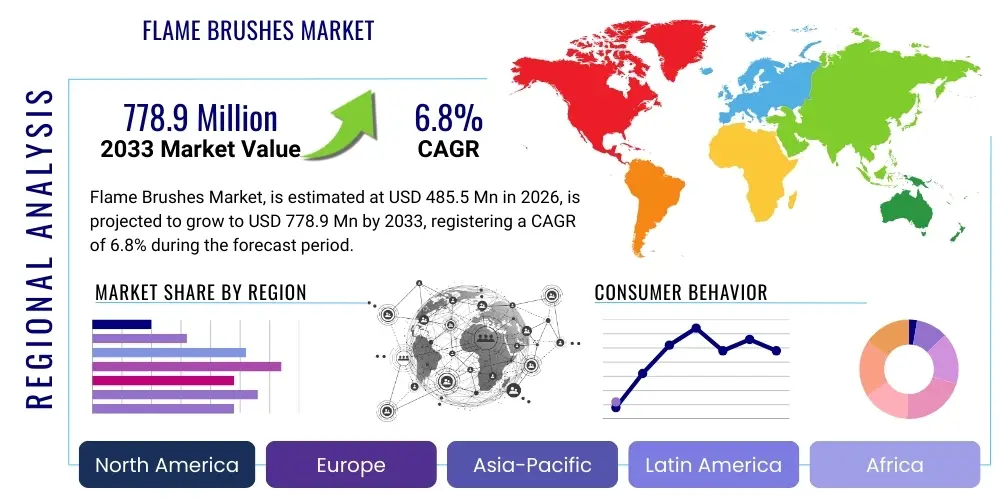

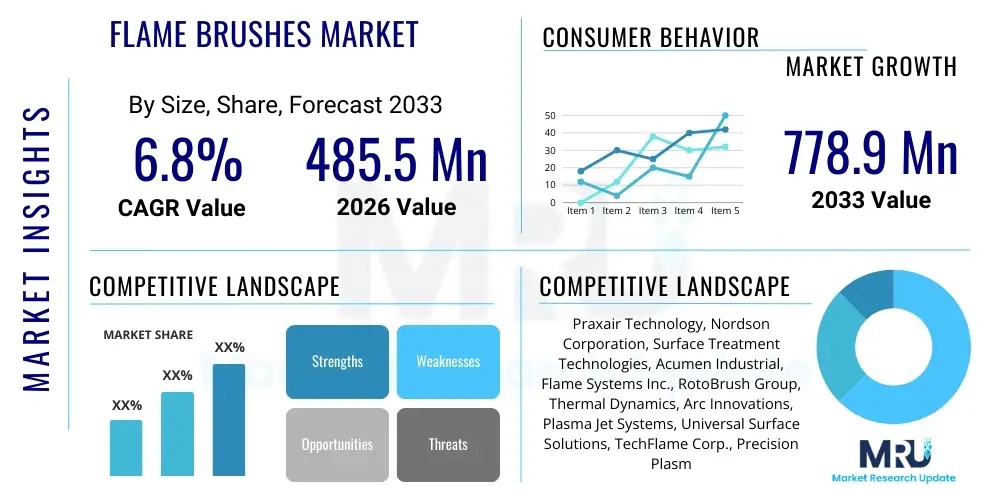

Flame Brushes Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438491 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Flame Brushes Market Size

The Flame Brushes Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $485.5 Million in 2026 and is projected to reach $778.9 Million by the end of the forecast period in 2033. This growth trajectory is fundamentally driven by increasing industrial demands for advanced, non-contact surface preparation techniques and specialized cleaning in high-temperature manufacturing environments, particularly within the aerospace, automotive coating, and specialized fabrication sectors. The market expansion reflects a shift towards technologies that offer higher precision and reduced material degradation compared to traditional mechanical brushing or chemical treatments.

Flame Brushes Market introduction

The Flame Brushes Market encompasses specialized tools and equipment primarily designed for surface modification, cleaning, and preparation using highly controlled thermal energy sources, often referred to as plasma or highly focused flame application devices. These instruments are utilized across a spectrum of industries where achieving precise surface energy, removing oxides or contaminants, or creating specific aesthetic finishes is critical. The technology leverages high-intensity thermal exposure to rapidly alter the surface material without causing significant structural damage to the substrate, positioning it as an essential tool in advanced manufacturing processes. Flame brushes differ significantly from conventional abrasive tools by relying on thermal and oxidative reactions to achieve the desired effect, offering superior speed and uniformity in many applications.

Major applications include the pre-treatment of plastics and composites to enhance adhesion for subsequent painting or bonding processes, high-speed cleaning of metallic components prior to welding or coating (such as thermal spray applications), and precise removal of paint or residue in sensitive restoration projects. The product description emphasizes controllability, portability, and efficiency, offering significant benefits over traditional methods. Flame brushing technology ensures minimal waste, reduces reliance on harmful chemical solvents, and provides rapid throughput capabilities, making it highly attractive to lean manufacturing environments and sectors operating under stringent environmental regulations. The inherent precision of these tools allows for localized treatment, minimizing impact on surrounding areas.

Driving factors for the adoption of flame brushes include the increasing complexity of engineered materials requiring tailored surface energy levels, stringent quality control standards in high-value industries like aerospace and medical devices, and the general industrial push towards automation and faster processing times. Furthermore, the growing global focus on sustainable manufacturing practices favors flame brushing systems, as they typically have a smaller environmental footprint compared to chemical etching or heavy abrasive blasting. The adaptability of the technology across different material types—from metals and ceramics to polymers—ensures broad market applicability and sustained demand across various industrial segments seeking optimized performance and regulatory compliance.

Flame Brushes Market Executive Summary

The Flame Brushes Market is experiencing robust growth driven by accelerating demand for specialized surface preparation techniques in high-precision manufacturing sectors. Key business trends indicate a strong move towards compact, automated, and robot-integrated flame brushing systems to enhance scalability and operational efficiency. Manufacturers are focusing heavily on developing brushes with superior energy control mechanisms, integrating sensors for real-time temperature monitoring, and offering multi-functional units capable of handling diverse materials. Strategic alliances between equipment providers and material science companies are shaping product innovation, aiming to address novel challenges presented by lightweight composites and advanced alloys. Investment in research and development (R&D) is concentrated on improving fuel efficiency and reducing the thermal footprint, aligning with global industrial sustainability goals.

Regionally, Asia Pacific (APAC) dominates the market, fueled by massive growth in the automotive, electronics manufacturing, and infrastructure development sectors, particularly in China, Japan, and South Korea, which require high-volume, precise surface treatments. North America and Europe, however, lead in technological adoption, focusing on niche, high-value applications such as aerospace component manufacturing and medical device sterilization preparation, driven by strict regulatory standards and high labor costs necessitating automation. Emerging markets in Latin America and the Middle East are showing accelerated uptake, largely concentrated within oil and gas infrastructure maintenance and localized manufacturing expansion. This geographical spread highlights the technology’s versatility and its critical role in various industrial economies globally.

Segment-wise, the market is characterized by differentiation based on heat source technology (e.g., plasma, oxy-fuel, catalytic) and application modality (manual vs. automated systems). The automated segment is projected to exhibit the highest CAGR due to widespread integration into production lines. By end-use, the automotive segment remains the largest consumer, utilizing flame brushes extensively for adhesion promotion and surface cleaning prior to painting. Simultaneously, the specialized coatings and aesthetics segment, encompassing sectors such as artistic metal finishing and high-end consumer goods, is rapidly gaining traction. These segment trends underscore a market balancing the demands of high-volume industrial throughput with specialized, high-tolerance niche applications, demanding continuous refinement in brush size, intensity control, and material compatibility.

AI Impact Analysis on Flame Brushes Market

User queries regarding the impact of Artificial Intelligence (AI) on the Flame Brushes Market frequently center on how AI can optimize the process parameters, predict equipment maintenance needs, and enhance quality control during high-speed operations. Key themes include the integration of machine vision for detecting surface defects post-treatment, the use of predictive algorithms to dynamically adjust flame intensity based on material feedback, and leveraging reinforcement learning to optimize brush path planning in complex geometries. Users are primarily concerned with reducing variability, minimizing material wastage due to overheating or insufficient treatment, and achieving verifiable, traceable results for compliance purposes. The expectation is that AI integration will transform flame brushing from a skilled operator task to a precision-engineered, autonomous process, substantially improving throughput and consistency, particularly in robotic welding and automated painting lines.

- AI-driven optimization of thermal parameters (temperature, velocity, mixture ratio) in real-time based on material composition and ambient conditions.

- Predictive maintenance scheduling for flame brush nozzles and fuel delivery systems, minimizing unexpected downtime and maximizing operational lifespan.

- Integration of AI-powered machine vision systems for post-treatment quality assurance, detecting subtle anomalies in surface energy or texture instantly.

- Enhanced robot path planning and collision avoidance using AI algorithms for precise treatment of components with intricate or variable geometries.

- Autonomous process control utilizing deep learning to self-calibrate systems and achieve specific, repeatable surface finishes required for certification.

- Simulation and digital twin creation to model the thermal impact of flame brushing on novel materials before physical application, accelerating R&D cycles.

DRO & Impact Forces Of Flame Brushes Market

The Flame Brushes Market dynamics are governed by a complex interplay of Drivers, Restraints, and Opportunities (DRO), significantly influencing its growth trajectory. The primary driver is the pervasive need for superior surface preparation in advanced manufacturing, where traditional mechanical abrasion or solvent cleaning falls short in achieving the necessary surface activation or cleanliness required for modern adhesion technologies and high-performance coatings. Restraints mainly revolve around the inherent safety risks associated with handling high temperatures and flammable gases, alongside the high initial capital investment required for automated, high-precision flame brushing equipment. Opportunities, conversely, are vast, driven by the emergence of new composite materials and the increasing industrial adoption of robotic systems that integrate flame brushing for enhanced process automation, particularly in sectors demanding zero-defect production standards. These forces collectively shape the market's competitive landscape and technological investment priorities.

Impact forces in the Flame Brushes Market relate specifically to technological advancements and regulatory pressures. The impact of technological evolution is substantial, with continuous improvements in thermal control systems, fuel efficiency, and nozzle designs making the process safer, faster, and more economical, thus increasing adoption rates across diverse industrial bases. Economic fluctuations, particularly in the manufacturing and construction sectors, exert a moderate impact, affecting capital expenditure on specialized equipment. Crucially, the increasing stringency of global Environmental, Social, and Governance (ESG) regulations strongly favors flame brushing as a greener alternative to chemical surface treatments, creating a powerful positive impact force that mandates industrial migration towards cleaner technologies. Furthermore, competitive intensity compels key market players to constantly innovate and differentiate their offerings through superior proprietary control software and service contracts.

The core drivers sustaining market momentum include the expansion of the electric vehicle (EV) sector, where pre-treatment of battery components and composite body panels is essential for durability and safety, and the burgeoning demand for specialized surface activation of medical implants and devices, which require bio-compatible and highly adhesive surfaces. Key restraints, besides cost and safety, include the specialized training required for operators to manage and maintain these complex systems, and the limited throughput capacity in extremely high-volume, low-margin applications where speed is paramount. However, the market is capitalizing on opportunities presented by additive manufacturing (3D printing), where flame brushing is emerging as a critical post-processing step to remove support structures and condition surfaces of complex printed parts. This balance between inherent technological limitations and massive application potential dictates the overall growth pace and strategic direction of the Flame Brushes Market through the forecast period.

Segmentation Analysis

The Flame Brushes Market is comprehensively segmented based on technology type, application modality, end-use industry, and geographical region, providing granular insights into market dynamics and consumer behavior across various industrial verticals. The segmentation by technology type differentiates systems based on the primary energy source utilized to generate the thermal effect, encompassing sophisticated plasma systems that offer superior control and localized heating, against traditional and more cost-effective oxy-fuel systems. Application modality splits the market into manual, semi-automated, and fully automated/robotic systems, reflecting the varied scale and complexity of end-user operations. This detailed structure allows stakeholders to precisely identify high-growth niches, tailor their product development to meet specific industrial demands, and refine strategic market entry approaches based on regional technological readiness and industrial maturity.

- By Technology Type:

- Plasma Flame Brushes

- Oxy-Fuel Flame Brushes

- Catalytic/Infrared Flame Systems

- High-Velocity Air-Fuel (HVAF) Systems (Specialized)

- By Application Modality:

- Manual/Handheld Systems

- Semi-Automated Systems

- Fully Automated/Robotic Systems

- By End-Use Industry:

- Automotive and Transportation (Pre-painting, Welding Preparation)

- Aerospace and Defense (Composite Surface Activation, De-oxidation)

- Electronics and Semiconductors (Cleaning, Surface Energy Adjustment)

- Medical Devices (Sterilization Preparation, Adhesion Promotion)

- Oil and Gas (Pipeline Maintenance, Coating Removal)

- Construction and Infrastructure (Surface Sealing, Restoration)

- Specialized Coatings and Aesthetics

Value Chain Analysis For Flame Brushes Market

The value chain for the Flame Brushes Market begins with upstream activities focused on the procurement and processing of raw materials, primarily specialized alloys for nozzle manufacturing, high-quality ceramics for insulation, and advanced electronic components for control systems and automation interfaces. Key upstream suppliers include industrial gas producers (for oxy-fuel systems), precision engineering firms providing fluid dynamics components, and software developers specializing in process control algorithms. The core manufacturing stage involves complex integration of these components, focusing on safety compliance, thermal stability, and ergonomic design for handheld units or robust integration features for robotic systems. Value is added significantly at this stage through proprietary nozzle design and the development of intelligent feedback loops necessary for precise surface treatment, establishing high barriers to entry for new competitors who lack expertise in thermal management and material science.

The distribution channel plays a critical role in connecting specialized manufacturers to diverse industrial end-users. Direct sales are prevalent for large, custom-integrated automated systems, allowing manufacturers to offer bespoke installation, training, and long-term maintenance contracts, establishing strong customer relationships. Indirect channels utilize specialized industrial equipment distributors and third-party system integrators, particularly for smaller, standardized handheld or semi-automated units. These distributors must possess deep technical knowledge about surface preparation to effectively service niche markets like medical device manufacturing or specialized automotive repair facilities. The effectiveness of the distribution network is crucial for market penetration, especially in geographically dispersed or emerging industrial economies, requiring distributors to stock specialized consumables and offer localized technical support efficiently.

Downstream activities involve the end-use application, maintenance, and eventual system upgrades. Significant value is captured by maintenance service providers who offer calibration, repair, and certification services for regulatory compliance, given the safety-critical nature of the equipment. Furthermore, the market benefits from continuous revenue streams generated through the sale of specialized consumables, such as replacement nozzles, gas cylinders, and proprietary monitoring sensors. The ultimate value delivery is realized by the end-user through improved product quality, enhanced manufacturing efficiency, and reduced environmental impact compared to legacy processes. Manufacturers increasingly focus on lifecycle service models and software updates to ensure continuous performance optimization and sustained downstream revenue generation, cementing long-term customer lock-in through superior after-sales support and technological modernization programs.

Flame Brushes Market Potential Customers

The potential customers for Flame Brushes Market solutions are predominantly high-value manufacturing and maintenance sectors requiring precise surface energy control or efficient coating removal without damaging the substrate material. These customers include large-scale Original Equipment Manufacturers (OEMs) in the automotive industry, where flame brushing is vital for preparing plastic bumpers and composite panels for paint adhesion, ensuring the longevity and aesthetic quality of the final product. Aerospace manufacturers represent another critical customer segment, utilizing the technology for de-oxidizing complex metal alloys prior to bonding or welding, and preparing advanced composite structures for structural adhesive application under stringent FAA/EASA regulatory scrutiny. These customers prioritize reliability, traceability, and the ability to handle exotic materials effectively.

Another significant group comprises specialized surface treatment contractors and job shops that provide outsourced preparation services to various industries. These businesses invest in flexible, high-throughput automated flame brushing systems to service multiple clients requiring diverse material processing capabilities, focusing heavily on reducing turnaround time and operational costs. Furthermore, the oil and gas industry represents a crucial potential customer base, utilizing mobile flame brushing units for pipeline inspection, maintenance, and the rapid removal of aged protective coatings or corrosion before applying new protective layers, where speed and minimal substrate disruption are paramount in harsh operating environments. For this segment, robust, field-deployable equipment designed for extreme conditions is a key purchasing criterion.

The market also targets niche segments such as high-end custom fabricators, artistic metalworkers, and the medical device sector. Medical device manufacturers, particularly those creating implants or surgical instruments, use flame brushing to achieve highly sterile and receptive surfaces for biocompatible coatings or permanent marking, where precision on a micro-scale is mandatory. These customers demand systems that comply with ISO 13485 standards and offer validated, repeatable results. Collectively, potential customers are unified by their need for a surface preparation technology that is cleaner, faster, more consistent, and ultimately more economical than chemical or mechanical alternatives for applications where quality failure is intolerable, driving continuous investment in sophisticated flame brushing solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $485.5 Million |

| Market Forecast in 2033 | $778.9 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Praxair Technology, Nordson Corporation, Surface Treatment Technologies, Acumen Industrial, Flame Systems Inc., RotoBrush Group, Thermal Dynamics, Arc Innovations, Plasma Jet Systems, Universal Surface Solutions, TechFlame Corp., Precision Plasma Tools, Metco Systems, Global Surface Prep, CleanCoat Robotics, Fusion Tech, Advanced Plasma Technologies, PyroClean Solutions, Jetstream Surface Prep, ThermoTech Automation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Flame Brushes Market Key Technology Landscape

The Flame Brushes Market technology landscape is dominated by sophisticated thermal engineering solutions designed to deliver highly controllable and uniform heat application. The most advanced systems utilize Cold Plasma Technology, which offers precise surface activation at lower temperatures than traditional combustion methods, significantly minimizing the risk of thermal damage to sensitive substrates like thin-film polymers or lightweight composites. Key technological advancements center on optimizing the plasma jet stream geometry and energy density, allowing for highly localized treatment and integration into complex robotic work cells. Furthermore, modern flame brushing equipment incorporates advanced sensor suites, including pyrometers and spectroscopic analyzers, enabling real-time feedback loops that automatically adjust gas mixture ratios or electrical input to maintain exact surface temperature requirements, thus ensuring process repeatability and verifiable quality control metrics necessary for regulatory compliance in demanding sectors like aerospace and medical devices.

Another crucial technological trend is the convergence of flame brushing systems with Industry 4.0 principles, facilitated by integrated IoT (Internet of Things) connectivity and proprietary software platforms. These systems collect and analyze vast amounts of operational data regarding gas consumption, operational hours, nozzle wear, and treatment effectiveness, feeding into centralized Manufacturing Execution Systems (MES) for holistic production management. This connectivity supports predictive maintenance models and facilitates remote diagnostics, drastically improving equipment uptime and reducing total cost of ownership. The focus on modular design is also prominent, enabling end-users to quickly swap out different brush heads or nozzles tailored for specific tasks—such as wide-area surface cleaning versus fine line activation—enhancing the versatility and operational flexibility of the core equipment platform, addressing the highly customized nature of modern manufacturing.

The continuous push for sustainability drives innovation in fuel and energy efficiency. Research is concentrated on developing high-efficiency catalytic systems that require less fuel or utilize alternative, cleaner energy sources, minimizing greenhouse gas emissions associated with the process. Furthermore, manufacturers are investing in highly ergonomic designs for manual flame brushes, incorporating lightweight, thermally isolated materials and intuitive controls to improve operator safety and reduce fatigue during prolonged use. The overall technology landscape is moving towards fully autonomous, self-optimizing thermal treatment cells that require minimal human intervention, ensuring that the Flame Brushes Market remains at the forefront of surface engineering solutions capable of meeting the stringent quality and environmental standards of the future global industrial base.

Regional Highlights

Geographical analysis reveals significant disparities in adoption rates and end-use application focus across major global regions, largely correlated with the maturity of local manufacturing sectors and regulatory environment concerning surface treatment methods. Asia Pacific (APAC) holds the leading position in market share, driven primarily by the high volume of automotive manufacturing, rapid infrastructure development, and substantial investment in the regional electronics supply chain, particularly in countries like China, India, and Vietnam. The demand in APAC is characterized by a need for high-throughput, moderately priced automated systems capable of large-scale surface preparation for consumer goods and general industrial components. This region's dominance is further solidified by favorable governmental policies supporting local industrial expansion and technology adoption in factory automation.

North America represents a mature, high-value market characterized by early adoption of advanced plasma flame brushing technologies, particularly within the aerospace and defense and high-end medical device manufacturing sectors. The regional focus is heavily weighted towards quality, traceability, and the integration of highly complex, robotic systems into existing production lines. Driven by stringent quality control standards and high labor costs, North American manufacturers prioritize automation, demanding solutions that offer verifiable process control and minimal risk of material damage. The presence of leading technology developers and significant R&D investment ensures continuous innovation tailored to the demands of specialty materials used in these highly regulated industries.

Europe, driven by the robust German and Italian manufacturing base, focuses on both automotive excellence and precision engineering. The European market distinguishes itself through a strong emphasis on sustainability and adherence to rigorous environmental directives (such as REACH), favoring flame brushing solutions as a cleaner alternative to traditional chemical processes. Demand is high for energy-efficient, low-emission oxy-fuel and plasma systems. The region also exhibits strong growth in the specialized coatings sector, utilizing flame brushes for aesthetically demanding applications and for surface treatment of recycled materials, aligning with the circular economy framework promoted by the European Union.

Latin America is emerging as a growth region, primarily fueled by the expansion of localized automotive assembly plants, heavy machinery manufacturing, and significant investment in the construction and infrastructure sectors. The market here is price-sensitive, initially favoring more cost-effective oxy-fuel and semi-automated systems. However, as foreign investment increases and manufacturing complexity rises, there is a clear trajectory towards adopting more sophisticated plasma systems to meet export quality standards. Brazil and Mexico are the regional hubs for demand, focusing on applications related to surface preparation for anticorrosion coatings and paint adhesion.

The Middle East and Africa (MEA) market growth is largely concentrated in sectors related to oil and gas exploration, energy infrastructure maintenance, and localized military/defense fabrication. The harsh operating environments prevalent in the Gulf Cooperation Council (GCC) countries necessitate robust, reliable flame brushing equipment for the maintenance and repair of pipelines, storage tanks, and industrial complexes, focusing heavily on coating removal and surface cleaning prior to inspection. Demand in Africa is nascent but growing, driven by mining and general infrastructure projects, requiring durable, easily transportable manual and semi-automated units suitable for remote site operation and maintenance.

- North America: Focus on aerospace, medical devices; high automation rate; leading in cold plasma technology adoption.

- Europe: Driven by strict environmental regulations (REACH); strong demand in automotive and precision engineering; emphasis on energy efficiency.

- Asia Pacific (APAC): Largest market share; high-volume demand from automotive and electronics; rapid adoption of automated systems in China and South Korea.

- Latin America: Emerging market; strong growth in localized manufacturing and construction; demand for cost-effective, durable equipment.

- Middle East and Africa (MEA): Growth driven by oil and gas infrastructure maintenance; preference for rugged, field-ready systems for coating removal and surface preparation in demanding environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Flame Brushes Market.- Praxair Technology

- Nordson Corporation

- Surface Treatment Technologies

- Acumen Industrial

- Flame Systems Inc.

- RotoBrush Group

- Thermal Dynamics

- Arc Innovations

- Plasma Jet Systems

- Universal Surface Solutions

- TechFlame Corp.

- Precision Plasma Tools

- Metco Systems

- Global Surface Prep

- CleanCoat Robotics

- Fusion Tech

- Advanced Plasma Technologies

- PyroClean Solutions

- Jetstream Surface Prep

- ThermoTech Automation

Frequently Asked Questions

Analyze common user questions about the Flame Brushes market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a Flame Brush and how does it differ from traditional abrasive methods?

A Flame Brush is a specialized industrial tool using highly controlled thermal energy (flame or plasma) to clean, activate, or modify a material surface. Unlike abrasive methods, it achieves surface preparation by oxidation and thermal activation rather than mechanical removal, resulting in superior adhesion promotion and minimal substrate damage, which is vital for composites and thin materials.

Which industries are the primary users of Flame Brushes for surface activation?

The primary users include the Automotive and Transportation sector, utilizing flame brushes for pre-treatment of plastic and composite parts before painting; the Aerospace and Defense sector for bonding preparation; and the Medical Device industry for preparing surfaces for specialized biocompatible coatings and sterilization.

How does the integration of AI affect the precision and quality of the Flame Brushing process?

AI significantly enhances precision by enabling real-time adjustments of thermal parameters and gas mixtures based on continuous sensor feedback. This optimization minimizes overheating risks, ensures uniform surface energy across complex geometries, and integrates machine vision for immediate, autonomous quality assurance post-treatment, ensuring higher consistency and traceability.

Are Flame Brushing systems considered environmentally friendly compared to chemical surface preparation?

Yes, Flame Brushing systems are generally considered more environmentally friendly than chemical surface preparation as they eliminate the need for hazardous solvents and volatile organic compounds (VOCs). The process typically produces fewer toxic byproducts and simplifies waste disposal, aligning closely with strict global ESG and industrial sustainability standards.

What are the key drivers for the high adoption rate of automated Flame Brushing systems?

The key drivers for automated system adoption are the need for high-speed throughput in mass production environments, the requirement for absolute process repeatability crucial for certification, and the ongoing industrial effort to mitigate high labor costs and safety risks associated with manual operation of high-temperature equipment in manufacturing lines.

The preceding analysis provides a foundational understanding of the Flame Brushes Market, detailing the technological advancements, critical growth drivers, and geographic dynamics shaping its future. The market's shift towards precision and automation, powered by advancements in plasma technology and AI integration, positions flame brushing as an indispensable technique for modern high-value manufacturing across global industrial sectors. Continued investment in R&D focusing on efficiency and environmental compliance will ensure sustained growth and market leadership throughout the forecast period.

Further examination into the competitive strategies of key players reveals a strong emphasis on patented nozzle designs and proprietary software control systems. Companies are strategically expanding their global footprint through localized manufacturing and service centers, particularly targeting the rapidly industrializing regions of Asia Pacific and Latin America. Strategic acquisitions and vertical integration are common tactics employed to secure supply chains for specialized thermal components and to consolidate market share in niche applications such as aerospace composite preparation and medical device surface engineering. The long-term viability of market participants will depend heavily on their ability to offer comprehensive, integrated solutions that seamlessly merge hardware robustness with sophisticated digital process control capabilities, addressing the increasing demand for verifiable, high-quality output in automated production environments.

Market segmentation based on technology type continues to show an accelerating divergence between traditional oxy-fuel systems, which maintain dominance in cost-sensitive heavy industrial applications (like shipbuilding and construction), and advanced plasma systems that capture premium pricing and market share in high-precision, low-volume sectors (like microelectronics and specialized coatings). Manufacturers are also heavily investing in modular solutions that allow users to scale their operations efficiently. For instance, designing equipment where the same base power unit can interface with interchangeable heads for different thermal intensities or gas mixtures provides immense flexibility, driving greater customer adoption across various application modalities, from small benchtop R&D use to full-scale robotic integration on large assembly lines. This diversification strategy is crucial for mitigating risks associated with reliance on a single end-use industry and capturing the full spectrum of demand within the industrial ecosystem.

In terms of regulatory impact, the Flame Brushes Market faces dual pressures. On one hand, safety and occupational health regulations regarding the use of high-temperature processes and industrial gases necessitate costly design features, such as advanced shielding, automated shutdown mechanisms, and continuous gas monitoring, contributing to the overall cost of equipment. On the other hand, the tightening grip of environmental regulations on solvent usage and waste disposal actively creates demand for flame brushing as a compliant, clean process alternative. This positive regulatory pressure is most evident in the European Union, where chemical restrictions incentivize the rapid migration away from conventional chemical etching and cleaning methods towards non-contact thermal treatments. Consequently, manufacturers prioritizing regulatory compliance and certified safety features are gaining a decisive competitive edge, positioning their products as the industry standard for sustainable surface preparation practices.

Looking forward, the influence of additive manufacturing (AM), or 3D printing, is poised to create a substantial new avenue for the Flame Brushes Market. As complex metallic and polymer parts are increasingly produced via AM, post-processing to remove residual powder, support structures, and to achieve optimal surface finish becomes a bottleneck. Flame brushing offers a high-speed, non-mechanical solution for smoothing surfaces and preparing them for subsequent coatings or treatments, overcoming limitations of traditional sandblasting or milling for intricate internal geometries. This emerging application requires the development of highly specialized, miniaturized flame brushes and micro-plasma jets capable of accessing and treating fine features, representing a key area of future technological investment and market opportunity that will sustain high growth rates for the automated and precision segments of the market in the latter half of the forecast period.

The global supply chain stability remains a moderate factor impacting the market, particularly concerning the availability of industrial gases and specialized electronic controllers sourced primarily from Asia. Geopolitical tensions and logistical disruptions can affect production timelines and increase procurement costs, thereby influencing the final price point for automated systems. To mitigate these risks, leading market participants are increasingly diversifying their sourcing strategies and establishing regional assembly plants closer to major end-user markets. This shift towards regionalization not only enhances supply chain resilience but also allows manufacturers to better customize their product specifications—such as complying with local electrical standards or utilizing locally preferred fuel sources—ultimately improving customer satisfaction and market access across various geographies simultaneously.

The human capital requirement within the Flame Brushes Market is also evolving. While initial restraints included the need for highly specialized operators, the introduction of advanced automation and AI-driven control systems is shifting the skill requirement from manual dexterity to process management and data interpretation. Manufacturers are now offering extensive training and certification programs focusing on software operation, predictive maintenance analysis, and advanced troubleshooting techniques for integrated robotic cells. This trend indicates that the market is professionalizing, moving away from reliance on operator skill towards reliance on system intelligence, thereby ensuring more consistent output and reducing the impact of human error, which is critical for zero-defect manufacturing mandates in high-stakes environments like aerospace component fabrication.

Finally, the strategic importance of intellectual property (IP) protection within the Flame Brushes Market cannot be overstated. Companies heavily invest in patenting novel nozzle geometries, proprietary gas mixing methods, and specific thermal profiles tailored for unique material combinations. This focus on IP creates a strong competitive advantage, allowing technology leaders to command premium pricing and safeguard their innovations against replication. The ongoing patent battles, particularly in the plasma technology segment, underscore the high value placed on these technological differentiators. Companies that successfully develop and protect unique solutions addressing specific industrial challenges—such as low-temperature activation of heat-sensitive polymers or ultra-fast de-oxidation of titanium alloys—are best positioned to dominate their respective market niches and dictate future technological standards within the global surface preparation industry.

The expansion of the electric vehicle (EV) market presents a unique and massive opportunity. EV battery production requires meticulous surface preparation for cell bonding and housing sealing to ensure safety and longevity. Flame brushing offers a reliable method for cleaning and activating the polymer and metal surfaces of battery components before the application of adhesives or sealants. Given the expected exponential growth in EV manufacturing across APAC, North America, and Europe, manufacturers supplying customized, high-precision flame brushing systems capable of integration into high-volume battery assembly lines are expected to see disproportionate growth. This segment demands specialized equipment designed to handle thermally sensitive battery materials with extreme precision, further driving innovation in cold plasma and low-impact thermal technology.

The analysis of competitive dynamics shows that while established industrial equipment providers lead in market share, smaller, specialized technology firms are driving significant innovation, particularly in the integration of AI and machine learning for process optimization. These smaller players often partner with major robotic manufacturers to offer turnkey automated solutions. The focus for competitive differentiation is moving beyond mere hardware performance to include the sophistication of the process control software, the ability to offer remote diagnostics, and the integration of certified quality verification modules. Long-term success requires a balance between robust, durable hardware necessary for harsh industrial environments and highly adaptable, intelligent software capable of meeting diverse and evolving surface treatment requirements across various materials.

In summary, the Flame Brushes Market is undergoing a rapid technological evolution, shifting its value proposition from simple surface cleaning to advanced surface engineering. The confluence of sustainability mandates, automation trends, and the demand for high-performance materials in critical sectors ensures a stable and accelerating growth trajectory. Regional market strategies must account for varying regulatory environments and industrial maturity levels, while product development must prioritize safety, efficiency, and integration capabilities to capitalize on emerging opportunities in additive manufacturing and the rapidly expanding electric vehicle supply chain. The strategic framework demands continuous innovation and strong intellectual property protection to maintain competitive relevance in this specialized yet crucial segment of the industrial equipment landscape.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager