Fireproof Glue Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437850 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Fireproof Glue Market Size

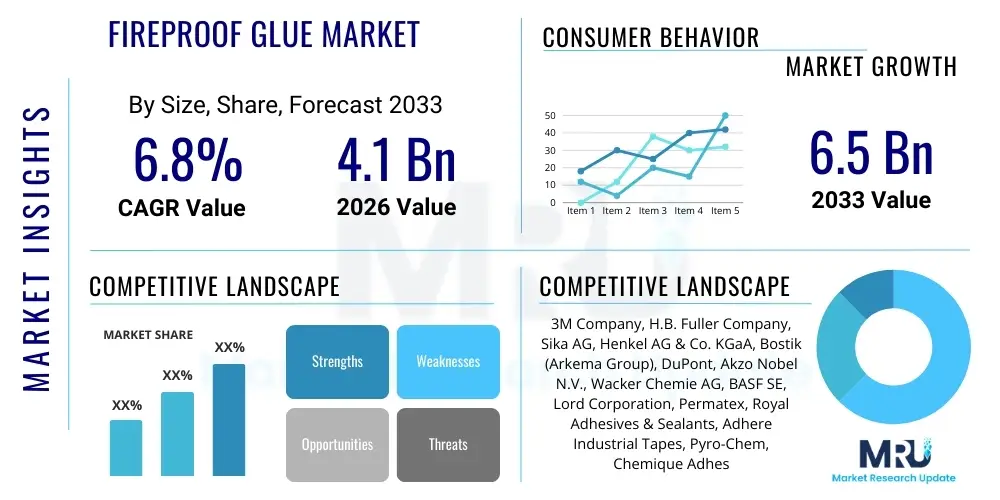

The Fireproof Glue Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 4.1 Billion in 2026 and is projected to reach USD 6.5 Billion by the end of the forecast period in 2033.

Fireproof Glue Market introduction

The Fireproof Glue Market encompasses specialized adhesive solutions designed to withstand extreme heat and prevent the spread of fire, crucial for enhancing safety and regulatory compliance across various industries. These adhesives, also known as fire-resistant or flame-retardant glues, are formulated using inorganic materials like silicates, ceramics, and specialty polymers, or organic compounds infused with intumescent additives that swell when exposed to heat, creating an insulating char layer. The primary function is to secure materials while maintaining structural integrity during a fire event, thereby offering valuable time for evacuation and mitigating property damage.

Major applications of fireproof glues span critical sectors including construction, where they are vital for sealing joints in fire-rated walls, doors, and insulation systems; automotive and aerospace industries, utilized in interior components and engine compartments to meet stringent safety standards; and in the electrical and electronics sector for protecting wiring harnesses and sensitive equipment. The inherent benefit of these products lies in their low smoke density and toxicity release compared to conventional adhesives, directly addressing growing concerns regarding fire safety in dense urban environments and high-risk industrial settings. Furthermore, their application simplifies complex firestopping procedures, offering a clean, reliable, and durable bonding solution.

The market is primarily driven by increasingly rigorous global building safety codes and fire protection standards mandated by regulatory bodies like NFPA (National Fire Protection Association) and ISO. Significant investment in infrastructure development, particularly in developing economies, coupled with the rapid expansion of electric vehicle (EV) manufacturing—which requires advanced thermal management and fire protection in battery enclosures—further propels demand. These adhesives are integral components in ensuring passive fire protection systems perform as intended, positioning them as non-negotiable elements in modern engineering and architectural design.

Fireproof Glue Market Executive Summary

The Fireproof Glue Market is experiencing robust expansion fueled by mandatory safety legislation and significant growth in specialized end-use sectors like aerospace, marine, and high-performance construction. Current business trends indicate a strong shift towards sustainable and eco-friendly formulations, moving away from halogenated flame retardants towards non-halogenated, often bio-based, alternatives to comply with evolving environmental regulations and consumer preferences for healthier materials. Key manufacturers are focusing heavily on R&D to develop adhesives that offer superior adhesion performance, flexibility, and longevity, particularly for dynamic applications subject to vibration and thermal cycling. Mergers, acquisitions, and strategic collaborations are common strategies adopted by leading players to consolidate market share, gain technological expertise, and expand their regional distribution networks, particularly in high-growth regions.

Geographically, the Asia Pacific (APAC) region dominates the market due to massive infrastructure projects in countries like China and India, coupled with rapid urbanization and industrialization, which necessitate adherence to modern fire safety standards in commercial and residential construction. North America and Europe, characterized by established regulatory frameworks and high safety awareness, represent mature markets focusing on retrofit and renovation projects, alongside high demand from the specialized automotive and aerospace manufacturing bases. Regional trends highlight growing demand for localized production capabilities to reduce supply chain vulnerability and address unique environmental conditions and regulatory requirements specific to different jurisdictions, such as specific toxicity standards for interior finishes.

Segmentation trends reveal that the inorganic fireproof glue segment, including ceramic and cementitious formulations, maintains a steady share due to its exceptional high-temperature stability, primarily used in heavy industrial and passive fire protection systems. However, the organic segment, particularly those based on advanced polyurethanes and epoxy systems with intumescent properties, is projected to register the fastest growth. This is attributable to their ease of application, versatility, and suitability for complex bonding tasks in the automotive and electronics industries. The building & construction sector remains the largest application segment, but the automotive segment, driven by electric vehicle battery fire protection requirements, is rapidly increasing its market influence and demanding specialized, lightweight fireproof adhesive solutions.

AI Impact Analysis on Fireproof Glue Market

User queries regarding AI’s influence on the Fireproof Glue Market frequently center on optimizing material formulation, predicting material performance under extreme fire conditions, and automating quality control processes in manufacturing. Users seek to understand how AI-driven simulations can replace expensive, physical burn tests and accelerate the development cycle of novel flame-retardant chemistries, particularly intumescent systems. Key concerns often revolve around the security of proprietary formulation data managed by AI models and the necessity for specialized datasets detailing complex thermal decomposition kinetics. The overriding expectation is that AI will dramatically reduce R&D time, enabling faster regulatory compliance, personalized product customization based on specific application environments (e.g., marine vs. aerospace), and optimizing supply chain logistics for raw materials based on predictive demand forecasting.

- AI accelerates R&D by simulating thermal stability and decomposition pathways of new adhesive chemistries, minimizing physical testing.

- Predictive maintenance schedules for manufacturing equipment are optimized using AI, ensuring consistent product quality and reducing downtime.

- AI algorithms analyze complex regulatory requirements across diverse regions, ensuring formulations meet localized fire and environmental standards efficiently.

- Machine learning models optimize supply chain dynamics, forecasting demand for specific raw materials (e.g., phosphorus, boron compounds) based on construction and manufacturing forecasts.

- AI-powered visual inspection systems automate quality control during the production process, verifying uniform coating thickness and absence of defects in packaged products.

- Digital twins of manufacturing plants aid in process optimization, increasing yield and energy efficiency in the high-temperature synthesis of inorganic adhesives.

DRO & Impact Forces Of Fireproof Glue Market

The dynamics of the Fireproof Glue Market are predominantly shaped by stringent fire safety regulations (Drivers), the inherent complexity and cost associated with high-performance materials (Restraints), and the burgeoning opportunity presented by technological integration in fast-growing sectors (Opportunity). These internal and external forces interact to create the competitive landscape and dictate investment priorities for market participants. The overall market growth trajectory is strongly positive, largely sustained by non-negotiable safety requirements across global construction and manufacturing standards, making fire protection materials essential inputs rather than discretionary purchases. The critical balance lies in innovating to overcome cost barriers while capitalizing on new application areas.

Key drivers include the global trend toward higher-density urban construction and stricter enforcement of passive fire protection measures in public and commercial buildings. Infrastructure modernization, especially in transportation (rail, marine, aviation), necessitates advanced adhesives capable of maintaining structural integrity under high temperatures and vibration. Conversely, the market faces restraints such as the relatively high cost of high-performance fire-retardant additives (e.g., specialty phosphorus or magnesium hydroxide compounds) compared to standard industrial adhesives. Furthermore, achieving both excellent adhesion and extreme fire resistance often requires complex, multi-component formulations that necessitate precise handling and application, increasing labor costs and complexity for end-users. The limited shelf life and requirement for specialized storage for certain two-part systems also act as constraints.

Significant opportunities are emerging from the shift towards non-halogenated, environmentally preferable fireproof glues, driven by regulatory bans on certain persistent organic pollutants (POPs). The rapidly expanding electric vehicle battery assembly market presents a substantial new vertical, requiring specialized thermal runaway protection adhesives. Moreover, the modular construction industry is increasingly adopting prefabricated fire-rated panels and components, creating scalable demand for bulk adhesive systems. Impact forces such such as rapid technological iteration, where new materials science advances quickly render older formulations obsolete, and intense regulatory pressure from global bodies continuously compel manufacturers to invest in novel, compliant solutions, fundamentally influence market direction and competitive differentiation.

Segmentation Analysis

The Fireproof Glue Market is meticulously segmented based on the chemical nature of the adhesive (Type), the specific environment or product where it is applied (Application), and the overarching industry utilizing the product (End-Use Industry). This segmentation is crucial for understanding specific market dynamics, pinpointing high-growth areas, and tailoring product development to meet specialized performance requirements. The market is highly specialized, with performance parameters such as service temperature, bond strength, curing time, and resistance to specific chemicals defining the suitability of a product within a segment. Analyzing these segments helps stakeholders appreciate the diverse material needs across the construction, transportation, and industrial maintenance sectors.

- By Type:

- Inorganic (e.g., Ceramic, Silicate, Cementitious)

- Organic (e.g., Epoxy, Polyurethane, Silicone, Acrylic, Phenolic)

- By Application:

- Construction (Residential, Commercial, Infrastructure)

- Industrial Equipment

- Automotive and Transportation (EV Batteries, Interiors, Engine Components)

- Marine and Shipbuilding

- Aerospace and Defense

- Electrical and Electronics (Wire and Cable Protection)

- By End-Use Industry:

- Building & Construction

- HVAC Systems

- Electrical & Electronics Manufacturing

- Automotive Manufacturing

- Oil & Gas and Power Generation

- By Chemistry/Formulation:

- Intumescent Adhesives

- Non-Intumescent Adhesives

Value Chain Analysis For Fireproof Glue Market

The value chain for the Fireproof Glue Market is complex, starting with the sourcing of specialized raw materials, moving through sophisticated manufacturing and formulation, and culminating in application by specialized contractors or integrated industrial manufacturers. The upstream segment involves the procurement of highly specific, high-purity chemicals, including base polymers (epoxies, silicones), inorganic fillers (silicates, ceramics), and critical flame-retardant additives such as phosphate esters, metal hydroxides, and intumescent systems (e.g., ammonium polyphosphate). Quality control at this stage is paramount, as the purity and particle size of these inputs directly influence the final adhesive's fire resistance, bond strength, and environmental compliance, placing significant importance on long-term relationships with specialized chemical suppliers.

The midstream process, involving formulation and manufacturing, is highly capital-intensive and requires extensive R&D capabilities. Manufacturers combine these raw materials using precision mixing, dispersion, and compounding technologies to create liquid, paste, or film adhesive products, tailored for specific fire ratings (e.g., Class A, specific hourly ratings) and application methods (e.g., dispensing, troweling, spray). Achieving the optimal balance between fire protection, mechanical performance (flexibility, shear strength), and processability is the core value addition in this stage. Intellectual property protection concerning unique intumescent systems and proprietary non-halogenated chemistries is a major competitive differentiator for large players like 3M and Henkel.

Downstream distribution channels typically utilize a hybrid approach. Direct sales are common for large industrial customers (e.g., aerospace manufacturers or large construction firms requiring bulk quantities and technical support), ensuring specialized application guidance. Indirect distribution relies heavily on specialized chemical distributors, construction supply houses, and MRO (Maintenance, Repair, and Operations) providers, which stock regional inventories and serve smaller contractors and repair businesses. The selection of the channel depends heavily on the product format; bulk industrial adhesives are often direct, while consumer or small contractor-focused sealants are widely distributed. Efficient logistics, including specialized transport for temperature-sensitive materials, is essential to maintain product integrity until application.

Fireproof Glue Market Potential Customers

Potential customers for fireproof glue are highly diversified, reflecting the critical need for fire safety across infrastructure, transportation, and specialized manufacturing. The largest end-user segment is the Building and Construction industry, comprising commercial real estate developers, residential builders, and specialized firestopping contractors who require adhesives for passive fire protection systems, including sealing gaps, fixing fire-rated insulation boards, and adhering intumescent strips around doors and windows. These buyers prioritize products with established fire certification (e.g., UL, FM Global ratings) and easy application properties suitable for high-volume work.

Another major customer base includes manufacturers in the Transportation sector, specifically automotive OEMs, aerospace component suppliers, and shipbuilding companies. In automotive manufacturing, fireproof glues are critical for protecting high-voltage battery packs in electric vehicles from thermal runaway, as well as bonding interior panels and carpeting where low smoke and flame spread is mandated. Aerospace companies use these highly engineered adhesives in cabin interiors and specialized structural components where weight reduction and extreme heat resistance are non-negotiable, requiring bespoke, often expensive, high-specification products.

Furthermore, the Electrical and Electronics industry, encompassing manufacturers of switchgear, control panels, wire harnesses, and industrial ovens, represents a significant customer group. These users deploy fireproof adhesives and sealants to encapsulate sensitive components, ensuring electrical insulation integrity and preventing fire propagation through cable penetrations, often demanding products with excellent dielectric properties alongside fire resistance. The critical nature of their applications means purchasing decisions are heavily influenced by regulatory compliance and product reliability over cost savings.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.1 Billion |

| Market Forecast in 2033 | USD 6.5 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, H.B. Fuller Company, Sika AG, Henkel AG & Co. KGaA, Bostik (Arkema Group), DuPont, Akzo Nobel N.V., Wacker Chemie AG, BASF SE, Lord Corporation, Permatex, Royal Adhesives & Sealants, Adhere Industrial Tapes, Pyro-Chem, Chemique Adhesives, ITW Performance Polymers, Momentive Performance Materials Inc., Master Bond Inc., Dymax Corporation, Huntsman Corporation, Tremco CPG Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fireproof Glue Market Key Technology Landscape

The technological landscape of the Fireproof Glue Market is characterized by continuous material science innovation aimed at improving fire resistance without compromising adhesion and environmental profiles. A central focus is the advancement of intumescent technology, where adhesive formulations incorporate compounds that swell dramatically when exposed to heat, forming a thick, insulating char layer that protects the substrate. Modern intumescent systems utilize highly optimized blends of acid sources (e.g., phosphoric acid derivatives), carbonific sources (e.g., polyols), and blowing agents (e.g., melamine derivatives) to achieve superior expansion ratios and char stability, allowing for thinner, lighter applications compared to older, bulkier fireproofing methods.

A second major technological theme revolves around the shift towards high-performance inorganic adhesives, particularly ceramic and silicate-based formulations. These technologies inherently possess exceptional thermal stability, capable of operating at temperatures where organic polymers completely decompose. Innovations here focus on improving the flexibility and crack resistance of these traditionally brittle materials through the use of nano-fillers and specific fiber reinforcements. These advances make inorganic glues viable for demanding applications like furnace linings, exhaust systems, and high-heat industrial equipment, where temperatures regularly exceed 500°C, extending their utility beyond traditional construction firestopping applications.

The market also sees significant technological disruption through the development of non-halogenated, environmentally preferable flame retardants, driven by stringent European Union (REACH) and global standards limiting toxic chemical usage. Manufacturers are increasingly relying on phosphorus, nitrogen, and boron compounds, or utilizing inherently fire-resistant polymers like polyimides and specialty silicones, to achieve fire ratings. Furthermore, advanced application techniques, including specialized robotics for automated dispensing in production lines (especially in the EV sector), and self-leveling or fast-curing formulations that reduce installation time on construction sites, are key areas of technological differentiation, enhancing efficiency and minimizing application errors.

Regional Highlights

- Asia Pacific (APAC): APAC is the fastest-growing market, driven by unprecedented infrastructure development in China, India, and Southeast Asian nations. Stringent adherence to international building codes, coupled with the rapid expansion of electronics manufacturing and the local production of automotive components, especially EVs, fuels high demand. The region benefits from lower manufacturing costs but is quickly adopting advanced non-halogenated technologies to align with global export standards.

- North America: This region holds a significant market share, characterized by high regulatory compliance (e.g., NFPA codes) and a strong focus on high-performance applications in aerospace and defense. The demand is stable, driven by renovation, maintenance (MRO), and the specialized needs of the U.S. automotive sector, particularly for high-specification, certified firestopping and sealant products required in commercial buildings.

- Europe: Europe is a mature market focused on innovation and environmental sustainability. Growth is moderated but underpinned by stringent environmental directives (REACH) promoting non-halogenated fire retardants. The region leads in the adoption of bio-based and sustainable fireproof adhesives, serving the advanced construction and specialized industrial equipment manufacturing sectors, particularly in Germany and the UK.

- Latin America (LATAM): The LATAM market is emerging, with growth tied to urbanization and increasing industrialization, particularly in Brazil and Mexico. Regulatory enforcement is gradually tightening, leading to increased demand for certified fireproof materials in large-scale commercial and public projects. Price sensitivity remains a key factor influencing product selection in this region.

- Middle East and Africa (MEA): Growth in MEA is highly concentrated in the Gulf Cooperation Council (GCC) states due to massive investments in commercial infrastructure (skyscrapers, airports) and energy projects (Oil & Gas). The requirement for high-performance adhesives suitable for extreme desert climates and strict adherence to global fire codes in prestige construction projects drives the premium segment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fireproof Glue Market.- 3M Company

- H.B. Fuller Company

- Sika AG

- Henkel AG & Co. KGaA

- Bostik (Arkema Group)

- DuPont

- Akzo Nobel N.V.

- Wacker Chemie AG

- BASF SE

- Lord Corporation

- Permatex

- Royal Adhesives & Sealants

- Adhere Industrial Tapes

- Pyro-Chem

- Chemique Adhesives

- ITW Performance Polymers

- Momentive Performance Materials Inc.

- Master Bond Inc.

- Dymax Corporation

- Huntsman Corporation

- Tremco CPG Inc.

Frequently Asked Questions

Analyze common user questions about the Fireproof Glue market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between fireproof, fire-resistant, and flame-retardant adhesives?

Fireproof adhesives are designed to withstand fire exposure for a prolonged period, typically maintaining structural integrity. Fire-resistant describes materials that can resist fire damage to a degree. Flame-retardant materials actively slow or prevent the spread of fire by inhibiting combustion or forming a protective char layer (intumescence), which is the most common mechanism in high-performance glues.

Which chemistry type dominates the market for high-temperature industrial applications?

Inorganic chemistries, specifically ceramic, silicate, and refractory cementitious adhesives, dominate high-temperature industrial applications above 500°C because they are inherently resistant to thermal decomposition, offering superior stability compared to organic polymer-based formulations.

How do global regulations, such as NFPA or REACH, influence the adoption of fireproof adhesives?

Global regulations enforce strict performance criteria (e.g., maximum smoke density, flame spread index) for materials used in construction and transportation. This directly drives demand for certified, high-performance adhesives and necessitates the shift towards non-halogenated formulations to comply with environmental mandates like REACH that restrict toxic flame retardants.

Is the electric vehicle (EV) battery segment a significant growth driver for the fireproof glue market?

Yes, the EV segment is a major growth driver. Fireproof and thermally conductive adhesives are essential for bonding battery cells and modules within the pack, providing critical protection against thermal runaway events and ensuring regulatory compliance for automotive fire safety standards (e.g., ECE R100).

What are the typical application methods for industrial fireproof glues?

Application methods vary by formulation, including standard dispensing via caulking guns for sealants, troweling for thick-bed adhesives, spraying for large surface coatings, and automated precision dispensing systems used in high-speed manufacturing environments like automotive assembly lines for two-part epoxy or silicone systems.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager