Flame Retardant Work Clothes Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431580 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Flame Retardant Work Clothes Market Size

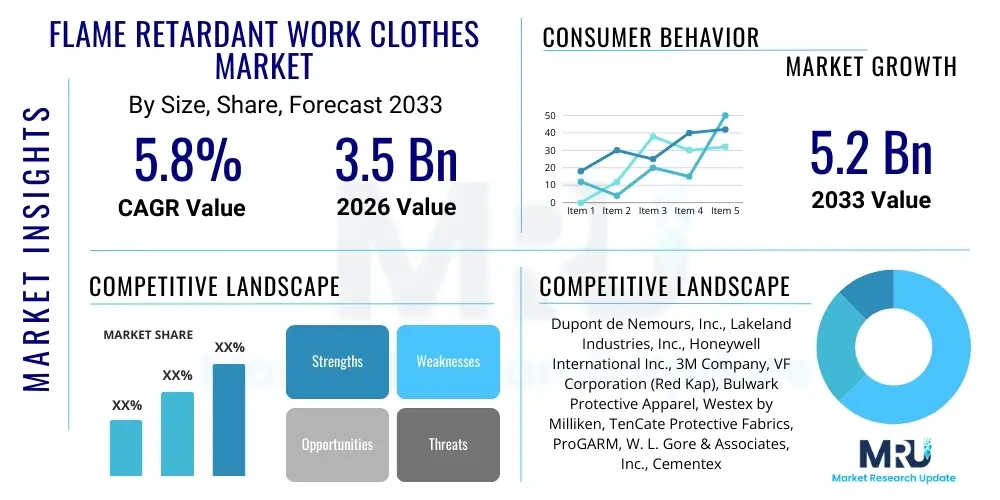

The Flame Retardant Work Clothes Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 5.2 Billion by the end of the forecast period in 2033.

Flame Retardant Work Clothes Market introduction

The Flame Retardant (FR) Work Clothes Market encompasses specialized personal protective equipment (PPE) designed to shield workers from thermal hazards, including arc flashes, flash fires, and radiant heat exposure. These garments are engineered using intrinsically flame-resistant fibers, such as aramids (Nomex, Kevlar), modacrylics, or treated cotton fabrics, which self-extinguish when the source of ignition is removed, preventing further combustion and minimizing burn injuries. This critical protective function is mandatory across numerous heavy industries where high-risk environments necessitate adherence to stringent national and international safety standards, such as NFPA 2112, NFPA 70E, and EN ISO 11612. The core value proposition of FR workwear lies in its ability to offer a vital layer of defense, thereby mitigating catastrophic workplace accidents and reducing associated liabilities for employers.

The market's sustained growth is fundamentally driven by the escalating implementation of occupational health and safety (OHS) regulations worldwide. Governments and regulatory bodies are continuously tightening mandates regarding worker safety, particularly in volatile sectors like oil & gas, petrochemicals, manufacturing, utilities, and electrical maintenance. Furthermore, the inherent durability and increasing comfort levels offered by modern FR materials have broadened their applicability beyond traditional hazardous zones, encouraging adoption in supportive roles within these industries. Technological advancements, particularly in developing lightweight, moisture-wicking, and multi-hazard protective fabrics (e.g., combining FR properties with chemical or electric shock resistance), are enhancing user acceptance and driving product innovation.

Major applications for FR work clothes span across various high-risk occupational settings. These garments are indispensable for professionals working in refining operations, where exposure to flammable materials is high, and in electrical power generation, where arc flash hazards are prevalent. Benefits derived from using compliant FR workwear include significant reduction in severe burn injuries, decreased downtime following safety incidents, improved adherence to legal requirements, and ultimately, enhanced worker confidence and productivity. Key driving factors include rigorous enforcement of safety protocols, increasing industrialization in emerging economies, heightened corporate focus on Environmental, Social, and Governance (ESG) criteria related to worker well-being, and continuous technological advancements improving fabric performance and aesthetics.

Flame Retardant Work Clothes Market Executive Summary

The Flame Retardant Work Clothes Market is poised for substantial expansion, characterized by robust growth in the Asia Pacific region, driven by rapid industrial infrastructure development and increasing regulatory oversight in countries like China and India. Business trends indicate a strong shift towards advanced material compositions, focusing on lightweight, sustainable, and multi-functional fabrics that address various workplace risks simultaneously, such as combining FR properties with anti-static and high-visibility features. Key stakeholders are investing heavily in supply chain resilience and vertical integration to manage raw material costs—specifically aramid fibers—and ensure compliance with diverse international safety certifications. The competitive landscape is becoming increasingly bifurcated, with large global players focusing on premium, high-specification products, while regional manufacturers target cost-effective solutions for localized industrial needs.

Regional trends demonstrate North America and Europe maintaining market dominance in terms of value, primarily due to established, strict regulatory frameworks (OSHA, EU directives) and high awareness levels among employers and labor unions. However, the highest growth rates are forecast for APAC and MEA, propelled by massive capital investments in energy, construction, and manufacturing sectors, which inherently raise the demand for standardized PPE. In these emerging markets, the transition from conventional, non-compliant workwear to certified FR apparel represents a significant volume opportunity. Furthermore, climate considerations are influencing material selection, particularly in hot and humid regions, where breathability and comfort are becoming paramount features requested by end-users, driving innovation in inherent fiber technology.

Segmentation trends highlight the overwhelming preference for inherently flame-resistant materials over chemically treated fabrics, despite the higher initial cost, due to superior durability and guaranteed protection throughout the garment's lifecycle. The oil and gas segment remains the dominant application area, although the utilities and electric power segment is rapidly gaining traction, driven by large-scale infrastructure projects requiring arc flash protection. The adoption of rental and leasing models for FR workwear is also an emerging trend, particularly among small to medium-sized enterprises (SMEs), offering cost predictability and simplifying the maintenance and replacement cycle necessary for compliance. Companies are also leveraging digitalization to offer customized sizing and predictive wear-out analysis, ensuring peak protection levels are always maintained for their workforce.

AI Impact Analysis on Flame Retardant Work Clothes Market

User inquiries regarding AI's influence on the FR Work Clothes Market primarily center on three areas: optimizing supply chain and inventory management, enhancing product design through predictive modeling, and improving safety compliance monitoring. Users are keen to understand how AI algorithms can predict raw material price fluctuations, forecast regional demand shifts based on industrial project pipelines, and minimize stock-outs of critical safety gear. A significant concern revolves around integrating sensor technology (smart textiles) with AI to provide real-time risk assessment (e.g., monitoring garment degradation, heat stress in the wearer, or proximity to arc flash hazards), moving the industry from passive protection to proactive safety management. The consensus is that AI will revolutionize backend logistics and front-end predictive maintenance of FR garments, rather than altering the fundamental flame-retardant chemistry itself.

- AI optimizes material procurement by predicting aramid fiber and treated cotton costs.

- Predictive maintenance schedules for FR garments are enhanced using AI analysis of wear and tear data.

- AI-driven supply chain management minimizes lead times for customized protective apparel, reducing inventory risks.

- Generative design algorithms assist in creating ergonomic and thermally efficient FR workwear patterns.

- Integration of smart textiles and AI enables real-time monitoring of thermal exposure and worker safety compliance on site.

- Machine learning models analyze accident data to recommend optimal FR garment specifications (e.g., ATPV rating) for specific job roles.

DRO & Impact Forces Of Flame Retardant Work Clothes Market

The market dynamics are defined by a powerful interplay of regulatory mandates (Drivers), material performance limitations and high costs (Restraints), and the emergence of smart PPE technologies (Opportunities). The primary driving force is the global proliferation of stringent worker safety regulations across high-hazard industries, necessitating immediate investment in certified FR apparel to avoid heavy penalties and operational shutdowns. Counterbalancing this growth are significant restraints, notably the high initial cost of premium inherent FR fabrics, such as meta-aramids, which can deter adoption in price-sensitive emerging markets, alongside the challenge of maintaining comfort and breathability without compromising protective performance. Impact forces, driven largely by regulatory shifts, ensure that compliance requirements continually push manufacturers toward innovation, while the inherent nature of thermal hazards establishes FR workwear as an irreplaceable component of industrial safety protocols.

Key drivers supporting market momentum include accelerating industrialization and urbanization in the Asia Pacific region, leading to expanded workforce numbers exposed to thermal risks in construction, energy, and manufacturing. Furthermore, heightened corporate accountability and the increased focus on corporate social responsibility (CSR) initiatives globally compel organizations to prioritize employee welfare, often exceeding minimum legal requirements. Opportunities lie in the development of sustainable, bio-based FR materials, moving away from petroleum-derived synthetics, aligning with global environmental goals. The integration of IoT and sensor technology into FR fabrics presents a major avenue for growth, offering enhanced functionality such as gas detection, vital sign monitoring, and automated logging of compliance status, transforming traditional workwear into connected safety platforms.

However, the market faces significant restraints beyond material cost, including challenges related to end-user education and the prevalent use of counterfeit or non-compliant FR products, particularly in regions with lax enforcement. The complexity of multiple international certification standards (e.g., specific requirements for electric arc, flash fire, and molten metal splash) creates operational barriers for global manufacturers. Furthermore, achieving an optimal balance between arc thermal performance value (ATPV), fabric weight, and comfort remains a constant technical challenge, especially for workers operating in extreme climates. These forces collectively dictate market trajectory: high regulatory pressure guarantees demand, while technological investment focuses on addressing cost-efficiency and performance constraints.

Segmentation Analysis

The Flame Retardant Work Clothes Market is segmented based on raw material type, product type, end-use industry, and geography. This granular analysis provides stakeholders with a clear view of where capital investment and strategic focus should be directed. The segmentation by raw material is crucial as it dictates the cost, durability, and specific protective capabilities (e.g., protection against specific temperature ranges or chemicals). The market is heavily tilted towards high-performance inherent materials which offer permanent FR properties, contrasting with cheaper, but less durable, chemically treated fabrics. Product segmentation reflects the diverse needs of various industrial roles, ranging from coveralls necessary for comprehensive protection in oil and gas to specialized jackets and pants used in electrical utility maintenance.

Analysis of the end-use industry segmentation reveals the Oil & Gas sector retaining the largest market share, driven by mandatory safety protocols concerning drilling, refining, and transportation activities which carry inherent risks of flash fires and explosions. However, the Utilities segment, encompassing electricity generation, transmission, and distribution, is projected to exhibit the highest growth rate, fueled by massive investment in grid modernization and renewable energy infrastructure that demands arc flash protection. Geographically, the market segmentation highlights the maturity and strict regulatory compliance of North America and Europe, versus the rapid expansion and regulatory evolution characterizing the Asia Pacific region, which presents the most significant long-term volume opportunity for manufacturers.

- Raw Material Type:

- Inherent Fabrics (Aramids, Modacrylics, PBI, PPO)

- Treated Fabrics (Treated Cotton, Treated Nylon)

- Blends and Composites

- Product Type:

- Coveralls and Overalls

- Jackets and Coats

- Pants and Trousers

- Shirts and Sweatshirts

- Accessories (Hoods, Gloves)

- End-use Industry:

- Oil & Gas

- Chemical and Petrochemical

- Utilities (Electric Power Generation and Distribution)

- Manufacturing and Metal Working

- Construction and Infrastructure

- Mining

- Firefighting and Emergency Services

Value Chain Analysis For Flame Retardant Work Clothes Market

The value chain for the Flame Retardant Work Clothes Market is characterized by highly specialized upstream material production and complex, multi-layered distribution networks downstream. The upstream segment is dominated by a few global chemical and fiber manufacturers responsible for producing high-specification FR raw materials like aramids and specialized chemical treatments. These raw materials, due to their patented production processes and high capital requirements, constitute a significant portion of the final garment cost. Fabric mills then process these fibers into textiles, focusing on characteristics such as weave, weight, thermal performance, and color fastness. Efficiency and quality control at this upstream stage are paramount, as the protective integrity of the final product hinges on the quality of the base fabric and chemical treatment application, demanding stringent adherence to standards like ISO 9001.

Midstream activities involve garment manufacturing, where fabric is cut, sewn, and customized to meet specific end-user requirements, including fitting corporate branding, adding reflective tapes, and incorporating specific pocket designs tailored for different job functions (e.g., specialized utility pockets for linemen). This stage requires specialized machinery and skilled labor to ensure that seams, closures, and garment construction do not compromise the FR properties. Downstream distribution is multifaceted, encompassing both direct sales channels to large multinational corporations (MNCs) and utility companies, and indirect channels relying on safety distributors, regional PPE suppliers, and authorized resellers. The shift towards e-commerce platforms is accelerating for smaller orders and standardized products, though technical sales and consultation remain critical for complex, high-ATPV requirements.

Direct sales are frequently utilized by key players to serve major accounts in the Oil & Gas sector, allowing for deep integration and maintenance contracts. Indirect distribution through third-party specialized safety equipment distributors provides reach into smaller industrial enterprises and diverse geographical regions where a localized support presence is necessary. The distribution channel must be highly responsive to spikes in demand resulting from new regulatory announcements or major industrial project launches. Overall, the value chain is focused on maintaining product authenticity to counteract counterfeit goods, ensuring traceability from fiber origin to end-user, thereby safeguarding the integrity of the crucial protective function these garments provide.

Flame Retardant Work Clothes Market Potential Customers

Potential customers, or end-users, of Flame Retardant Work Clothes are predominantly organizations operating in environments with significant exposure to thermal hazards, flash fire risks, or electrical arc flashes. These include vertically integrated energy companies (upstream exploration, midstream transport, and downstream refining), public and private utility providers (electrical power, water, and gas), heavy manufacturing facilities (steel mills, aluminum smelting plants), and large-scale construction contractors. The purchasing decision for FR workwear is almost exclusively driven by mandatory compliance with federal safety laws and corporate risk mitigation policies, often bypassing traditional consumer purchasing dynamics. Buyers prioritize certified protective performance (e.g., specific Arc Thermal Performance Value or ATPV ratings), durability, comfort for extended wear, and verifiable compliance documentation.

Within these organizations, procurement decisions are typically centralized, involving safety officers, risk management teams, and sometimes union representatives who collectively assess product specifications against operational hazards. Key decision criteria include the total cost of ownership (TCO), factoring in the longevity of the garment over its laundering cycles, and the vendor's ability to supply customized sizing and managed inventory services. The customer base can be segmented into large enterprises, which often demand specialized, bespoke solutions and volume discounts, and Small to Medium Enterprises (SMEs), which generally rely on standardized, readily available compliant solutions offered through regional distributors. The most influential buyers remain the global Oil and Gas majors and national power grid operators, whose compliance requirements often set de facto standards for the rest of the market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 5.2 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dupont de Nemours, Inc., Lakeland Industries, Inc., Honeywell International Inc., 3M Company, VF Corporation (Red Kap), Bulwark Protective Apparel, Westex by Milliken, TenCate Protective Fabrics, ProGARM, W. L. Gore & Associates, Inc., Cementex Products, Inc., Ballyclare International, Drägerwerk AG & Co. KGaA, Ansell Ltd., Kappler Inc., PBI Performance Products, Inc., Sioen Industries NV, National Safety Apparel, Workrite Uniform Company, Portwest Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Flame Retardant Work Clothes Market Key Technology Landscape

The technology landscape of the Flame Retardant Work Clothes Market is undergoing continuous evolution, driven by material science advancements focused on enhancing protection, comfort, and longevity. The primary technological focus remains on improving fiber chemistries. This includes the development of meta-aramids and para-aramids (e.g., Nomex, Kevlar) that offer high thermal stability and inherent resistance without relying on chemical treatments. Recent innovations center on hybrid fabrics that strategically blend different fibers, such as aramids with modacrylic or cotton, to achieve specific performance goals, such as moisture management, reduced weight, and improved tensile strength while maintaining a certified Arc Thermal Performance Value (ATPV) rating suitable for diverse environments, particularly hot and humid climates prevalent in Southeast Asia and the Middle East.

A secondary, but highly influential, technological trend is the rise of smart textiles and IoT integration within FR workwear. This involves embedding micro-sensors and conductive threads into the garments to monitor critical parameters in real-time. For instance, sensors can track the garment’s exposure history to extreme heat, UV radiation, or chemical solvents, providing data on degradation levels and signaling when the protective properties might be compromised. Other integrated technologies include GPS tracking, heart rate monitoring, and specialized sensors for detecting hazardous gases, effectively turning the garment into an active safety device. This technological convergence shifts the focus from purely passive protection to proactive, data-driven safety management, providing immense value to safety-conscious industrial operators.

Furthermore, technology related to fabric finishing and sustainability is gaining traction. Manufacturers are deploying advanced finishing techniques, such as nano-coatings and specialized polymer incorporation, to enhance features like oil and water repellency, ensuring the FR integrity is not compromised by liquid contamination. On the sustainability front, there is increasing investment in developing bio-based FR polymers and materials derived from recycled sources, responding to growing demand from corporate clients for environmentally responsible PPE. These technological shifts are not only improving safety standards but also driving up the total cost of finished goods, thereby impacting pricing strategies across the market spectrum.

Regional Highlights

- North America: North America, particularly the United States and Canada, represents a mature market segment, driven primarily by the strict enforcement of regulations mandated by OSHA and NFPA standards (e.g., NFPA 70E for electrical safety and NFPA 2112 for industrial flash fires). The high market value is sustained by sophisticated demand from the extensive Oil & Gas (Permian Basin, Gulf of Mexico operations) and Utilities sectors, which require premium, high-ATPV protective solutions. The region is characterized by high adoption rates of inherent FR materials and a strong focus on advanced, multi-hazard protective solutions, including cold weather FR gear.

- Europe: The European market is highly fragmented but robust, propelled by comprehensive European Union directives (e.g., PPE Regulation (EU) 2016/425) requiring CE certification. Key markets like Germany, the UK, and France show strong demand stemming from their advanced manufacturing, petrochemical, and automotive industries. Europe leads in the adoption of sustainable FR textile technologies and is pioneering regulatory standardization across member states. The emphasis here is on certified quality, traceability, and ergonomics, driving demand for specialized and highly comfortable FR garments.

- Asia Pacific (APAC): APAC is the fastest-growing market globally, fueled by rapid industrialization, large-scale infrastructure projects (especially in power generation and rail), and emerging regulatory standards in China, India, and Southeast Asia. While cost-sensitivity remains a factor, increasing foreign investment and the presence of global MNCs are raising overall safety standards, compelling local players to adopt international certifications. The sheer size of the workforce and the rapid expansion of the manufacturing base make APAC the primary future volume driver for mass-produced and treated FR fabrics.

- Middle East and Africa (MEA): This region is dominated by massive investments in the oil, gas, and petrochemical industries (particularly in Saudi Arabia, UAE, and Qatar). The demand here is highly specific, requiring high-performance FR workwear capable of enduring extreme heat and harsh operating conditions. Procurement is often centralized through national oil companies (NOCs), favoring suppliers who offer comprehensive service contracts and high-grade inherent FR solutions that meet international standards (ASTM, ISO).

- Latin America: Growth in Latin America is steady, linked mainly to mining operations (Chile, Peru) and oil and gas activities (Brazil, Mexico). Market penetration is accelerating due to modernization efforts and governmental pushes for stricter adherence to occupational safety protocols. The market is typically served by global distributors, though local production capacity is gradually increasing, focusing primarily on treated cotton solutions for cost efficiency.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Flame Retardant Work Clothes Market.- Dupont de Nemours, Inc.

- Lakeland Industries, Inc.

- Honeywell International Inc.

- 3M Company

- VF Corporation (Red Kap)

- Bulwark Protective Apparel

- Westex by Milliken

- TenCate Protective Fabrics

- ProGARM

- W. L. Gore & Associates, Inc.

- Cementex Products, Inc.

- Ballyclare International

- Drägerwerk AG & Co. KGaA

- Ansell Ltd.

- Kappler Inc.

- PBI Performance Products, Inc.

- Sioen Industries NV

- National Safety Apparel

- Workrite Uniform Company

- Portwest Ltd.

Frequently Asked Questions

Analyze common user questions about the Flame Retardant Work Clothes market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between inherent and treated Flame Retardant fabrics?

Inherent FR fabrics utilize fibers that are naturally flame-resistant at the molecular level (e.g., aramids), providing permanent protection that does not wash out. Treated FR fabrics use standard materials like cotton that are chemically processed to achieve FR properties; the protection level may degrade over the garment's lifecycle, necessitating stricter washing protocols and tracking.

Which end-use industry drives the highest demand for FR Work Clothes globally?

The Oil and Gas industry consistently drives the highest demand, requiring comprehensive FR protection due to the severe flash fire and explosion risks inherent in drilling, refining, and transportation operations. This sector mandates high-performance, certified apparel meeting standards like NFPA 2112.

What is ATPV and why is it crucial in selecting Flame Retardant workwear?

ATPV stands for Arc Thermal Performance Value, a rating measured in calories per square centimeter (cal/cm²). It represents the maximum amount of thermal energy a fabric can withstand before a second-degree burn injury might occur. This rating is critical, especially in the utilities sector, to ensure the garment provides adequate protection against specific electrical arc flash hazards.

How is the rise of smart textiles influencing the FR Work Clothes Market?

Smart textiles integrate sensors into FR workwear, transforming passive protection into active safety management. This technology allows for real-time monitoring of garment integrity, heat stress on the worker, and exposure to hazards, enhancing preventative safety measures and compliance tracking through data analytics.

What regulatory standards are essential for FR workwear manufacturers?

Globally essential standards include NFPA 2112 (Flash Fire Protection), NFPA 70E (Arc Flash Protection), EN ISO 11612 (Protection against Heat and Flame in Europe), and ASTM F1506 (Arc-Rated Materials). Adherence to these strict specifications is mandatory for accessing high-value industrial markets.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager