pharmaceuticals, Food & Beverage, Chemicals & Materials, Mineral Processing, Cosmetics, Ceramics & Glass, Energy Storage (Battery Materials).

- By Operating Principle: Impact/Attrition, Shear/Compression, Agitation/Media.

- By Operation Mode: Batch, Continuous.

Value Chain Analysis For Fine Grinder Market

The value chain for the Fine Grinder Market begins with the upstream sourcing of specialized raw materials, primarily high-grade metals (e.g., stainless steel, wear-resistant alloys) and advanced ceramic components (for grinding media and liners) required to withstand extreme abrasive and corrosive environments. Critical upstream activities involve precision machining and fabrication, where intellectual property related to stress tolerance and geometric design of internal components is paramount. Manufacturers then focus on integrating these components with sophisticated control systems, including automation hardware and software that manage process variables (e.g., air flow, media charge, temperature control), transforming raw components into validated, high-performance comminution systems.

The midstream involves the distribution and sales channels, which are typically bifurcated into direct and indirect routes. Direct sales are common for high-value, customized systems, especially those destined for regulated industries like pharmaceuticals, where the Original Equipment Manufacturer (OEM) handles installation, validation (IQ/OQ/PQ), and long-term service contracts. Indirect channels involve regional distributors or agents who provide local market penetration, technical support, and faster spare parts supply for less specialized or smaller-scale equipment. Service provision, including predictive maintenance agreements, equipment refurbishment, and process optimization consultancy, forms a significant and high-margin part of the midstream value proposition.

Downstream analysis focuses on the end-users and their specific integration requirements. Fine grinders are typically integrated into complex processing lines (e.g., continuous pharmaceutical granulation lines or mineral beneficiation plants). The primary downstream value addition lies in the ability of the equipment to deliver final product specifications consistently, reducing product waste, and ensuring compliance. Key downstream buyers, such as major chemical conglomerates or pharmaceutical giants, prioritize total reliability and validated performance over initial cost. The specialized nature of fine grinding equipment ensures a strong relationship between the OEM and the end-user, often leading to long-term partnerships focused on continuous process improvement and capacity scaling.

Fine Grinder Market Potential Customers

Potential customers for fine grinding equipment are concentrated in industries where particle size and surface area critically influence the quality, function, and performance of the end product. Pharmaceutical manufacturers are primary buyers, utilizing fine grinders for micronization to increase the bioavailability and dissolution rate of Active Pharmaceutical Ingredients (APIs), a process fundamental to drug efficacy. These end-users demand ultra-clean, sterile, and validated systems that comply strictly with Good Manufacturing Practices (GMP) and possess advanced features for inert gas processing to handle sensitive or explosive powders, often necessitating specialized jet mill technology.

Another significant customer base resides within the chemical and advanced materials sector, including manufacturers of high-performance plastics, specialty polymers, paints, coatings, and composite fillers. These customers rely on fine grinding to achieve precise pigment dispersion, enhance mechanical strength, or control the rheological properties of their products. For materials like ceramic precursors or conductive metal powders used in electronics, the potential buyer requires mills capable of producing highly uniform, contamination-free particles, often requiring materials like zirconia grinding media to prevent metallic contamination.

Furthermore, the rapidly expanding energy storage sector represents a high-growth customer segment. Battery manufacturers, particularly those involved in producing cathode and anode materials for lithium-ion cells, require advanced fine grinding and mixing systems to achieve highly uniform particle size distribution for optimal electrode packing density and electrochemical performance. These applications demand specialized inert atmosphere grinding solutions to handle moisture-sensitive and volatile components, positioning them as essential high-volume, high-specification buyers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.45 Billion |

| Market Forecast in 2033 | USD 3.90 Billion |

| Growth Rate | CAGR 6.8 % |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hosokawa Micron Corporation, Netzsch-Feinmahltechnik GmbH, The Mühlenbau und Industrieanlagen Lösing GmbH (MIKRONS), IKA Works GmbH & Co. KG, Union Process, Inc., Ecutec, Bühler AG, KMPT AG, Sweco (A Durco Company), Shenyang Center for Grinding Technology Co., Ltd., Sturtevant, Inc., Malvern Panalytical, FLSmidth, Metso Outotec, KHD Humboldt Wedag International AG, Glen Mills Inc., SANKO Giken Co., Ltd., TEMA GmbH. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fine Grinder Market Key Technology Landscape

The technological landscape of the Fine Grinder Market is defined by continuous innovation focused on improving energy efficiency, achieving narrower particle size distributions (PSD), and minimizing contamination. Central to this evolution is the advancement of stirred media mill technology, which utilizes high-speed rotation and fine grinding beads (often ceramic) to impart high energy to materials in a slurry, making it highly effective for producing sub-micron and nano-scale powders required by the advanced ceramics and electronics industries. Key technological developments in stirred media mills include enhanced cooling systems to manage thermal load during high-intensity grinding and the use of sophisticated computational fluid dynamics (CFD) modeling to optimize media movement and reduce wear, extending the lifespan of critical components and maintaining purity.

Another significant area of technological focus is the integration of process analytical technology (PAT) and Industrial Internet of Things (IIoT) sensors directly into grinding equipment. Modern fine grinders are equipped with real-time laser diffraction sensors that instantaneously measure particle size distribution, feeding data back to the machine’s control system. This closed-loop control allows for rapid, automated adjustments of operational parameters—such as air classifier speed in jet mills or pressure settings in HPGRs—to maintain tight product specifications irrespective of slight variations in raw material feed. This level of automation is critical for validating processes in regulated environments and is instrumental in reducing reliance on manual sampling and laboratory analysis, substantially increasing overall throughput efficiency and reducing cycle times.

Furthermore, innovation in material handling and component longevity remains a persistent technological driver. Given the extremely abrasive nature of many materials processed, manufacturers are constantly developing superior wear-resistant internal linings (e.g., specialized polymers, high-purity alumina, silicon carbide) to minimize metallic contamination, which is paramount in battery and pharmaceutical applications. The optimization of air classification systems within dry grinding processes is also crucial, enabling highly precise separation of finished product from coarser particles, thereby ensuring a narrow and consistent final particle size distribution without requiring excessive re-circulation or over-grinding, which saves energy and prevents material degradation.

Regional Highlights

- Asia Pacific (APAC): APAC is the largest and fastest-growing market for fine grinders, primarily fueled by massive industrial expansion, particularly in China and India. The region dominates global production in bulk chemicals, construction materials, consumer electronics, and is the epicenter of the lithium-ion battery manufacturing boom, driving enormous demand for high-capacity, specialized grinding equipment for raw mineral processing and precursor material preparation. Regulatory standards, while catching up to Western norms, focus heavily on output capacity and competitive pricing, though environmental regulations are increasingly driving demand for more energy-efficient and closed-loop grinding systems.

- North America: Characterized by mature industrialization and stringent regulatory oversight, North America focuses on high-precision and validated grinding solutions, especially within the pharmaceutical and high-end specialty chemical industries. The region prioritizes automation, data integrity, and compliance (e.g., FDA validation), leading to higher adoption rates of smart, sensor-equipped jet mills and pharmaceutical-grade ball mills. Investment is focused on replacement cycles, modernization, and incorporating AI-driven predictive maintenance technologies to ensure minimal operational risk and maximum uptime in high-value production environments.

- Europe: The European market is highly sophisticated, driven by sustainability goals, advanced R&D in materials science, and strong regulations promoting energy efficiency (e.g., EU Green Deal mandates). Key demand comes from advanced ceramics, automotive coatings, and premium food processing sectors. European manufacturers lead in developing novel grinding media and environmentally friendly processing techniques, emphasizing closed-circuit systems, dust control, and minimum specific energy consumption (SEC), positioning them at the forefront of technological innovation and high-quality, specialized equipment demand.

- Latin America (LATAM): The LATAM market growth is closely tied to its strong mineral extraction industry (copper, gold, iron ore) and expanding cement/construction sectors. Demand is typically for robust, high-throughput, and durable grinding equipment (such as HPGRs and large-scale ball mills) capable of handling harsh, high-volume processing demands. Investment often focuses on upgrading outdated comminution circuits to improve energy efficiency and recovery rates in mining operations, driven by global commodity prices.

- Middle East & Africa (MEA): This region shows moderate growth, primarily centered around petrochemical derivatives, cement production, and specific precious mineral processing. Equipment demand is often tailored for handling unique local raw materials (e.g., high-abrasion ores) and is characterized by a high reliance on international OEMs for technical support, installation, and spare parts supply due to limited local high-tech manufacturing infrastructure.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fine Grinder Market.- Hosokawa Micron Corporation

- Netzsch-Feinmahltechnik GmbH

- The Mühlenbau und Industrieanlagen Lösing GmbH (MIKRONS)

- IKA Works GmbH & Co. KG

- Union Process, Inc.

- Ecutec

- Bühler AG

- KMPT AG

- Sweco (A Durco Company)

- Shenyang Center for Grinding Technology Co., Ltd.

- Sturtevant, Inc.

- Malvern Panalytical (Equipment and analysis)

- FLSmidth

- Metso Outotec

- KHD Humboldt Wedag International AG

- Glen Mills Inc.

- SANKO Giken Co., Ltd.

- TEMA GmbH

- Alpine Hosokawa Micron (division)

- Clyde Process Solutions

Frequently Asked Questions

Analyze common user questions about the Fine Grinder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary driving factor for the growth of the Fine Grinder Market?

The primary driver is the escalating global demand for high-specification, ultrafine powders and nano-materials across regulated industries, particularly pharmaceuticals (for enhanced bioavailability) and advanced electronics/battery manufacturing (for improved material performance and density).

Which segment of the Fine Grinder Market is expected to witness the highest growth rate?

The Application segment related to Energy Storage (specifically lithium-ion battery materials, including cathode and anode precursors) is projected to exhibit the highest CAGR due to unprecedented global investment and expansion in electric vehicle and grid storage manufacturing capacity.

How does AI technology affect the operational costs of fine grinding equipment?

AI significantly reduces operational costs by implementing predictive maintenance, thereby decreasing unplanned downtime, and optimizing real-time processing parameters to maximize throughput while minimizing the specific energy consumption (kWh per unit of product).

What are the main technological challenges facing fine grinding manufacturers?

Key technological challenges include minimizing energy consumption during ultra-fine comminution, developing highly wear-resistant materials to prevent contamination, and creating validated systems that can guarantee tight particle size distribution (PSD) repeatability in highly regulated environments.

Which regional market holds the dominant share in the fine grinding industry?

The Asia Pacific (APAC) region currently holds the dominant market share, driven by rapid industrialization, large-scale chemical production, extensive mineral processing operations, and its leading role in global battery component manufacturing.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager