Flame Retardant Polyester Fiber Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431810 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Flame Retardant Polyester Fiber Market Size

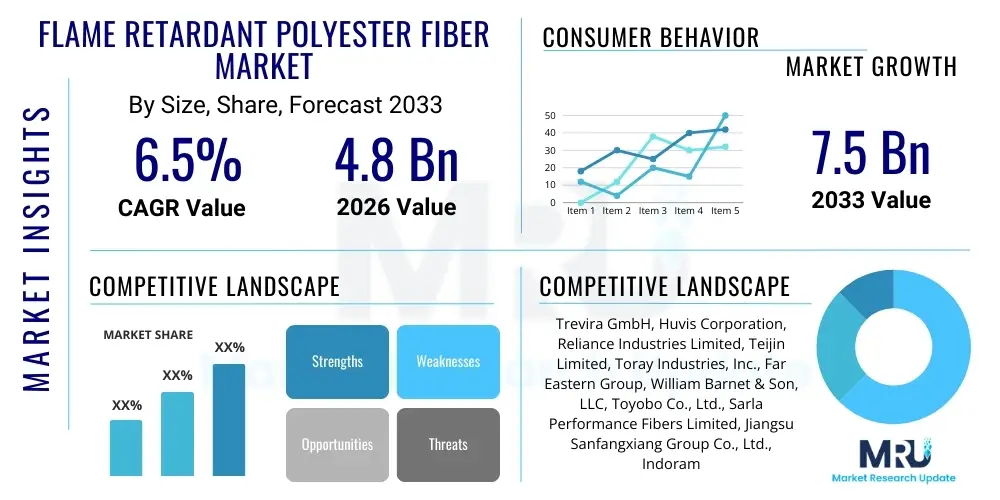

The Flame Retardant Polyester Fiber Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 4.8 Billion in 2026 and is projected to reach USD 7.5 Billion by the end of the forecast period in 2033.

Flame Retardant Polyester Fiber Market introduction

The Flame Retardant Polyester Fiber Market encompasses specialized synthetic fibers engineered to significantly inhibit ignition and slow the spread of fire. These fibers are distinct from standard polyester due to the incorporation of flame-retardant (FR) additives—either intrinsically modified during polymerization (co-polymerization) or applied externally as a finish. This modification is crucial for meeting stringent fire safety regulations across various industries, providing a vital safety layer in materials that might otherwise pose a fire risk, particularly in enclosed spaces or high-occupancy environments. The inherent durability and cost-effectiveness of polyester, combined with enhanced fire resistance, position FR polyester fibers as a primary choice over many traditional materials, fueling steady market expansion.

The product finds major applications across diverse sectors, prominently in textiles for home furnishings such as curtains, upholstery, and mattresses, where public safety standards are paramount. Furthermore, its use extends heavily into technical textiles, automotive interiors, transportation (aerospace and rail), and protective apparel, including specialized uniforms and industrial workwear. These fibers are valued not only for their thermal performance but also for maintaining the desirable properties of polyester, such as resistance to shrinking, stretching, mildew, and chemical degradation. The continuous evolution of additive technology, shifting from halogenated to non-halogenated (such as phosphorus-based) systems, reflects the industry's commitment to both performance efficacy and environmental sustainability, ensuring the material remains competitive and compliant with emerging global safety and ecological mandates.

Key benefits driving market adoption include compliance with global fire safety certifications (e.g., NFPA, IMO, EN standards), superior wash fastness for intrinsically FR types, reduced smoke generation compared to untreated materials, and excellent physical stability. The primary driving factors are the increasing global urbanization and the resultant boom in construction activities requiring fire-safe interiors, coupled with tightening regulatory frameworks mandated by governments, particularly in North America and Europe, following high-profile fire incidents. Additionally, the rapid growth of the travel and tourism sector necessitates fire-safe bedding and interior materials in hotels and cruise ships, further accelerating the demand for these specialized textile products.

Flame Retardant Polyester Fiber Market Executive Summary

The Flame Retardant Polyester Fiber Market is currently characterized by significant growth, driven predominantly by stricter global fire safety regulations and rapid infrastructural development, especially in the Asia Pacific region. Key business trends include a strong industry pivot toward sustainable, non-halogenated flame retardant systems (such as phosphorus and nitrogen compounds) to address growing health and environmental concerns associated with traditional bromine- and chlorine-based additives. Manufacturers are focusing heavily on developing fibers that achieve permanent, intrinsic flame resistance, ensuring the safety properties are maintained throughout the product lifecycle, even after repeated washing or exposure to harsh environmental conditions. Mergers and acquisitions, along with strategic partnerships between chemical suppliers and fiber producers, are becoming common strategies to secure supply chains and integrate innovative FR technologies quickly into mass production lines.

Regionally, Asia Pacific leads the market, propelled by massive manufacturing capabilities in China and India, alongside burgeoning demand from the construction, automotive, and consumer electronics sectors. North America and Europe, however, remain critical markets characterized by high value consumption and stringent regulatory adherence, focusing particularly on high-performance applications like aerospace, high-speed rail, and highly protective workwear. These developed regions are the primary adopters of premium, intrinsically flame-retardant fibers. Emerging markets in Latin America and MEA are showing accelerating growth rates as they harmonize local building codes and public safety standards with international best practices, thus creating new avenues for market penetration by major global players.

Segment trends highlight the dominance of the inherent/intrinsic FR fiber segment due to superior durability and permanence of flame resistance compared to topical finish treatments, despite the higher initial cost. Application-wise, the Contract Textiles and Transportation segments are witnessing the fastest growth due to regulatory mandates requiring fire-safe materials in public spaces and mass transit systems. Within Contract Textiles, the demand for fire-resistant upholstery and vertical textiles (draperies) in commercial buildings, schools, and hospitals is paramount. Furthermore, the development of multi-functional fibers that combine flame retardancy with other beneficial properties, such as microbial resistance or enhanced moisture wicking, represents a significant technological avenue for market differentiation and premium pricing strategies.

AI Impact Analysis on Flame Retardant Polyester Fiber Market

User queries regarding AI's influence in the Flame Retardant Polyester Fiber market primarily revolve around optimizing R&D processes, improving quality control, and enhancing supply chain efficiency. Users frequently ask how AI can accelerate the discovery of new, non-toxic flame retardant chemistries and how machine learning can predict the fire performance of novel fiber formulations before costly physical testing. Key concerns center on the capital investment required for adopting AI-driven monitoring systems in manufacturing and the potential disruption to traditional chemical formulation expertise. Expectations are high regarding AI’s ability to streamline raw material procurement, predict market demand fluctuations, and facilitate predictive maintenance on complex extrusion and spinning machinery, leading to reduced waste and optimized production output while ensuring consistent compliance with stringent safety standards.

- AI-driven Predictive Modeling: Accelerating the discovery and formulation of next-generation, environmentally friendly flame retardant chemicals, simulating molecular interactions and thermal decomposition paths.

- Manufacturing Optimization: Utilizing machine learning algorithms to fine-tune spinning parameters (temperature, pressure, speed) for intrinsic FR fiber production, minimizing defects and maximizing efficiency.

- Quality Control and Compliance: Implementing computer vision systems and AI-based sensor analytics for real-time monitoring of FR fiber homogeneity and ensuring immediate detection of non-compliant batches.

- Supply Chain Resilience: Applying AI to forecast raw material volatility (polymers and FR additives), optimizing inventory levels, and mitigating supply chain risks associated with complex specialty chemical sourcing.

- Sustainable Process Enhancement: Using AI to optimize energy consumption in resource-intensive processes like polymerization and extrusion, aligning manufacturing practices with global sustainability goals.

DRO & Impact Forces Of Flame Retardant Polyester Fiber Market

The market is primarily driven by escalating global mandates for fire safety across residential, commercial, and public infrastructure, particularly in high-density urban areas, which necessitate the adoption of certified flame-retardant materials. However, growth is significantly restrained by the high initial cost associated with intrinsic FR treatments compared to standard polyester, and persistent consumer skepticism regarding the long-term health effects of certain legacy flame retardant chemicals, even as the industry pivots toward safer alternatives. Opportunities abound in the development of highly specialized FR fibers for niche high-growth sectors such as electric vehicle battery components (requiring thermal management) and advanced protective fabrics for industrial applications. These market dynamics are heavily influenced by the oscillating regulatory pressures in developed nations and the rapidly increasing competitive landscape in Asia Pacific, where manufacturing scale dictates pricing power.

Impact forces heavily shape market trajectories, with regulatory bodies acting as the primary catalyst. The shift towards non-halogenated, environmentally preferred chemistries is not just a trend but a forceful mandate in many European and North American jurisdictions, compelling manufacturers to invest heavily in R&D to reformulate existing products. Technological innovation focuses on integrating superior fire-blocking capabilities without compromising the aesthetic and physical characteristics of the fabric, crucial for high-end contract furniture. Economic factors, particularly the volatile pricing of key petrochemical feedstocks (like PTA and MEG used in polyester production) and specialty FR additives, impose significant pressure on profit margins, forcing companies to seek efficiency through vertical integration or advanced manufacturing techniques. Social forces, reflecting growing public awareness of chemical exposure, continuously push the industry toward safer, more sustainable product offerings.

The market faces the dual challenge of meeting performance demands (high Limiting Oxygen Index or LOI) while simultaneously addressing sustainability concerns (low toxicity, high recyclability). This necessitates a delicate balance in formulation science. The competitive intensity is high, characterized by a few global chemical giants providing the foundational FR technology and numerous regional textile processors vying for volume contracts. Successful market navigation requires continuous innovation, stringent quality control to ensure regulatory compliance, and effective communication to end-users about the safety and environmental profile of the flame retardant materials used, especially concerning non-leaching, permanent fire resistance.

Segmentation Analysis

The Flame Retardant Polyester Fiber Market is comprehensively segmented based on the type of flame retardancy treatment, the physical form of the fiber, the specific application area, and the geographic region. The foundational distinction lies between intrinsic (inherent) and topical (finished) treatments, defining the permanence and cost structure of the end product. Further segmentation by application is critical, as the required fire safety standards vary dramatically between transportation, home textiles, and specialized protective gear, dictating the necessary performance level and regulatory compliance. This detailed segmentation allows producers to target specific high-value sectors with tailored fiber products that meet precise safety and functional requirements while optimizing their manufacturing processes for cost-efficiency and performance.

- By Type of Flame Retardancy:

- Intrinsic/Inherent FR Fibers (Co-polymerized or Modified Polymer Structure)

- Topical/Finished FR Fibers (Surface Coating or Dip Treatment)

- By Fiber Form:

- Staple Fiber

- Filament Yarn (FDY, DTY, POY)

- By Application:

- Contract Textiles (Hospitality, Healthcare, Institutional)

- Home Textiles (Bedding, Upholstery, Drapery)

- Transportation (Automotive, Aerospace, Rail)

- Protective Apparel (Industrial Workwear, Military/Defense)

- Other Industrial Applications (Filters, Insulation)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Flame Retardant Polyester Fiber Market

The value chain for flame retardant polyester fiber is multifaceted, starting with the upstream supply of raw materials and extending through specialized processing to final market distribution. Upstream analysis focuses on the sourcing of key petrochemical derivatives (Purified Terephthalic Acid or PTA, and Monoethylene Glycol or MEG) necessary for basic polyester polymerization, alongside the procurement of highly specialized flame retardant chemicals, predominantly non-halogenated compounds (e.g., organophosphorus compounds, metal hydroxides). The quality and consistency of these specialized additives are crucial, as they determine the ultimate thermal stability and fire performance of the resulting fiber. Key industry players often invest heavily in securing long-term contracts with specialized chemical producers to stabilize input costs and ensure supply reliability, mitigating risks associated with highly regulated specialty chemical markets.

The midstream involves the core manufacturing processes, including polymerization, compounding of FR additives into the polymer melt (for intrinsic fibers), spinning (melt extrusion), and subsequent texturizing or finishing operations to produce staple fibers or various types of filament yarns. This stage requires high technical expertise and significant capital investment in advanced machinery capable of handling modified polymer melts without degradation. Efficiency and quality control at this stage are paramount, as the permanent nature of the FR property depends on perfect integration into the fiber structure. Manufacturers must also comply with multiple international standards throughout the production process, involving rigorous fire testing procedures and quality assurance protocols.

Downstream analysis covers the transformation of the fibers into textiles and final products, followed by distribution. Processors convert fibers into fabrics (weaving, knitting, non-woven), often integrating specialized dyeing and finishing treatments. The final products—ranging from commercial drapery to automotive seating—are then distributed through highly specialized channels. Direct distribution is common for large B2B contracts (e.g., supplying major automotive OEMs or hospitality chains), while indirect channels involve fabric converters, distributors, and ultimately, retailers or specialized installation contractors. The success of the distribution channel hinges on providing comprehensive product documentation, including official fire test certificates, which are essential for final product acceptance by end-user industries and regulatory bodies.

Flame Retardant Polyester Fiber Market Potential Customers

The primary consumers of flame retardant polyester fibers are large-scale commercial entities and industrial manufacturers governed by strict public safety and fire code regulations. Key end-users include contract textile buyers in the hospitality sector (hotels, resorts, cruise lines) and the institutional sector (hospitals, nursing homes, schools), all of which require furnishings and vertical textiles to meet rigorous fire standards (e.g., Cal TB 133, NFPA 701). The necessity for permanent fire resistance that survives frequent cleaning cycles makes inherent FR polyester particularly attractive to these institutional buyers who prioritize longevity and maintenance cost reduction alongside safety compliance.

Another major segment comprises manufacturers within the transportation industry—specifically automotive Tier 1 suppliers, aerospace component manufacturers, and rail car interior outfitters. These customers demand lightweight, durable, and extremely fire-safe materials for seating, carpeting, wall coverings, and insulation, complying with standards such as FAR 25.853 (aerospace) and stringent rail fire requirements. The protective apparel industry also represents a significant buyer base, utilizing FR polyester blends for industrial workwear, military uniforms, and specialized gear where exposure to heat, sparks, and flash fires is a risk, requiring inherent protection that maintains performance over the garment’s lifespan.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.8 Billion |

| Market Forecast in 2033 | USD 7.5 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Trevira GmbH, Huvis Corporation, Reliance Industries Limited, Teijin Limited, Toray Industries, Inc., Far Eastern Group, William Barnet & Son, LLC, Toyobo Co., Ltd., Sarla Performance Fibers Limited, Jiangsu Sanfangxiang Group Co., Ltd., Indorama Ventures Public Company Limited (IVL), Sateri (a subsidiary of RGE), Barnhardt Manufacturing Company, DAK Americas, and W. L. Gore & Associates. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Flame Retardant Polyester Fiber Market Key Technology Landscape

The technological landscape of the Flame Retardant Polyester Fiber market is primarily defined by the methods used to incorporate the FR chemical into the polymer matrix. The most advanced technique involves intrinsic flame retardancy, typically achieved through copolymerization or the addition of specialist flame retardant compounds directly into the polymer melt prior to extrusion. Leading intrinsic technologies utilize phosphorus-based compounds, which function in the condensed phase by promoting char formation upon exposure to heat, effectively insulating the underlying material and limiting the release of flammable gases. These chemical modifications ensure that the flame retardancy is a permanent feature of the fiber, resistant to washing, abrasion, and aging, offering a superior and sustainable safety solution compared to surface treatments.

In contrast, topical finishing technologies, while cost-effective, rely on surface application of FR chemicals after the fiber or fabric is produced. Although modern topical finishes have improved dramatically, including advanced micro-encapsulation techniques, they inherently suffer from reduced durability, as the FR chemical can be removed or degraded through repeated laundering or environmental exposure. Technological focus in this area is on improving the binder systems and curing processes to maximize the wash fastness of the finish. However, the overall trend is pushing towards intrinsic technologies, which provide reliable compliance for high-specification applications and minimize the environmental impact associated with the finishing processes.

A critical emerging area of technological innovation is the synthesis of completely novel, synergistic flame retardant systems. This involves combining different non-halogenated chemistries (e.g., phosphorus, nitrogen, and inorganic metal oxides like antimony trioxide) to achieve superior fire performance profiles, often targeting specific regulatory requirements such as reduced smoke density and lower toxicity of combustion products. Manufacturers are also heavily investing in processes that allow for the high-speed spinning of these modified polymers without sacrificing the physical properties (tenacity, dyeability, handle) of the final fiber. Furthermore, sustainable technologies, including utilizing recycled PET (rPET) as the base polymer while successfully integrating FR properties, are gaining traction to meet circular economy objectives without compromising essential safety standards.

Regional Highlights

- Asia Pacific (APAC): APAC dominates the global market both in terms of production capacity and consumption growth. This region is driven by rapid industrialization, massive infrastructure projects (commercial and residential construction), and expanding automotive manufacturing bases in China, India, and Southeast Asia. Regulatory environments are tightening, pushing local manufacturers to adopt international fire standards, particularly in the contract textile segment.

- North America: Characterized by mature markets and extremely stringent fire safety codes (e.g., California Technical Bulletin 117-2013, FAA regulations). Demand is high for premium, intrinsically FR fibers, especially in the aerospace, institutional bedding, and high-specification protective apparel sectors. The shift away from halogenated chemistries is most pronounced here due to public health concerns.

- Europe: A high-value market focused on innovation and sustainability. European regulations (such as REACH and various EU Directives) heavily influence the choice of FR additives, strongly favoring non-halogenated, environmentally benign options. Key demand sectors include public transport (rail and bus interiors) and high-end contract furnishings, requiring compliance with standards like EN 45545 (for railway applications).

- Latin America (LATAM): An emerging market showing significant potential. Growth is fueled by increasing foreign investment in infrastructure and construction, particularly in Brazil and Mexico. The market is slowly standardizing its safety codes, leading to a rising, albeit price-sensitive, demand for FR textiles in public buildings and local automotive production.

- Middle East and Africa (MEA): Growth is robust, driven by large-scale commercial and hospitality developments (especially in the UAE and Saudi Arabia) and expansion in oil and gas infrastructure, which mandates high-performance protective workwear. The high-end segment aligns closely with European safety standards, while volume consumption often prioritizes cost-effective, durable solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Flame Retardant Polyester Fiber Market.- Trevira GmbH

- Huvis Corporation

- Reliance Industries Limited

- Teijin Limited

- Toray Industries, Inc.

- Far Eastern Group

- William Barnet & Son, LLC

- Toyobo Co., Ltd.

- Sarla Performance Fibers Limited

- Jiangsu Sanfangxiang Group Co., Ltd.

- Indorama Ventures Public Company Limited (IVL)

- Sateri (a subsidiary of RGE)

- Barnhardt Manufacturing Company

- DAK Americas

- W. L. Gore & Associates

- Kolon Industries, Inc.

- Aditya Birla Group

- Fibertex Nonwovens A/S

Frequently Asked Questions

Analyze common user questions about the Flame Retardant Polyester Fiber market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary drivers of demand for Flame Retardant Polyester Fiber?

The demand is fundamentally driven by increasingly stringent global fire safety regulations, particularly those governing materials used in public spaces, transportation (aerospace, rail), and high-occupancy commercial buildings (hotels, hospitals). The shift toward non-halogenated, safer FR chemistries is also expanding market acceptance.

What is the difference between intrinsic and topical flame retardancy?

Intrinsic (inherent) flame retardancy is achieved by chemically modifying the polymer structure during manufacturing, making the fire resistance permanent and resistant to washing. Topical flame retardancy involves applying a chemical coating to the finished fiber or fabric, which can degrade or wash out over time, offering a less durable solution.

Which geographic region dominates the Flame Retardant Polyester Fiber Market?

The Asia Pacific (APAC) region currently holds the largest market share, driven by its expansive manufacturing capacity and booming demand from construction, automotive, and consumer goods sectors, coupled with rapid adoption of international fire safety standards.

Are halogen-free flame retardant fibers safer and more commonly used now?

Yes, the industry is rapidly transitioning toward non-halogenated (halogen-free) FR chemistries, primarily phosphorus and nitrogen compounds, due to mounting environmental and health concerns associated with traditional halogenated additives. These alternatives are safer and increasingly mandated by major markets like the EU and North America.

What key applications utilize these specialized fibers?

Key applications include Contract Textiles (upholstery, curtains in hotels and hospitals), Transportation (car seats, airplane interiors), and Protective Apparel (firefighter uniforms, industrial workwear), where certified fire safety performance is non-negotiable.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Flame Retardant Polyester Fiber Market Statistics 2025 Analysis By Application (Clothing, Home Textiles, Public Utility), By Type (Inherent FRP Staple Fiber, Treated FRP Staple Fiber), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Flame Retardant Polyester Fiber Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Inherent FRP Staple Fiber, Treated FRP Staple Fiber), By Application (Clothing, Home Textiles, Public Utility, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager