Fish Box Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434467 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Fish Box Market Size

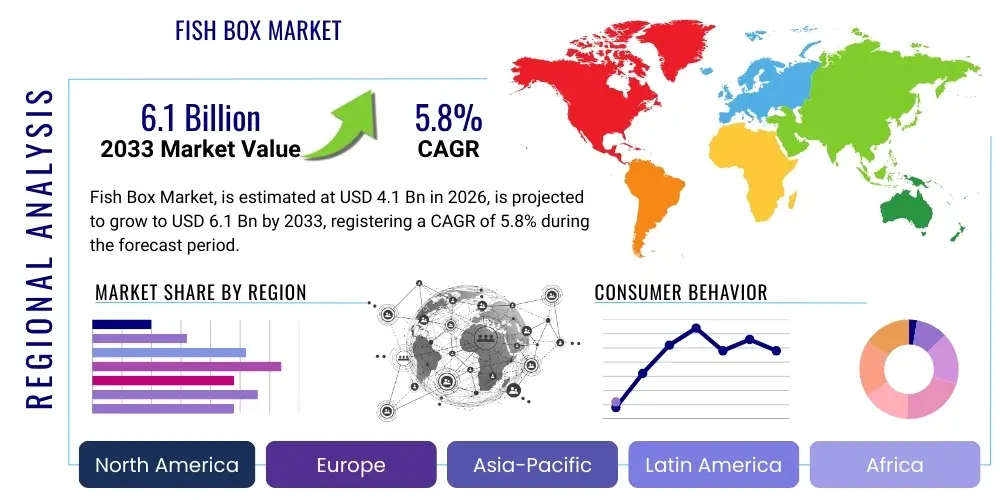

The Fish Box Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.1 Billion in 2026 and is projected to reach USD 6.1 Billion by the end of the forecast period in 2033.

Fish Box Market introduction

The Fish Box Market encompasses the global trade of containers specifically designed for the handling, storage, and transportation of fresh and frozen fish and seafood. These specialized containers are crucial for maintaining the cold chain integrity, ensuring product quality, and extending the shelf life of highly perishable marine products from the point of catch or harvest through to the consumer. Driven primarily by the increasing global demand for seafood, advancements in international trade logistics, and stringent food safety regulations, the market is characterized by a shift towards sustainable and high-performance packaging solutions.

The product range within this market is diverse, including boxes made from expanded polystyrene (EPS), various plastics (such as high-density polyethylene, HDPE), wood, and increasingly, innovative corrugated cardboard designs incorporating specialized barrier coatings. EPS remains highly popular due to its excellent thermal insulation properties, lightweight nature, and cost-effectiveness, which are critical features for minimizing temperature fluctuations during transit. However, sustainability concerns are propelling the demand for reusable and recyclable plastic boxes, particularly in closed-loop supply chains used by large aquaculture operations and seafood processors. The primary applications span the entire seafood value chain, including deep-sea fishing vessels, large-scale aquaculture farms, centralized processing facilities, wholesale distribution networks, and final-mile retail delivery.

Major driving factors include the continuous expansion of the aquaculture sector globally, which requires standardized, hygienic packaging for high-volume output. Furthermore, stricter governmental regulations concerning seafood traceability and hygiene, particularly in developed economies like the European Union and North America, necessitate the use of high-quality, approved packaging materials. The inherent benefits of using specialized fish boxes—such as superior insulation, reduced cross-contamination risk, efficient stacking and handling, and compliance with international shipping standards—cement their position as indispensable assets in the perishable goods logistics sector, ensuring profitability and consumer safety across global markets.

Fish Box Market Executive Summary

The Fish Box Market is exhibiting robust growth, propelled by fundamental business trends centered around sustainability and cold chain efficiency. Regional seafood consumption patterns, particularly the rising middle-class demand in Asia Pacific and the stringent quality standards maintained in Europe, dictate regional trend variances. A significant business trend involves the shift from single-use EPS boxes toward modular, reusable plastic containers, driven by corporate commitments to reduce packaging waste and improve supply chain resilience. Technological advancements, such as RFID tagging and smart packaging integration for temperature monitoring, are enhancing logistical transparency and reducing spoilage, thereby increasing the value proposition of specialized fish boxes in high-value seafood transportation.

Geographically, the Asia Pacific region is forecast to dominate the market size, largely due to massive aquaculture production in countries like China, Vietnam, and Indonesia, coupled with expanding intra-regional trade. Europe, while smaller in volume, leads in technological adoption and regulatory compliance, driving premiumization in high-grade plastic and recyclable box segments. Regional trends also show Latin America and the Middle East accelerating investment in modern cold storage infrastructure, which subsequently mandates the use of reliable, standardized fish packaging for import and export activities. These emerging regions offer substantial growth opportunities for standardized and insulated packaging providers targeting improved food security and reduced post-harvest losses.

Segment trends highlight the dominance of the Expanded Polystyrene (EPS) material segment due to its historical reliability and low cost, particularly in fragmented, long-haul supply chains. However, the Plastic segment (HDPE and other reusable materials) is projected to record the highest Compound Annual Growth Rate (CAGR) as major processing and distribution companies invest heavily in closed-loop systems. In terms of application, the Aquaculture segment is expected to be the fastest-growing end-user, correlating directly with the rapid global expansion of farmed fish production. The retail distribution segment is also evolving rapidly, demanding more aesthetically pleasing, retail-ready packaging solutions that simplify shelf display while maintaining temperature control.

AI Impact Analysis on Fish Box Market

User queries regarding AI's impact on the Fish Box Market typically revolve around how artificial intelligence and machine learning (ML) can optimize logistics, predict demand fluctuations for raw materials, and enhance quality control during transit. Key user themes center on predictive maintenance of packaging lines, smart inventory management within large cold storage facilities, and using AI algorithms to determine optimal box sizes and materials based on specific shipment routes, ambient conditions, and transit times. Concerns also include the required capital investment for implementing these technologies and the integration challenges with legacy supply chain systems. Expectations are high regarding AI's potential to dramatically reduce spoilage rates by flagging potential cold chain breaches earlier than traditional monitoring systems.

The direct manufacturing of the physical fish box itself sees minimal AI application, but the surrounding ecosystem—logistics, cold chain management, and inventory optimization—is profoundly affected. AI algorithms analyze massive datasets, including weather patterns, traffic congestion, handling durations, and historical temperature logs, to construct highly accurate models for predicting thermal stability requirements. This predictive capability directly influences procurement decisions, allowing processors to select the most appropriate insulation level or box design for a given journey, leading to significant cost savings and minimized risks of product degradation. Furthermore, AI-driven demand forecasting enables manufacturers of fish boxes to optimize their production cycles for EPS or plastic molds, reducing waste and improving responsiveness to seasonal or geopolitical trade variations.

In quality assurance and traceability, machine vision powered by AI is beginning to be deployed to inspect the structural integrity and cleanliness of reusable plastic fish boxes returning from circulation. This automation ensures that only packaging meeting stringent hygiene standards is re-entered into the supply chain, a process previously reliant on manual, often inconsistent, inspection. This enhancement in quality control, coupled with ML-driven route optimization that minimizes transit time and maximizes thermal efficiency, demonstrates AI’s role as a critical tool for driving efficiency and reliability in the seafood cold chain, thus indirectly elevating the demand for high-specification, smart-ready fish boxes capable of integrating sensors.

- AI optimizes cold chain routes and timing, reducing reliance on maximum insulation packaging and potentially lowering material costs.

- Machine Learning (ML) enhances predictive demand forecasting for fish box manufacturers, optimizing inventory and production schedules.

- AI-powered sensor integration facilitates real-time tracking of temperature and humidity within smart fish boxes, preventing spoilage.

- Computer vision systems accelerate quality inspection and sanitation verification of reusable plastic fish boxes.

- Advanced analytics supports material choice optimization based on specific route thermodynamics and regulatory requirements.

DRO & Impact Forces Of Fish Box Market

The dynamics of the Fish Box Market are shaped by a complex interplay of Drivers (D), Restraints (R), Opportunities (O), and internal/external Impact Forces. Key drivers include the consistent growth of the global seafood trade and the expansion of the aquaculture industry, which demands specialized packaging for efficient handling and preservation. However, the market faces significant restraints, primarily revolving around environmental pressures related to single-use plastics, particularly Expanded Polystyrene (EPS), leading to regulatory scrutiny and consumer preference shifts. Opportunities emerge from the development of advanced biodegradable materials and the integration of smart technologies (IoT, RFID) into packaging for enhanced traceability and cold chain monitoring. These forces collectively dictate market investment priorities, pushing innovation toward sustainable and technologically advanced packaging solutions while managing cost-effectiveness in a commodity-driven sector.

Major driving forces securing market expansion are the increasing affluence in developing nations, leading to higher consumption of protein-rich seafood, and stricter global food safety standards implemented by regulatory bodies like the FDA and EFSA. These standards require superior insulation and hygienic surfaces, bolstering demand for high-grade packaging. Conversely, the primary restraints—the fluctuating price of petrochemical-derived raw materials (critical for both EPS and plastic boxes) and the logistical challenges associated with managing the return and cleaning of reusable plastic boxes (Reverse Logistics)—add complexity and cost to the supply chain. The persistent global effort to reduce plastic waste creates regulatory hurdles, forcing manufacturers to invest heavily in R&D for alternative, sustainable materials, often at higher production costs.

The primary opportunities lie in the commercialization of bio-based or fully recyclable fish box designs that offer thermal performance comparable to EPS. Furthermore, the rapid digitalization of supply chains creates an opportunity for specialized packaging suppliers to offer "packaging-as-a-service," integrating tracking technology and providing comprehensive temperature-controlled logistics solutions rather than merely selling containers. The collective impact forces—such as environmental legislation, global trade agreements affecting seafood exports, and consumer activism regarding ocean plastic pollution—exert continuous pressure on market participants to innovate. This ensures that only companies adopting sustainable manufacturing practices and offering robust, verifiable cold chain solutions will maintain long-term competitive advantages and meet evolving regulatory and societal expectations.

Segmentation Analysis

The Fish Box Market is primarily segmented based on the material used for construction, the capacity of the box, and the specific application or end-user industry. This segmentation provides a granular view of market dynamics, revealing varying growth rates, price points, and competitive landscapes across different product categories. The Material segment—spanning EPS, plastic, wood, and corrugated cardboard—is crucial as it determines thermal performance, reusability, and environmental impact. The Capacity segment reflects the diversity of operational scale, ranging from small, artisanal fishing operations to massive, industrialized processing facilities. Analyzing these segments helps stakeholders tailor product development and marketing strategies to specific logistical and sustainability demands of end-users.

- By Material:

- Expanded Polystyrene (EPS)

- Plastic (HDPE, LDPE)

- Corrugated Cardboard

- Wood and Others

- By Capacity:

- Small (1 kg to 10 kg)

- Medium (10 kg to 30 kg)

- Large (Above 30 kg)

- By Application/End-User:

- Fishing Industry (Onboard Vessels)

- Aquaculture Farms

- Seafood Processing Facilities

- Retail and Distribution (Wholesale, Supermarkets)

Value Chain Analysis For Fish Box Market

The value chain for the Fish Box Market begins with the upstream procurement of raw materials, mainly petrochemical derivatives (for EPS and plastic) and cellulose fibers (for corrugated board). Upstream analysis focuses on the cost volatility of key polymers, which significantly impacts the final product price and manufacturer margins. Efficiency in polymerization and molding processes is critical for cost leadership. Manufacturers then convert these materials into finished boxes, often involving high-precision injection molding for reusable plastic or specialized expanded bead processing for EPS. Key manufacturing activities include thermal testing, structural design for stacking efficiency, and ensuring compliance with hygiene standards required by international food regulations.

Downstream analysis involves the distribution, usage, and disposal or reuse phases. Once manufactured, the boxes are distributed through direct sales channels to large seafood processors and aquaculture operations, or via indirect channels (industrial packaging distributors) to smaller enterprises and fishing fleets. The core value addition occurs when the box is utilized to maintain the cold chain—crucial for high-value species like salmon or tuna. In this phase, the efficiency of the box directly translates into reduced spoilage and increased market reach for the seafood producer. The end of the life cycle dictates whether the box is recycled, disposed of (common for EPS), or cleaned and returned for reuse (typical for plastic HDPE boxes).

Distribution channels are bifurcated between direct supply and indirect distribution networks. Direct channels offer customized solutions, volume discounts, and strong technical support, preferred by major vertically integrated companies. Indirect channels, utilizing specialized industrial packaging wholesalers and logistics providers, are essential for reaching disparate smaller fishing communities and seasonal operations. The shift toward reusable plastic necessitates sophisticated reverse logistics systems managed either directly by the packaging supplier or outsourced to specialized logistics firms, adding a layer of complexity and cost to the downstream activities, but promising long-term environmental and economic efficiency.

Fish Box Market Potential Customers

The primary consumers and end-users of fish boxes span the entire breadth of the seafood supply chain, where reliable temperature management is non-negotiable. Major potential customers include large-scale seafood processing facilities that require standardized, high-volume packaging for global export. These processors often utilize a mix of single-use EPS for long-distance air freight and durable, reusable plastic boxes for processing and local truck distribution. The requirement for regulatory compliance and efficient handling drives their purchasing decisions, prioritizing suppliers offering reliable insulation and customizable dimensions suitable for palletization and automation.

Another significant customer base comprises the burgeoning global aquaculture industry, particularly salmon, shrimp, and whitefish farms. Aquaculture operations, characterized by predictable, high-volume harvests, often invest in closed-loop systems utilizing high-density polyethylene (HDPE) fish boxes. These customers value durability, ease of cleaning, and traceability features (e.g., integrated QR codes or RFID tags) that enhance inventory management and sanitation protocols across their centralized farming and harvesting sites. The consistency of their supply allows for long-term contractual agreements with specialized packaging providers focusing on reusable solutions.

Retail and wholesale distribution entities, including large supermarket chains and global seafood importers, also constitute a vital customer segment. Retailers increasingly demand ‘retail-ready’ packaging that simplifies handling and display while minimizing environmental footprint. These customers are driving the demand for corrugated cardboard fish boxes with specialized moisture barriers, which offer a balance between insulation, sustainability, and aesthetic appeal for direct display. Finally, independent fishing fleets and cooperatives represent a large, fragmented customer base, often preferring cost-effective, readily available EPS boxes for immediate onboard use and primary storage until port unloading.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.1 Billion |

| Market Forecast in 2033 | USD 6.1 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sirap Gema, Sealed Air Corporation, DS Smith PLC, Saeplast (RPC Group), Orbis Corporation, Schoeller Allibert, Finnfoam Oy, Lineage Logistics (Packaging Arm), Smurfit Kappa Group, Greiner Packaging International, Winpak Ltd., Pactiv Evergreen Inc., Klöckner Pentaplast, Cascades Inc., Huhtamaki Oyj, IPL Plastics, Loadhog Ltd., Tri-Wall Group, Thermoshoe, and Delta Pak. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fish Box Market Key Technology Landscape

The technology landscape in the Fish Box Market is primarily focused on material science innovation aimed at enhancing thermal efficiency and sustainability, alongside digital integration for optimized supply chain management. In materials, significant R&D efforts are targeting novel bio-based polymers and advanced barrier coatings for corrugated cardboard, seeking to match the insulation capabilities of EPS without the associated environmental burden. Techniques like Vacuum Insulated Panels (VIP) are occasionally utilized for extremely high-value or temperature-sensitive seafood, though cost remains a barrier for mass market adoption. Furthermore, manufacturing technologies such as advanced injection molding are being refined to produce lighter yet structurally robust reusable plastic boxes that withstand the harsh marine and industrial environments, ensuring a longer usable lifespan.

Digital technologies are rapidly integrating into the fish box infrastructure, transforming it from a mere container into a smart logistical asset. The incorporation of Internet of Things (IoT) sensors, often embedded or affixed to the boxes, allows for continuous, real-time monitoring of internal temperature, humidity, and location during transit. This sensor data, utilizing technologies such as RFID and NFC, is crucial for maintaining accountability and verifying cold chain compliance, particularly important for international shipments subject to strict regulatory oversight. Data analytics platforms then process this information, providing actionable insights for logistics managers to intervene proactively if temperature excursions are detected, significantly mitigating spoilage risk and improving overall product safety and traceability.

Beyond material and tracking technologies, manufacturing processes are increasingly adopting automation and precision engineering. Automated packaging lines are essential for high-volume processors, demanding boxes with standardized dimensions and precise stacking features to work seamlessly with robotics. This drive for efficiency has pushed box manufacturers to invest in advanced CAD and simulation software to design optimal geometries for strength and heat retention. Furthermore, specialized sanitization technologies, including UV-C light treatment and automated washing systems, are becoming standard requirements for maintaining the hygiene of reusable plastic fish boxes, complementing the digital traceability features and ensuring compliance with stringent food safety regulations globally.

Regional Highlights

Regional dynamics heavily influence the type and volume of fish boxes utilized globally, reflecting variations in seafood production, consumption patterns, and environmental legislation. The Asia Pacific (APAC) region is the undisputed leader in market volume, driven by its massive scale of aquaculture (particularly China, India, and Southeast Asia) and robust domestic seafood consumption. APAC relies heavily on cost-effective packaging solutions, with EPS dominating for initial transport and local distribution. However, environmental awareness is rising, especially in countries like Japan and South Korea, fostering increasing adoption of higher-grade plastic and corrugated options, particularly in the export-oriented segments seeking compliance with Western standards. The sheer volume of fish processing and trade activity in APAC necessitates high production capacity for packaging materials.

Europe represents a mature market characterized by stringent food safety standards and a strong focus on sustainability. European regulations, particularly those concerning single-use plastics and waste management, are actively propelling the transition towards reusable plastic fish boxes in closed-loop systems, championed by large retailers and seafood cooperatives. Countries like Norway and Iceland, major seafood exporters, invest heavily in highly insulated, durable plastic boxes for long-haul shipping to maintain premium quality. The European market prioritizes high-quality, traceable packaging solutions, making it a key region for the testing and adoption of smart packaging technologies and innovative bio-based materials designed to reduce environmental impact.

North America (NA) exhibits a dual market structure. The US market is large and geographically diverse, requiring packaging solutions optimized for varied transit times and conditions, leading to strong demand for both high-insulation EPS and specialized corrugated options. Canada, a significant seafood exporter, often aligns with European standards regarding quality and traceability. NA is also a strong adopter of automation in processing, demanding standardized box designs compatible with robotic handling systems. Latin America (LATAM) and the Middle East and Africa (MEA) are emerging growth regions. LATAM's increasing aquaculture output (e.g., Chile, Ecuador) drives demand for reliable, standardized packaging for international export. MEA, particularly the Gulf Cooperation Council (GCC) nations, shows growing demand driven by increased refrigerated imports and infrastructure development in cold chain logistics, focusing on durable plastic solutions for demanding environmental conditions.

- Asia Pacific (APAC): Dominates market volume due to high aquaculture production; growing focus on moving from traditional EPS to advanced recyclable plastics in export-oriented sectors.

- Europe: Leads in technological adoption and sustainability mandates; high demand for reusable plastic boxes and smart packaging compliant with strict EU food safety regulations.

- North America (NA): Characterized by demand for automated handling compatibility and robust insulation for diverse climates and long-distance inland transport.

- Latin America (LATAM): Rapid growth driven by export expansion in aquaculture sectors; increasing need for standardized, internationally compliant packaging solutions.

- Middle East and Africa (MEA): Growth stimulated by improved cold chain infrastructure investment and rising reliance on packaged, imported seafood, driving demand for durable, insulated containers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fish Box Market.- Sirap Gema (Synbra Technology)

- Sealed Air Corporation

- DS Smith PLC

- Saeplast (RPC Group)

- Orbis Corporation

- Schoeller Allibert

- Finnfoam Oy

- Lineage Logistics (Packaging Arm)

- Smurfit Kappa Group

- Greiner Packaging International

- Winpak Ltd.

- Pactiv Evergreen Inc.

- Klöckner Pentaplast

- Cascades Inc.

- Huhtamaki Oyj

- IPL Plastics (Now a part of Groupe BergaMet)

- Loadhog Ltd.

- Tri-Wall Group

- Thermoshoe

- Delta Pak

Frequently Asked Questions

Analyze common user questions about the Fish Box market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is driving the market shift away from Expanded Polystyrene (EPS) fish boxes?

The primary driver is global environmental regulation and corporate sustainability commitments aimed at reducing single-use plastic waste. EPS is difficult and costly to recycle, leading major retailers and seafood processors to adopt durable, reusable plastic containers or innovative corrugated cardboard alternatives to improve supply chain circularity and meet consumer expectations.

How does the integration of IoT technology benefit the seafood cold chain?

IoT sensors embedded in smart fish boxes provide continuous, real-time data on internal temperature and location. This data is critical for validating cold chain integrity, reducing product spoilage by allowing proactive intervention, and ensuring regulatory compliance and traceability throughout complex international shipping routes.

Which material segment is projected to show the highest growth rate (CAGR)?

The Plastic segment, particularly high-density polyethylene (HDPE) reusable containers, is projected to exhibit the highest CAGR. This growth is fueled by increasing investment in closed-loop systems by aquaculture farms and seafood processors, valuing the durability, hygiene, and long-term cost-efficiency of reusable packaging over single-use options.

What role does aquaculture play in the demand for specialized fish boxes?

Aquaculture is the fastest-growing end-user sector, driving demand for standardized, hygienic fish boxes. The high volume and predictable harvest cycles of farmed fish necessitate robust, stackable packaging solutions, often reusable plastic, to ensure efficient processing and standardized export readiness, thereby stabilizing high-volume demand.

What are the main logistical challenges associated with reusable plastic fish boxes?

The main challenge is managing reverse logistics—the collection, transportation, centralized cleaning, and redistribution of the empty boxes. This process requires significant capital investment in dedicated washing facilities, robust tracking systems, and efficient coordination to ensure high utilization rates and consistent hygiene standards.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager