Fishing Cages and Nets Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437044 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Fishing Cages and Nets Market Size

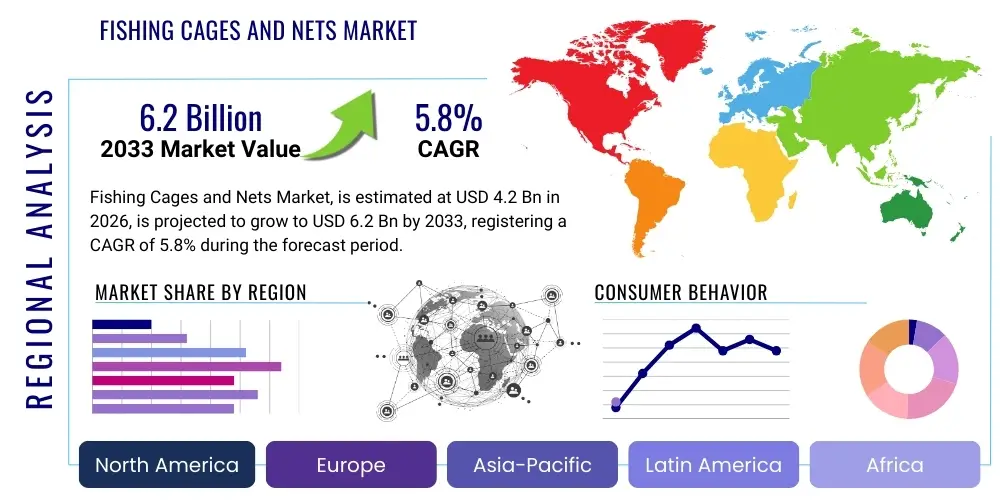

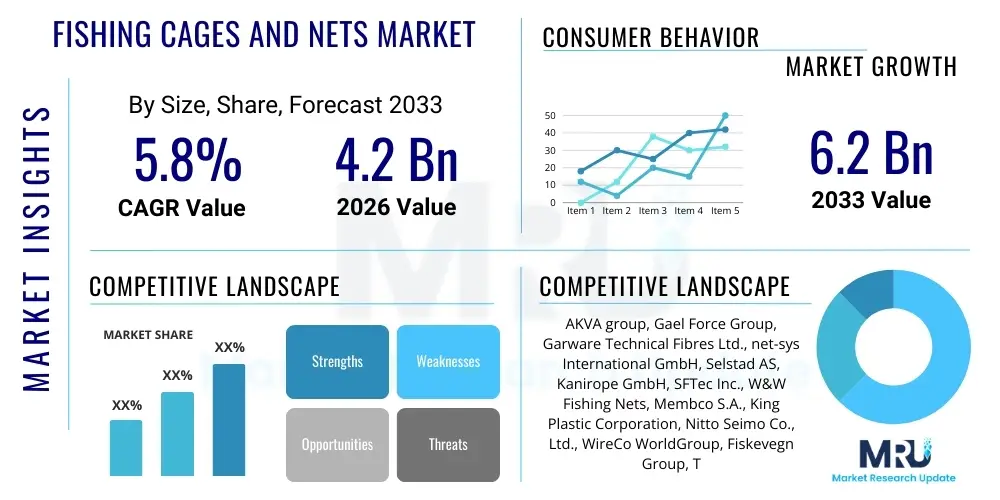

The Fishing Cages and Nets Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.2 Billion in 2026 and is projected to reach USD 6.2 Billion by the end of the forecast period in 2033.

The steady growth trajectory of this market is primarily fueled by the accelerating global demand for seafood, necessitating more efficient and larger-scale commercial fishing operations and, crucially, the expansion of the aquaculture sector. Modern fishing gear, including advanced net cages and high-tenacity nets, plays an indispensable role in maximizing yield while often adhering to stricter environmental regulations aimed at minimizing ghost fishing and bycatch. Investment in durable, sustainable, and high-performance materials such as High-Density Polyethylene (HDPE) and specialized nylon is a key driver underpinning this valuation increase over the forecast period.

Fishing Cages and Nets Market introduction

The Fishing Cages and Nets Market encompasses a wide range of products essential for both wild-catch fisheries and controlled aquaculture environments. These products include large-scale submersible net cages used in offshore farming, traditional gillnets, trawls, purse seines, and specialized traps and pots. The fundamental purpose of these tools is to efficiently capture, hold, and manage aquatic organisms, supporting global food security and economic activity across coastal and inland regions. Innovation in materials science, particularly the shift toward more robust and environmentally friendly synthetic fibers, is constantly redefining product longevity and operational efficiency.

Major applications of fishing cages and nets span industrial and artisanal commercial fishing, which relies on gear designed for deep-sea environments and high-volume catches, and the burgeoning aquaculture industry, where net pens and rigid cages are critical infrastructure for raising salmon, tuna, shrimp, and various finfish species. Key benefits derived from the adoption of modern, high-quality gear include reduced operational costs due to enhanced durability, improved selective fishing capabilities that reduce unintended bycatch, and significantly higher yields in controlled farming systems. The increasing focus on sustainable harvesting practices globally is also driving the adoption of gear that meets stringent international standards, thereby bolstering market value.

Driving factors for market expansion include the substantial growth of the global population and the corresponding surge in demand for protein sources, making aquaculture an increasingly viable and necessary sector. Furthermore, technological advancements in net design—such as knotless netting, anti-fouling treatments, and automated net cleaning systems—improve the productivity and lifespan of the equipment, encouraging replacement and upgrade cycles among commercial operators and fish farmers. Government initiatives supporting sustainable fisheries management and investment in blue economy infrastructure also contribute significantly to the positive market momentum.

Fishing Cages and Nets Market Executive Summary

The Fishing Cages and Nets Market is undergoing a transformation characterized by the convergence of traditional marine practices with high-tech materials and digital monitoring systems. Business trends indicate a movement toward consolidation, where leading global manufacturers are acquiring smaller regional players to expand their geographical reach and enhance their technological portfolios, particularly concerning anti-fouling solutions and robust material compositions like UHMWPE (Ultra-High Molecular Weight Polyethylene). Vertical integration, especially among companies servicing the offshore aquaculture segment, is a defining business strategy, aiming to control the supply chain from raw material processing to final equipment installation and maintenance services.

Regional trends highlight the undeniable dominance of the Asia Pacific (APAC) region, driven by massive aquaculture production volumes in countries such as China, Vietnam, and Indonesia, coupled with extensive traditional fishing fleets. However, North America and Europe are exhibiting rapid growth in the high-value segment, focusing on advanced, large-scale offshore cage systems that comply with strict environmental mandates and utilize sophisticated sensor technology for fish health monitoring and environmental data collection. These regions prioritize sustainability and technological integration, driving demand for premium, durable netting solutions and automated systems.

Segment trends show that while nylon remains a workhorse material, the HDPE segment is experiencing the fastest growth due to its superior strength-to-weight ratio, resistance to UV degradation, and lower maintenance costs in corrosive marine environments. By application, the aquaculture segment is outpacing the commercial fishing segment, reflecting the strategic global shift toward farmed seafood production as wild stocks face increasing pressure. Specifically within aquaculture, submersible and semi-submersible cage systems are gaining traction, driven by the necessity to move farming operations further offshore to mitigate environmental impact and capitalize on better water quality.

AI Impact Analysis on Fishing Cages and Nets Market

Common user questions regarding AI's impact typically revolve around how artificial intelligence can enhance operational efficiency, ensure the sustainability of aquaculture operations, and mitigate risks such as disease outbreaks and equipment failure. Users are particularly interested in the deployment of AI for real-time monitoring of net integrity and fish behavior, inquiring about the feasibility and cost-effectiveness of integrating sophisticated machine learning algorithms with existing sensor networks. The consensus points to high expectations regarding predictive maintenance, automated feeding schedules optimized by behavioral analysis, and the use of computer vision for biomass estimation, thereby reducing human intervention and enhancing data accuracy. The primary themes center on achieving higher yields with fewer resources while simultaneously guaranteeing ethical and sustainable practices through objective, data-driven decision-making.

The influence of AI is revolutionizing the design, deployment, and management of fishing cages and nets, moving the industry toward 'smart aquaculture' and predictive fishing models. AI-driven systems leverage data collected from underwater cameras, hydroacoustic sensors, and environmental probes (measuring temperature, salinity, oxygen levels) to provide comprehensive situational awareness. This continuous data stream, processed by machine learning models, allows farm operators to detect subtle changes in fish health or stress levels much earlier than traditional methods, leading to preemptive intervention and minimizing losses due to disease or suboptimal conditions. Furthermore, AI contributes to structural integrity monitoring, analyzing visual and sensor data from nets to predict stress points or potential damage from storms or marine predators, thereby extending the lifespan of expensive cage infrastructure.

In the context of wild fisheries, AI assists in optimizing trawling patterns and net deployment by integrating data on ocean currents, fish aggregation patterns, and environmental factors to maximize targeted catch efficiency while minimizing fuel consumption and non-target species interaction. This represents a significant step toward complying with global mandates for sustainable fisheries. For net manufacturers, AI algorithms are also being utilized in the material testing and design phase, simulating real-world stresses and environmental pressures to engineer stronger, lighter, and more durable netting materials, speeding up the product development cycle and delivering superior long-term performance.

- AI-driven predictive maintenance forecasts net damage, reducing unexpected failure and operational downtime.

- Machine learning optimizes automated feeding systems based on real-time fish appetite and biomass estimation, improving feed conversion ratios.

- Computer vision systems, powered by AI, autonomously monitor fish health, detecting parasites and diseases early within cage environments.

- AI algorithms analyze oceanographic data to guide commercial fishing vessels toward optimal fishing grounds, enhancing catch efficiency and selectivity.

- Integration of AI with sonar and sensor technology provides precise, continuous monitoring of environmental parameters inside aquaculture cages, ensuring compliance and optimal growing conditions.

DRO & Impact Forces Of Fishing Cages and Nets Market

The market dynamics are governed by a complex interplay of Drivers, Restraints, and Opportunities, which collectively constitute the Impact Forces shaping the industry's evolution. A primary driver is the necessity to meet the escalating global seafood demand, which places immense pressure on both wild-catch fisheries and farmed production, spurring investment in efficient harvesting infrastructure. Simultaneously, the industry faces significant restraints, notably stringent environmental regulations aimed at mitigating habitat damage and plastic pollution, alongside the technical challenge of persistent biofouling (the accumulation of organisms on submerged surfaces), which necessitates frequent, costly cleaning and maintenance.

Opportunities in the market center around innovation in smart technology and material science. The development of advanced anti-fouling coatings that are ecologically safe and the integration of sophisticated monitoring technologies (sensors, robotics) within cages represent critical avenues for growth, offering solutions to major operational hurdles. Furthermore, the global shift toward establishing large-scale, deep-water offshore aquaculture facilities, which require exceptionally robust, high-tensile nets and rigid cage structures, presents a lucrative niche for advanced equipment suppliers. These factors interact as impact forces, where regulatory shifts often compel technological adaptation (a restraint driving opportunity), leading to market growth in specific high-tech segments.

The major impact forces driving long-term change include shifting consumer preferences toward sustainably sourced protein, which mandates transparency and traceability throughout the supply chain, increasing the demand for certified, high-standard equipment. Moreover, climate change impacts, such as warming waters and increased storm frequency, necessitate the engineering of cages and nets capable of withstanding harsher marine conditions, pushing manufacturers to invest heavily in resilient materials and superior structural design. The competitive environment is also impacted by intellectual property related to knotless netting technologies and non-toxic treatments, creating barriers to entry and consolidating market leadership around innovators.

Segmentation Analysis

The Fishing Cages and Nets Market is broadly segmented based on Material Type, Product Type, Application, and Design, providing a detailed view of specific growth pockets and demand trends across the industry. Material segmentation, which includes traditional nylon, high-performance HDPE, durable polyester, and advanced synthetic materials like Aramid and Dyneema, reflects varying requirements for strength, elasticity, and anti-abrasion properties across different geographical and operational environments. Product Type segmentation distinguishes between various catch methods, such as trawls, gillnets, purse seines, and specialized cage systems for aquaculture, each serving distinct commercial objectives and market needs. Understanding these segment dynamics is crucial for suppliers aiming to tailor product offerings to the rapidly evolving demands of both industrial fishing fleets and modernized aquaculture farms.

The Application segmentation clearly delineates the market into Aquaculture and Commercial Fishing, with Aquaculture exhibiting the faster growth rate due to global investment trends in farmed seafood production. Within the aquaculture segment, further sub-segmentation based on the environment (offshore, nearshore, land-based recirculation systems) is becoming increasingly relevant, driving demand for specialized cage designs—submersible cages for rough waters versus surface cages for calmer areas. Regional segmentation remains vital, as regulatory frameworks and preferred fishing methods vary significantly between regions like Asia Pacific, which dominates in volume, and North America/Europe, which lead in high-value, technologically integrated solutions.

- Material Type

- Nylon

- High-Density Polyethylene (HDPE)

- Polyester

- Other Advanced Synthetics (e.g., Ultra-High Molecular Weight Polyethylene - UHMWPE)

- Product Type

- Trawls

- Gillnets

- Purse Seines

- Cages/Net Pens (Fixed, Floating, Submersible)

- Traps and Pots

- Application

- Aquaculture (Marine, Freshwater)

- Commercial Fishing (Industrial, Artisanal)

- Water Environment

- Marine (Saltwater)

- Freshwater (Inland Lakes and Rivers)

Value Chain Analysis For Fishing Cages and Nets Market

The value chain for the Fishing Cages and Nets Market begins with the upstream sourcing of raw materials, primarily petrochemical derivatives used to manufacture synthetic polymers such as nylon, polyethylene, and polyester. The quality and cost of these raw polymers are critical determinants of the final product's strength, durability, and market price. Following material sourcing, the manufacturing phase involves complex processes including fiber extrusion, spinning, twisting, and knotting (or knotless weaving), where specialized machinery is required to achieve the high tensile strength and uniform mesh size demanded by the industry. Efficiency and waste reduction in this phase directly influence the manufacturer's profit margins and environmental footprint, with modern factories adopting automation to enhance precision.

Distribution channels represent a critical midstream segment, encompassing both direct sales and indirect routes. Direct sales are often utilized for large, customized aquaculture projects, where manufacturers work closely with major fish farming corporations to design and install specific cage systems. Indirect channels involve a network of regional distributors, wholesalers, and specialized marine equipment retailers who manage inventory and provide local support to small to medium-sized commercial fishing operations and artisanal fishers. The effectiveness of the distribution network, particularly the ability to deliver timely repairs and replacement components, significantly impacts end-user satisfaction and operational continuity.

Downstream analysis focuses on the end-users, primarily large-scale aquaculture enterprises and commercial fishing fleets, whose purchasing decisions are heavily influenced by the gear's lifespan, biofouling resistance, compliance with local regulations, and overall efficiency in yield maximization. The industry is also supported by auxiliary services, including specialized net cleaning services, repair facilities, and technology integrators who install sensors and monitoring equipment within cages. This integrated approach ensures that the gear not only functions effectively but also provides valuable operational data, completing the value circle from polymer production to high-tech marine asset management.

Fishing Cages and Nets Market Potential Customers

The primary customers for fishing cages and nets fall into several distinct categories based on their operational scale and specialization. The largest segment comprises industrial aquaculture operators, ranging from multinational corporations managing vast offshore salmon or tuna farms to large regional entities focusing on shrimp, sea bass, or tilapia production. These customers require high-volume, extremely durable, and often technologically integrated net systems, including specialized submersible cages and robust mooring solutions. Their purchasing criteria prioritize long-term investment, structural resilience against harsh weather, and sophisticated anti-fouling capabilities to minimize maintenance costs and ensure optimal fish health and growth rates.

Another major customer group is the large-scale commercial fishing fleet, which utilizes modern trawls, purse seines, and gillnets for high-volume catches of species such as cod, tuna, or anchovies. These fleets demand gear optimized for efficiency, selectivity, and compliance with national and international fishing quotas and regulations, driving demand for materials that offer high breaking strength and low drag resistance. Their purchasing cycles are often influenced by regulatory changes dictating gear specifications (e.g., mesh size limits, mandatory escape panels) and the need to replace equipment degraded by constant exposure to extreme marine conditions.

Beyond these industrial sectors, a significant customer base includes small and medium-sized artisanal fishing communities and coastal operators, particularly prevalent in developing regions. Although they purchase lower volumes individually, their collective demand for traditional nets, traps, and pots made from reliable, cost-effective materials like standard nylon and polyester remains substantial. Furthermore, government agencies, marine research institutions, and conservation organizations also serve as niche customers, requiring specialized netting and caging systems for monitoring endangered species, conducting stock assessments, or managing aquatic resources within protected marine areas.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.2 Billion |

| Market Forecast in 2033 | USD 6.2 Billion |

| Growth Rate | CAGR 5.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | AKVA group, Gael Force Group, Garware Technical Fibres Ltd., net-sys International GmbH, Selstad AS, Kanirope GmbH, SFTec Inc., W&W Fishing Nets, Membco S.A., King Plastic Corporation, Nitto Seimo Co., Ltd., WireCo WorldGroup, Fiskevegn Group, Tufline Fish Nets, Inc., CNR Holding A/S, Morenot Group AS, Badinotti Group S.p.A., Hanes Supply, Inc., Cotesi - Companhia de Têxteis, Cords Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fishing Cages and Nets Market Key Technology Landscape

The technology landscape within the Fishing Cages and Nets Market is rapidly evolving, driven primarily by the need for greater sustainability, enhanced durability, and improved operational monitoring. A core technological focus is on material science, specifically the shift from traditional materials to advanced polymers like High-Density Polyethylene (HDPE) and Ultra-High Molecular Weight Polyethylene (UHMWPE). These materials offer significantly improved strength-to-weight ratios and superior resistance to abrasion and UV degradation compared to standard nylon or polyester, extending the operational lifespan of the gear and reducing replacement frequency. Furthermore, knotless netting technology is gaining prominence, as it offers a smoother surface profile that reduces injury to farmed fish, improves hydrodynamics (allowing better water flow), and minimizes the surface area available for biofouling attachment.

Another crucial technological development is the implementation of effective, environmentally acceptable anti-fouling solutions. Biofouling, the growth of marine organisms on the nets, reduces water exchange, diminishes oxygen levels for the fish, and increases the weight of the structure, demanding frequent, costly cleaning operations. Current innovations focus on non-toxic coatings, often based on silicone or specialized polymers, which create slick surfaces that impede organism adhesion without releasing harmful biocides into the marine environment. These passive anti-fouling strategies are increasingly being mandated by regulatory bodies in key aquaculture regions, positioning this technology as a significant market differentiator and growth area for chemical and material suppliers.

Furthermore, the integration of digital technologies and the Internet of Things (IoT) is fundamentally changing how cages and nets are managed. This includes the deployment of sophisticated underwater sensor networks that continuously monitor parameters such as net tension, structural integrity, water quality, and fish biomass. Remotely Operated Vehicles (ROVs) and autonomous underwater vehicles (AUVs), often guided by AI, are used for high-precision net inspection and cleaning, reducing the necessity for manual diving and improving safety. This technology landscape transforms the net cage from a passive containment structure into an active, data-generating asset, allowing for precision aquaculture management and enhancing resilience against environmental hazards.

Regional Highlights

Asia Pacific (APAC): The APAC region is the undisputed leader in both the volume of market consumption and production capacity, largely due to China's immense aquaculture industry and the extensive fishing fleets operated by Southeast Asian nations such as Vietnam, Indonesia, and Thailand. Regional growth is driven by massive governmental support for seafood production and a high concentration of artisanal fishing activities. While the region uses a mix of traditional and modern gear, there is an accelerating trend toward adopting advanced, durable cages and nets to improve efficiency and meet increasing export quality standards, particularly in high-value finfish farming.

Europe: Europe represents a high-value market segment characterized by stringent environmental regulations and a focus on sustainable, large-scale offshore aquaculture, particularly in Norway (salmon farming) and the Mediterranean. The market demands premium products, emphasizing technological integration, non-toxic anti-fouling solutions, and materials that guarantee high survivability and welfare standards for farmed fish. Technological innovation, including the use of specialized deep-water submersible cages and advanced monitoring systems, is predominantly initiated and adopted in this region, setting global benchmarks for quality and sustainability.

North America: The North American market, centered primarily in the US and Canada, exhibits robust demand driven by a growing appetite for farmed seafood and increasing investment in establishing high-tech marine aquaculture facilities, particularly in coastal areas previously resistant to fish farming. Regulatory frameworks are strict, necessitating investments in gear designed to prevent escape and minimize interaction with wild stocks. The region shows strong adoption rates for automated net cleaning services and highly resilient materials capable of withstanding rough oceanic conditions typical of the Pacific and North Atlantic coasts.

Latin America: Latin America is a significant producer, particularly in countries like Chile (salmon) and Ecuador (shrimp). The market features a blend of traditional fishing practices and rapidly modernizing aquaculture sectors. While cost sensitivity remains a factor for smaller operators, the large commercial aquaculture entities are actively seeking high-performance nets and cage systems to maximize export revenue and improve efficiency, particularly focusing on gear that offers durability and effective disease containment.

Middle East and Africa (MEA): The MEA region is experiencing emerging growth in its aquaculture sector, supported by government diversification initiatives aiming to enhance local food security and reduce reliance on imports. Investment is focused on establishing marine fish farms in the Gulf and coastal African nations. Demand is segmented, with high-tech solutions favored by Gulf states for their advanced infrastructure projects, while basic, durable netting is sought after in many African nations to support community-based fisheries and initial farming projects.

- Asia Pacific (APAC): Dominates in volume due to aquaculture scale in China and Southeast Asia; rapid adoption of knotless nets.

- Europe: Leads in high-value, sustainable offshore farming; high demand for bio-friendly anti-fouling treatments and sensor integration.

- North America: Strong growth driven by investment in marine aquaculture expansion; focus on gear resilience and escape prevention compliance.

- Latin America: Major producer, especially Chile and Ecuador; increasing need for durable gear that meets international export standards.

- Middle East and Africa (MEA): Emerging market driven by food security goals; mixed demand for basic and advanced systems depending on national investment capacity.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fishing Cages and Nets Market.- AKVA group

- Gael Force Group

- Garware Technical Fibres Ltd.

- net-sys International GmbH

- Selstad AS

- Kanirope GmbH

- SFTec Inc.

- W&W Fishing Nets

- Membco S.A.

- King Plastic Corporation

- Nitto Seimo Co., Ltd.

- WireCo WorldGroup

- Fiskevegn Group

- Tufline Fish Nets, Inc.

- CNR Holding A/S

- Morenot Group AS

- Badinotti Group S.p.A.

- Hanes Supply, Inc.

- Cotesi - Companhia de Têxteis

- Cords Ltd.

Frequently Asked Questions

Analyze common user questions about the Fishing Cages and Nets market and generate a concise list of summarized FAQs reflecting key topics and concerns.What materials are driving sustainability in modern fishing net production?

High-Density Polyethylene (HDPE) and Ultra-High Molecular Weight Polyethylene (UHMWPE) are primary drivers of sustainability, offering exceptional durability and reduced need for frequent replacement, which minimizes waste. Additionally, the development of non-toxic, bio-friendly anti-fouling coatings is crucial for ecological integrity.

How is the market addressing the environmental issue of biofouling in aquaculture cages?

The market addresses biofouling through two main avenues: utilizing non-biocidal coatings (e.g., silicone-based, naturally slick polymers) that prevent organisms from adhering, and integrating automated net cleaning systems, often operated by ROVs, which minimize manual labor and damage to the net structure.

Which application segment shows the fastest growth rate in the Fishing Cages and Nets Market?

The Aquaculture segment is currently demonstrating the fastest growth rate, driven by significant global investment in large-scale offshore fish farming projects and the strategic necessity for advanced, durable containment systems to meet rising global seafood demand.

What role does Artificial Intelligence (AI) play in modern net cage management?

AI is essential for advanced cage management, primarily through predictive maintenance of net structures, optimized automated feeding schedules based on behavioral analytics, and real-time monitoring of fish health and biomass estimation using computer vision systems.

What is the primary factor restraining market growth in developed regions?

The most significant restraint in developed regions, such as North America and Europe, is the increasing stringency of environmental regulations regarding marine plastics, net disposal, and the prohibition of traditional toxic anti-fouling chemicals, requiring manufacturers to invest heavily in costly R&D for compliant solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager