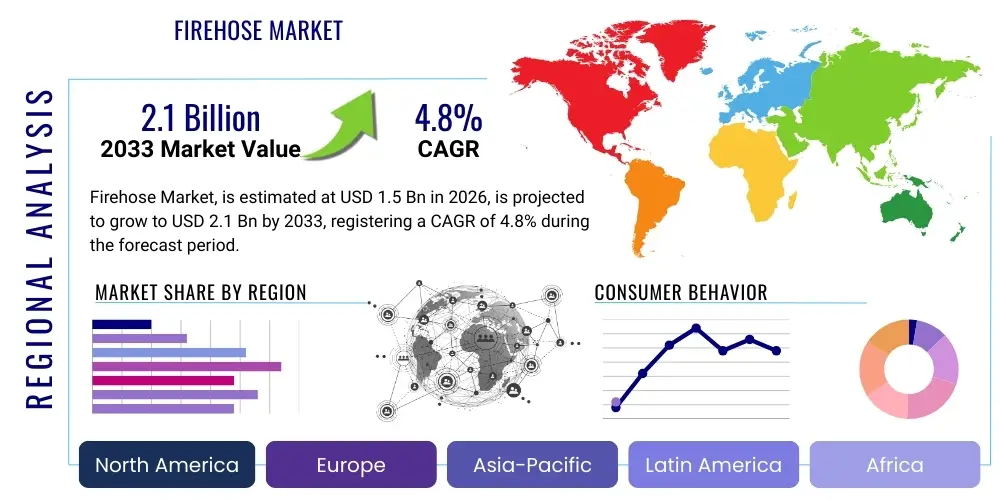

Firehose Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435911 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Firehose Market Size

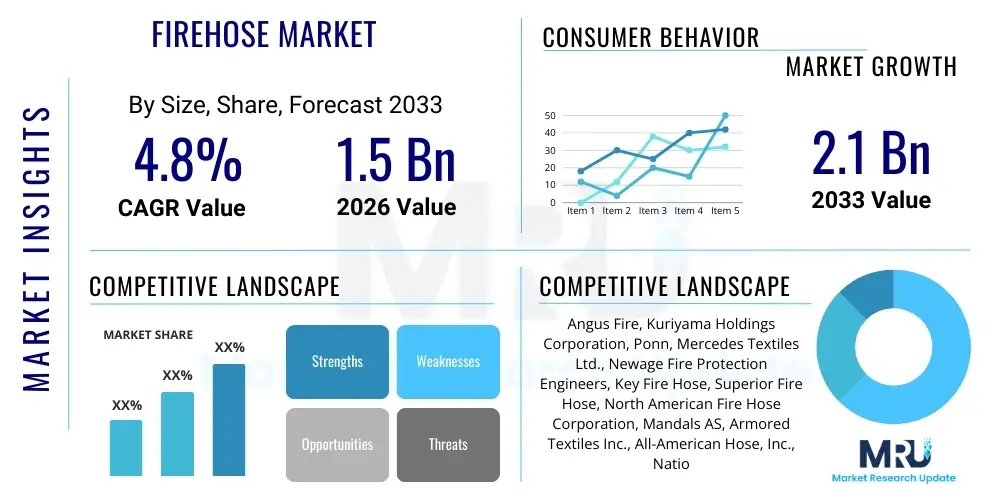

The Firehose Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.1 Billion by the end of the forecast period in 2033. This growth trajectory is significantly influenced by escalating global regulatory mandates concerning fire safety in both commercial and residential infrastructure, particularly in rapidly urbanizing regions across Asia Pacific and Latin America. The continuous need for replacement and upgrade of aging fire suppression equipment in mature economies further stabilizes the market size, ensuring consistent demand for durable and high-performance fire hose solutions.

The calculation of market size incorporates various factors, including volume sales of standard industrial hoses, specialty hoses designed for extreme environments (such as high-pressure mining or chemical facilities), and the rising adoption of lay-flat and jacketed hoses manufactured from advanced synthetic materials like polyurethane and high-grade rubber. The increasing complexity of construction projects, coupled with stricter compliance standards enforced by organizations like NFPA (National Fire Protection Association), dictates a higher average selling price and drives value growth. Furthermore, large-scale infrastructure investments, including port development, oil and gas terminals, and massive warehouse facilities, require substantial quantities of specialized fire suppression systems, directly impacting the market valuation.

Firehose Market introduction

The Firehose Market encompasses the production, distribution, and sale of flexible conduits specifically designed to carry water or other fire-extinguishing agents under high pressure. These products are indispensable components of active fire protection systems used globally by professional fire services, industrial facilities, and building management systems. Fire hoses are crucial in minimizing property damage and safeguarding lives, serving as the essential link between a water source (like a hydrant, pump, or tank) and the point of application of the extinguishing agent. The core product categories include attack hoses, supply hoses, relay hoses, and specialty hoses tailored for marine, chemical, and aviation environments, differing primarily in diameter, material composition, and pressure rating.

Major applications for fire hoses span municipal firefighting, which demands high durability and reliability, industrial sectors such as manufacturing and processing plants, where specialized hoses resistant to chemicals and abrasion are required, and the construction industry, utilized for temporary safety measures during building phases. The primary benefits of modern fire hoses include exceptional flexibility, reduced weight dueiness to synthetic materials, superior resistance to ozone and UV exposure, and enhanced operational lifespan compared to traditional canvas hoses. These factors contribute significantly to improved firefighter efficiency and safety. The market is driven by mandatory safety codes, increasing infrastructure spending in developing nations, and ongoing technological advancements in material science focusing on lightweight, stronger, and more maintenance-friendly hose designs, which continuously refresh the product lifecycle and spur consistent demand across diverse geographical markets.

Firehose Market Executive Summary

The Firehose Market is characterized by steady expansion, propelled by stringent global safety regulations and increasing urbanization, which necessitates robust fire protection infrastructure. Business trends indicate a strong shift towards synthetic materials such as polyester and polyurethane due to their superior performance, lower weight, and enhanced resistance to mold and abrasion compared to traditional rubber or linen. Key industry players are focusing on product differentiation through specialized coatings and high-pressure resistance capabilities, targeting niche industrial applications, particularly in the oil and gas and petrochemical sectors. Mergers, acquisitions, and strategic partnerships centered around enhancing global distribution networks and technological capabilities remain central to maintaining competitive advantage and expanding market penetration in high-growth areas.

Regionally, the Asia Pacific (APAC) stands out as the fastest-growing market, driven by rapid industrialization, massive construction projects, and the implementation of formalized safety standards mirroring those in Western nations. North America and Europe, while mature, maintain substantial market shares, primarily fueled by replacement cycles and the adoption of technologically advanced, certified equipment to comply with evolving NFPA and EN standards. Emerging markets in Latin America and MEA are exhibiting high growth potential due to increasing foreign investment in infrastructure and stricter governmental oversight on workplace and public safety. These regional dynamics highlight a diversified demand profile, ranging from large volume procurement in emerging markets to high-value, specialized orders in developed economies.

Segmentation trends show that the synthetic hose segment, particularly those utilizing polyurethane liners and polyester jackets, dominates the market due to its versatility and lightweight nature, significantly easing firefighter workload. The high-pressure hose sub-segment is expected to demonstrate the highest CAGR, catering to increasingly tall buildings and complex industrial environments where greater pump efficiency is necessary. Furthermore, the End-User segmentation reveals that the Industrial sector, encompassing manufacturing, mining, and oil processing, contributes significantly to market revenue, demanding specialized, high-specification products that command a premium price point, thus sustaining market value growth.

AI Impact Analysis on Firehose Market

User inquiries regarding the impact of Artificial Intelligence on the Firehose Market commonly center on efficiency, preventative maintenance, and supply chain optimization rather than the physical product itself. Users frequently ask if AI can predict hose failures, automate inventory management for replacement parts, or optimize water pressure systems connected to the hoses. The key themes revolve around how AI-driven predictive analytics can extend the service life of expensive fire protection assets and ensure rapid response capabilities. Concerns often touch upon the initial investment required for integrating smart sensors and machine learning infrastructure into existing fire safety protocols. Expectations are high regarding AI's potential to revolutionize training simulators for firefighters, providing realistic, data-driven scenarios that improve the effective handling and utilization of fire hoses under stress, thereby enhancing overall operational effectiveness and safety standards across fire departments.

- AI-driven Predictive Maintenance: Utilizing sensor data embedded in hose couplings or nearby infrastructure to anticipate wear, tear, or pressure vulnerabilities before catastrophic failure occurs, significantly reducing downtime.

- Optimized Inventory Management: AI algorithms can forecast demand for specific hose types and sizes based on historical usage, climate patterns, and urban development projects, leading to leaner supply chains.

- Automated Training Simulation: Implementing AI to create hyper-realistic, dynamic virtual reality training scenarios that measure firefighter performance in handling and maneuvering fire hoses efficiently under various stress conditions.

- Smart Water Flow Regulation: AI systems integrated with pumping equipment can dynamically adjust water pressure and flow rates based on real-time data from the fire scene, optimizing the use of the fire hose and conserving water resources.

- Quality Control and Manufacturing: Machine vision systems powered by AI are being used in manufacturing processes to detect minute material defects in the jacket or liner, ensuring consistent product quality and reducing warranty claims.

DRO & Impact Forces Of Firehose Market

The dynamics of the Firehose Market are fundamentally shaped by a confluence of accelerating drivers, persistent restraints, and compelling opportunities, all contributing to the overall impact forces exerted on market growth. The principal driver is the globally increasing emphasis on public safety and the corresponding tightening of fire safety regulations and building codes, particularly in fast-growing metropolitan areas. Conversely, the market faces restraints such as the fluctuating costs of raw materials, notably synthetic fibers and rubber polymers, and the lengthy, rigorous certification processes required for new products, which can slow down innovation adoption. Opportunities are abundant in developing specialized hoses for extreme environments and utilizing advancements in smart materials and IoT integration to offer value-added solutions to end-users.

The primary driving forces encompass mandatory infrastructure safety upgrades, the constant need for replacement due to regulatory service life requirements (typically 10-20 years), and rapid industrial expansion in emerging economies requiring large-scale fire suppression systems. Restraints include the market saturation in highly developed economies like the US and Western Europe, where growth is primarily dependent on replacement cycles rather than new installations, and intense price competition, especially from manufacturers in the Asia Pacific region producing standard specification hoses. These factors create a complex operational environment where manufacturers must balance compliance, cost management, and technological innovation to maintain profitability.

Impact forces are heavily skewed by government spending on municipal fire services and increasing insurance industry requirements, which often mandate the use of certified, high-grade equipment. Opportunities for long-term growth lie in penetrating specialized markets, such as the deployment of fire hoses in advanced robotics for hazardous firefighting (where human access is restricted) and developing lighter, more ergonomic hoses that minimize musculoskeletal strain on operational personnel. Successfully navigating the complex regulatory landscape, leveraging digital supply chain efficiencies, and focusing on product innovation that reduces overall total cost of ownership for end-users are critical determinants of competitive success in this evolving market.

Segmentation Analysis

The Firehose Market is comprehensively segmented based on material type, product diameter, operating pressure, and end-user application, allowing for a detailed analysis of specific demand patterns and growth drivers within niche categories. Segmentation by material type—which includes natural fibers, rubber, and synthetic materials (polyester, polyurethane)—is critical as material choice directly influences the hose’s weight, durability, and chemical resistance. Product diameter segmentation helps differentiate between attack hoses (smaller diameter for maneuverability) and supply/relay hoses (larger diameter for high volume flow). Furthermore, the application split between Municipal, Industrial, and Commercial sectors dictates the specification requirements, with industrial applications often requiring the highest specifications regarding pressure and abrasion resistance, commanding premium pricing and driving value-added segments of the market.

- By Material Type:

- Natural Fiber Hoses

- Rubber Hoses

- Synthetic Hoses (Polyester, Polyurethane)

- By Product Diameter:

- Up to 1.5 inches

- 1.5 inches to 2.5 inches

- Above 2.5 inches (Large Diameter Hoses)

- By Operating Pressure:

- Low Pressure Hoses

- Medium Pressure Hoses

- High Pressure Hoses

- By Application:

- Municipal/Civil Fire Departments

- Industrial (Oil & Gas, Chemical, Manufacturing, Mining)

- Commercial & Residential Buildings

- Marine & Shipping

- Aviation

- By Distribution Channel:

- Direct Sales (Government tenders, Large Industrial Clients)

- Indirect Sales (Distributors, Retailers)

Value Chain Analysis For Firehose Market

The Firehose Market value chain begins with upstream activities focused on the procurement and processing of raw materials, primarily synthetic fibers (polyester, nylon), rubber compounds (EPDM, nitrile), and specialized thermoplastic polymers like polyurethane. Key upstream analysis reveals that manufacturers are highly dependent on global petrochemical markets, where volatility in crude oil prices can directly impact the cost of polymer-based materials, subsequently affecting production costs and final product pricing. Strategic partnerships with key polymer suppliers or vertical integration are vital strategies for mitigating supply chain risks and ensuring a consistent flow of high-quality, certified raw components necessary for hose construction, especially high-tenacity polyester jacket materials that meet rigorous international standards for burst strength and abrasion resistance.

The midstream phase involves the core manufacturing process, which includes weaving the outer jacket, lining the interior with rubber or specialized polymer coatings, curing, and coupling the hoses with brass or aluminum fittings. Efficiency in manufacturing, particularly minimizing waste during the extrusion and vulcanization processes, is a critical determinant of profitability. Distribution channels, forming the downstream segment, are bifurcated into direct and indirect routes. Direct sales are predominant for large-volume municipal contracts and specialized industrial clients (like major refinery operators) who require customized specifications and direct technical support. Indirect channels, involving specialized safety equipment distributors and general industrial retailers, are crucial for reaching smaller commercial customers and managing replacement demand across dispersed geographical areas.

Successful management of the value chain relies heavily on maintaining rigorous quality control at every stage, given the life-safety application of the product. Manufacturers invest heavily in product testing and certifications (UL, FM, NFPA compliance) to establish trust and access premium market segments. The selection of the most effective distribution channel—whether direct engagement for maximizing margins on large tenders or leveraging distributor networks for wider market access and localized after-sales support—is paramount for operational success. Optimizing logistics to ensure timely delivery of heavy, bulky fire hoses, particularly in emergency replacement scenarios, further highlights the importance of an integrated and responsive supply chain model.

Firehose Market Potential Customers

Potential customers for the Firehose Market are diverse but largely centered around entities responsible for active fire suppression, safety, and infrastructure management. The largest and most consistent end-users are municipal and governmental civil defense organizations, including local, state, and national fire departments, which require standardized, high-volume purchases of durable hoses for general firefighting operations. These customers are driven by regulatory compliance, budgetary cycles, and the need for equipment that integrates seamlessly with existing national infrastructure, such as hydrant systems and pumpers, often procured through structured government tenders based on NFPA or equivalent certification standards.

Another significant customer base lies within the Industrial sector, encompassing high-risk environments such as petrochemical plants, oil refineries, mining operations, power generation facilities, and large-scale manufacturing units. These facilities require specialized, often customized hoses that offer exceptional resistance to heat, corrosive chemicals, and high abrasive forces. Procurement decisions in this sector are driven by stringent internal safety protocols, insurance liability requirements, and the need to protect high-value assets, often favoring premium-priced, technically advanced hoses that offer longevity and specialized material construction, such as hoses designed to handle foam concentrates or specialized dry chemical agents.

Finally, the Commercial and Residential sectors constitute a steady stream of customers, primarily through contractors, building management companies, and marine/aviation operators. Commercial high-rise buildings mandate the installation and periodic replacement of hoses connected to standpipe systems, adhering strictly to local building codes. Similarly, the aviation industry (airports and aircraft maintenance facilities) and the marine industry (ships, ports, offshore platforms) represent niche, high-value customers requiring specialized, compact, and certified lightweight hoses for specific operational environments. The purchasing decisions in these segments are primarily influenced by mandatory inspection schedules and compliance with international safety protocols like SOLAS or FAA regulations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.1 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Angus Fire, Kuriyama Holdings Corporation, Ponn, Mercedes Textiles Ltd., Newage Fire Protection Engineers, Key Fire Hose, Superior Fire Hose, North American Fire Hose Corporation, Mandals AS, Armored Textiles Inc., All-American Hose, Inc., National Fire Protection Co., Sika AG, Thermoid Inc., Chhatariya Fire Hose, BullDog Hose Company, Shanghai Pangu Industrial Co., Ltd., Zikua Fire Fighting Equipment Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Firehose Market Key Technology Landscape

The Firehose Market technology landscape is undergoing a slow but significant transformation, primarily driven by material science innovation and the integration of digital features. The most crucial advancements involve the development of high-tenacity synthetic jacket materials, such as high-grade polyester and aramid fibers, which offer significantly improved abrasion resistance, tensile strength, and reduced weight compared to older nylon or natural fiber counterparts. Lining technologies have also progressed, with polyurethane (PU) liners gaining prominence over traditional rubber due to their lighter weight, thinner profile, and superior resistance to mildew and harsh chemicals. These material innovations directly translate into better operational efficiency, making the hoses easier to deploy and retrieve, and extending their service life under rigorous conditions, which is highly sought after by municipal fire departments aiming to minimize operational expenditure.

Beyond materials, the market is beginning to explore the integration of IoT and smart manufacturing concepts. While the core product remains mechanical, manufacturers are focusing on integrating specialized coupling technologies and smart tagging (RFID or NFC chips) to facilitate digital tracking, inventory management, and maintenance scheduling. These technological additions allow end-users to accurately log the usage, inspections, and pressure test history of each hose segment, ensuring compliance with mandatory safety standards and optimizing the replacement cycle. This digitalization trend caters specifically to large industrial clients and sophisticated fire departments managing extensive inventories across multiple locations, enhancing asset management and traceability throughout the entire product lifespan, moving the market towards preventative maintenance models.

Further technological advancements include specialized coating applications designed to enhance resistance against oil, extreme heat, and UV degradation, crucial for hoses used in outdoor industrial or marine settings. The adoption of large diameter hoses (LDH) and specialized relay pumping systems also represents a technological shift, enabling fire services to move massive volumes of water efficiently over long distances. The constant drive is towards creating a "zero-maintenance" hose that is extremely durable, lightweight, and capable of operating under higher pressures, thus requiring continuous research and development into polymer chemistry and weaving techniques to achieve the optimal balance of flexibility, strength, and longevity for critical fire suppression applications.

Regional Highlights

The global Firehose Market exhibits significant regional disparities in growth rate, product specifications, and regulatory compliance. North America, characterized by its mature infrastructure and stringent safety mandates (NFPA standards), commands a substantial market share. Growth here is primarily driven by mandatory replacement cycles, continuous investment in specialized equipment for professional fire services, and high demand from the industrial and petrochemical sectors in the Gulf Coast region and Canada. The US market emphasizes high-quality, certified hoses, often leading the adoption of new material technologies like lightweight polyurethane linings and advanced coating systems to ensure compliance and firefighter safety.

Europe represents another key region, driven by strict European Union safety directives (EN standards) and high environmental consciousness. Western European countries maintain steady replacement demand, while Eastern European nations show higher growth potential due to infrastructure modernization and the alignment of local regulations with EU norms. The focus in Europe is often on sustainability and innovative hose designs that minimize water usage or offer extended operational life. Germany, the UK, and France are major consumption hubs, with significant investments in both municipal and industrial fire protection systems, fueling demand for medium-to-high pressure hoses tailored to dense urban environments.

Asia Pacific (APAC) is projected to be the fastest-growing market globally, fueled by unprecedented levels of construction, urbanization, and industrial expansion, particularly in China, India, and Southeast Asian countries. As these nations adopt and enforce stricter building codes and workplace safety standards, the demand for both standard and high-specification fire hoses is skyrocketing. While price sensitivity remains a factor, the long-term infrastructural push, coupled with increasing government spending on municipal fire services, guarantees strong market expansion. This region is critical for market entry strategies, requiring manufacturers to balance cost-competitiveness with certification adherence to penetrate diverse national markets effectively.

Latin America and the Middle East & Africa (MEA) are emerging markets displaying robust potential. Latin American growth is driven by significant mining and oil & gas activities, which require heavy-duty, industrial-grade hoses. MEA, particularly the GCC countries, sees significant investment in megaprojects (commercial, residential, and oil infrastructure), resulting in a high demand for advanced fire protection systems that meet international safety standards. The deployment of specialized equipment in harsh desert and maritime environments further differentiates demand in these regions, favoring manufacturers capable of supplying hoses resistant to extreme temperatures, UV, and aggressive sand abrasion, ensuring sustained, albeit localized, high-value growth.

- North America: Dominant market share fueled by stringent NFPA standards and consistent municipal upgrades; strong demand for lightweight synthetic hoses and specialized industrial applications (petrochemicals). Key countries include the United States and Canada.

- Europe: Mature market driven by regulatory compliance (EN standards) and mandatory service life replacement; growing emphasis on sustainability and technologically advanced material compounds; significant consumption in Germany, UK, and France.

- Asia Pacific (APAC): Highest CAGR driven by rapid urbanization, industrial growth, and infrastructure development in China, India, and ASEAN countries; market characterized by a mix of price-sensitive standard hoses and high-specification industrial products.

- Latin America: Emerging market growth tied to expansion in the mining sector and large-scale infrastructure projects; increasing adoption of international safety norms drives the shift toward certified, durable hoses.

- Middle East and Africa (MEA): High-value demand generated by large oil & gas projects and complex commercial construction in GCC nations; requirement for specialized hoses capable of enduring extreme heat and harsh operating conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Firehose Market.- Angus Fire

- Kuriyama Holdings Corporation

- Ponn

- Mercedes Textiles Ltd.

- Newage Fire Protection Engineers

- Key Fire Hose

- Superior Fire Hose

- North American Fire Hose Corporation

- Mandals AS

- Armored Textiles Inc.

- All-American Hose, Inc.

- National Fire Protection Co.

- Sika AG

- Thermoid Inc.

- Chhatariya Fire Hose

- BullDog Hose Company

- Shanghai Pangu Industrial Co., Ltd.

- Zikua Fire Fighting Equipment Co., Ltd.

- United Fire and Safety

- Holmatro Group

Frequently Asked Questions

Analyze common user questions about the Firehose market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the key drivers for the growth of the synthetic fire hose segment?

The synthetic fire hose segment is primarily driven by superior performance attributes, including reduced weight (enhancing firefighter maneuverability), increased resistance to abrasion, mildew, and chemical degradation, and longer operational lifespans compared to traditional rubber or linen hoses. Mandatory regulatory compliance requiring lightweight, durable equipment further accelerates adoption globally.

How do regulatory standards like NFPA and EN impact Firehose Market dynamics?

NFPA (North America) and EN (Europe) standards critically impact the market by setting rigorous minimum specifications for burst pressure, materials, and service life. Compliance with these standards is mandatory for accessing large municipal and commercial tenders, ensuring a consistently high demand for certified, high-quality products, thereby limiting the entry of non-compliant, low-cost manufacturers.

Which geographical region offers the highest growth potential for fire hose manufacturers?

The Asia Pacific (APAC) region offers the highest growth potential, largely driven by rapid and extensive urbanization, unprecedented industrial expansion, and the increasing implementation of modern, formalized fire safety legislation across major economies like China and India, creating substantial new demand for fire protection systems.

What is the typical lifespan and replacement cycle for industrial fire hoses?

The typical lifespan of a high-quality industrial fire hose, subject to rigorous testing and maintenance, ranges from 10 to 20 years, depending on usage frequency and material type. Mandatory replacement cycles, often enforced by national safety bodies or insurance requirements, dictate that hoses must be tested and possibly replaced every 5 to 10 years to ensure operational integrity and compliance.

Is the integration of IoT technology relevant to the physical fire hose product?

Yes, the integration of IoT is relevant, primarily through the use of RFID or NFC smart tags embedded in hose couplings. This technology does not change the physical water conveyance but allows for digital asset tracking, automatic logging of pressure test results, and optimized inventory management, moving fire services towards data-driven preventative maintenance models.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager