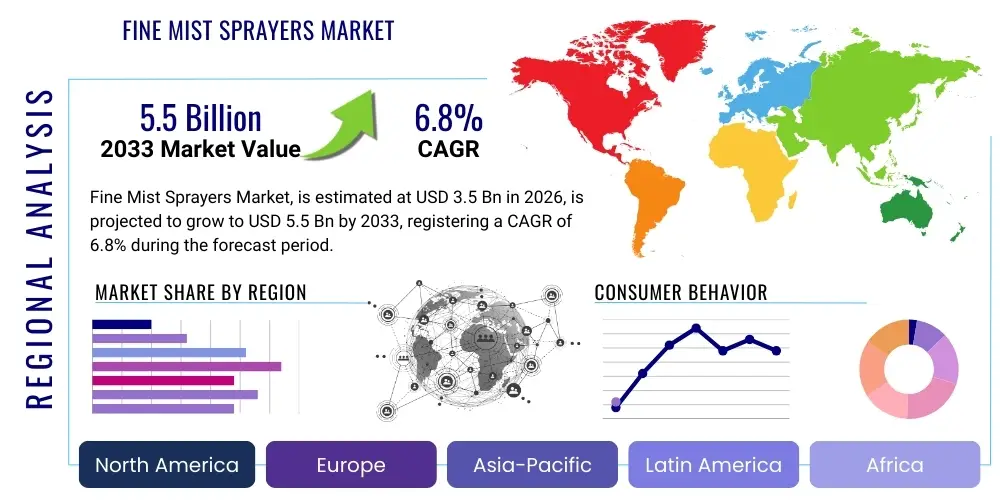

Fine Mist Sprayers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437166 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Fine Mist Sprayers Market Size

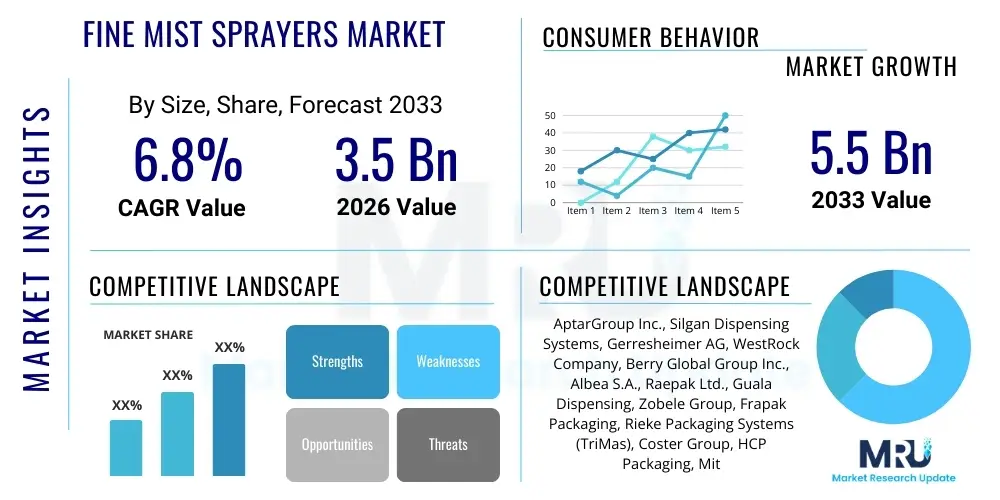

The Fine Mist Sprayers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 5.5 Billion by the end of the forecast period in 2033.

Fine Mist Sprayers Market introduction

The Fine Mist Sprayers Market encompasses the manufacturing and distribution of dispensing systems designed to atomize liquids into extremely small, uniform droplets. These dispensing devices are crucial components in various packaging solutions, particularly those requiring controlled application and broad surface coverage, such as perfumes, cosmetic setting sprays, pharmaceutical nasal sprays, and various cleaning products. The market growth is inherently tied to the expansion of consumer packaged goods (CPG), healthcare, and personal care industries, where aesthetics, precision, and user experience are paramount.

Fine mist sprayers offer significant benefits over traditional pump mechanisms, including superior coverage efficiency, reduced product wastage, and enhanced portability. Their typical construction involves a pump, housing, dip tube, and actuator, engineered to deliver a consistent, measured dose of product with each activation. Major applications span high-end fragrances, sunscreens, hair care products, and topical medications. Driving factors include increasing consumer demand for sophisticated and convenient packaging formats, stringent regulatory standards in pharmaceutical delivery requiring precise dosing, and a global shift toward smaller, travel-sized product packaging.

Fine Mist Sprayers Market Executive Summary

The Fine Mist Sprayers Market is characterized by robust business trends centered on sustainability and technological innovation. Manufacturers are heavily investing in monomaterial and PCR (Post-Consumer Resin) sprayer components to meet stringent environmental regulations and consumer demand for eco-friendly packaging. Key business strategies involve vertical integration to secure raw material supply chains and strategic partnerships with major beauty and pharmaceutical companies to co-develop custom dispensing solutions. The shift towards waterless formulations and concentrated products in the cosmetic sector further drives the need for highly efficient, dose-controlled fine mist systems, thereby sustaining premium pricing for technologically advanced dispensers.

Regionally, the Asia Pacific (APAC) market is witnessing the fastest growth, propelled by rapidly expanding middle-class populations, increased spending on personal grooming products, and the localization of manufacturing hubs for global CPG giants, particularly in China and India. North America and Europe remain mature markets, driven primarily by technological replacement cycles, strong demand in the pharmaceutical segment (nasal and oral sprays), and the adoption of high-barrier materials to extend product shelf life. Regulatory harmonization efforts in the EU regarding aerosol safety and VOC emissions are also influencing design specifications, favoring mechanical pump systems over traditional aerosols where possible.

Segment trends highlight a strong preference for pump type fine mist sprayers over crimp-on variants, offering greater flexibility and refill potential, aligning with circular economy initiatives. The material segment shows dominance by plastic polymers (PP, PE) due to cost-effectiveness and versatility, although glass and aluminum containers paired with mist sprayers are gaining traction in the luxury fragrance segment. In terms of end-use, cosmetics and personal care maintain the largest share, while the pharmaceutical segment, requiring specialized anti-bacterial and measured-dose actuation, commands the highest average selling prices (ASP), promising profitable growth opportunities.

AI Impact Analysis on Fine Mist Sprayers Market

Users frequently inquire about how AI can optimize the manufacturing efficiency, quality control, and predictive maintenance within the highly automated Fine Mist Sprayers production process. Common questions revolve around implementing AI vision systems to detect micro-defects in pump components, using machine learning algorithms to predict equipment failure downtime, and leveraging generative AI to rapidly prototype new sprayer designs that maximize atomization efficiency or minimize material usage. The central user expectation is that AI integration will significantly reduce waste, minimize assembly errors common in high-speed production lines, and facilitate real-time supply chain adjustments based on volatile demand signals from the beauty and healthcare sectors.

Furthermore, users are keen to understand AI's role in personalizing the spray experience. This involves analyzing consumer usage patterns to inform the design of actuators that offer customized tactile feedback or adjust the spray angle and volume based on specific application requirements (e.g., face vs. body mist). While direct AI involvement in the final product itself is minimal, its impact on operational excellence, quality assurance, and accelerating the design-to-market cycle is expected to be transformative, leading to higher quality, lower cost dispensers and meeting the stringent compliance requirements of pharmaceutical clients.

- AI-driven vision systems enhance quality control by detecting microscopic defects in sprayer components (e.g., springs, gaskets) at high production speeds.

- Machine learning models predict maintenance needs for injection molding and high-speed assembly lines, drastically reducing unplanned downtime and improving Overall Equipment Effectiveness (OEE).

- AI optimizes inventory management and supply chain logistics by predicting fluctuating demand from CPG and pharmaceutical clients, minimizing overstocking or stockouts of specialized components.

- Generative design tools, powered by AI, are accelerating the creation of novel nozzle geometries for superior atomization and precise dose delivery characteristics.

- AI facilitates enhanced product traceability and regulatory compliance by digitally tracking component origins and assembly parameters throughout the manufacturing lifecycle.

DRO & Impact Forces Of Fine Mist Sprayers Market

The Fine Mist Sprayers Market is primarily driven by the escalating demand for advanced dispensing solutions across the high-growth cosmetics, personal care, and pharmaceutical sectors, where product differentiation is often achieved through superior packaging and application experience. The convenience, measured dosing capabilities, and aesthetic appeal offered by fine mist sprayers make them indispensable for modern product formats like facial mists, setting sprays, and high-value topical drugs. Furthermore, the global emphasis on sanitation and personal hygiene, particularly post-pandemic, has boosted demand for fine mist sprayers in specialized antiseptic and hand sanitizer formulations, particularly for non-aerosol, pump-based systems that offer portability and controlled release.

However, the market faces significant restraints, chiefly concerning the complexity of achieving truly sustainable fine mist sprayer designs. The typical multi-material construction (plastic, metal spring, glass marble) complicates recycling processes, posing a challenge for manufacturers aiming for mono-material solutions. Additionally, fluctuations in polymer resin prices, coupled with high initial capital investment required for precision tooling and high-speed assembly machinery, introduce operational cost volatilities. Intellectual property disputes related to patented pump technologies also restrict market entry and innovation for smaller manufacturers.

Opportunities abound in developing high-value, child-resistant and tamper-evident fine mist sprayers specifically tailored for the pharmaceutical and cannabis industries, where regulatory requirements necessitate advanced safety features. Furthermore, the adoption of B2B e-commerce platforms simplifies procurement for mid-sized CPG brands, streamlining the supply chain for customized components. The increasing consumer preference for refillable packaging systems offers manufacturers an avenue to redesign durable, high-quality pump mechanisms that withstand repeated use, promoting a circular economy model and boosting replacement part sales. These forces collectively shape the competitive landscape, emphasizing innovation in both precision engineering and environmental accountability.

Segmentation Analysis

The Fine Mist Sprayers market is extensively segmented based on material, capacity, end-use application, and dispensing mechanism, allowing for targeted product development catering to specialized industry needs. Material composition, primarily plastics (PP, PE, PET), metals (aluminum), and glass, dictates the product's chemical compatibility, barrier properties, and aesthetic finish. Capacity segmentation reflects the primary end-user requirement, ranging from micro-dose systems (under 10 ml) essential for pharmaceutical nasal sprays to larger volume units (over 100 ml) used in household cleaning or hair care products. End-use remains the most crucial segmentation dimension, clearly dividing the market into high-volume, cost-sensitive consumer goods sectors and precision-required, high-margin pharmaceutical sectors.

- By Type:

- Crimp-on Sprayers (often used in fragrance)

- Screw-on/Pump Sprayers (dominant in cosmetics and personal care)

- By Material:

- Plastic (Polypropylene (PP), Polyethylene (PE), PET)

- Metal (Aluminum)

- Glass

- By Capacity:

- Under 10 ml (Micro-dosing)

- 10 ml to 50 ml (Personal/Travel Size)

- 50 ml to 100 ml (Standard Size)

- Above 100 ml (Household/Bulk Size)

- By End-Use Application:

- Cosmetics and Personal Care (Fragrance, Skincare, Haircare)

- Pharmaceutical (Nasal, Oral, Topical Delivery)

- Household Cleaning and Air Fresheners

- Food and Beverage (Flavorings)

- Others (Automotive, Industrial)

Value Chain Analysis For Fine Mist Sprayers Market

The value chain for fine mist sprayers begins with upstream analysis, which involves the sourcing of primary raw materials—specialty polymer resins (PP, PE, POM for pump components), metals for springs and external shielding (aluminum/steel), and glass or plastic for dip tubes and containers. The cost structure is highly sensitive to the volatile prices of petrochemical derivatives, necessitating robust hedging strategies by major manufacturers. Key upstream players include major chemical and resin producers who supply specialized, high-purity materials essential for consistent atomization and chemical stability, especially crucial for pharmaceutical applications where leaching is a major concern. Establishing stable, long-term supply agreements is vital for maintaining margins and ensuring compliance with material specifications.

The midstream process is dominated by precision engineering, covering the injection molding of plastic components, stamping of metal springs, and high-speed automated assembly. Differentiation occurs at this stage through proprietary pump technology, such as specialized engine designs, closure systems (snap-on vs. screw-on), and advanced actuator shapes that define the user experience. Distribution channels are varied, encompassing direct sales for large, customized contracts with multinational CPG firms (direct channel) and utilization of regional packaging distributors and brokers (indirect channel) to serve smaller and regional cosmetic brands. Effective inventory management and robust logistics infrastructure are critical for timely delivery across dispersed global manufacturing bases.

Downstream analysis focuses on the end-use applications, where fine mist sprayers integrate into the finished packaged goods across cosmetics, pharmaceuticals, and household sectors. The performance of the sprayer—measured by dose consistency, leak resistance, and spray pattern quality—directly impacts the consumer perception and effectiveness of the final product. Strong partnerships with packaging design agencies and filling operations are essential, as the fine mist sprayer must be perfectly compatible with high-speed automated filling lines. The final customer selection is heavily influenced by quality certification (ISO, GMP), reliability, and increasingly, the demonstrable sustainability credentials of the dispensing mechanism.

Fine Mist Sprayers Market Potential Customers

The primary customers for fine mist sprayers are large multinational corporations and specialized firms operating within the Fast-Moving Consumer Goods (FMCG), personal care, and regulated healthcare sectors. These end-users demand dispensers that offer technical precision, reliability, and brand alignment. In the cosmetics sector, customers such as L'Oréal, Estée Lauder, and Coty seek highly aesthetic, premium sprayers for fragrances and setting mists that provide a luxurious user experience and consistent dose delivery, often prioritizing custom colors and metalized finishes.

In the pharmaceutical industry, potential customers include global drug manufacturers and generic drug producers focused on nasal spray decongestants, allergy treatments, and transdermal sprays. For these clients, the absolute priorities are dose accuracy (measured in microliters), regulatory compliance (FDA/EMA approval), and specialized features like anti-microbial components and child-resistant closures. These high-value segments require extensive validation and quality documentation from sprayer manufacturers, often resulting in long-term supply contracts.

The third major customer segment includes household and industrial chemical producers, such as Reckitt Benckiser and P&G, who require cost-effective, durable sprayers for air fresheners, spot cleaners, and surface sanitizers. While cost efficiency is a major factor here, there is a growing demand for chemically resistant sprayers capable of handling harsh, concentrated formulations. All customer segments are increasingly demanding packaging that integrates Post-Consumer Recycled (PCR) content and designs that facilitate end-of-life recycling, influencing procurement decisions heavily towards sustainable dispensing solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 5.5 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | AptarGroup Inc., Silgan Dispensing Systems, Gerresheimer AG, WestRock Company, Berry Global Group Inc., Albea S.A., Raepak Ltd., Guala Dispensing, Zobele Group, Frapak Packaging, Rieke Packaging Systems (TriMas), Coster Group, HCP Packaging, Mitani Valve Co. Ltd., Kwangdong Pharmaceutical Co. Ltd., Kinmou Inc., Yonwoo/COSMECCA KOREA, Sunstar Engineering Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fine Mist Sprayers Market Key Technology Landscape

The technological landscape of the Fine Mist Sprayers Market is currently focused on enhancing atomization quality, improving dosing accuracy, and prioritizing environmental sustainability through design innovation. A major technological trend is the development of ultra-fine mist sprayers capable of generating droplet sizes below 30 microns, which is crucial for achieving superior coverage in high-end cosmetic setting sprays and maximizing bioavailability in pharmaceutical nasal drug delivery. This requires extremely tight tolerance manufacturing, often utilizing advanced computer-numerical control (CNC) machining and micro-injection molding techniques to ensure consistent nozzle aperture and internal pump chamber volume.

Another crucial technological advancement involves the integration of non-metal contact parts and specialized material engineering to handle aggressive or viscous formulations, particularly relevant in the household cleaning and sun care sectors. Manufacturers are replacing traditional metal springs with plastic springs (spring-less technology) to achieve full recyclability (mono-material design) and enhance chemical resistance, simultaneously addressing consumer safety concerns regarding metal contamination. This shift requires sophisticated polymer chemistry knowledge and high-precision assembly automation to maintain reliable pump function without the traditional metal component.

Furthermore, digital packaging technologies are beginning to penetrate this market. Although nascent, the incorporation of Near Field Communication (NFC) tags or QR codes directly onto the sprayer actuator or collar is being explored. This enables direct consumer interaction for tracking product authenticity, refill status, or dosage compliance monitoring (especially in pharmaceuticals). The core focus remains on advanced fluid dynamics modeling and simulation during the design phase to predict and optimize spray performance before tooling investment, significantly reducing time-to-market for innovative dispenser solutions.

Regional Highlights

- Asia Pacific (APAC): Positioned as the fastest-growing region, APAC is driven by the burgeoning cosmetic market in China, South Korea, and Japan, coupled with rapid urbanization and increased per capita spending on health and wellness products. Localization of global manufacturing operations and the rising domestic pharmaceutical industry, particularly in India, fuel high demand for both standard and specialized fine mist pump systems.

- North America: A mature market characterized by high consumer standards and stringent regulatory frameworks, particularly for pharmaceutical dispensing devices. Growth is steady, primarily fueled by innovation in sustainable packaging (PCR content adoption) and strong demand in the premium fragrance and nutraceutical spray sectors. Focus is on high-precision, patented dosing technology.

- Europe: This region is highly sensitive to sustainability mandates, driving a rapid transition toward mono-material and refillable sprayer systems, particularly in key markets like Germany, France, and the UK. The established cosmetics industry and the strong presence of major packaging manufacturers ensure continuous investment in high-quality, aesthetically appealing fine mist solutions compliant with REACH regulations.

- Latin America (LATAM): Exhibit moderate growth, primarily centered in Brazil and Mexico, supported by the expanding domestic personal care sector. Market characteristics include a demand for cost-competitive standard fine mist sprayers, though premiumization is observed in the high-end fragrance segment catering to affluent consumers.

- Middle East and Africa (MEA): Growth is primarily concentrated in the Gulf Cooperation Council (GCC) countries due to high imports of luxury perfumes and cosmetic products. The region presents opportunities for manufacturers supplying bespoke, aesthetically premium fine mist sprayers for the local fragrance industry, demanding high-quality finishing and reliable pump mechanisms.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fine Mist Sprayers Market.- AptarGroup Inc.

- Silgan Dispensing Systems

- Gerresheimer AG

- WestRock Company

- Berry Global Group Inc.

- Albea S.A.

- Raepak Ltd.

- Guala Dispensing

- Zobele Group

- Frapak Packaging

- Rieke Packaging Systems (TriMas)

- Coster Group

- HCP Packaging

- Mitani Valve Co. Ltd.

- Kwangdong Pharmaceutical Co. Ltd.

- Kinmou Inc.

- Yonwoo/COSMECCA KOREA

- Sunstar Engineering Inc.

- Dispensing Dynamics International

- Summit Packaging Systems Inc.

Frequently Asked Questions

Analyze common user questions about the Fine Mist Sprayers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between fine mist sprayers and standard pumps, and why is the fine mist market growing rapidly?

Fine mist sprayers atomize liquid into very small, uniform droplets (typically under 100 microns) using a highly controlled mechanism, ensuring superior coverage and reduced product waste compared to standard lotion pumps. The market is growing due to increasing demand for aesthetically pleasing packaging, precise dosing required in pharmaceutical applications, and consumer preference for convenient, non-aerosol spray formats in cosmetics and personal care.

How is sustainability impacting the design and material choice in the Fine Mist Sprayers Market?

Sustainability is driving innovation toward mono-material designs, often utilizing recycled plastics (PCR content), to simplify the end-of-life recycling process. Manufacturers are eliminating non-recyclable components, such as metal springs, by employing spring-less or all-plastic pump engine technologies to meet consumer and regulatory demands for environmentally responsible packaging solutions.

Which end-use application segment commands the highest price premium for fine mist sprayers?

The Pharmaceutical segment commands the highest price premium. This is attributed to the necessity for extremely precise, validated dose delivery (measured in microliters), stringent material compatibility requirements, specialized anti-microbial features, and the need for comprehensive regulatory compliance (e.g., ISO 13485 certification) that increases manufacturing costs and complexity.

What are the key technical specifications potential buyers look for when sourcing fine mist sprayers?

Buyers prioritize technical specifications such as output volume per stroke (dosing accuracy), spray pattern diameter and consistency, chemical compatibility with the product formulation, leakage prevention capabilities, and the overall lifespan or durability (number of actuations) of the pump mechanism.

Which geographical region is projected to experience the fastest growth in fine mist sprayer consumption?

The Asia Pacific (APAC) region is projected to experience the fastest consumption growth. This acceleration is driven by the massive expansion of the regional cosmetics industry, increasing consumer disposable income in emerging economies like China and India, and the establishment of local manufacturing hubs supporting global CPG brand supply chains.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager