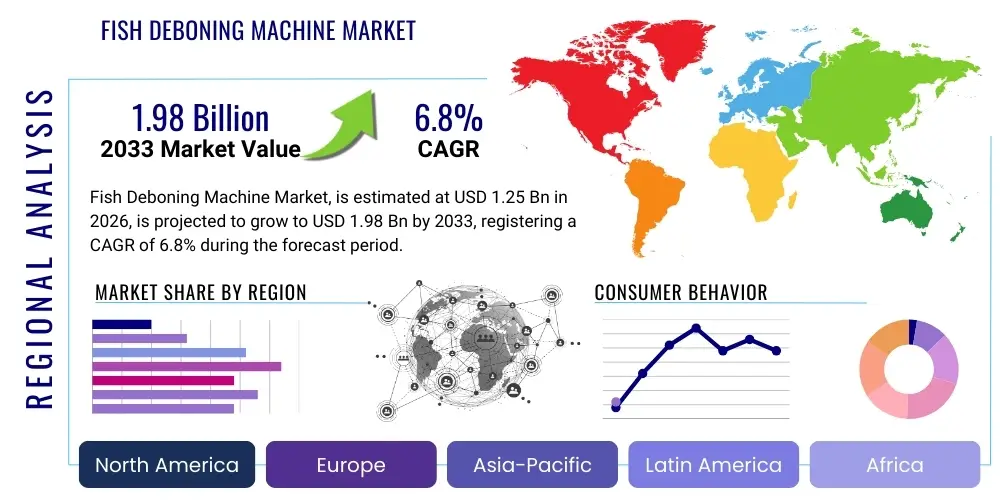

Fish Deboning Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438716 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Fish Deboning Machine Market Size

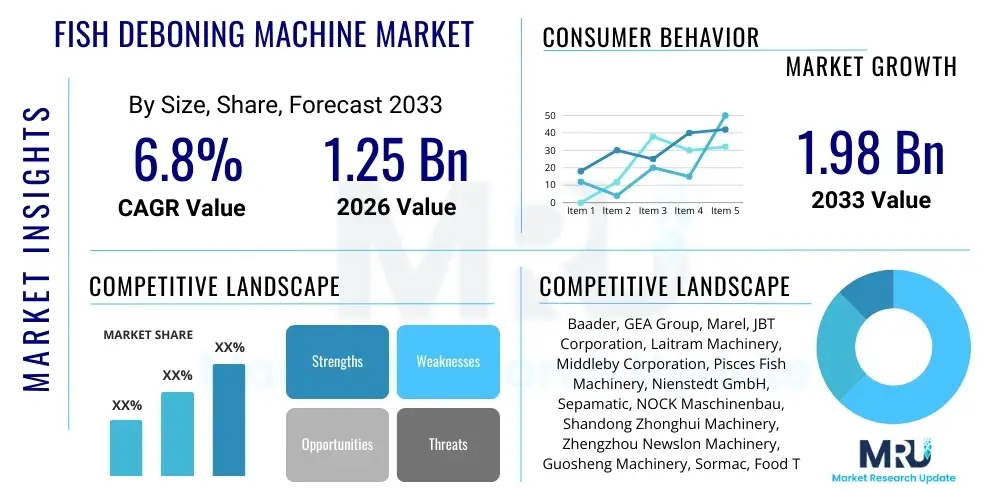

The Fish Deboning Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.98 Billion by the end of the forecast period in 2033.

Fish Deboning Machine Market introduction

The Fish Deboning Machine Market encompasses automated and semi-automated equipment designed to mechanically separate the flesh of fish from bones, skin, and fins with high efficiency and minimal yield loss. These specialized machines are integral to modern seafood processing lines, addressing the need for rapid processing of large volumes of fish, ensuring consistent product quality, and significantly reducing manual labor costs. Products range from smaller, versatile processors used in artisanal settings to large, industrial-scale systems capable of handling tons of raw material per hour, catering to diverse needs across the global aquaculture and wild-catch seafood sectors. The core function is improving the safety and marketability of fish products, particularly for producing surimi, fish paste, minced fish, and other processed seafood items where bone fragments are unacceptable.

The operational mechanism typically involves pressing the fish raw material against a perforated drum or screen, utilizing varying pressures to force the soft flesh through the perforations while retaining the harder bone and skin material on the outside. This process ensures maximum meat recovery (yield rates often exceeding 75% depending on the species) while maintaining hygienic standards essential for food safety compliance. Key applications include the processing of white fish, pelagic species, and freshwater fish for human consumption and also for byproduct utilization in pet food or fish meal manufacturing. The continuous refinement of deboning technology focuses on enhancing versatility across species, reducing operational noise, and minimizing the temperature increase of the processed meat, which is critical for preserving quality and shelf life.

Driving factors propelling market growth include the escalating global demand for convenience seafood products, the increasing operational expenditure associated with manual processing labor, and stringent global food safety regulations mandating zero tolerance for bone contaminants in processed fish products. Furthermore, the expansion of the aquaculture industry, particularly in Asia Pacific, requires high-throughput processing solutions to handle farmed fish efficiently. Technological advancements, such as sensor integration and precision cutting mechanics, are making these machines more appealing by offering greater yields and lower maintenance requirements, solidifying their status as indispensable assets within the seafood value chain.

Fish Deboning Machine Market Executive Summary

The Fish Deboning Machine Market is characterized by robust growth driven primarily by automation imperatives in the global food processing sector and the sustained rise in per capita seafood consumption. Business trends indicate a strong shift towards integrated processing lines where deboning machines are networked with filleting and skinning equipment, offering end-to-end solutions that maximize throughput and operational efficiency. Furthermore, manufacturers are increasingly focusing on developing modular and customizable equipment to address the diverse requirements arising from processing different fish species, ranging from cod and salmon to mackerel and tilapia. Investment in corrosion-resistant, food-grade stainless steel construction remains paramount, reflecting the industry's commitment to hygiene and longevity in harsh marine environments. The market exhibits competitive dynamics, with established players innovating in high-pressure processing technologies to preserve the structural integrity of the fish meat.

Regional trends highlight the Asia Pacific region as the dominant market, fueled by massive aquaculture production volumes in countries like China, Indonesia, and Vietnam, necessitating large-scale industrial deboning solutions for surimi and fish paste production. North America and Europe, characterized by high labor costs and strict regulatory standards, are witnessing strong adoption of fully automated, high-precision machines that minimize human interaction and ensure traceability. Segment trends show that the Screw Press Deboners segment, favored for its high throughput and versatility, maintains a leading market share, although the Belt Press Deboners are gaining traction due to their suitability for more delicate fish species where meat structure preservation is critical. The market for machines tailored to specific fish sizes (e.g., small fish processors) is also expanding, driven by optimization goals within targeted fisheries and processing plants.

Overall, the market trajectory is positive, reflecting the critical role of deboning technology in supporting the modernization and scaling of the seafood industry. Key strategic concerns for market participants revolve around supply chain resilience, customization capability, and compliance with varying international health and safety certifications (such as HACCP and FDA standards). Future growth is expected to be significantly influenced by technological integrations, including advanced sensor systems for quality control and predictive maintenance protocols facilitated by industrial IoT (IIoT), further solidifying the necessity of these machines in optimizing resource utilization and profitability for processors globally.

AI Impact Analysis on Fish Deboning Machine Market

User queries regarding the impact of Artificial Intelligence (AI) and machine learning (ML) on the Fish Deboning Machine Market often center on optimizing yield, enhancing quality control, and predictive maintenance capabilities. Common themes explored include whether AI can differentiate between desirable meat textures and bone fragments in real- time, how ML algorithms can optimize machine pressure settings for varied fish sizes without manual recalibration, and the potential for autonomous defect detection in the processed fish paste. Users are particularly interested in the transition from traditional mechanical systems to smart deboners that learn from processing data to minimize meat loss and ensure superior, bone-free output, viewing AI as the crucial link for achieving true operational efficiency and reducing dependency on operator expertise for fine-tuning machinery based on variable raw material quality.

- AI-Powered Yield Optimization: Machine learning algorithms analyze real-time input data (species, size, texture) to dynamically adjust machine parameters (pressure, screen size, speed), maximizing meat recovery rates.

- Predictive Maintenance: AI models monitor vibration, temperature, and current consumption patterns of critical components (screws, drums) to forecast potential mechanical failures, significantly reducing unplanned downtime.

- Enhanced Quality Control: Vision systems integrated with deep learning models identify and categorize contaminants (bone fragments, skin residue) in the processed paste with sub-millimeter precision, improving product safety.

- Autonomous Calibration: ML enables machines to automatically recalibrate deboning pressure based on sensor feedback regarding the stiffness of the fish carcass, ensuring consistent performance across batches.

- Inventory and Throughput Management: AI systems integrate deboning output data with plant-wide Enterprise Resource Planning (ERP) systems, optimizing flow rate and inventory management for downstream processing stages.

DRO & Impact Forces Of Fish Deboning Machine Market

The Fish Deboning Machine Market is dynamically influenced by a synergistic combination of market drivers, operational restraints, and substantial opportunities, collectively defining the landscape and trajectory. Drivers are predominantly linked to the global shift towards automated food processing, necessity for higher throughput due to increasing consumption of seafood, and regulatory pressure for enhanced food safety, mandating bone-free products. Conversely, restraints involve the significant initial capital investment required for high-capacity machinery, the technical complexity of maintaining advanced systems, and challenges in developing universally efficient machines capable of handling the structural diversity across hundreds of commercial fish species. Opportunities emerge through emerging markets adopting industrial processing, the integration of smart technologies (IoT, AI), and the growing demand for sustainable processing practices that maximize resource utilization.

The intrinsic impact forces within this market operate across multiple levels. Competitive intensity remains high, driven by technological differentiation and pricing strategies among key manufacturers, particularly those vying for dominance in high-volume regions like Asia Pacific. Supplier power is moderate, influenced by the specialized components (e.g., high-grade stainless steel, precision motors) required for machine construction. Buyer power is substantial, especially among large industrial processors and multinational food corporations, who demand stringent performance metrics, customization, and comprehensive after-sales support, often dictating terms related to yield guarantee and operational reliability. Furthermore, the threat of substitutes, while low (manual deboning is inefficient for industrial scale), is countered by the continuous improvement in related technologies like advanced filleting machines that reduce the residual bone content before deboning.

The overall impact forces necessitate that manufacturers continuously invest in research and development to offer faster, more hygienic, and species-versatile machines. Regulatory compliance acts as a double-edged force: while it drives adoption of superior technology (driver), it also increases the cost and complexity of market entry (restraint). The market's resilience is tied to global demographics and rising income levels, particularly in developing economies, which elevate the demand for convenient, processed seafood items. Successfully navigating these forces requires a strategic focus on efficiency gains, robust after-sales service networks, and targeted innovation to address species-specific processing challenges.

Segmentation Analysis

The Fish Deboning Machine Market is comprehensively segmented based on machine type, capacity, application, and geographical region, providing a structured understanding of market dynamics and targeted industry needs. Segmentation by type differentiates between technologies like Screw Press Deboners, which use high pressure suitable for coarser fish mince production, and Belt Press Deboners, preferred for maintaining the integrity of meat intended for higher-grade products like surimi or fish portions. Capacity segmentation (small, medium, large) directly correlates with the scale of the end-user operations, from small-scale fish markets to large industrial processing hubs. Application breakdown highlights the primary uses, such as producing minced fish, surimi, and fish paste, reflecting varied processing requirements and quality standards globally. This granular segmentation allows manufacturers to tailor marketing strategies and product development efforts toward specific high-growth areas within the seafood value chain.

- By Type:

- Screw Press Deboners

- Belt Press Deboners (Drum Separators)

- Bone Separators (Pneumatic and Hydraulic)

- Integrated Processing Systems

- By Capacity:

- Low Capacity (Up to 500 kg/hr)

- Medium Capacity (500 kg/hr to 2,000 kg/hr)

- High Capacity (Above 2,000 kg/hr)

- By Application:

- Minced Fish and Surimi Production

- Fish Paste and Sausages

- Fish Meal and Feed Production

- Other Seafood Processing (e.g., bone residue processing)

- By End User:

- Fish Processing Plants

- Commercial Fisheries

- Aquaculture Farms

- Food Service and Retail Preparation Centers

Value Chain Analysis For Fish Deboning Machine Market

The value chain for the Fish Deboning Machine Market begins with upstream activities involving the sourcing of highly specialized materials, predominantly food-grade stainless steel (SS304 and SS316) for corrosion resistance, and precision components such as motors, gears, screens, and hydraulic systems. Key manufacturers maintain strong relationships with specialized metal fabricators and component suppliers to ensure quality, longevity, and regulatory compliance. Research and development activities focused on improving yield percentage, reducing energy consumption, and enhancing sanitation protocols form a crucial part of the value creation at this stage. Patents covering novel screw designs or pressure regulation mechanisms provide competitive advantages to market leaders.

Downstream activities center on the efficient distribution, installation, and robust after-sales support of the machinery. Distribution channels are typically complex, involving direct sales teams for large, customized industrial projects, and regional distributors or agents for accessing smaller markets or providing localized maintenance services. Direct channels are prevalent for specialized, high-capacity machines requiring bespoke integration into existing processing lines, ensuring that technical specifications are met precisely. Indirect channels leverage established distribution networks that possess expertise in seafood processing equipment and can handle logistics, import/export regulations, and local servicing requirements across diverse geographical regions.

The final phase involves end-user utilization (fish processors, surimi producers) and maintenance, where the total cost of ownership (TCO) becomes critical. Manufacturers add significant value through training programs, availability of spare parts, and preventative maintenance contracts, ensuring high uptime and optimized machine performance over its lifespan. The efficiency of the machine directly impacts the profitability of the fish processor, making the quality of the deboned meat and the yield percentage the most important value determinants throughout the entire chain. Therefore, the strategic integration of advanced monitoring technology (IoT sensors) supports proactive maintenance, extending the value proposition long after the initial sale.

Fish Deboning Machine Market Potential Customers

The primary consumers and end-users of Fish Deboning Machines are entities operating within the industrial and commercial seafood processing ecosystem globally. These customers prioritize high throughput, hygiene, operational reliability, and yield efficiency above all else. The largest segment of buyers comprises large-scale fish processing plants, which handle massive volumes of both wild-catch and farmed fish destined for further processing, often requiring multiple high-capacity deboning units to meet continuous production schedules. These plants are the major purchasers of advanced, automated systems integrated into full processing lines.

Another significant group includes specialized surimi and fish paste manufacturers, particularly dominant in Asian markets, where the quality of the mince directly impacts the final product grade. These users require machines capable of producing extremely fine, high-quality, bone-free paste while minimizing protein denaturation caused by heat or excessive pressure. Additionally, companies involved in byproduct utilization, such as fish meal and pet food manufacturers, represent a growing customer base, utilizing deboning technology to separate low-value meat and bone residue efficiently, maximizing raw material utilization and contributing to sustainable waste management practices within the fisheries sector.

Smaller-scale commercial fisheries, large restaurant chains engaging in centralized preparation, and localized aquaculture operations also represent potential markets, though they typically purchase lower to medium-capacity, more versatile machines. Their buying decisions are often influenced more heavily by ease of operation, footprint size, and investment cost rather than sheer throughput capacity. However, all customer groups share the essential need for machines compliant with stringent international food safety standards, particularly those concerning material contact surfaces and ease of sterilization.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.98 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Baader, GEA Group, Marel, JBT Corporation, Laitram Machinery, Middleby Corporation, Pisces Fish Machinery, Nienstedt GmbH, Sepamatic, NOCK Maschinenbau, Shandong Zhonghui Machinery, Zhengzhou Newslon Machinery, Guosheng Machinery, Sormac, Food Technology Laitram, Seydelmann, K&G Wetter, Velec, Skaginn 3X, Fomaco |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fish Deboning Machine Market Key Technology Landscape

The technological landscape of the Fish Deboning Machine Market is defined by continuous innovation focused on precision, sanitation, and versatility across diverse biological inputs. A cornerstone technology involves specialized filtering systems, primarily stainless steel drums or screens with precisely calibrated apertures (ranging typically from 1.0 mm to 5.0 mm), which determine the final texture and purity of the separated meat. Advanced hydraulic and pneumatic systems are employed to regulate the pressure applied during the separation process, ensuring that adequate force is used to recover the meat without crushing the bones, which would contaminate the final product. The ongoing technological evolution emphasizes closed-loop monitoring systems that provide real-time feedback on pressure and temperature, crucial for preserving the quality and color of the fish meat.

Modern machines incorporate significant advancements in material science and design, utilizing hygienic, easy-to-clean components (Clean-In-Place, or CIP systems) that minimize bacterial buildup and simplify sterilization, meeting rigorous HACCP and regulatory standards. Furthermore, there is a distinct trend towards modular design, enabling processors to quickly interchange drums and screws to adapt a single machine for different fish species or product specifications, thereby maximizing operational flexibility. The integration of Variable Frequency Drives (VFDs) and energy-efficient motors is standard, addressing the industry's need to reduce high operational power consumption associated with continuous processing.

The most forward-looking technology involves the adoption of Industrial Internet of Things (IIoT) sensors and integrated analytics platforms. These technologies allow machines to report performance metrics, temperature anomalies, and operational status remotely, facilitating predictive maintenance and optimizing machine settings through data analysis. This shift towards smart processing equipment is critical for high-volume processors aiming for near-zero downtime and maximum yield consistency. Future technology will likely focus heavily on non-destructive testing methods, potentially utilizing advanced sensor arrays to assess the texture and bone structure of the fish before processing, enabling unparalleled precision and customization of the deboning process.

Regional Highlights

Regional dynamics play a crucial role in shaping the demand and adoption patterns within the Fish Deboning Machine Market, heavily influenced by local fishing industries, aquaculture output, consumer preferences, and labor cost structures. Asia Pacific (APAC) stands out as the global leader, driven by its massive contribution to global aquaculture, particularly in the production of low-cost species used for surimi and fish paste. Countries like China, Vietnam, Thailand, and Indonesia require high-capacity, robust screw press deboners to handle continuous, large-scale industrial throughput. The growth in disposable income in these regions also fuels domestic demand for processed seafood, further incentivizing investment in efficient machinery.

Europe represents a mature market characterized by stringent quality standards and high labor costs, leading to strong demand for fully automated, high-precision belt press deboners, particularly in countries like Norway, Iceland, and Germany. These markets prioritize machines capable of handling higher-value species (like cod and salmon) while maintaining optimal texture and preserving meat integrity for premium products. Innovation in Europe is focused heavily on sanitation, energy efficiency, and compliance with the latest European Union food safety directives.

North America, similarly driven by high labor costs and rigorous FDA standards, demonstrates steady adoption of advanced, automated systems. The market here demands versatile equipment capable of processing a wide range of wild-catch species (e.g., Alaska Pollock) efficiently. Latin America and the Middle East & Africa (MEA) are emerging markets, showing increasing adoption fueled by growing local seafood processing industries and modernization initiatives. While still characterized by smaller overall market size, these regions present significant long-term growth opportunities as industrialization of fishing and aquaculture sectors accelerates, requiring entry-level and medium-capacity deboning solutions.

- Asia Pacific (APAC): Dominates the market due to expansive aquaculture output (especially surimi-grade fish) and high demand for minced fish products. Key users are large processing hubs in China and Southeast Asia demanding high-throughput screw press technology.

- Europe: Characterized by high labor substitution rates and strict hygiene regulations, driving demand for automated, precision belt press systems for high-value species like salmon and whitefish.

- North America: Focuses on operational efficiency and compliance with FDA regulations, leading to high uptake of technologically advanced, robust machinery for processing major wild-catch species.

- Latin America: Emerging growth region driven by the expansion of regional fishing fleets and increasing internal demand for processed seafood, focusing on adopting medium-capacity machines.

- Middle East and Africa (MEA): Growth is tied to government investment in food security and local fishing industry modernization, creating opportunities for entry-level and efficient deboning technologies.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fish Deboning Machine Market.- Baader

- GEA Group

- Marel

- JBT Corporation

- Laitram Machinery (Subsidiary: Laitram)

- Middleby Corporation

- Pisces Fish Machinery

- Nienstedt GmbH

- Sepamatic

- NOCK Maschinenbau

- Shandong Zhonghui Machinery

- Zhengzhou Newslon Machinery

- Guosheng Machinery

- Sormac

- Food Technology Laitram

- Seydelmann

- K&G Wetter

- Velec

- Skaginn 3X

- Fomaco

Frequently Asked Questions

Analyze common user questions about the Fish Deboning Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Screw Press and Belt Press Fish Deboners?

Screw press deboners utilize high pressure via a rotating screw against a perforated drum, yielding a finer, high-volume mince suitable for surimi, but potentially generating more heat. Belt press deboners use a gentler process, squeezing the flesh through a mesh belt, preserving the structure and texture of the meat, making them ideal for premium fish products.

How does AI technology improve the yield efficiency of modern deboning machines?

AI integrates with sensors to analyze the varying physical characteristics (species, stiffness, temperature) of the raw fish in real-time, allowing the machine to dynamically adjust deboning pressure and speed, minimizing meat loss and maximizing recovery rates compared to static manual settings.

Which geographical region holds the largest market share for Fish Deboning Machines?

The Asia Pacific (APAC) region commands the largest market share, driven primarily by the colossal scale of its aquaculture operations, particularly for species used in surimi production, necessitating continuous, high-capacity industrial deboning equipment.

What are the key maintenance challenges associated with industrial deboning equipment?

Key maintenance challenges include rapid wear and tear of specialized screens and screws due to constant friction with bone residue, corrosion from saltwater environments, and the need for rigorous, daily sanitization procedures (CIP systems) to prevent microbial contamination and ensure food safety compliance.

Is the Fish Deboning Machine Market growth primarily driven by aquaculture or wild-catch fisheries?

While both sectors contribute significantly, the primary growth driver is the expansion and industrialization of global aquaculture, which demands standardized, high-volume processing machinery to handle large, consistent batches of farmed fish efficiently, particularly in emerging Asian markets.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager