Flame Retardant PP Granules Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435822 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Flame Retardant PP Granules Market Size

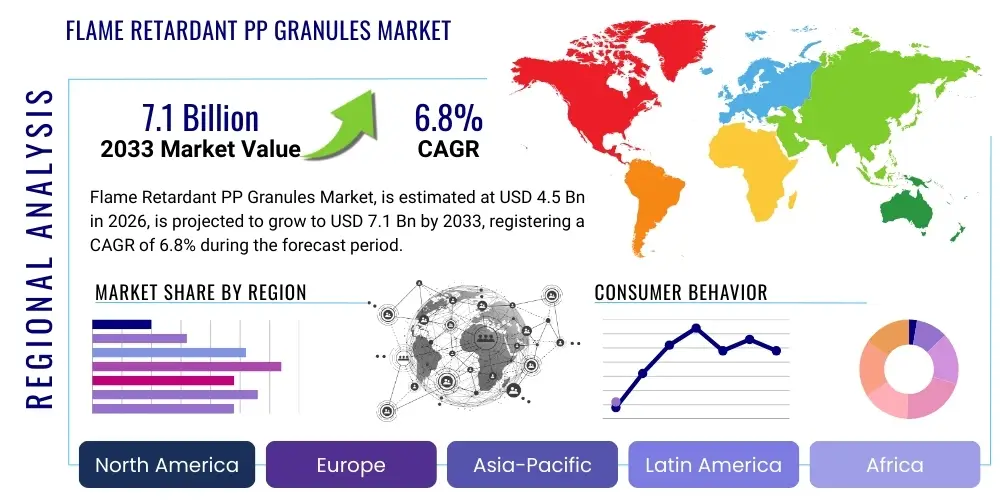

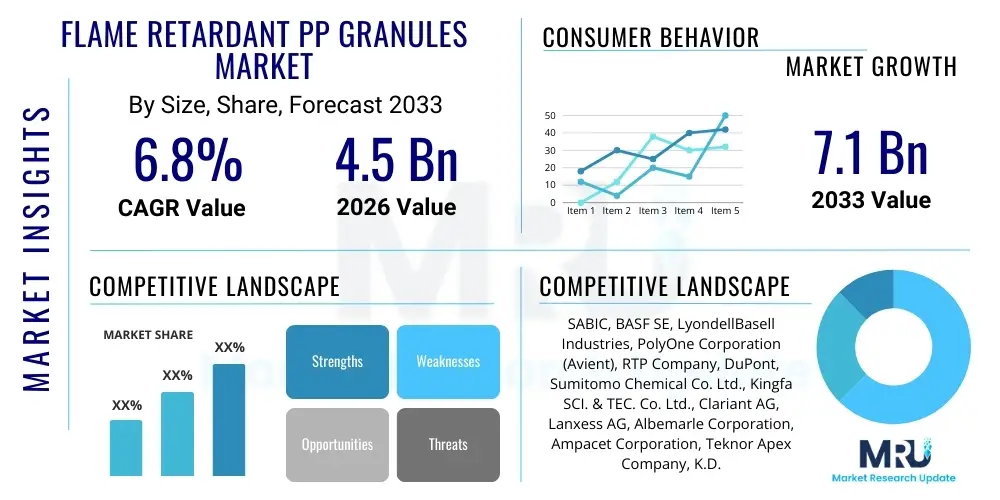

The Flame Retardant PP Granules Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 7.1 Billion by the end of the forecast period in 2033. This substantial expansion is fundamentally linked to the increasing global emphasis on safety standards across critical industries, particularly in electronics and electric vehicle manufacturing. The demand for materials that comply with strict fire safety certifications (such as UL94 standards) is fueling the necessity for high-performance, easy-to-process flame retardant polypropylene solutions.

Flame Retardant PP Granules Market introduction

The Flame Retardant PP Granules Market encompasses the manufacturing, distribution, and application of specialized polypropylene (PP) compounds enhanced with fire-suppressing additives. These granules are formulated to significantly reduce the flammability of final plastic products, ensuring compliance with global fire safety regulations. The core product description involves thermoplastic polymers, predominantly homopolymer or copolymer PP, compounded with various flame retardants, categorized primarily into halogenated and non-halogenated types, depending on the required fire classification and environmental mandates. These compounds offer superior mechanical properties, excellent processability, and cost-effectiveness compared to alternative engineering plastics, making them highly versatile.

Major applications of these granules span the Electrical and Electronics (E&E) sector for components such as circuit breaker housings, connectors, and appliance casings, the Automotive industry for interior components and battery module parts, and the Construction sector for piping, fittings, and cable insulation. The primary benefit of utilizing these materials is the enhanced safety profile they impart to end-products, preventing ignition and slowing fire spread, crucial for protecting life and property. Furthermore, the light weight and durability of PP, combined with flame retardancy, allow manufacturers to achieve regulatory compliance without significantly compromising product performance or adding undue weight, which is particularly vital in e-mobility.

Driving factors for market growth include the rising complexity and power density of electronic devices, which inherently increase fire risk, and the rapid expansion of the Electric Vehicle (EV) market where thermal runaway mitigation in battery systems necessitates robust flame retardant casings and components. Moreover, increasingly strict governmental mandates and building codes worldwide, especially regarding public safety and consumer protection, compel industries to adopt superior flame retardant solutions. The ongoing shift towards environmentally friendly, non-halogenated flame retardants, driven by regulations such as RoHS and REACH, also stimulates innovation and market expansion into advanced formulations.

Flame Retardant PP Granules Market Executive Summary

The Flame Retardant PP Granules Market is characterized by robust growth, driven primarily by evolving regulatory landscapes and technological advancements in end-use sectors like E&E and Automotive. Key business trends indicate a definitive strategic shift toward developing and commercializing non-halogenated flame retardant (NHFR) formulations, utilizing phosphorus-based compounds and mineral hydroxides. Manufacturers are heavily investing in research and development to improve the processing window and mechanical performance of NHFR grades to match or exceed the performance of traditional halogenated compounds. Mergers and acquisitions focused on securing specialized additive technology and expanding geographic manufacturing footprints are prevalent, aiming to achieve supply chain resilience and economies of scale in this competitive, compliance-driven environment.

Regional trends highlight Asia Pacific (APAC) as the dominant market, driven by its massive electronics manufacturing base and rapidly accelerating automotive production, particularly in China and India. North America and Europe demonstrate mature markets characterized by stringent environmental regulations, pushing demand for premium, sustainable NHFR products suitable for high-end applications, especially in aerospace and critical infrastructure. The focus in these Western regions is less on volume growth and more on high-margin, specialized technical grades that meet specific vertical standards, such as those required for railway or marine applications.

Segment trends reveal that the Non-Halogenated segment is exhibiting the highest Compound Annual Growth Rate, underscoring the success of regulatory pressures and consumer preference for safer chemistries. Among applications, the Automotive segment, particularly components related to EV battery housings and charging infrastructure, is showing exceptional growth due to the immense safety requirements surrounding high-voltage battery systems. Furthermore, within the processing segment, injection molding remains the leading technique for producing complex, intricate components like appliance chassis and electrical connectors, thereby sustaining strong demand for highly flowable, flame retardant granule grades.

AI Impact Analysis on Flame Retardant PP Granules Market

User queries regarding the impact of Artificial Intelligence (AI) on the Flame Retardant PP Granules Market often center on how AI can accelerate material discovery, optimize formulation complexity, and enhance predictive quality control. Key concerns revolve around the transition from empirical testing to predictive modeling, particularly how AI algorithms can effectively model the complex interaction between PP matrices, various flame retardant additives (such as intumescent systems or metal hydroxides), and compounding parameters to achieve specific fire ratings (e.g., UL 94 V-0) and mechanical specifications simultaneously. Users expect AI tools to significantly reduce the R&D cycle time and lower the cost associated with extensive physical testing, ultimately leading to faster deployment of customized, high-performance, and regulatory-compliant PP formulations, especially the challenging non-halogenated types. Furthermore, there is significant interest in how AI-driven analysis of real-world fire data can inform safer product design and material selection, ensuring market relevance.

- AI accelerates R&D by simulating material properties and thermal stability before lab synthesis, drastically cutting prototyping time.

- Machine learning algorithms optimize additive loading levels and particle size distribution to achieve desired UL 94 standards with minimal material usage.

- Predictive maintenance and quality control in compounding lines utilize AI to ensure consistency in batch production, minimizing variation in flame retardancy performance.

- AI-driven supply chain analysis enhances risk mitigation for sourcing critical, specialized flame retardant chemicals and monomers.

- Computational material informatics allows for the rapid identification and design of novel, environmentally compliant non-halogenated flame retardant molecules.

- Enhanced process control through deep learning monitors extrusion temperatures and shear rates to prevent degradation of heat-sensitive additives during granule production.

DRO & Impact Forces Of Flame Retardant PP Granules Market

The dynamics of the Flame Retardant PP Granules Market are heavily influenced by a confluence of regulatory drivers, complex technological restraints, and significant opportunities emerging from sustainability trends. Key drivers include the global tightening of fire safety regulations, mandatory use of certified materials in infrastructure, and the expansion of the electronics and electric vehicle sectors, which intrinsically require enhanced thermal management and fire resistance. These drivers create an unavoidable market pull for highly specialized and certified polymer compounds. Conversely, the market faces strong restraints, primarily concerning the technical challenge of achieving high flame retardancy (like V-0 at low thickness) using non-halogenated systems without sacrificing essential mechanical strength or processing ease. The escalating cost of specialized phosphorus and nitrogen-based additives further pressures manufacturers' margins and compound pricing.

Opportunities are predominantly centered around the transition to sustainable and environmentally benign non-halogenated formulations. The ability to innovate compounds that meet both stringent fire safety (e.g., DIN 4102, EN 45545) and ecological standards (e.g., Blue Angel, EPEAT) represents a crucial competitive advantage. Furthermore, the massive growth in 5G infrastructure, renewable energy installations, and data centers provides high-volume, high-specification application avenues for advanced PP granules. Strategic partnerships between additive suppliers, polymer producers, and final product manufacturers are pivotal for fast-tracking material adoption and ensuring application-specific customization, unlocking niche market potential in sectors such as medical devices requiring biocompatible FR materials.

The major impact forces structuring this market include regulatory pressure (a strong external force dictating material requirements), technological innovation (an internal force driving R&D into safer alternatives), and pricing sensitivity (a market force impacting raw material selection and profitability). The regulatory environment, particularly in the EU and North America, acts as a primary catalyst, often banning or severely restricting the use of certain legacy halogenated compounds, thereby forcing immediate, large-scale material transitions. Technological advancements in miniaturization and thermal management further heighten the need for compounds with extremely low smoke density and toxicity, demanding continuous formulation refinement to maintain market competitiveness and address increasing safety expectations from both industry and consumers.

Segmentation Analysis

The Flame Retardant PP Granules market is fundamentally segmented based on the type of flame retardant incorporated, the specific end-use application, and the manufacturing process employed for the final product. Understanding these segmentations is critical for market participants to tailor their product offerings and strategic focus. The market is primarily bifurcated into halogenated and non-halogenated types, reflecting the industry's response to regulatory shifts toward sustainability. Halogenated compounds, while historically dominant due to their high efficiency and low cost, are steadily losing share. Non-halogenated options, including mineral fillers (like ATH and MDH) and phosphorus compounds (like APP and RDP), are driving future growth due to their superior environmental and health profiles. Application segmentation highlights the crucial role of these materials in enhancing safety in high-risk environments such as electrical installations and moving machinery.

- By Type of Flame Retardant:

- Halogenated Flame Retardant PP Granules (e.g., Brominated FRs)

- Non-Halogenated Flame Retardant (NHFR) PP Granules

- Mineral Hydroxides (ATH, MDH)

- Phosphorus-based Compounds (Red Phosphorus, Organophosphates)

- Nitrogen-based Compounds (Melamine Derivatives)

- Intumescent Systems

- By Application:

- Electrical and Electronics (E&E)

- Appliance Housings

- Connectors and Sockets

- Circuit Breaker Components

- Cable Jacketing and Insulation

- Automotive (Interior, Under-the-hood, Battery Components)

- Construction and Building Materials (Pipes, Fittings, Ducts)

- Consumer Goods and Home Furnishings

- Others (Aerospace, Marine, Industrial Equipment)

- Electrical and Electronics (E&E)

- By Processing Technology:

- Injection Molding

- Extrusion (Sheet, Film, Profile)

- Thermoforming

Value Chain Analysis For Flame Retardant PP Granules Market

The value chain for Flame Retardant PP Granules begins with the upstream procurement of base polymers (Polypropylene resin) and specialized flame retardant additives, which are typically sourced from the chemical industry. Upstream analysis involves assessing the price volatility of propylene monomer and the availability of key additives such as specialty phosphorus chemicals or magnesium hydroxide, which directly influence the input costs for compounders. Innovation and competitive differentiation often start at this stage, with additive producers developing synergistic systems to maximize fire protection efficiency at lower loading levels, thereby preserving the mechanical properties of the final PP compound. Effective supply chain management is crucial here to ensure a consistent supply of highly pure and specialized chemical components necessary for achieving regulatory compliance.

The central manufacturing stage involves compounding, where specialized machinery (twin-screw extruders) processes the PP resin, additives, stabilizers, and colorants into homogeneous granules. Compounders are critical players, bridging the gap between raw material suppliers and end-users. Their technical expertise determines the final properties, including melt flow index, impact strength, and critical flame ratings. The distribution channel spans both direct sales to major OEMs (Original Equipment Manufacturers) in the automotive and E&E sectors and indirect sales through specialized plastics distributors who service smaller volume users and custom molders. Direct channels allow for closer technical collaboration and customized material development, while indirect channels provide market reach and quick inventory access.

Downstream analysis focuses on the application sectors, primarily high-volume end-users like appliance manufacturers and automotive Tier 1 suppliers. These entities convert the granules via injection molding or extrusion into finished components. Their material selection criteria are rigorous, demanding consistency, colorability, and specific mechanical thresholds alongside mandated fire safety levels. The increasing complexity of end-product design, driven by miniaturization and performance demands, places pressure on compounders to provide highly technical support and precise material documentation. Successful players in the market offer not just the granules, but comprehensive material solutions, including testing and regulatory compliance assistance.

Flame Retardant PP Granules Market Potential Customers

The potential customers and end-users of Flame Retardant PP Granules are highly diversified across industries where safety and regulatory compliance are paramount concerns. These buyers are typically large-scale manufacturers operating within regulated environments, seeking consistent material quality to maintain product certifications (such as CE marking or UL listing). The primary purchasing criteria include the achievable fire rating (e.g., UL 94 V-0 or 5VA), the impact of the material on processing time, the mechanical strength retention after compounding, and increasingly, the environmental impact (favoring non-halogenated options). Customers range from global multinational corporations producing consumer electronics to highly specialized manufacturers focused on niche infrastructure components, all requiring high-volume supply and consistent technical support to integrate these specialized polymers into their production lines seamlessly.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 7.1 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SABIC, BASF SE, LyondellBasell Industries, PolyOne Corporation (Avient), RTP Company, DuPont, Sumitomo Chemical Co. Ltd., Kingfa SCI. & TEC. Co. Ltd., Clariant AG, Lanxess AG, Albemarle Corporation, Ampacet Corporation, Teknor Apex Company, K.D. Feddersen, LATI S.p.A., HFFR Compounders, Washington Penn Plastic Co., Astra Polymers, Techmer PM, ALBIS PLASTIC GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Flame Retardant PP Granules Market Key Technology Landscape

The technology landscape governing the Flame Retardant PP Granules market is dynamic, driven by the need to balance fire performance, mechanical integrity, and environmental responsibility. The primary technological focus revolves around advanced compounding techniques and the continuous evolution of flame retardant additive chemistry. Twin-screw extrusion technology remains the bedrock of granule production, utilized for its ability to achieve homogeneous dispersion of high additive loadings within the polymer matrix. Recent advancements include optimizing screw designs and temperature profiles to handle sensitive non-halogenated additives, such as intumescent systems, which are prone to decomposition or premature activation during compounding, ensuring the final granule structure maximizes efficiency and stability.

A major area of technological innovation is in the formulation of non-halogenated flame retardants (NHFRs). This includes developing micro-encapsulation techniques for red phosphorus to enhance processing safety and moisture resistance, as well as refining surface treatments for mineral hydroxides (like ATH and MDH) to improve compatibility with the non-polar PP matrix. Improved compatibility leads to better mechanical properties in the final product, addressing a historical weakness of highly filled NHFR compounds. Furthermore, synergistic flame retardant systems, which combine two or more additive types (e.g., phosphorus with nitrogen synergists) to achieve superior flame inhibition at lower overall additive concentrations, are becoming standard practice, driven by cost and performance optimization requirements.

Digitalization and simulation technologies, often leveraging AI and computational fluid dynamics (CFD), are increasingly used to model the thermal decomposition pathways of various PP/additive combinations. This predictive modeling capacity allows manufacturers to rapidly screen new formulations for fire performance, smoke characteristics, and toxicity, accelerating the time-to-market for novel, high-specification materials required in specialized applications like high-voltage EV battery modules or fire-rated cable conduits. The shift towards engineered, highly tailored compounds necessitates these advanced modeling tools to ensure the complex interactions between the base resin and specialty additives are precisely controlled during the manufacturing process.

Regional Highlights

- Asia Pacific (APAC): The APAC region commands the largest market share due to its standing as the global manufacturing hub for electronics, appliances, and automotive components. Rapid industrialization, combined with rising disposable incomes, fuels massive construction and infrastructure projects, all demanding fire-safe materials. Regulatory tightening in major economies like China (GB Standards) and India (BIS standards) is transitioning the market swiftly towards non-halogenated solutions, despite cost pressures. The burgeoning Electric Vehicle industry in East Asia is a massive consumer of high-performance, thermal-resistant PP granules for battery peripherals, making this region the primary driver of volume growth and technological scaling.

- North America: Characterized by highly stringent safety standards, particularly those mandated by Underwriters Laboratories (UL) and the National Fire Protection Association (NFPA), North America is a critical market focusing on high-specification, high-margin products. Demand is concentrated in highly regulated sectors like data centers, specialized automotive manufacturing, and aerospace. The market has largely transitioned to non-halogenated solutions, driven by strong environmental consciousness and state-level restrictions on certain halogenated compounds. Innovation focuses on materials offering low smoke and low toxicity (LSZH) properties, catering to sensitive indoor environments and public transport systems.

- Europe: Europe is a leader in adopting environmentally advanced and sustainable flame retardant technologies, heavily influenced by directives such as REACH and RoHS, which strictly limit hazardous substances. The European market prioritizes non-halogenated, often phosphorus-based and intumescent, systems, demanding excellent technical performance alongside environmental compliance. Key growth sectors include rail transport (governed by EN 45545), demanding specialized FR-PP compounds for interiors, and the high-end industrial machinery sector. European manufacturers are focused on closed-loop recycling and circular economy initiatives, integrating recycled PP with flame retardants, presenting a unique technological challenge and market opportunity.

- Latin America: This region presents a market with emerging growth potential, driven by urbanization and modernization of infrastructure, especially in Brazil and Mexico. While historically more cost-sensitive, leading to a higher usage of traditional halogenated compounds, there is a gradual shift towards international safety standards. The construction and domestic appliance sectors are the primary consumers. Market development is strongly linked to foreign investment and the establishment of local manufacturing facilities by global OEMs, which bring their material specification requirements and drive local adoption of high-quality FR granules.

- Middle East and Africa (MEA): Growth in the MEA region is heavily concentrated in the Gulf Cooperation Council (GCC) countries, fueled by massive government-led construction and energy infrastructure projects. Demand is particularly strong for FR compounds used in cable infrastructure and high-rise building materials, often requiring compliance with international standards (e.g., NFPA and British Standards). The market is sensitive to project cycles and commodity pricing but shows increasing interest in advanced materials for specialized industrial applications like oil and gas processing facilities that require extreme fire resistance and chemical stability.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Flame Retardant PP Granules Market.- SABIC

- BASF SE

- LyondellBasell Industries

- PolyOne Corporation (Avient)

- RTP Company

- DuPont

- Sumitomo Chemical Co. Ltd.

- Kingfa SCI. & TEC. Co. Ltd.

- Clariant AG

- Lanxess AG

- Albemarle Corporation

- Ampacet Corporation

- Teknor Apex Company

- K.D. Feddersen

- LATI S.p.A.

- HFFR Compounders

- Washington Penn Plastic Co.

- Astra Polymers

- Techmer PM

- ALBIS PLASTIC GmbH

Frequently Asked Questions

Analyze common user questions about the Flame Retardant PP Granules market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary differences between halogenated and non-halogenated FR PP granules?

Halogenated (HFR) granules contain elements like bromine or chlorine, which are highly effective and cost-efficient but often release toxic smoke. Non-halogenated (NHFR) granules, based on phosphorus or mineral fillers, are environmentally safer, producing less smoke and toxicity, though they typically require higher loading levels and can be costlier to formulate while maintaining mechanical properties.

Which end-use application drives the highest demand for Flame Retardant PP Granules globally?

The Electrical and Electronics (E&E) sector historically drives the highest volume demand due to strict mandatory fire safety standards (UL 94) for appliances, circuit breakers, and wiring components. However, the Automotive sector, specifically electric vehicle (EV) battery systems, is emerging as the fastest-growing application segment due to severe thermal management and fire mitigation needs.

How do Flame Retardant PP Granules achieve UL 94 V-0 certification?

The UL 94 V-0 rating requires that a vertically oriented material sample self-extinguishes within 10 seconds, with no flaming drips. This is achieved by incorporating additives that function either through a gas-phase mechanism (interrupting the flame chemistry) or a condensed-phase mechanism (forming a protective char layer or cooling the material, common with intumescent and mineral systems).

What regulatory factors are currently shaping the future of the FR PP market?

The European Union's REACH regulation and Restriction of Hazardous Substances (RoHS) directives, alongside similar environmental policies globally, are the main drivers forcing compounders to phase out legacy halogenated retardants. This necessitates substantial investment in developing high-performance, sustainable, and compliant non-halogenated alternatives.

What impact does the use of flame retardants have on the recyclability of PP?

Incorporating high levels of flame retardant additives, especially mineral fillers, can complicate the mechanical recycling of PP by potentially degrading the polymer matrix or interfering with subsequent processing. However, manufacturers are developing specialized additive packages and compounding techniques designed to maintain recyclability and minimize additive degradation during multiple heat cycles.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager